二手 MOORE 450-CPZ #9395059 待售

網址複製成功!

單擊可縮放

ID: 9395059

Grinding machine

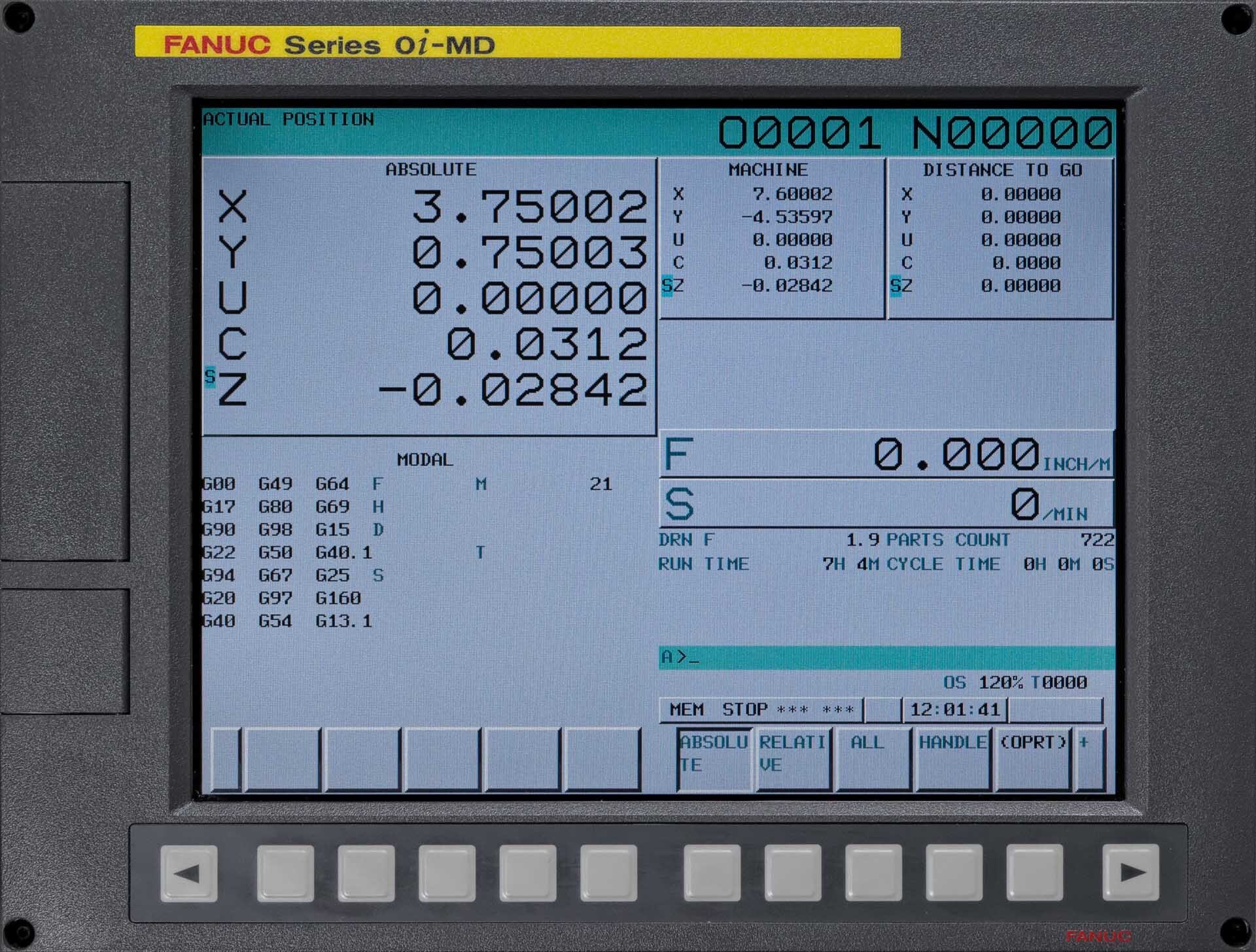

FANUC Oi-MD Controller

Y-axis: 10.5" CNC cross travel

X-axis: 17.5" CNC longitudinal travel

Z-axis: 3.5" CNC vertical travel

360° CNC rotation of C axis (Automatic C axis Normalcy)

