二手 MATRIX 205 #9201811 待售

網址複製成功!

單擊可縮放

ID: 9201811

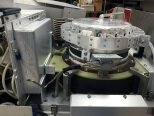

晶圓大小: 6"

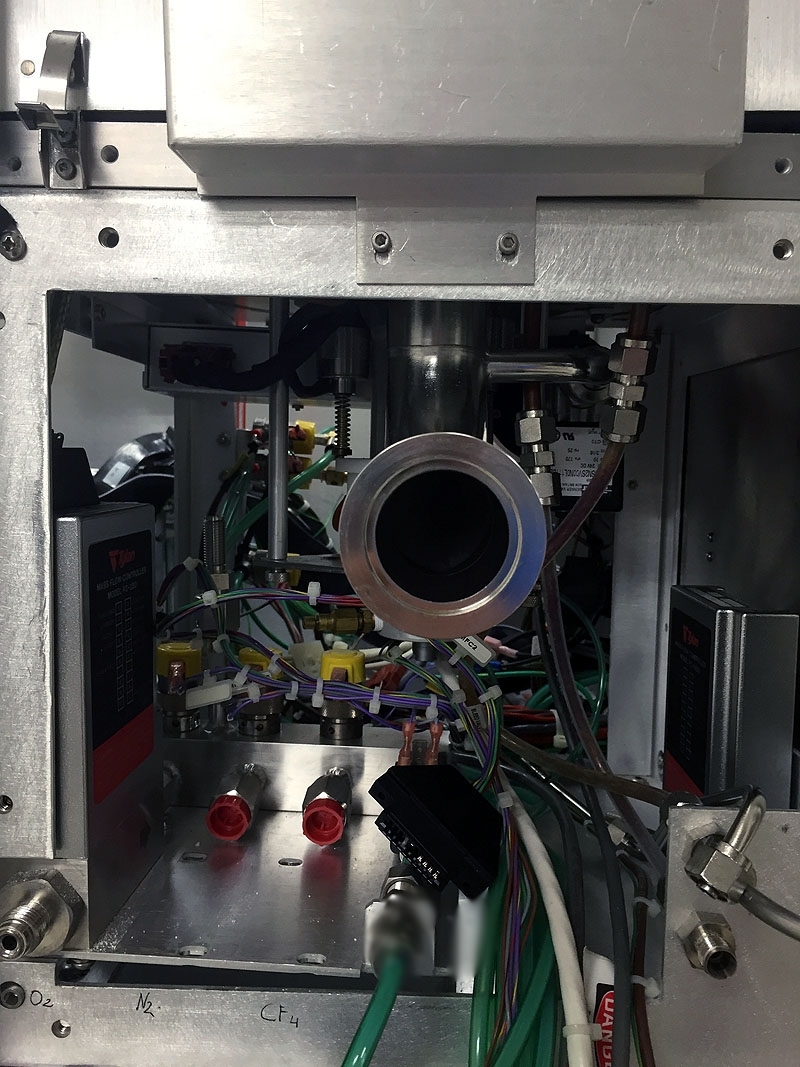

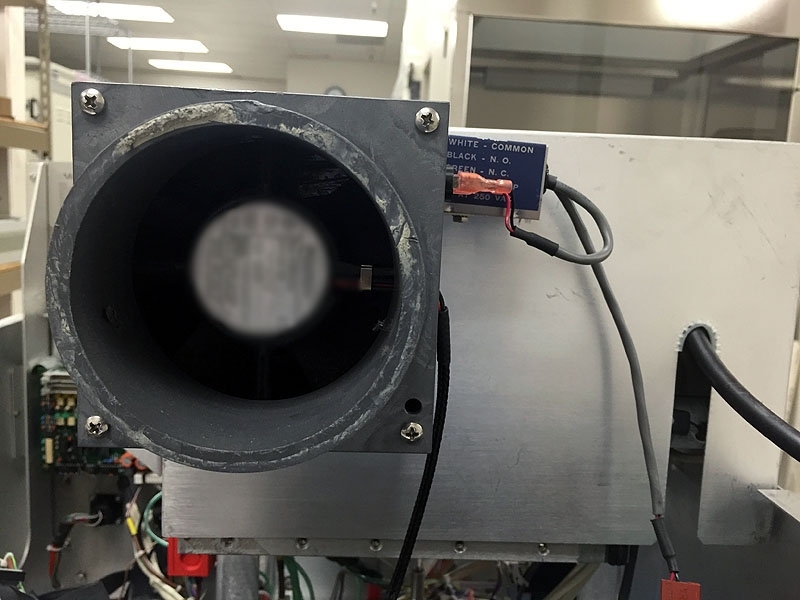

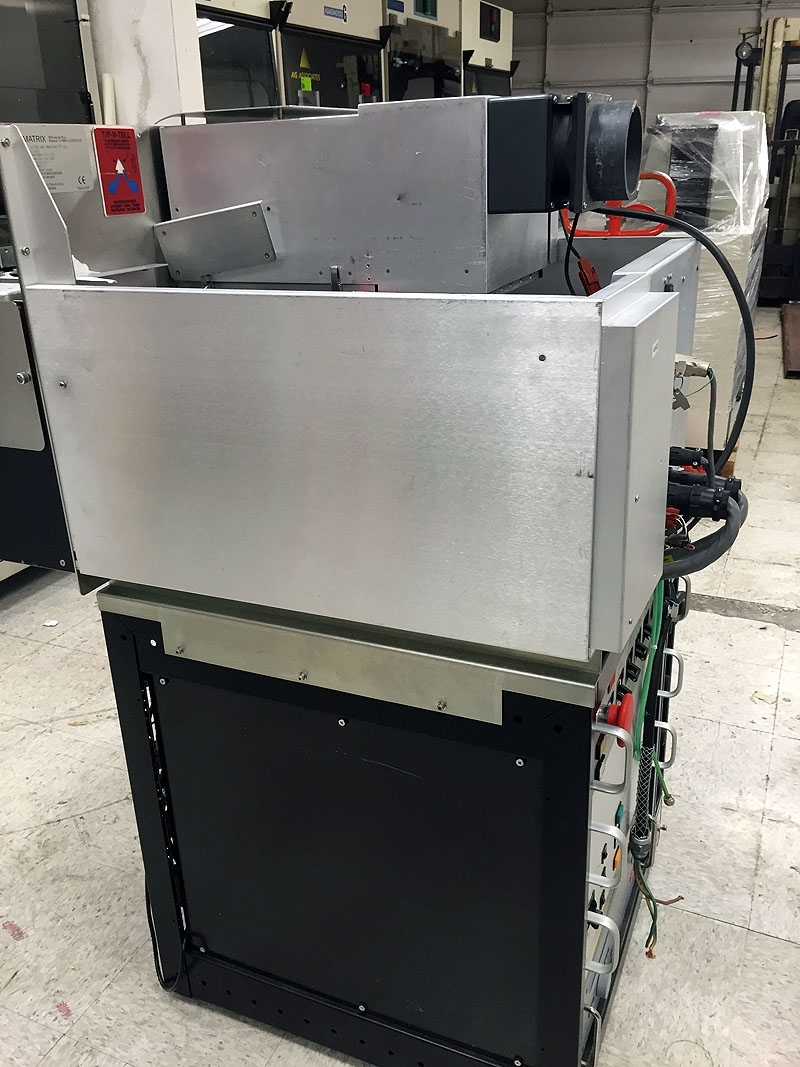

Plasma asher / descum dry clean system, 6"

Including ranging:

50mm up to 150mm

The system optimizes vital device parameters:

Enhanced gate oxide integrity

Reduced threshold and capacitance voltage shifts

Reduced contact resistance / Oxidation

Photoresist Stripping:

High dose implant

Post-polysilicon etch

Post-metal etch

Post-oxide etch

Controlled resist removal:

Post-develop descum (pre-etch)

Dry / wet process capability

Uniformity capability (<5% 1σ)

