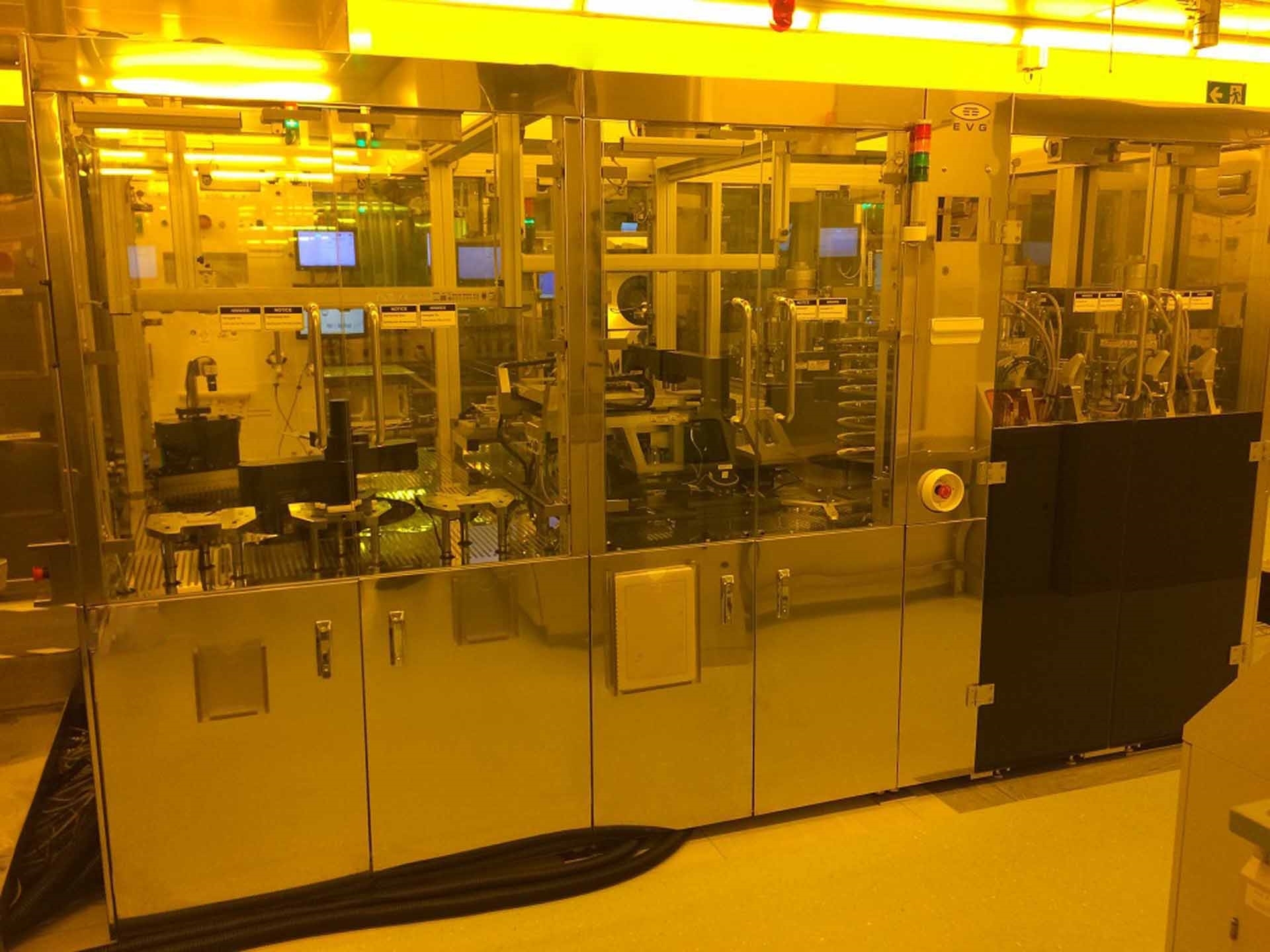

二手 EVG / EV GROUP Gemini #9229293 待售

看起來這件物品已經賣了。檢查下面的類似產品或與我們聯系,我們經驗豐富的團隊將為您找到它。

單擊可縮放

已售出

ID: 9229293

晶圓大小: 8"

優質的: 2013

Automated wafer bonding system, 8"

Substrate handling module:

Between alignment stage and load cassette

Loading / Unloading: 4-Axis industrial robot

With external optical prealigner

Wafer handling:

End effector for robot unit

With vacuum from bottom side

Bond chuck handling module:

Between alignment station and bond chamber

Automated operation of up to (4) bond modules

Unclamp station with handshake to linear transfer station

Cassette station:

