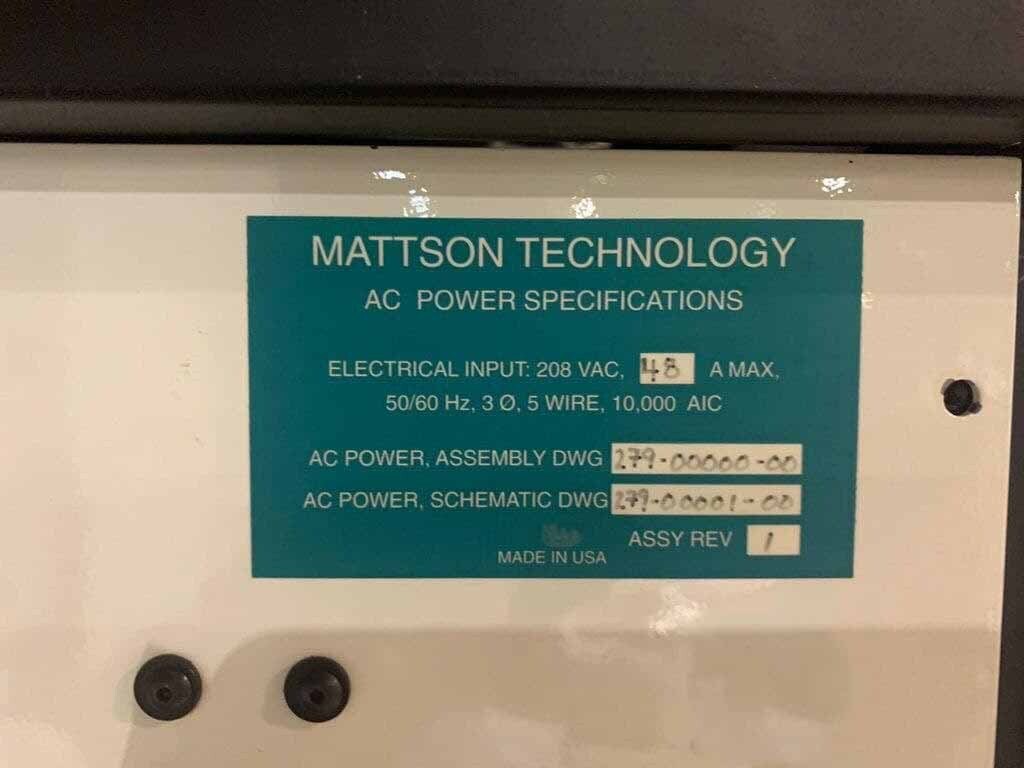

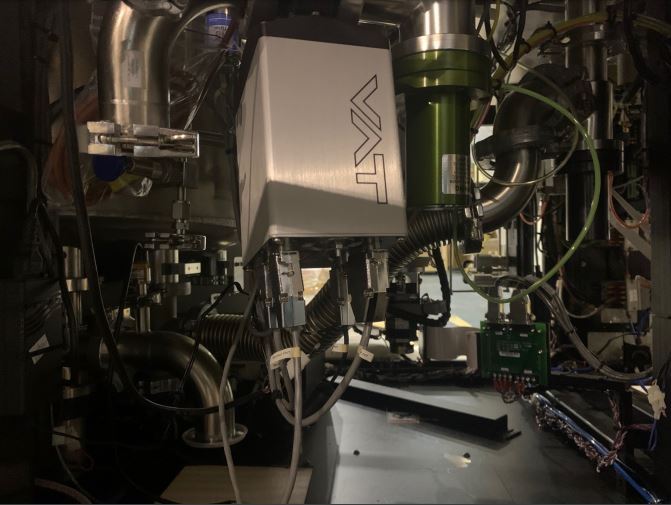

二手 MATTSON Aspen II #9398659 待售

網址複製成功!

