二手 ESC 9200 #39586 待售

網址複製成功!

單擊可縮放

ID: 39586

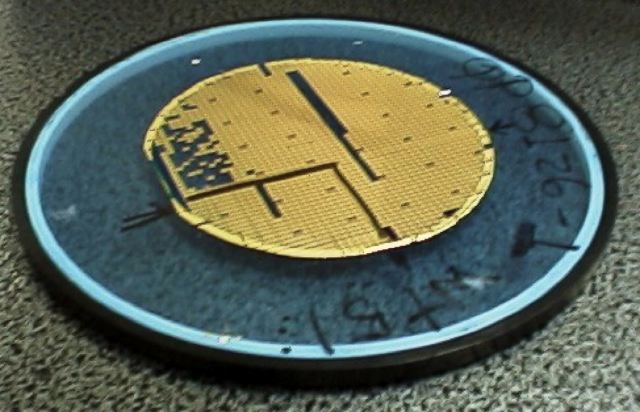

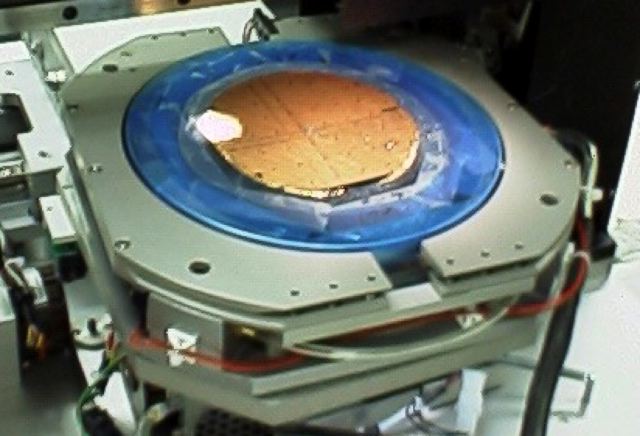

晶圓大小: 8"

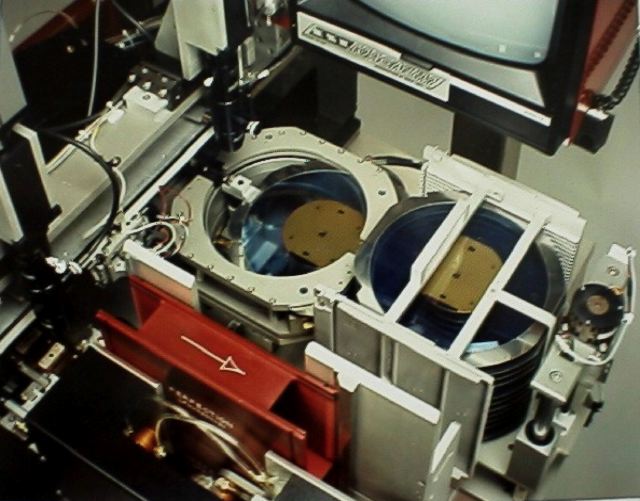

Epoxy die attach machine with Cognex vision

8" wafer with auto cassette

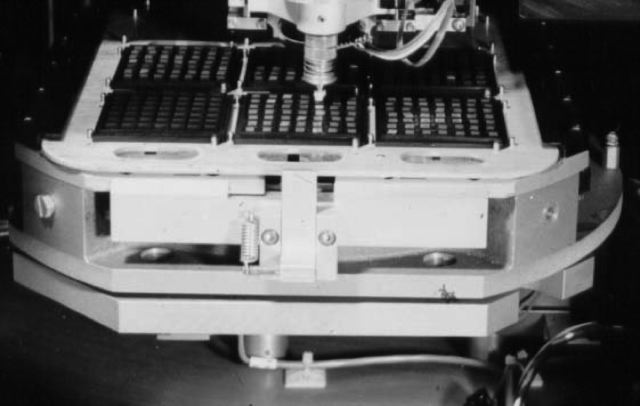

Auto indexer or 4" x 20" matrix x-y table to handle many diferent devices

Unstack to Magazine or Magazine to Magazine

Matrix Capability: Up to 8” wafer capability

Capable of picking die from wafer on film frame, wafer on rings, waffle packs, and gel packs