Rapid traverse rate: 60 IPM

Contouring rate: 15 IPM

Ultra-precision ball screws on the X and Y axes, with motors

Encoders mounted directly on ball screws for high accuracy

Precision roller bearing way system with accordion way covers

Oil bath for ball screw

FANUC Closed loop AC digital servo drive motors with quick connector

FANUC Closed loop AC digital servo drive system (25 A peak)

Automatic lubrication systems with low-level alarms for roller-way system

Programmable, ball screw driven, Z-axis

Programmable main spindle speeds CW / CCW / OFF (Planetary)

Programmable chop grind ON / OFF with head-up micro switch

Programmable air grinding spindle ON / OFF

Programmable 110 VAC outlets ON / OFF

Programmable U-axis outfeed

Manual pulse generator (hand wheel) for easy setup

X, Y, U, C and Z home switches with indicator lights

X,Y, C and Z limit switches

X,Y, C and Z limit switch indicator lights

Minimum Programmable resolution: 0.000010"

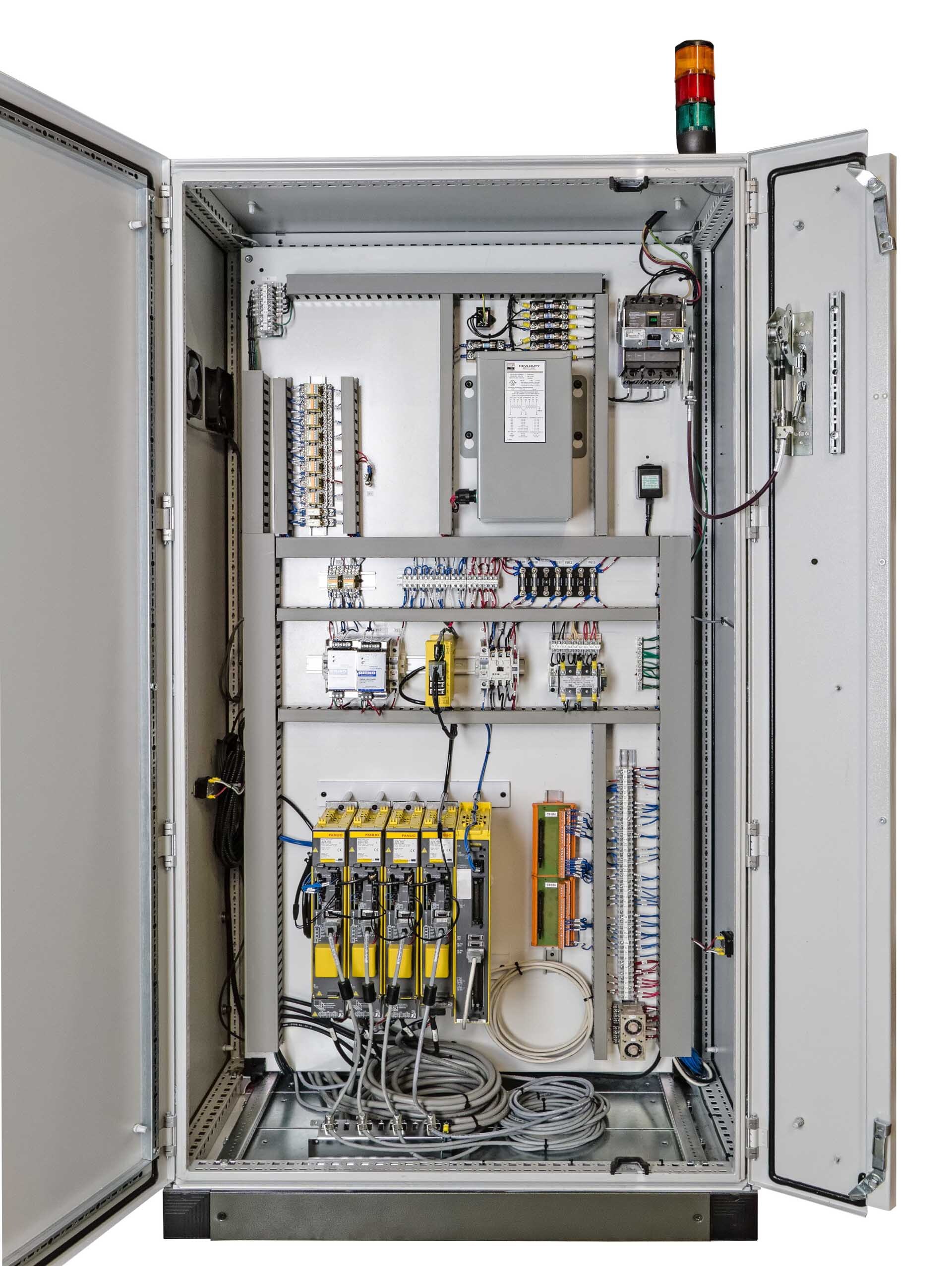

Pendant-type control cabinet mounted in a stand-alone electronics

(3) Coats of high gloss epoxy paint

Includes:

Spindle bearing

Outfeed bearing

U-cup, packing, wiper, seal, and o-*ring

Head thermometer

Chop valves (2-way and 4-way)

Micro switch

Link and link pins

Re-grind quill keyway

Scraping of the column geometry correction

Spotting of table surface

The lapping of the table and saddle ways for proper roller bearing contact

Accuracy:

Positioning accuracy: 0.000080"

Contouring accuracy: 0.000120"

Control:

5-Axis, 32-byte, microprocessor CNC

Graphics display with zoom functions

