二手 ESC ELAS #9131115 待售

網址複製成功!

單擊可縮放

ID: 9131115

晶圓大小: 6"-8"

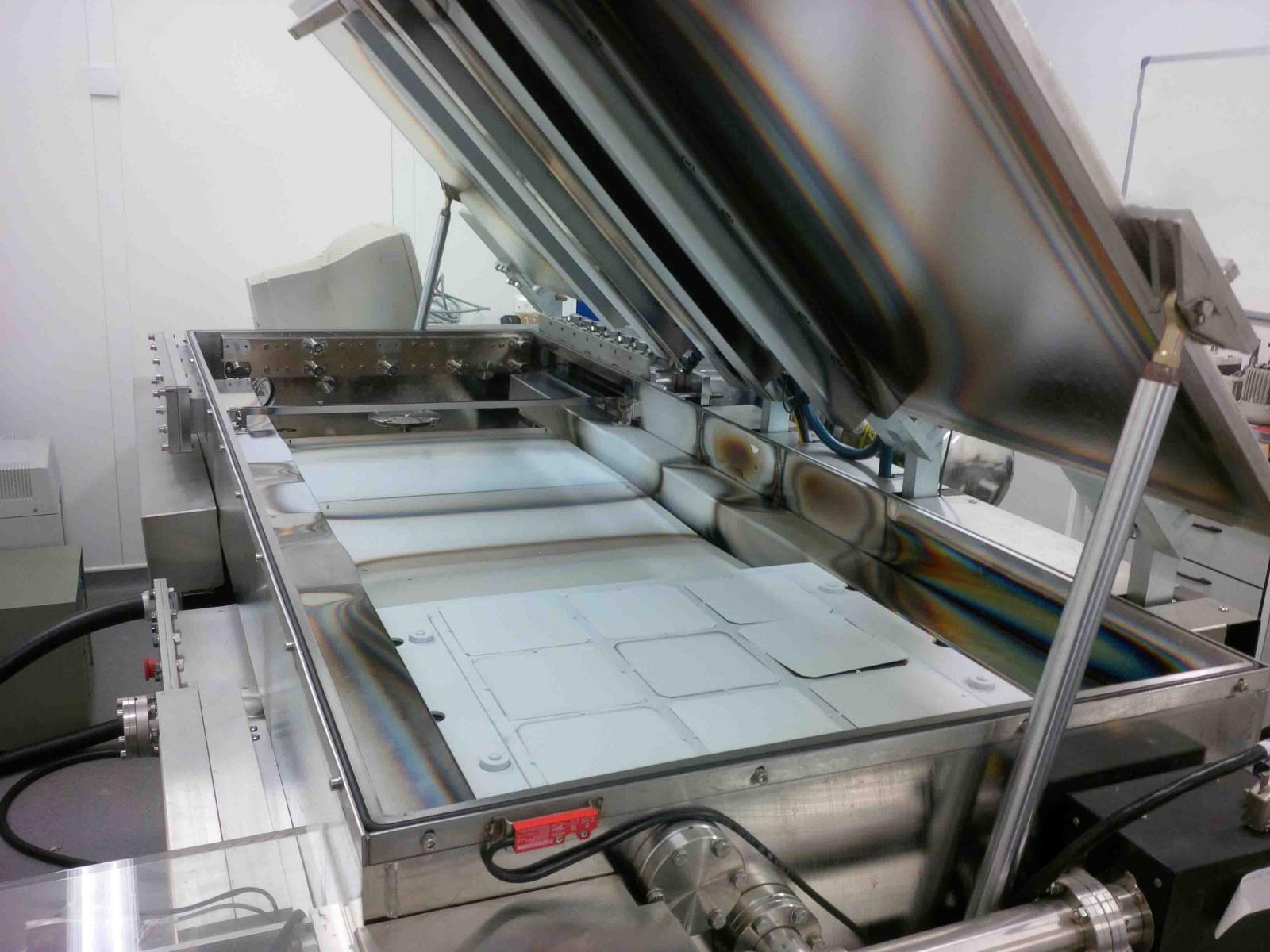

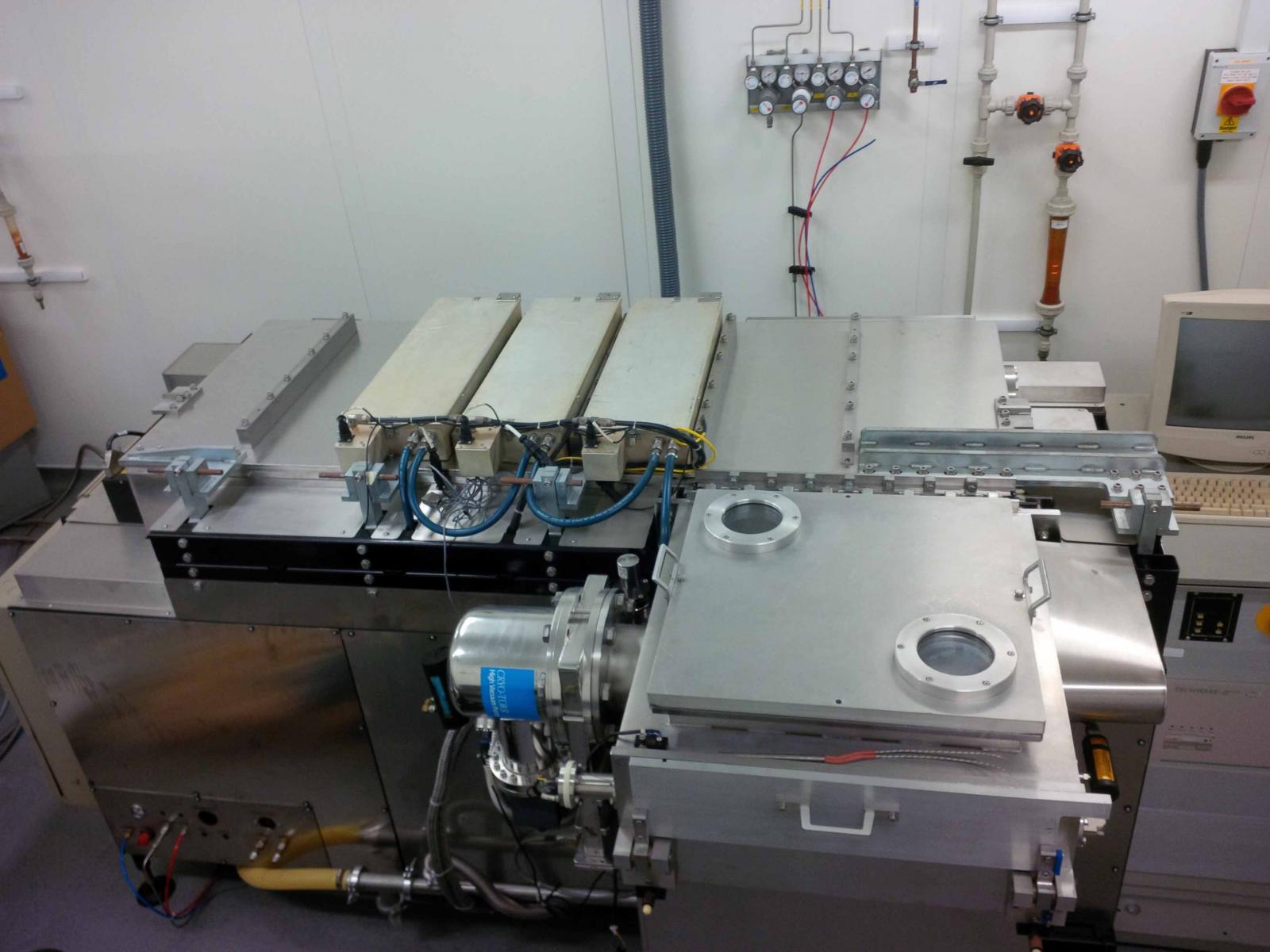

RF / DC Sputtering system, 6"-8"

RF Magnetron

RF Diode operation

Loadlock cryo pump, 8"

Chamber, 10"