GaAs, InP wafer strip and descum

Thin film head resist cleaning

Opto-electronic devices cleaning

MEMS

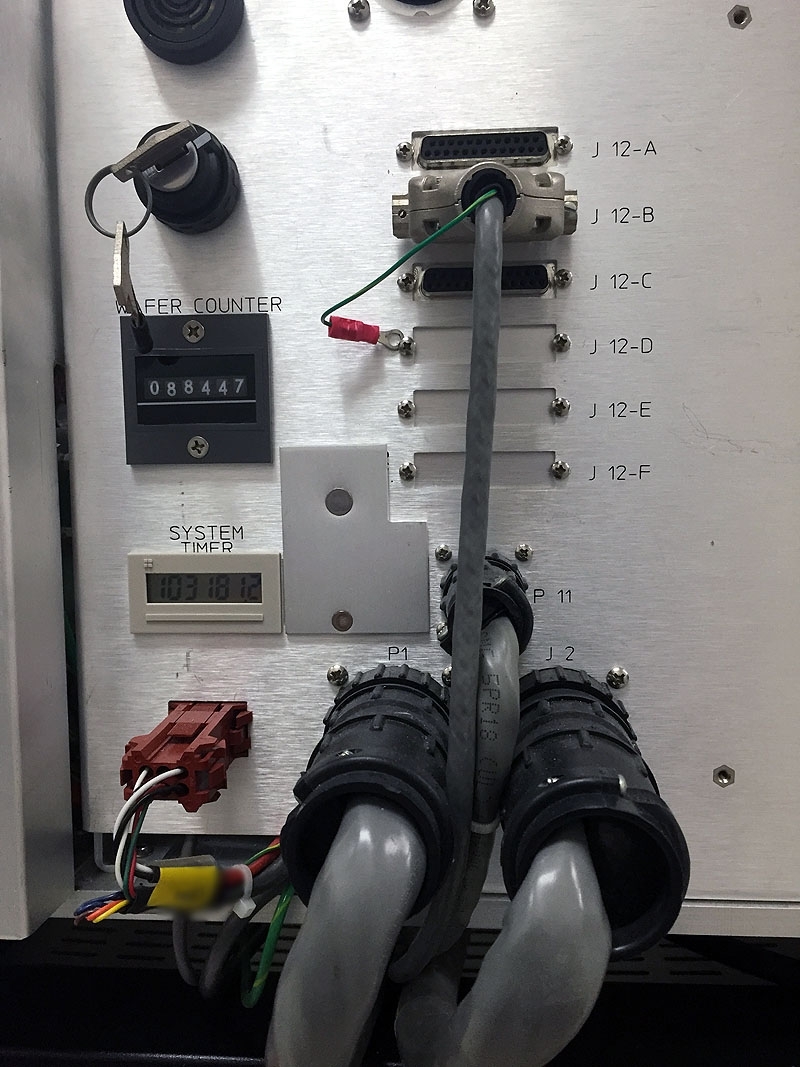

Single wafer multi-Step Processing:

Precisely controlled & repeatable stripping of each wafer

(3) programmable steps + overstrip

Capable of long process times for exceptional control

High throughput:

35 WPH on 150mm substrate

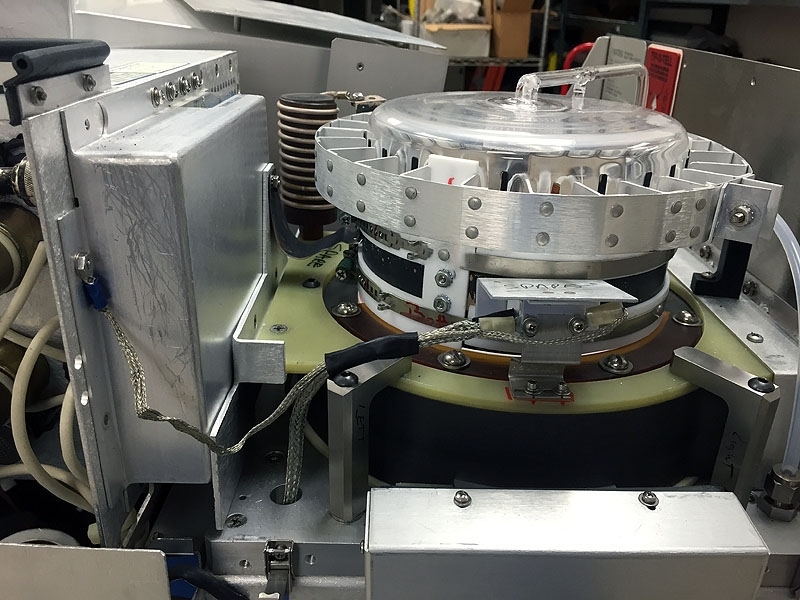

Aluminum Wafer Chuck:

Fast

Precise

Uniform removal of resist

Low Particles:

0.1 particles (>0.3μm) added per cm2

Proven System Performance:

700 System ones in use worldwide

95% uptime

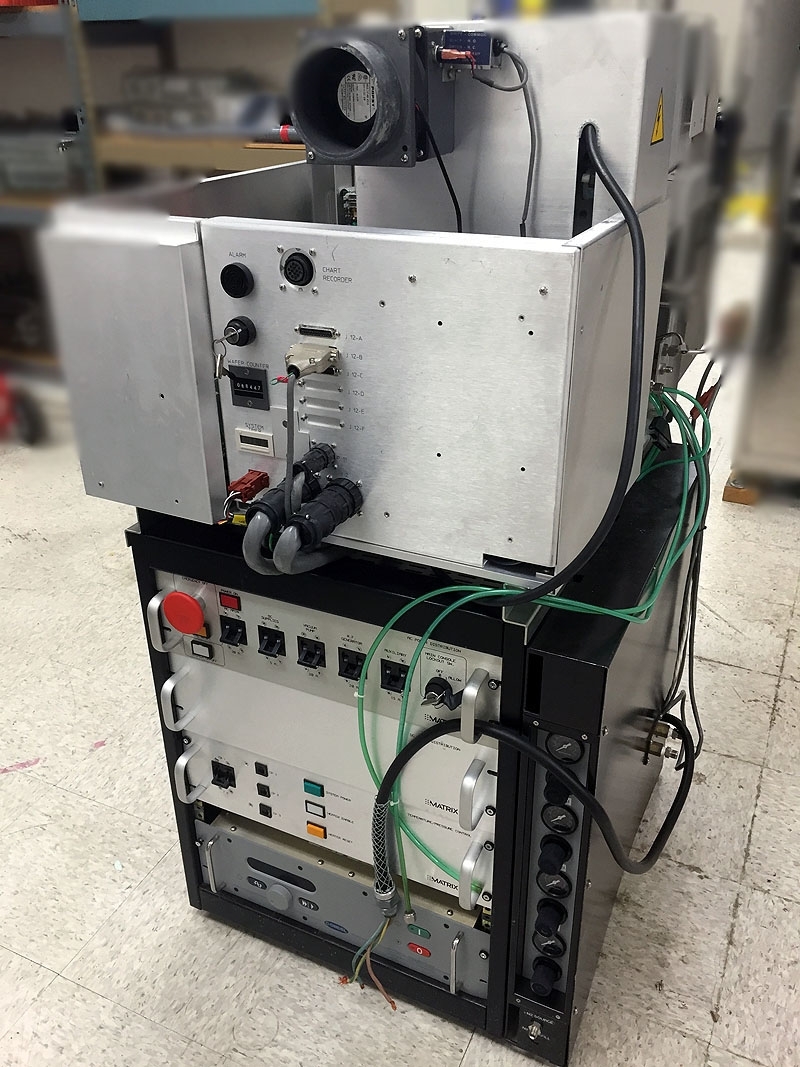

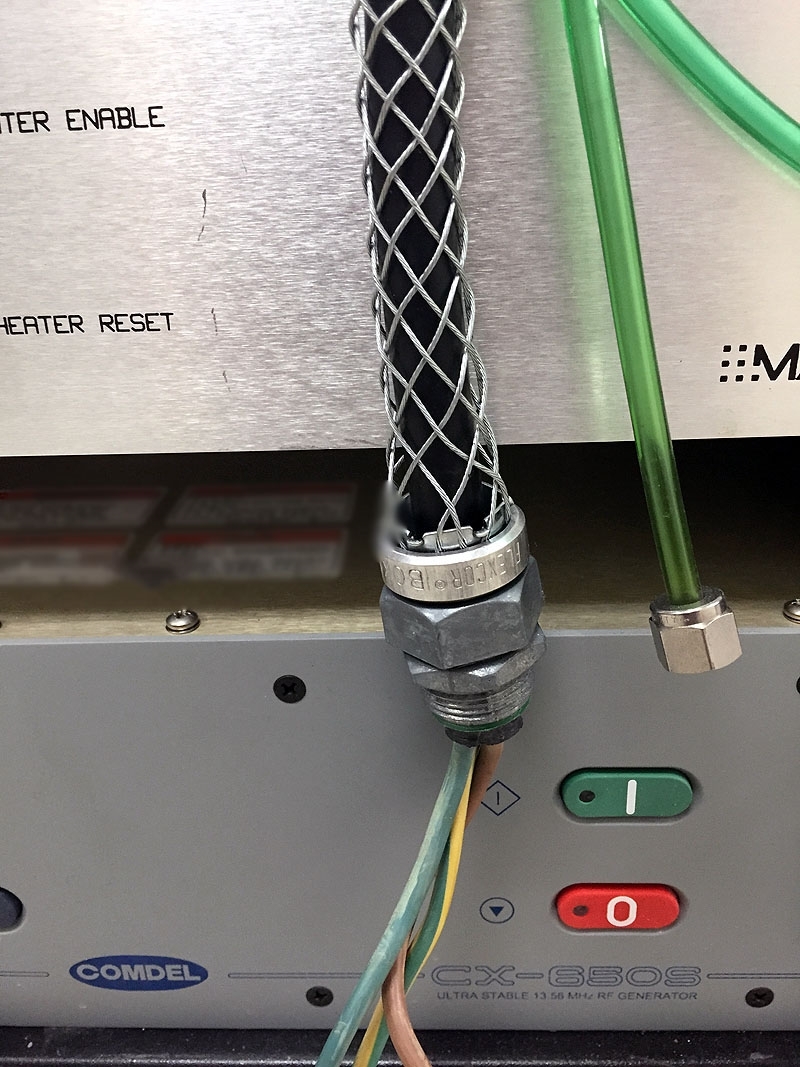

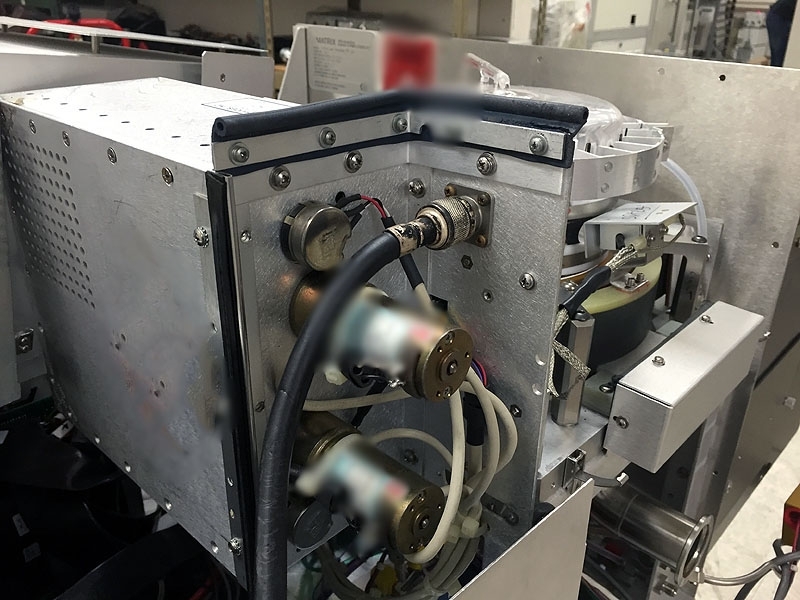

Proven Reactor Design:

Closed-loop temperature control

Stable range for strip:

150°C – 250ºC (+/-5°C)

For descum:

70°C – 150ºC .