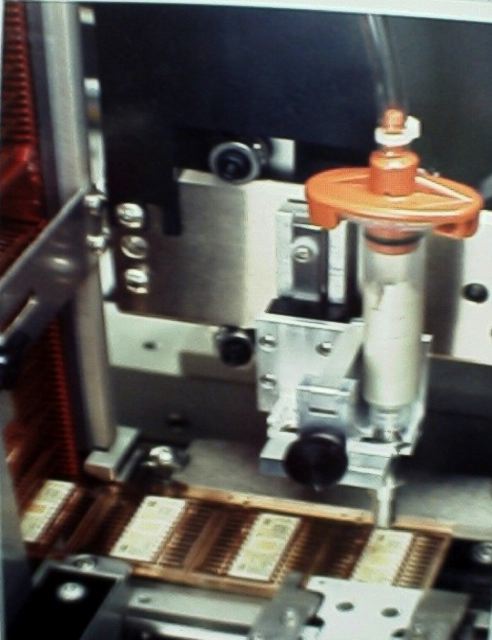

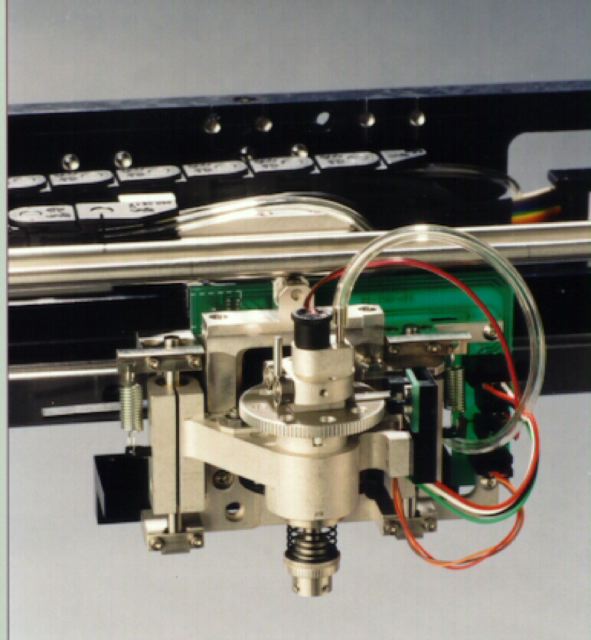

Programmable Syringe dispenser

Leadframe input: Dual unstacker with paper separator

Programmable magazine input

Programmable Gripper Indexer

Pattern Recognition System (PRS): Ink dot or broken corners to skip die

SECS/GEM compliant for wafer mapping

ALPS compatible

Linear Pick Bondhead

Programmable Approach Speeds

Y programmable scrub (amplitude, time and frequency)

Rotary Bondhead available

Die Presentation: Waffle / gel pack, film frame, wafer ring

Wafer Handler: Film Frame or Wafer Ring, Automatic wafer changer available

Small Footprint

Rack mounted electronics serviceable from the front

Simple Mechanisms allow easy servicing & accessibility

User friendly operator interface (via Light Pen touch screen)

Up to 100 recipes on HDD

Can be configured to your products process or as is configuration and condition

~2000 vintage.

ESC 9200模具附件是一種用於將模具固定在沖壓機的烤盤上的機器。它是專為將高價值、高密度的模具附著在鐵板上而設計的。這確保了印刷機與模具之間的安全連接,並且還有助於減少與模具盤斷裂、雙夾緊和模具部署錯誤相關的機器停機時間。9200模具連接器使用兩級工藝將高密度模具牢固地連接到棧板上。在第一階段,在模具下方的一個腔室內產生真空,該腔室將金屬碎片吸塵。腔室內部是一個真空板,它首先將幾滴粘合劑塗抹在棧板上,其次使用針輪將模具移動到位以進行附著。初始定位後,階梯式凸輪機構將模具移動到所需的精確位置。模具完全就位後,電動nutrunner會將模具向下拉到粘合劑塗層的棧板上,並施加必要的力使其靠近板。最後將nutrunner和階梯式凸輪松開,模具牢固地附著在板上。ESC 9200模具附件專為大批量應用而設計,循環時間約為3.5秒,以確保高價值模具固定在鐵板上。機器也很容易使用,操作設置簡單,可以在幾秒鐘內更改。整個機器結構牢固,其部件質量很高-包括重型鎖定螺栓,以確保模具牢固地固定在棧板上。總體而言,9200模具接頭是將高價值和高密度模具連接到烤盤上的可靠解決方案。它的兩個階段的過程是高效的,其穩健的設計和構造確保可靠的性能,即使在大容量的環境。

還沒有評論