Rectangular

Heliarc welded

304 Stainless steel plate: 16 mm

View-port: Pyrex window

Pump-out port: 225 mm Diameter

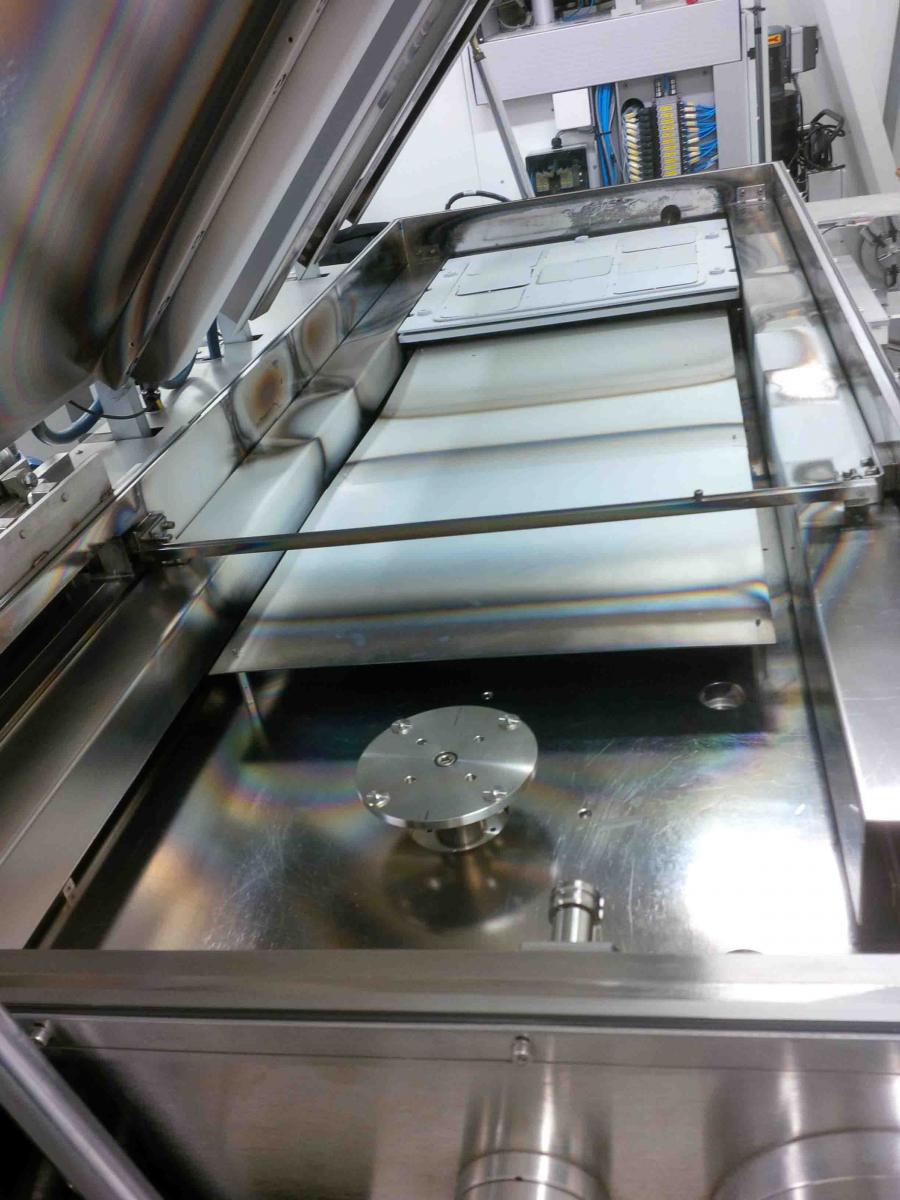

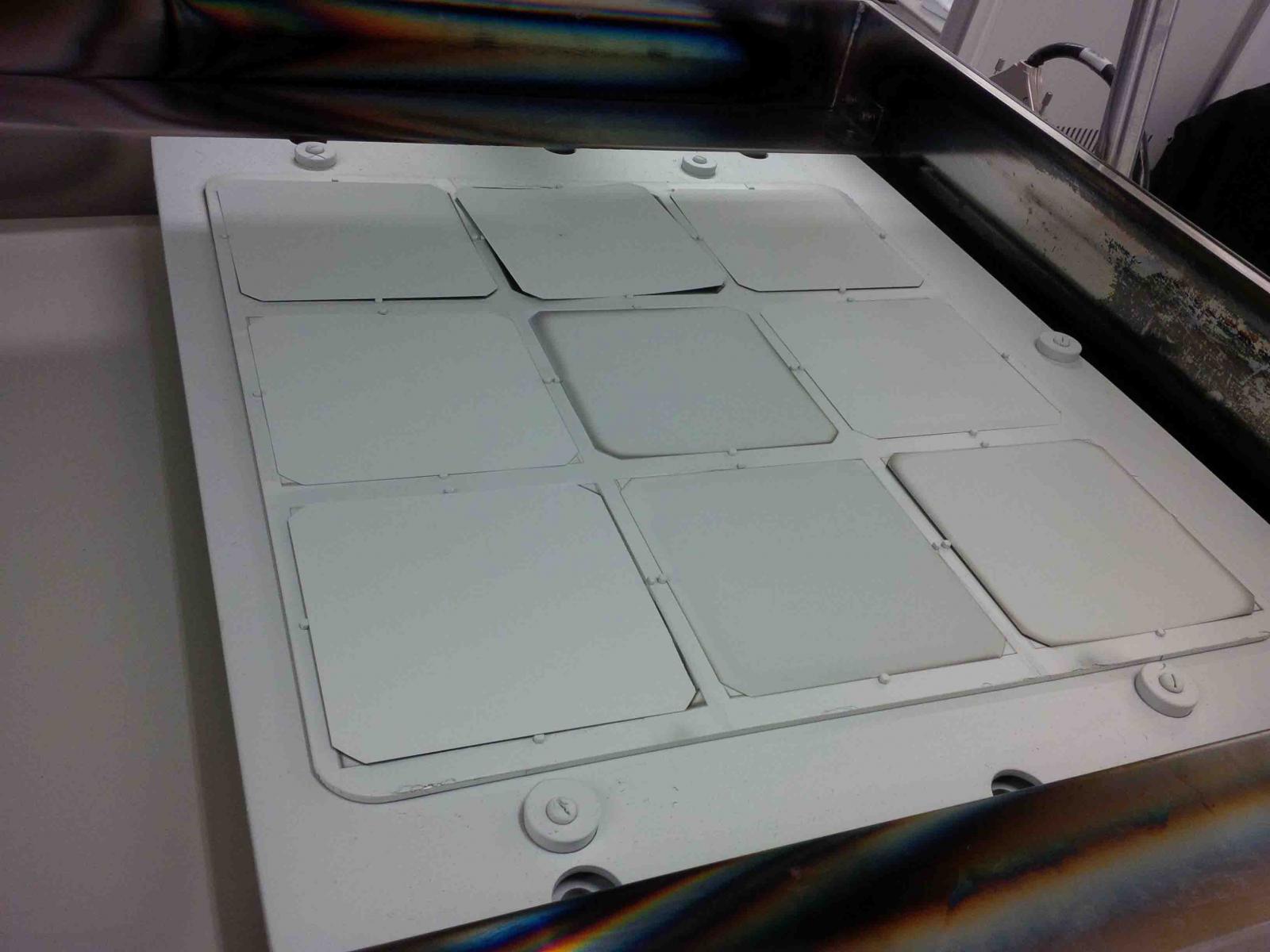

Load lock:

2-Level elevator

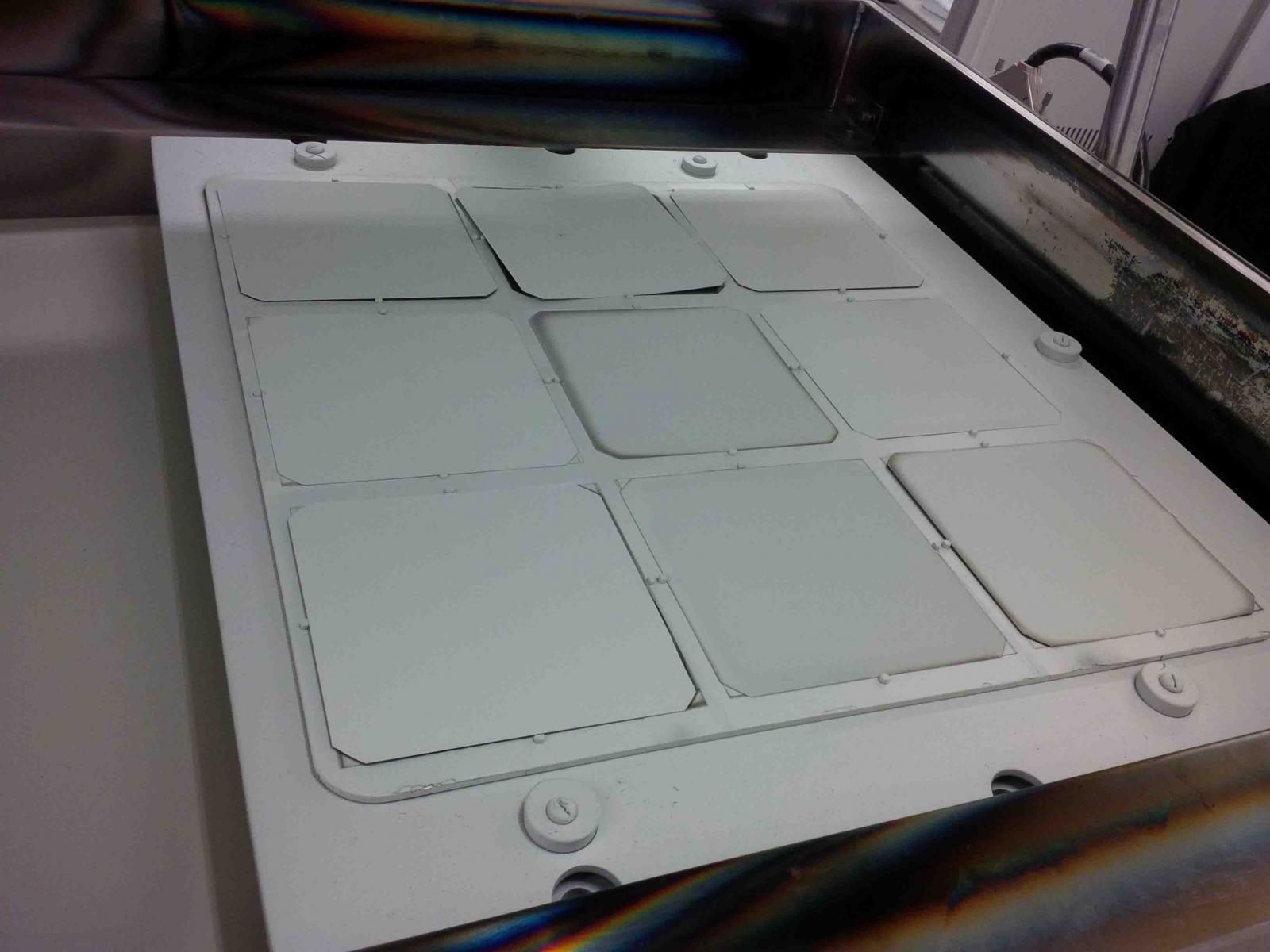

Non-coated pallets loaded on upper level

Processed pallets unloaded from lower level

VITON O-ring

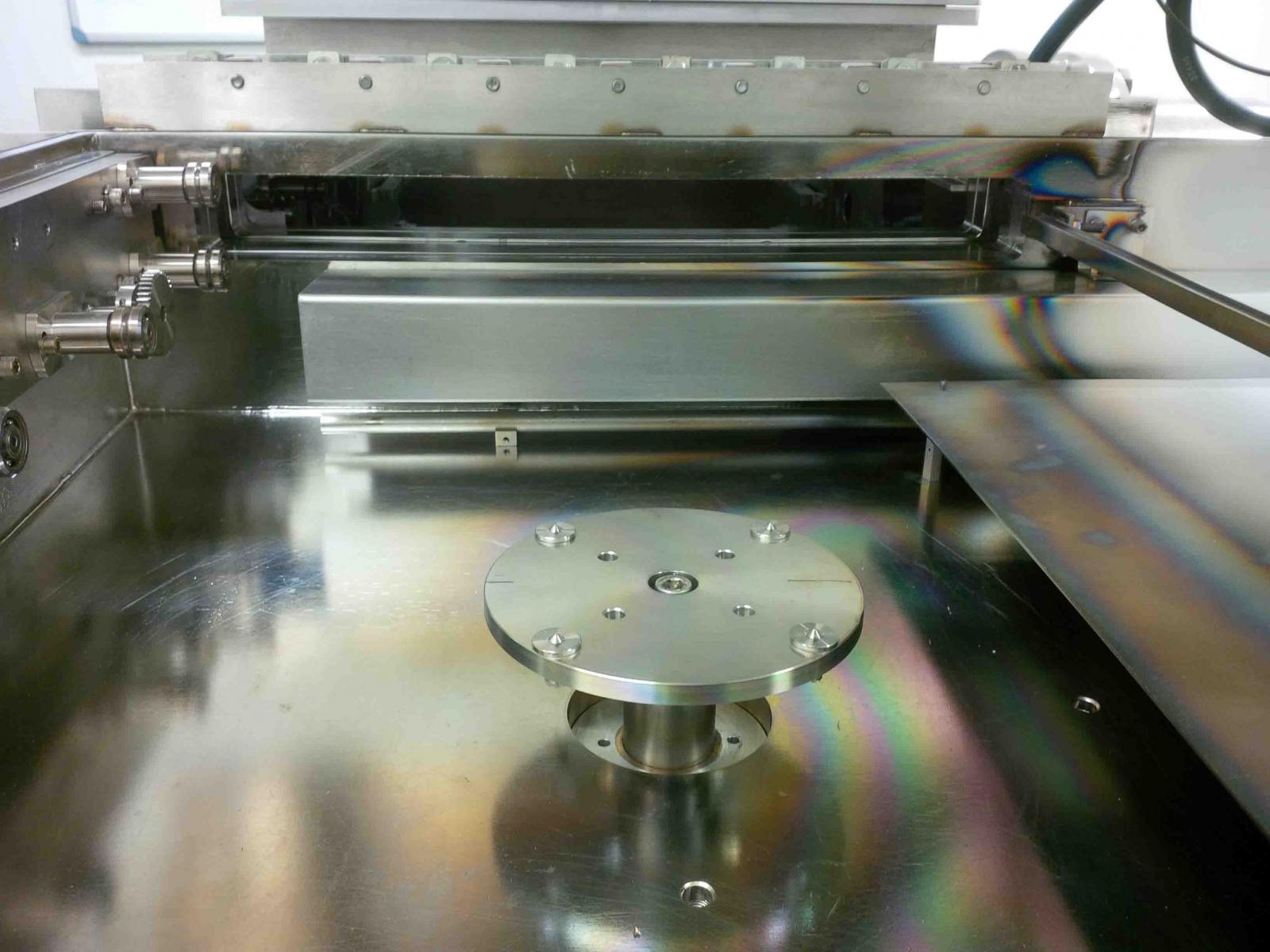

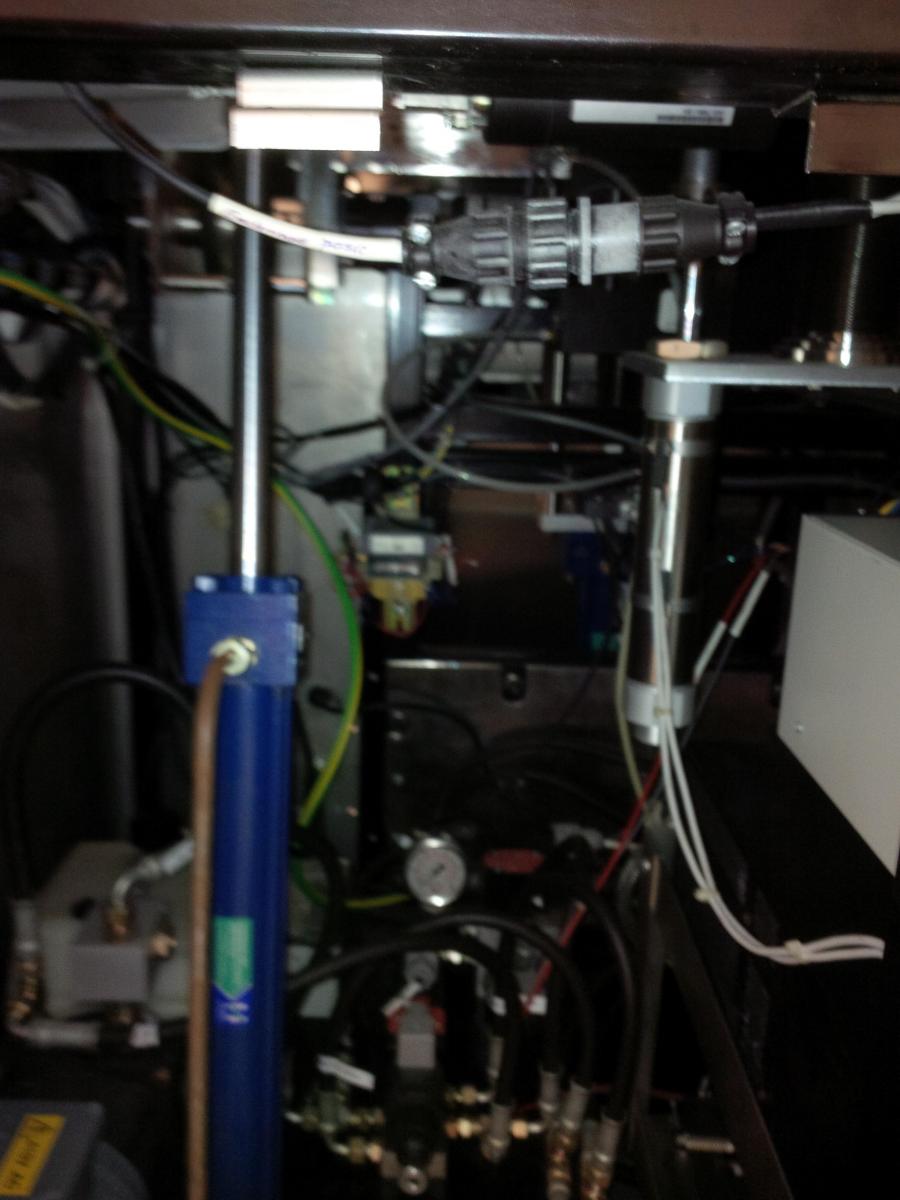