Flat screen color LCD, 10.4"

Sealed Mylar pushbutton keyboard with tactile and audible feedback

Menu-driven editing and modification

(10) Operating modes: Automatic, single block, playback, teach-in, dry run, jog / Zero setting, editing, input / Output, tool offsets, and special modes

Automatic C-axis normalcy:

Absolute / Incremental programming

Inch / Metric conversion

Standard 4 megabytes of memory

Minimum resolution: 0.000010"

Wheel compensation

Manual federate override: 0-120%

Mirror imaging

Subroutines with nesting

Linear interpolation

Cartesian and polar coordinate programming

Machine federate display

Wheel radius compensation

Program dwells

Manual data input via keyboard

Programmable zero offsets

3-axis simultaneous rapid positioning

Scaling factors

Help graphics

Zoom up / Down

Continuous and incremental jog

Canned cycles

Bolt circle programming

Circular and rectangular pocket grinding

Hole grinding cycles

Controlled comer rounding

Multiple absolute zeros

Programmable safety limits

DNC Communication

RS-232 Communication.

MOORE 450-CPZ晶圓研磨、研磨和拋光系統是一種全自動的研磨、研磨和拋光任何尺寸晶圓的解決方案。它能夠產生各種晶圓尺寸和厚度的亞微米精度,從直徑不超過8英寸的小骰子晶圓到厚度不超過10mm。它在一臺機器中結合了三個過程,使它能夠在一個周期內研磨、研磨和拋光。450-CPZ配備高功率研磨電動機,能夠達到高達12,000 RPM的速度。這有助於實現高精度,不折不扣。其先進的電子設備提供全自動控制,允許精確的操作和可重現的精度。MOORE 450-CPZ配備高精度數控主軸,提供小於一微米的機械重復性。數控主軸能夠使用金剛石和立方氮化硼等一系列磨料進行研磨、研磨和拋光。這樣可以確保在研磨、研磨和拋光過程中保持最高精度。此外,450-CPZ能夠處理濕磨,使其適合在一系列的加工過程中使用。MOORE 450-CPZ還得益於先進的安全功能,包括非接觸式傳感器和自動關閉裝置。這有助於防止機器發生故障時損壞機器和晶片。此外,該機還配備了直觀的用戶友好界面,便於操作。450-CPZ晶片研磨、研磨和拋光系統是任何需要研磨、研磨和拋光晶片的工業應用的理想選擇。MOORE 450-CPZ具有高性能、精確的數控主軸和安全的操作,是實現亞微米精度結果的絕佳選擇。

還沒有評論