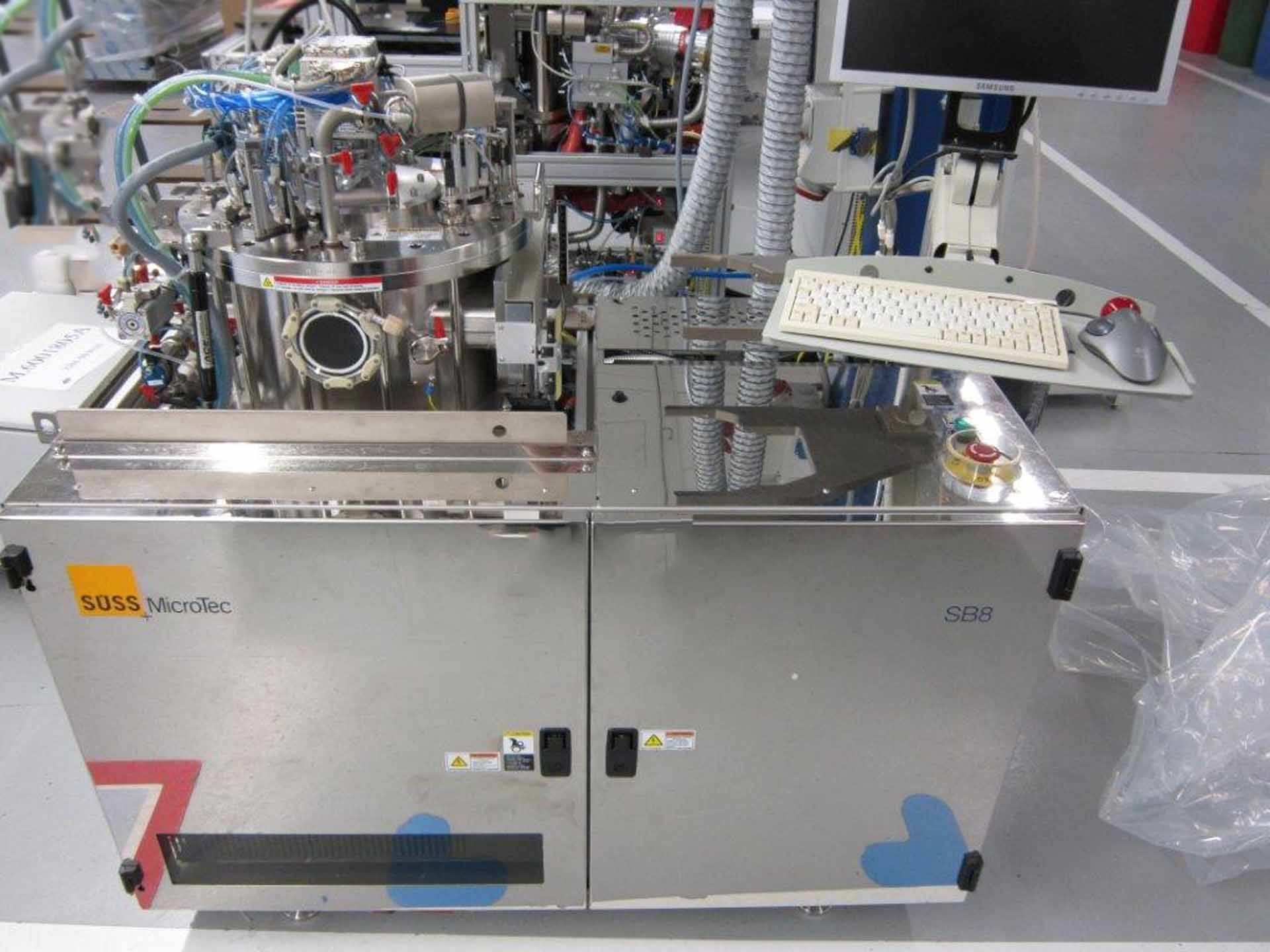

二手 KARL SUSS / MICROTEC SB 8e #9212773 待售

看起來這件物品已經賣了。檢查下面的類似產品或與我們聯系,我們經驗豐富的團隊將為您找到它。

單擊可縮放

已售出

ID: 9212773

Wafer bonder

P/N: 100059734

Bonding of aligned substrates: 4"-8" in diameter

Base machine specifications:

Aligned wafer transport fixture: Manual loading / Unloading

Automatic process data recording with selectable interval

Polished stainless steel cabinet

Motorized Z axis for automated wafer stack thickness compensation

Transport fixture loading slide

Process chamber:

Electro polished process bond chamber with controllable insertion of process gases

Automated open / Close process chamber door with integrated safety light barrier (VAT door)

Automatic chamber purge during process door cycling to avoid chamber

Media supplies:

Clean dry air: 6 Bar

Process nitrogen: 7 – 75 Bar

Vacuum 100 mbar (abs) for pressure bond tools

Control system:

User & maintenance interface

Operating system: Windows

Network connection: Ethernet

External communication: USB Connection

PC Flat panel monitor with keyboard and trackball

Hot chuck(s) SB8 GEN2 with industrial temperature controller

Industrial temperature controller for enhanced precision temperature control

Rapid setup of temperature ramps with fast controller profiling & control of heaters

Lower hot bond chuck with temperature control from ambient to 500°C

Resistive heater with active air cooling

Temperature control: +/- 3 degrees

Programmable temperature ramps

Temperature uniformity: +/- 2.0%

Heating / Cooling performance:

Heating: 30°C /min

Cooling up to 28°C/min machine and configuration depending

Kit, upstream control:

For bonding from atmospheric pressure down to of 5e-5m bar with turbo pump option

Downstream controller:

Pressure range: Absolute 1 - 1000 mbar up to 3000mbar with over pressure kit option

Flow between 05 & 13 l/min (Depending on pressure) adjustable by manual valve

Signal status tower:

P/N: 100075936SB

Light tower with three lights & buzzer for machine status indication

Lights configured & customized

Multiple process gases kit:

P/N: 100059766

Automated gas selection for up to 4 process gases (N2 Plus three gases)

Recipe controlled automated selection of one of four process gases

Configurable process gas names

Supports all inert gases

Forming gas with a maximum concentration of 5% & synthetic Air (80%N2 20%O2)

Clean PFA teflon process gas tubing

Turbo pump with scroll pump:

P/N: 100059752

For high vacuum to 5e-5mbar

Turbo molecular pump

Scroll pump type: EDWARDS XDS

Dry lubricant free

Chemically resistant

Clamp / Spacer unit with sequential spacer removal:

P/N: 100060409

Hardware & software for individual spacer removal & clamp arm control

Options: Bonder to lift one clamp

Spacer force free and to set the clamp again

Programmable actuation, improves post bond alignment capability

Standard tool force generation:

P/N: 100059765

Option: Bonder to control the bond force via cascaded two point control system

Bond force values:

Minimum force: 300N

Maximum force: 20kN

Maximum ramp rate: Up to 3.7kN/min

P/N: QW1001312

Force range capability 500N - 20kN with 6" / 8" wafer

Spring loaded center pin: Diameter 12mm

Heater temperature range: Ambient plus 10°C up to 500°C

P/N: W1002902

SiC Pressure plate and sandwich plate(upper & lower): 8", Diameter

Pressure plate: (3) Cut outs for spacers and clamps

P/N: W1023794

Compatible with SUSS MicroTec bond aligners, for 8" wafers

Clamp arms included

P/N: W1026899

TiN Coated stainless steel: 0.2 mm thick

Power requirements:

380-400 VAC, 20 A, 50 Hz

200-208 VAC, 25 A, 50/60 Hz.

KARL SUSS/MICROTEC SB 8e是一種全自動、多功能、中型模具粘合器。它配備了全自動視覺系統,以確保模具精確放置到基板上及其對應的電線粘合過程。這種粘合劑利用了兩個可以在超聲波和熱壓之間改變的線鍵頭。該粘合劑還具有完全集成的加熱級,溫度範圍可調節至400 °C,以確保高效可靠的粘合。MICROTEC SB8E提供了一個非常大的工作平臺(195 x 145毫米)和可調鍵頭高度(最多60毫米)。此功能使其適合不同的封裝類型和應用變體。低功耗(300W)使其易於使用和經濟高效,同時提供可靠和準確的粘合過程。該粘合器還具有自動焊料焊接應用程序,並可選擇采用額外的電線粘合技術,如金線或銀線粘合。粘合器還配備了可調節的晶片卡盤和真空清洗系統,用於將模具精確放置到基板上。它也可以配置用於不同的電源直至3000V。總體而言,KARL SUSS SB8 E型粘合機是一款功能強大、功能先進的粘合機,適用於半導體行業的多種應用。該粘合劑可用於原型制作、晶圓級封裝(WLP)和低批量生產。由於其用戶友好的設計、直觀的界面和堅固的構造,粘合器是用於自動模具連接過程和線鍵應用的可靠工具。

還沒有評論