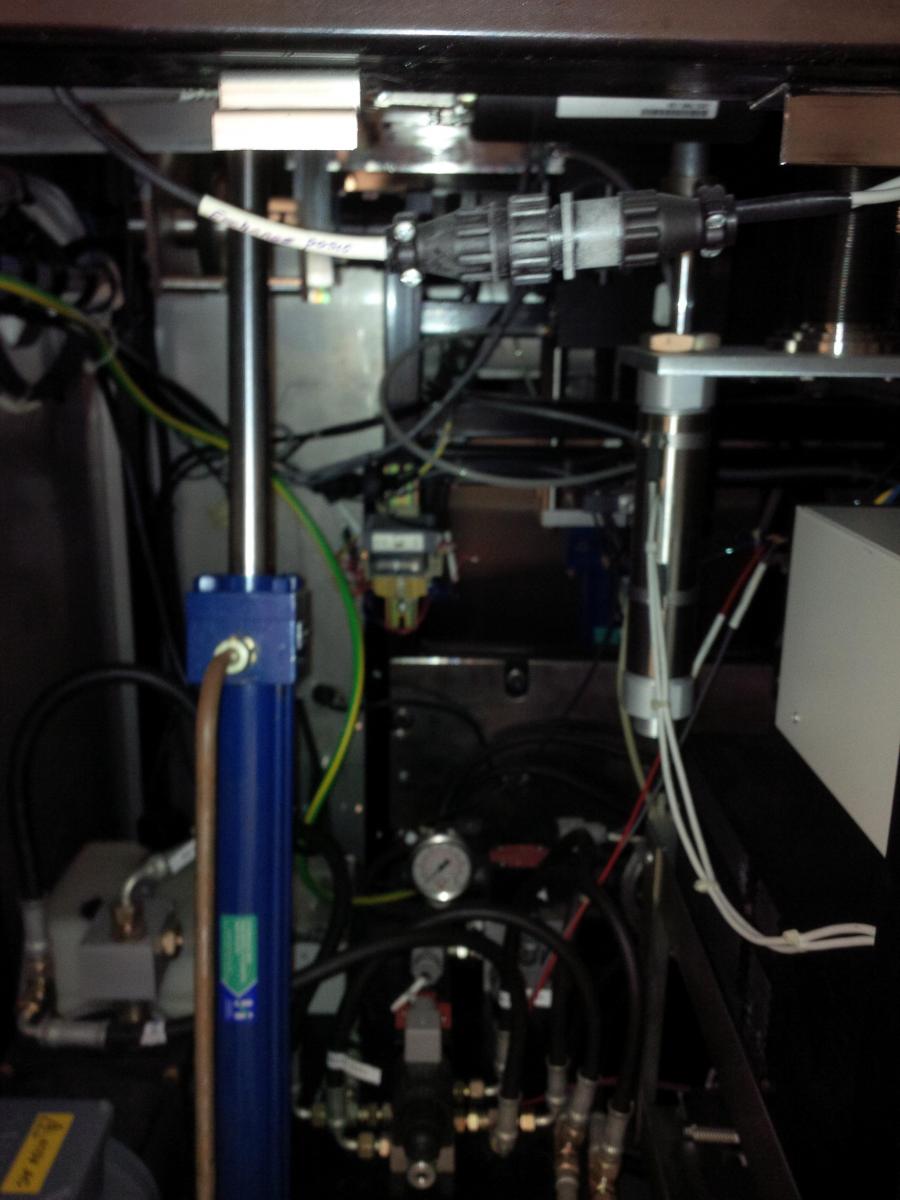

Feedthrough:

Linear bellows

Magnetically coupled drive

Drive:

Hydraulics

Low pressure drive

Motion:

Loading and unloading

Fully-automatic computer controlled

Capacity:

Diameter wafers: 6-150 mm

Diameter wafers: 4-200 mm

Drive:

Precision DC motor

With optical encoder feedback control

Chain drive

Labyrinth shielded

Option: DC Bias / RF Bias

Coating speed: 3-350 cm/min, Bi-directional

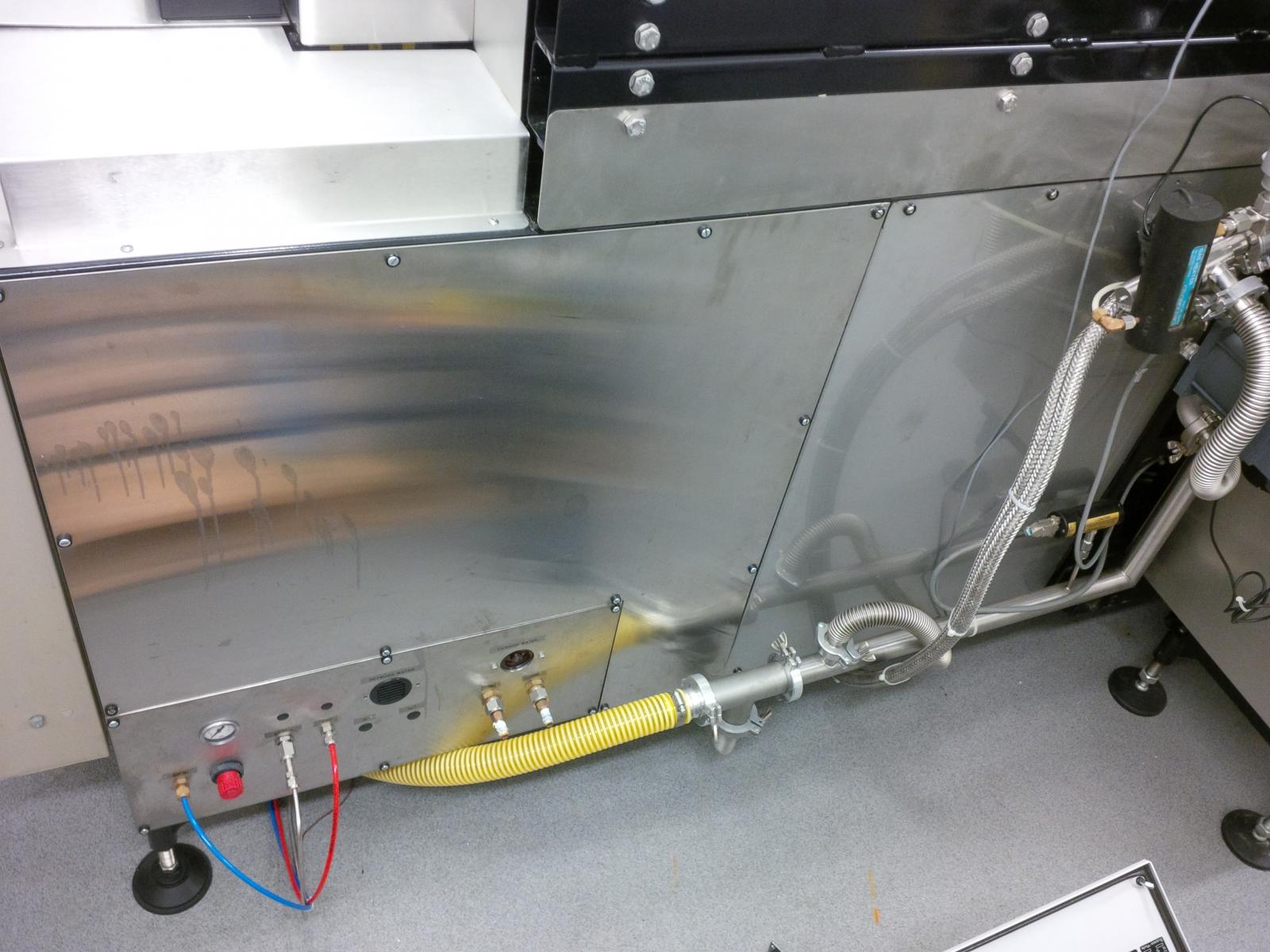

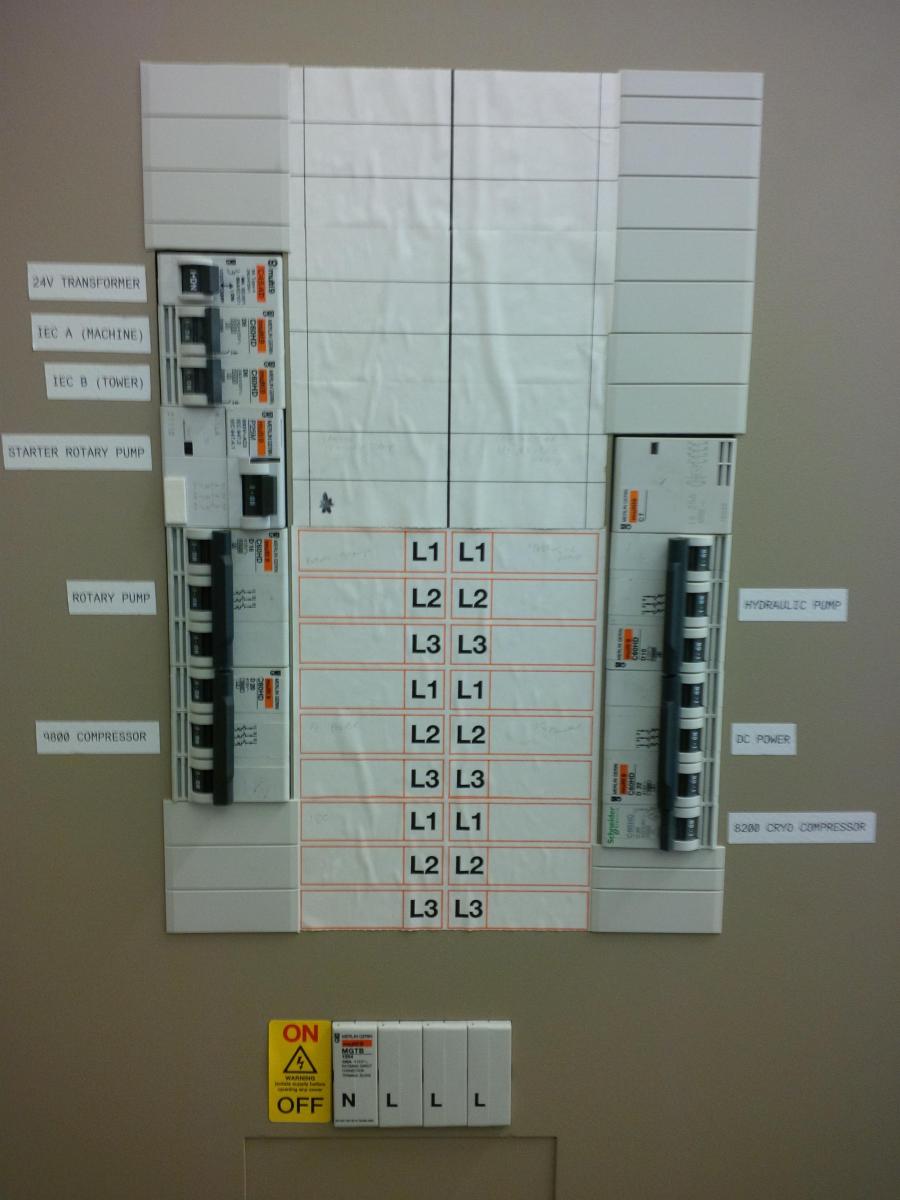

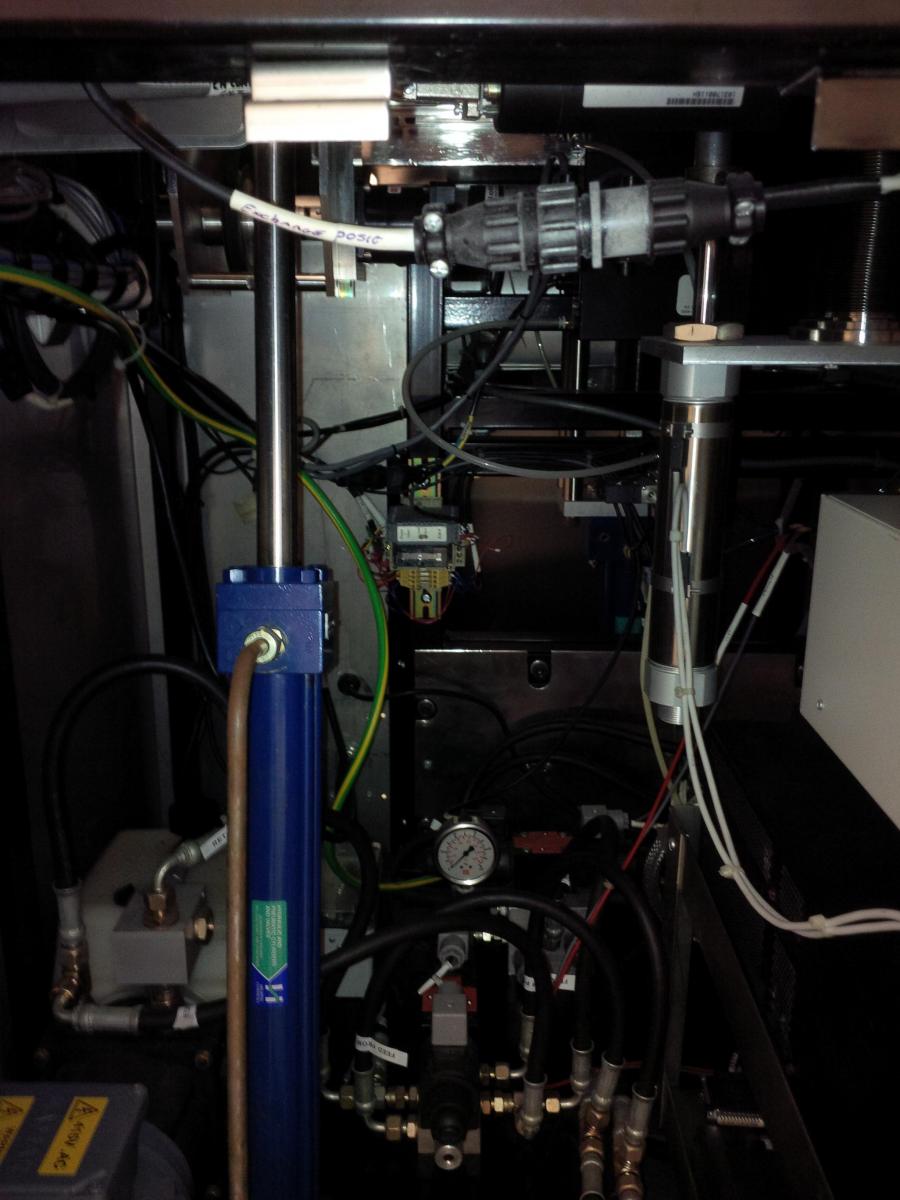

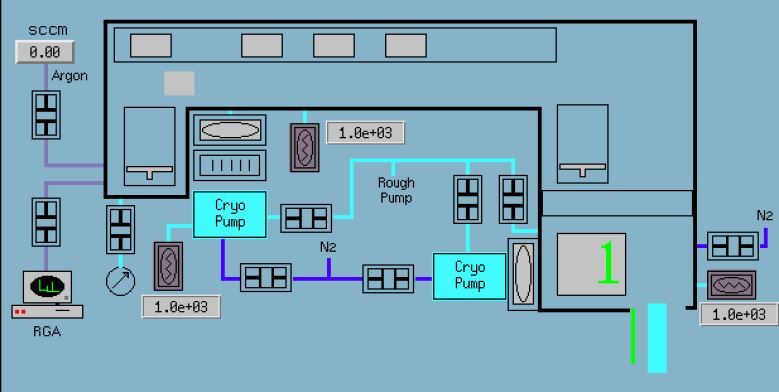

Vacuum system:

Load lock

CTI-CRYOGENICS Cryo-Torr 8 Vacuum pump

Vacuum valve: 6" ASA (7-1/8" Diameter) Gate valve

Electro-pneumatic operation

Valves: 1-1/2" Bellows sealed

Electro-pneumatic operation

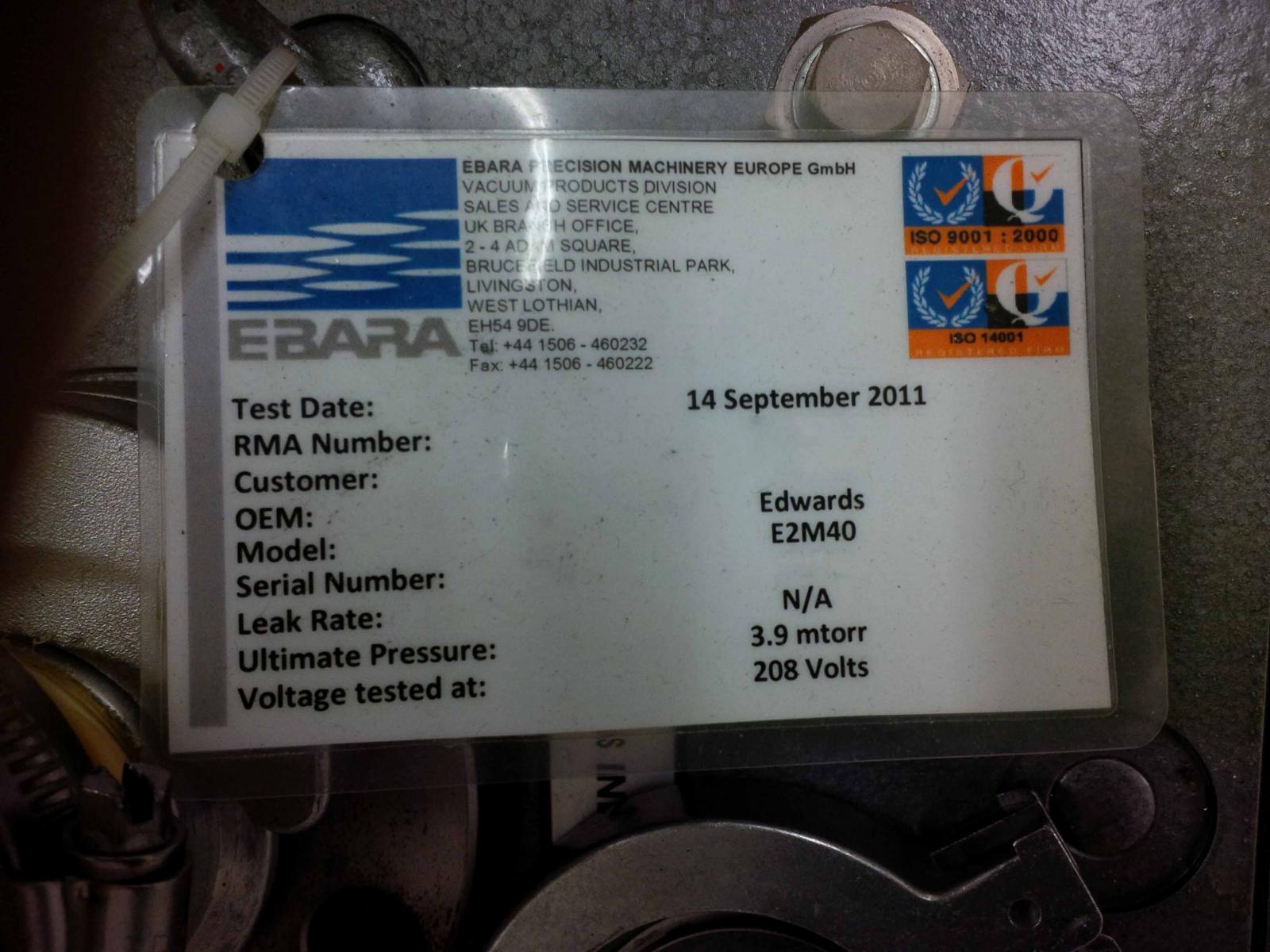

Roughing pump: 27 CFM (762 l/min)

With process chamber

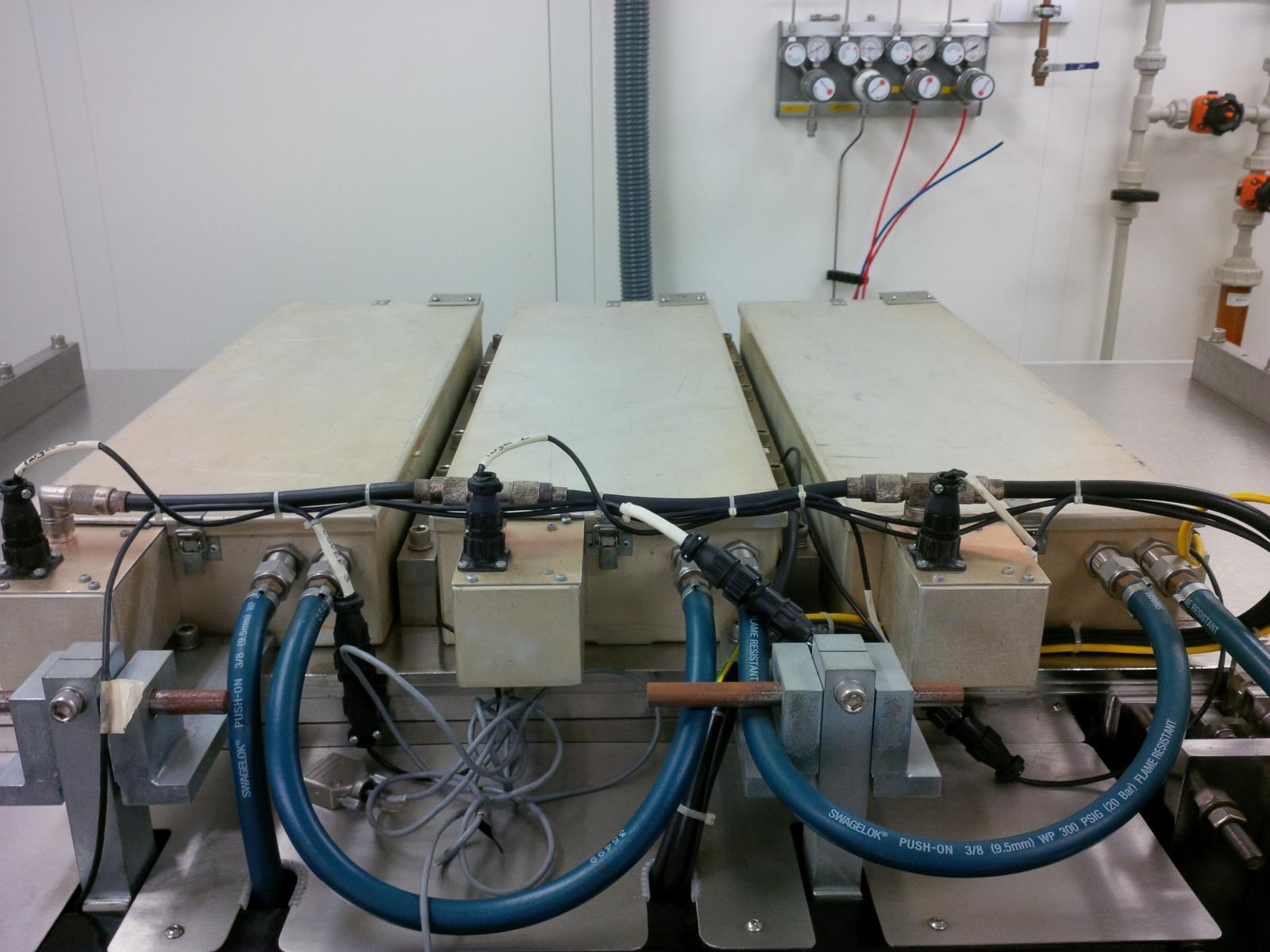

Main chamber:

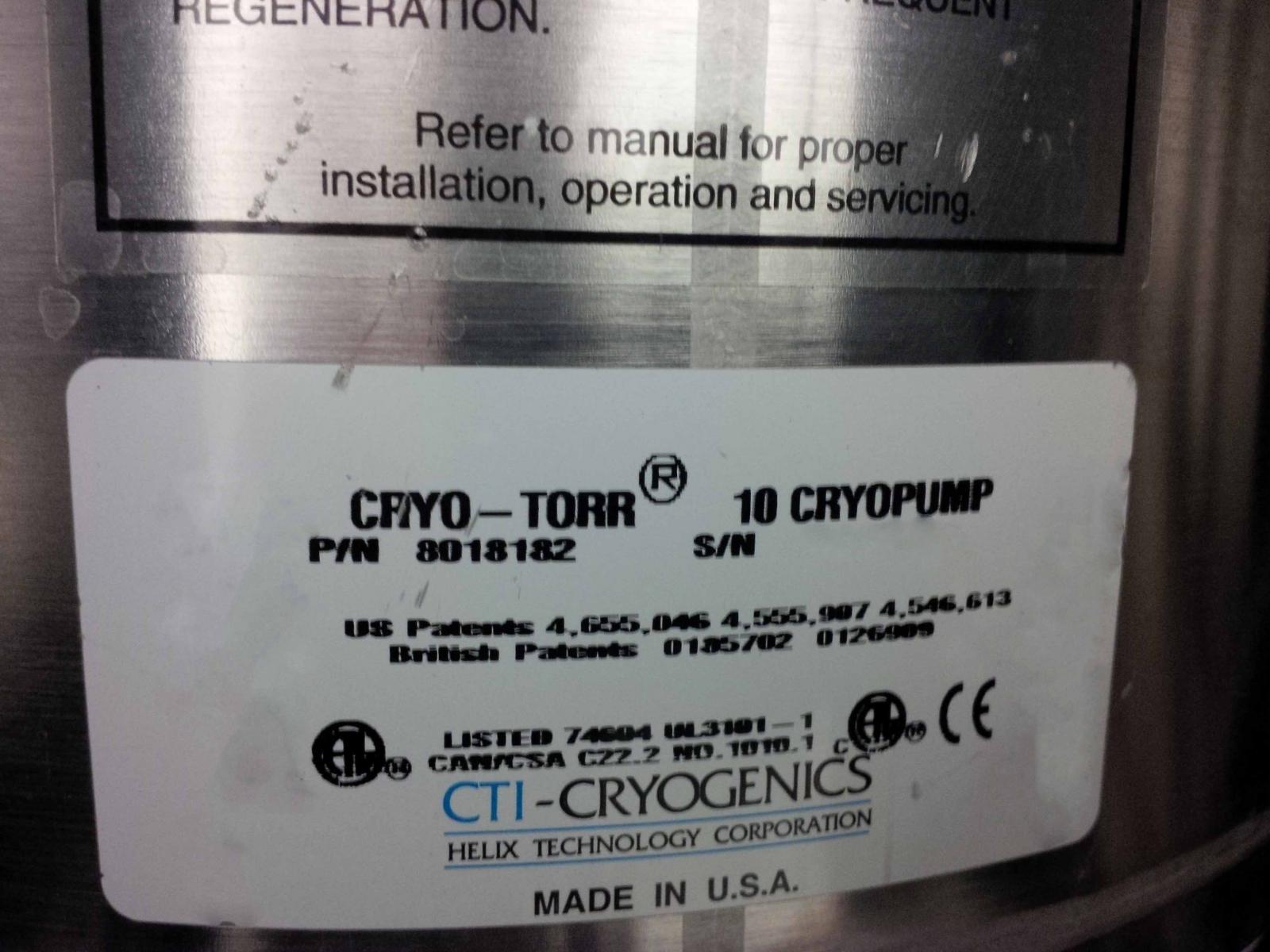

CTI-CRYOGENICS Cryo-Torr 10 Vacuum pump

Vacuum valve: ASA Gate valve, 10"