Present sensor

Empty sensor

Graphical user interface for manual and fully automated operation

Independent sequence

Monitoring

Data storage

Wafer ID reader:

SEMI T1 (Barcode)

SEMI M12, SEMI M13 (Both alphanumeric)

SEMI T7 (Data matrix code)

High resolution alignment stage with DC servomotors in X, Y and Θ

Top and bottom wafer chuck with position measurement system

Fully motorized split field microscope for double side viewing

High resolution digital CCD cameras

Integrated magnification unit: 1x - 3x

Alignment with split field microscope

Objective: 5x

Loading chuck, 4"-6"

Bond module:

Universal bond chamber with top and bottom side heaters

Flag pulling mechanism

Up to 550°C and 3.5 kN

Atmospheric capabilities down to 1 x 10^-3 mbar (7.5 x 10^-4 Torr)

Pressure: 3 bar abs.

Connections for evacuation, purge and vent

Independent temperature controllers for top and bottom side of each chamber

Electronic pressure regulator for controlled contact force

Pneumatic wafer bow pin:

For most accurate alignment of separated wafers

Spring-loaded pin in bond chamber

Rapid cooling for top and bottom side heater:

For symmetric top / Bottom side cooling at identical

Forced water cooling

Silent operation

Programmable cooling rate

Increased piston force: Up to 10 kN (2250 lbf)

Resolution: 3 N steps

Pressure disk, 4"-6"

Universal bond chuck, 4"-6"

For anodic, thermo compresion and eutetic bonding process

Bond chuck with mechanical wafer direct clamping

Bond chuck out of titanium

Vacuum equipment with bypass system:

Pump time: < 2min from 1000 to 1 x 10^-3 mbar

Gas backfill time: < 10sec from high vacuum to 1 bar

Purge connections for process gas

Pump down time: From ambient to 2 mbar abs. pressure < 60s

Vacuum controller: 1 - 1000 mbar

Resolution: 1 mbar

Accuracy +/-0, 5% / +/-3 mbar

With piezo gauge and control valve

Minimum controllable pressure: 1mbar abs

Hardware:

SEMI-E4:

Semi Equipment Communication Standard (SECS-1)

Message transfer: Hardware interface RS232

SEMI E37:

High speed Secs Message Service (HSMS)

Generic services

Hardware interface: Ethernet TCP/IP

Tooling with system:

Bond chucks with graphite: 9 x 6”

Graphite pressure disks: 4 x 6”

Objective:

Bottom and top alignment

With standard 5x objectives with red LED

Second N2 line is installed in each module

Controlled with needle and bypass valves

Includes:

Chiller

(4) Vacuum pumps

(4) Turbo pumps are installed in chambers

Operating system: MS-Windows

2013 vintage.

EVG/EV GROUP Gemini Bonder是一款生產就緒、高通量、自動化的晶圓粘合工具,具有精確、可重復的粘合效果。該工具為粘合劑粘合薄片提供了堅固的平臺,為亞毫米公差提供了晶圓級封裝。EVG Gemini Bonder旨在為晶圓鍵合過程帶來最大的吞吐量、精度和可重復性。它的高級功能包括控制溫度、壓力和時間。這樣可以確保堅固耐用和可靠的粘結。此外,EV GROUP Gemini Bonder還具有直觀的用戶界面、自動化和可重復的過程,並具有可調參數以確保最高產量。Gemini Bonder占地面積小,真空頭低,是小型和大型生產過程的理想解決方案。該系統包括一個自動加載/卸載模塊,用於晶片直徑不超過8英寸。負載/卸載模塊包括精密噴嘴,可精確、重復地輸送粘結流體。它還有一個四頭鍵合站,最多可以容納四個不同的鍵合過程。該站與紫外線粘合劑和凝膠系統完全兼容。它還包括自動對準,以及可編程壓力和溫度坡道。EVG/EV GROUP Gemini Bonder還提供全面的流程控制和實時反饋,能夠保存和加載以前運行的流程以實現可重復性。它利用聯機菜單來選擇、監視和控制所有的流程功能。EVG Gemini Bonder還具有易於使用的GUI(圖形用戶界面),允許用戶實時監控、調整和調整流程參數。EV GROUP Gemini Bonder兼容各種包裝和基材材料,配置性強,參數可調範圍廣。容易與其他系統整合,且噪音低,使其適合各種潔凈室環境。此外,系統還與一系列可選的硬件模塊兼容,這些模塊允許您使用更多的下遊應用程序。例子包括激光切割、光刻、基於視覺的門控等等。這使得Gemini Bonder成為許多晶圓粘合應用的誘人選擇。

還沒有評論