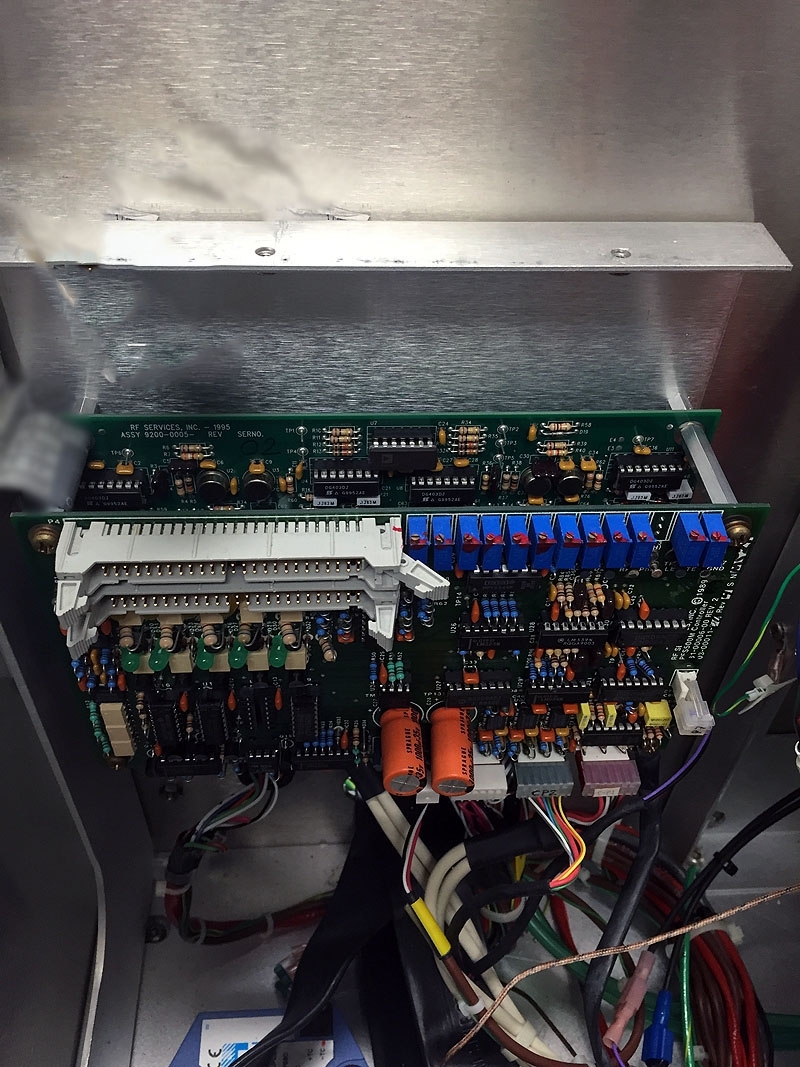

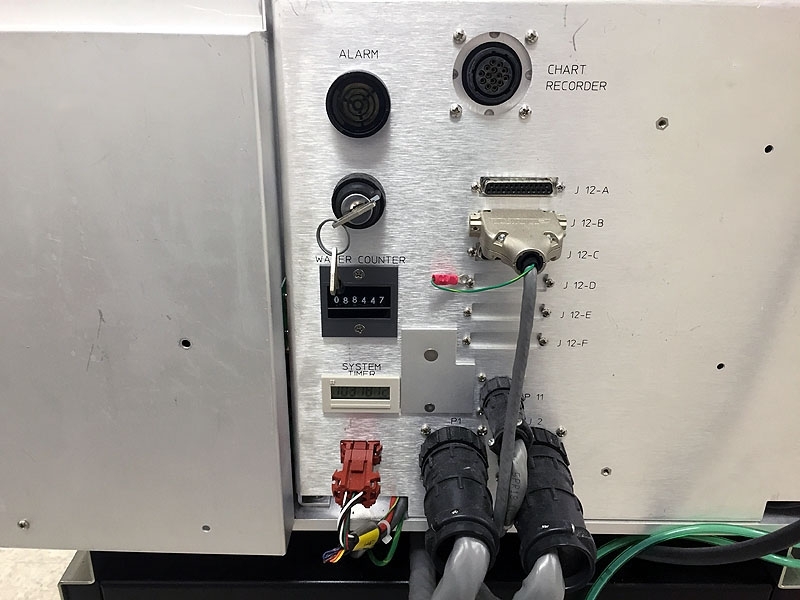

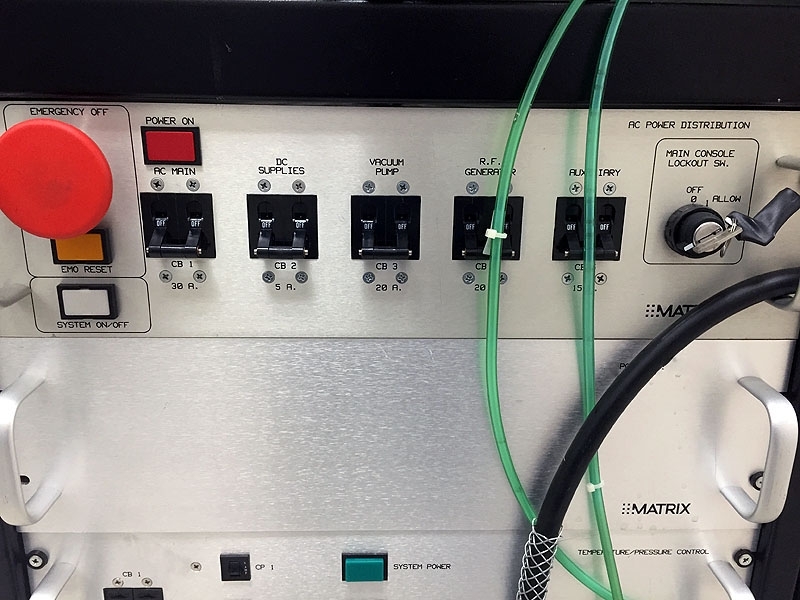

MATRIX 205是一種在微電子工業中常用的蝕刻器/asher,以便在晶圓的表面上創建復雜的形狀、圖案和圖像。該裝置配備了高真空系統,使其能夠精確蝕刻精細電路等幾何形狀,並且能夠進行非常高分辨率的成像。通過設備的使用,除了通過清洗、平面化和蝕刻後清洗等各種其他任務外,還可以蝕刻各種尺寸的形狀,如線條、弧形、多邊形和圓圈。該裝置采用低溫泵來提供超高真空和離子源來提供蝕刻均勻性。蝕刻過程由電場驅動,通常在圓柱形腔室中產生。蝕刻圖樣的形狀和大小由用於蝕刻過程的氣體類型,以及用於饋送離子源的電流和電壓決定。該裝置還包括一個真空冷卻器、一個支架和一個視圖端口,並且能夠產生一個線寬低至0.5微米。蝕刻和清潔過程非常有效,通常需要大約五分鐘才能完成。蝕刻圖案精度小於1微米。此外,205可以一次執行多個蝕刻任務,能夠同時執行三個或更多蝕刻步驟。這意味著該設備可用於快速產生復雜的電路,而無需手動更改蝕刻過程。此外,該設備具有內置的監視器和診斷系統,使其能夠提供即時反饋並排除可能出現的任何過程問題。MATRIX 205可靠性高,易於使用,價格合理。它是微電子工業中產生復雜圖樣、電路和圖像的理想工具。

還沒有評論