Electro-pneumatic operation for gas throttling

Load lock and cryo regeneration: 27 CFM Mechanical pump

Anti-back-streaming trap for mechanical pump

1-1/2" Bellows sealed electro-pneumatic operation

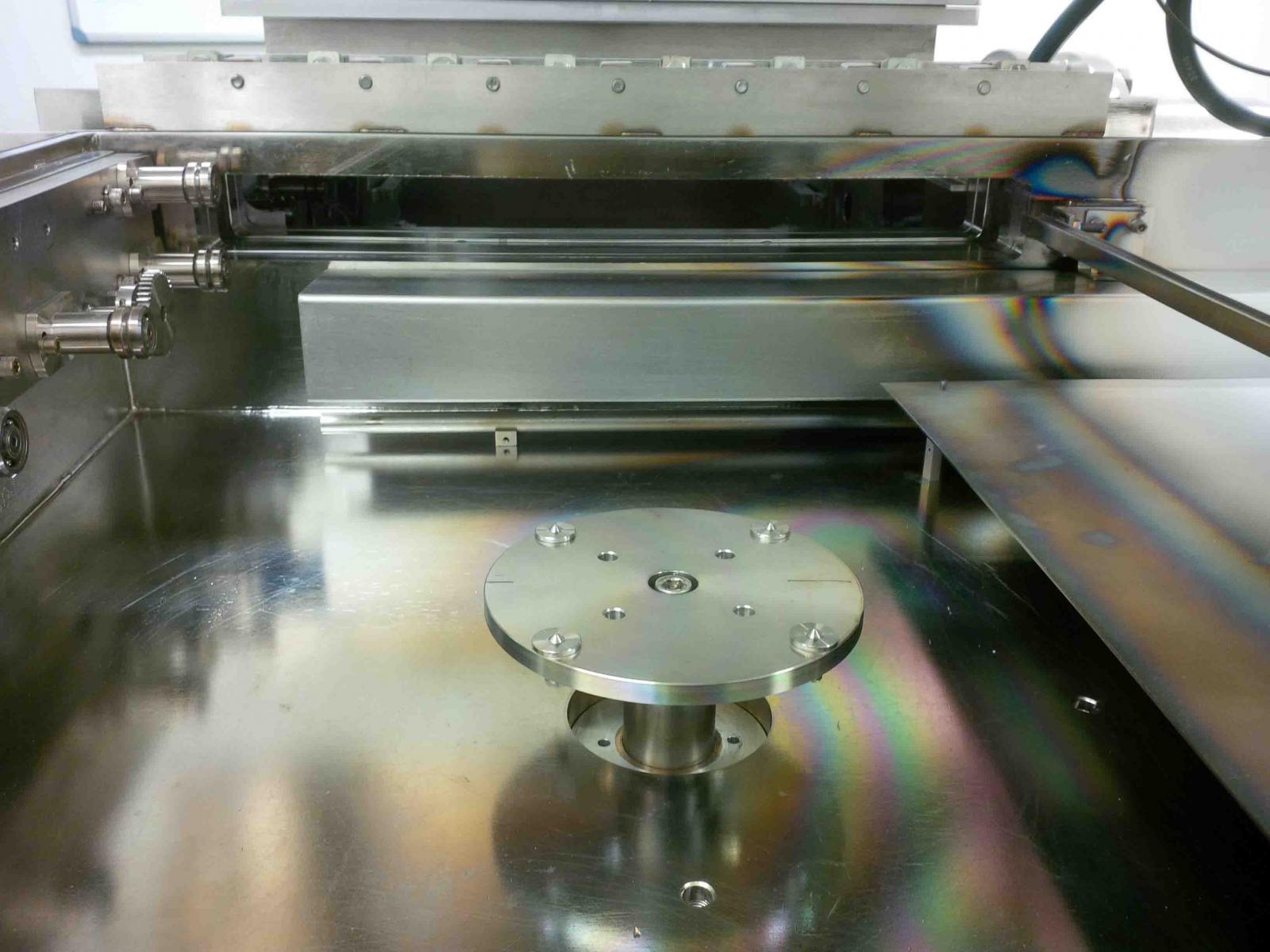

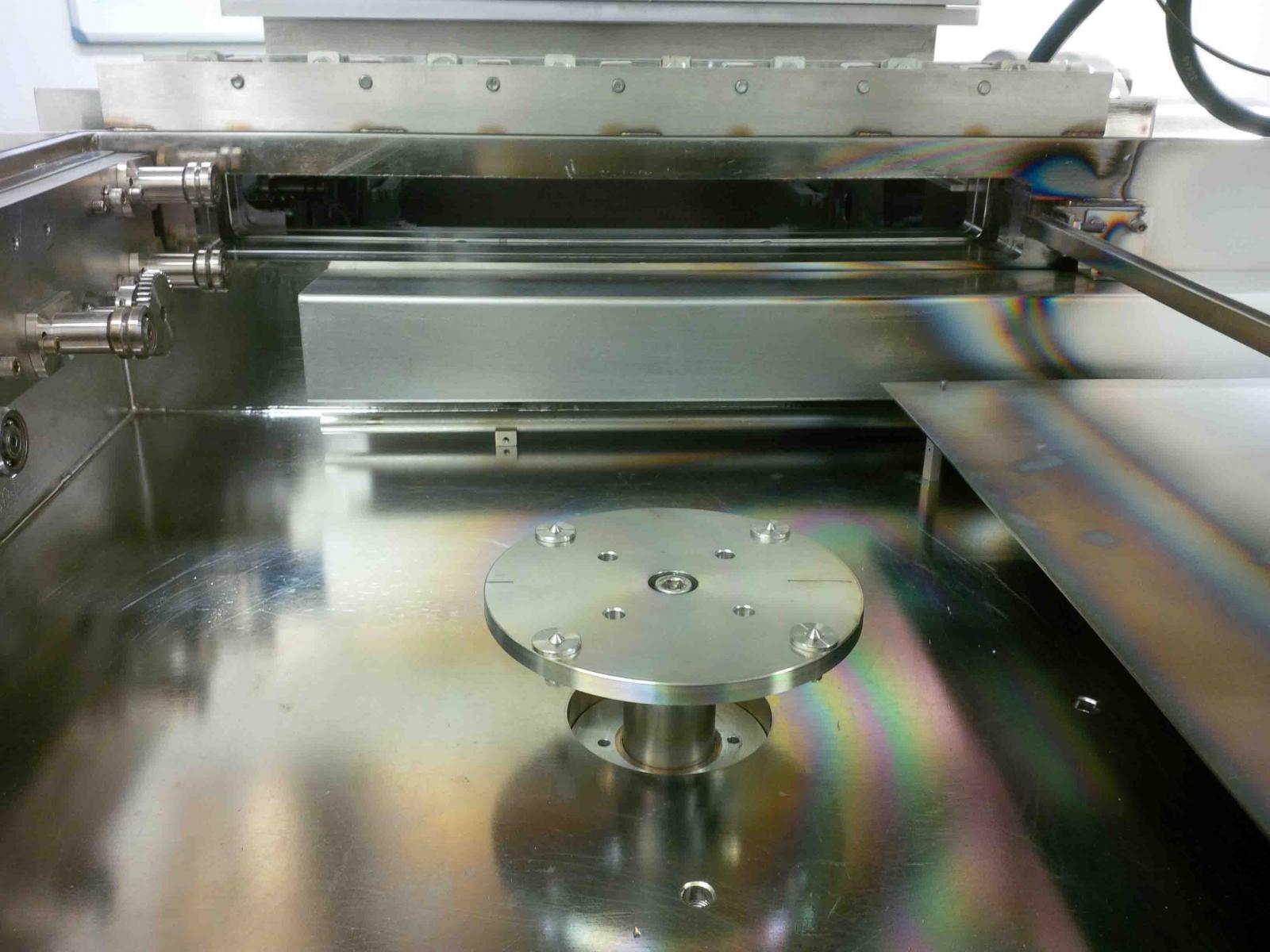

Etch platform:

Moves vertically to engage / Disengage the pallet

Cooling: Water-cooled

Material: Stainless steel

Insulator: Pyrex

Dark space shield: Stainless steel

Residual gas analyzer

RF Generator:

Continuously-rated and specifically designed for sputtering: 1 kW

ISM Frequency: 13.56 MHz

FCC and OSHA

DC Magnetron power supply:

ADVANCED ENERGY Pinnacle Power supply, 12 kW

System performance specifications:

Process parameter control ranges:

Description / Minimum / Maximum / Units

Sputtering pressure / 1 / 90 / Millitor

Scan speed (bi-directional) / 3 / 350 / cm/min

DC Sput / 100 / 12,000 / Watts

RF Sput / 0.02 / 2.10 / kVA

- / 0.1 / 2.00 / kW

Etch revel (Note 2) / 0.02 / 1.50 / kVA

- / 0.1 / 1.50 / kW

DC Bias capability:

Internal mechanism: DC Power

DC Bias activated during DC sputtering

Power supplies: 150 V.

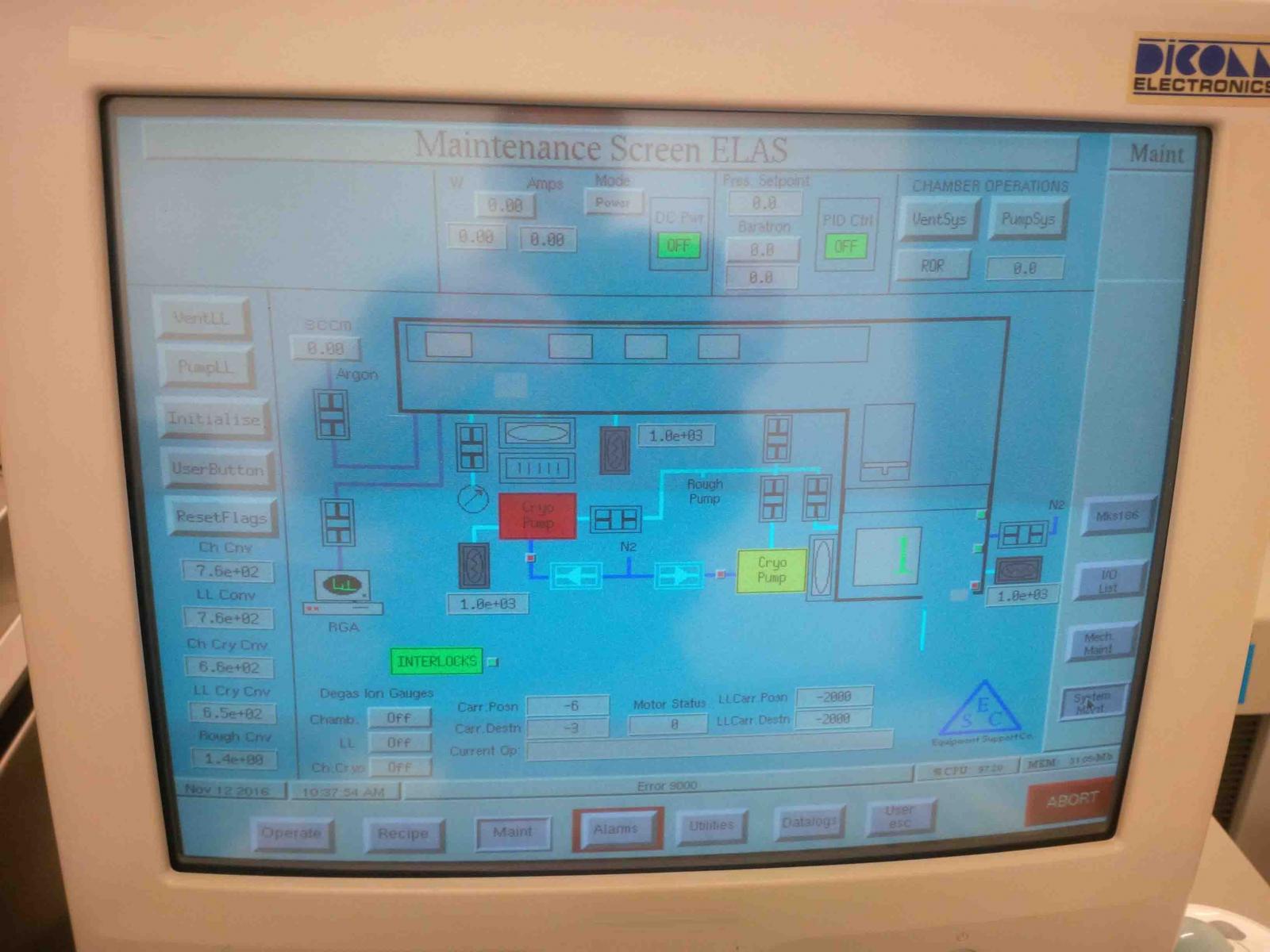

ESC ELAS是一種電化學蝕刻/灰化設備,旨在滿足現代薄膜電子的精密蝕刻要求。它是一個堅固而高效的蝕刻系統,利用高密度、脈沖直流功率進行快速、均勻的處理。該單元設計用於廣泛的蝕刻應用,包括金屬、氧化物、聚合物等可蝕刻薄膜材料。該工藝能夠實現每分鐘高達幾百納米的蝕刻速率,對選擇性、深度、線寬和表面粗糙度進行非常精確的控制。ELAS機器是建立在成熟的技術,包括一個密封,銅套軀幹絕緣和耐腐蝕。該機組還配備了集成加熱元件,以保持穩定的溫度和自調壓力調節的功率調節蝕刻室。這確保了統一的蝕刻過程,並促進了極其精確的可重復結果。為達到最佳蝕刻速率,該工具采用了多種蝕刻機構,包括化學氣相沈積或CVD,以及高溫爐工藝。單獨控制的惰性氣氛允許更長的蝕刻時間,產生更深的蝕刻。或者,在真空環境中使用等離子體蝕刻可以實現效率更高的短時蝕刻。ESC ELAS資產可以處理範圍廣泛的晶圓尺寸,從小型芯片到大型矩形面板。它還配備了XYZ級,允許在處理過程中精確放置和固定工人。該模型還包括電子束和X射線蝕刻工藝,以獲得更精確的蝕刻結果。所有這些功能結合在一起,使ELAS成為精確蝕刻需求的絕佳選擇。該裝置非常可靠,能夠持續產生高質量的蝕刻結果。此外,它允許用戶通過高級診斷程序持續監控蝕刻過程,並提供高重復性的結果。因此,它是工業市場上高精度電子生產應用的理想選擇。

還沒有評論