二手 TEL / TOKYO ELECTRON TELINDY B #9014197 待售

看起來這件物品已經賣了。檢查下面的類似產品或與我們聯系,我們經驗豐富的團隊將為您找到它。

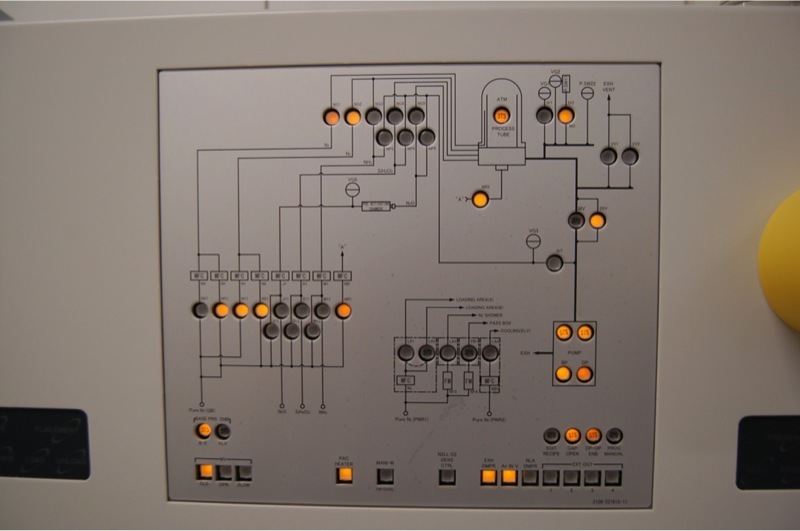

單擊可縮放

已售出

ID: 9014197

晶圓大小: 12"

Vertical diffusion furnaces, 12"

Base unit for DCS HTO process

Includes:

Cabinets / units / controllers included

Furnace cabinet (including ultra-clean air flow system)

Scavenger and water cooling unit

Power supply unit (U/P box)

(Includes control unit, transformers, SCR, and breaker unit)

Main controller (WAVES)

Temperature controller

FOUP and wafer handling automation included

FOUP load port

FOUP transfer

18 FOUP stocker

FIMS port

KHI wafer load automation

Variable pitch change mechanism (w/5 fork)

Auto tube shutter

Boat elevator w/ boat rotation mechanism

Mid temp heater: VMM-56-002 1 Included

Includes outer/inner T/C

Integrated gas system for DCS HTO 1 Included

N2O gas stick 1 stick Included

DSC gas stick 1 stick Included

Purge N2

Vacuum vent

Exhaust vent

Piping tape heater

PAC (Pre Activation Chamber)

Vacuum foreline configurations

Stainless steel manifold

80A foreline piping

Foreline heater

APC main valve

Vacuum gauge & pressure switch

US safety (S2-0302, S8-0999)

Quartzware set for DCS HTO 1 Included

(Including x2 of 75 slots Ladder Boat)

System options:

N2 Load lock option 1 Included

- O2 analyzer - NGK SH-302

- O2 consumption rate controller

Dual boat operation 1 Included

N2 boat cooling shower 1 Included

Fixture for start up and maintenance 1 Included

Final valve unit 1 Included

NH3 coating capability

Hi-temp capacity (<850°C)

2007 vintage.

TEL/TOKYO ELECTRON TELINDY B是蝕刻器的一種,又稱asher。它是一種半導體和光伏器件制造設備,包括真空系統、工藝源單元和工藝單元。它采用電子束技術和專用軟件機器來控制蝕刻過程的均勻性和準確性。蝕刻器依賴於其工具的三個主要組成部分-真空資產、工藝源模型和工藝單元。真空設備從腔室抽出空氣和氣體,其中心是渦輪分子泵。另一方面,過程源系統在供應等離子源氣體方面起著關鍵作用,這些氣體通過質量流控制器、壓力控制器和多氣體穿孔管的集成網絡進入。最後,工藝單元通過控制所施加的氣體壓力、流速、功率和設備的定時,在室內傳遞蝕刻過程。由於電子束蒸發器的作用,TEL TELINDY B蝕刻器可以在蝕刻過程中提供高精度和控制。該梁用於控制薄膜源在厚度控制上的蒸發,還具有選擇性塗覆板的能力。蝕刻器還允許通過使用晶圓CD(臨界尺寸)測量機布置許多用於蝕刻的工藝層。TOKYO ELECTRON TELINDY B蝕刻器還具有出色的溫度控制能力,可以幫助調節不同底物之間的均勻性。這種蝕刻器的另外一個好處是,操作員有能力利用腔室壓力、冷卻氣體壓力和氣體流速等工藝參數,以便根據他們的需要量身定制蝕刻工藝。最後,蝕刻器非常先進,因為它配備了直觀的軟件工具,使操作員能夠優化蝕刻過程並自動執行許多任務。這使得操作員更容易調整不同的工藝參數,並確保蝕刻工藝的結果是一致和準確的。總體而言,TELINDY B是一種高度先進的蝕刻器,具有電子束蒸發器,以確保精確度和對蝕刻過程的控制。操作員可以利用過程參數來根據自己的需要定制蝕刻過程,而直觀的軟件資產可確保某些任務的易用性和自動化。

還沒有評論