單擊可縮放

ID: 9398659

晶圓大小: 8"

ICP System, 8"

MATTSON Endpoint detection system

With fixed filters: 430 and 520

Cable length: 19 ft

(3) RF Cables and signal cables

(2) Heaters

MFC

Chambers:

Back chamber:

366 MHz CPU: Analog in and PCB out

Floppy Disk Drive (FDD): DI/DO Cards

Chassis: Power supply

Gas channel: Bottom feed channel

Cool down station: No water cooling

Gas lines

Right chamber:

366 MHz CPU: SEC II Card

Floppy Disk Drive (FDD): Robot stepper (SMC-PC3)

Chassis: Backing plain

Gas channel: Junction box

Cool down station: Lexan plates

Gas lines with filters

Front end:

26" Opening with separate operator interface

4-Color light tower

Operator / Engineering monitor: TFT Design monitor

Gas box with sub frames

EMO Buttons

Interlock circuit: Push button switches

Hanging panels

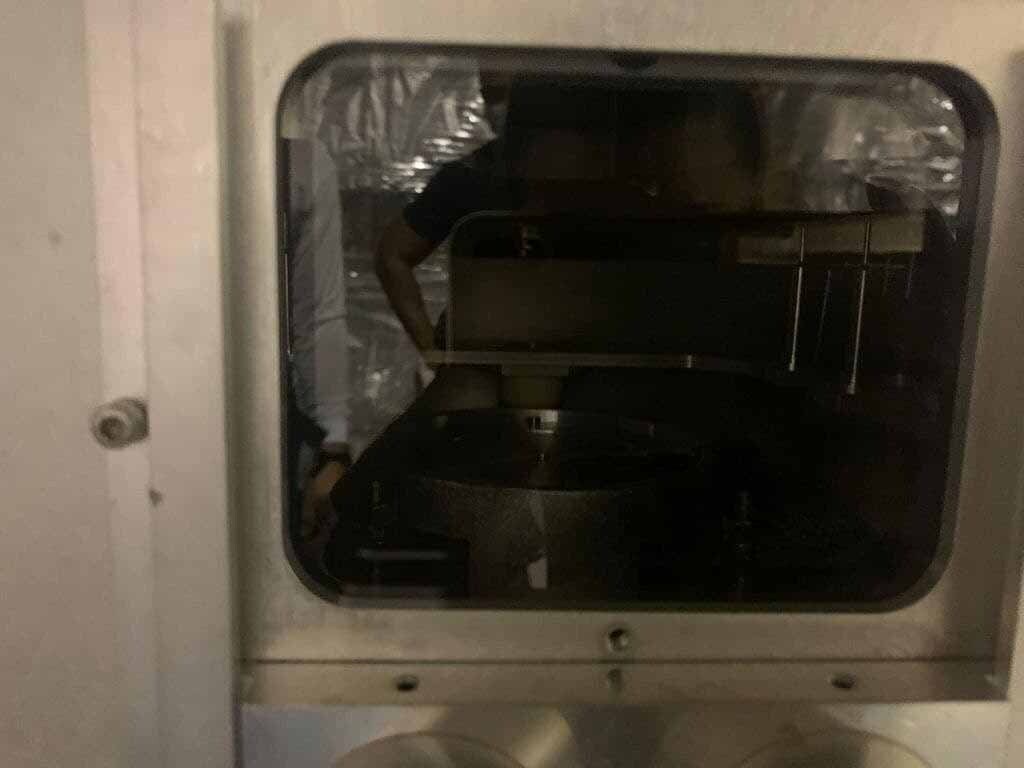

Load lock:

Single load lock

(2) Cassette stations

Capability of queuing lots

Pin search assembly: Proximity sensors

Load lock seal: Lip seal

Platform and cassette:

(4) 25-Slot cassettes

Rotating cassette nests, 8"

Cool down station: Flat cool down station without water lines

Load lock fast exchange

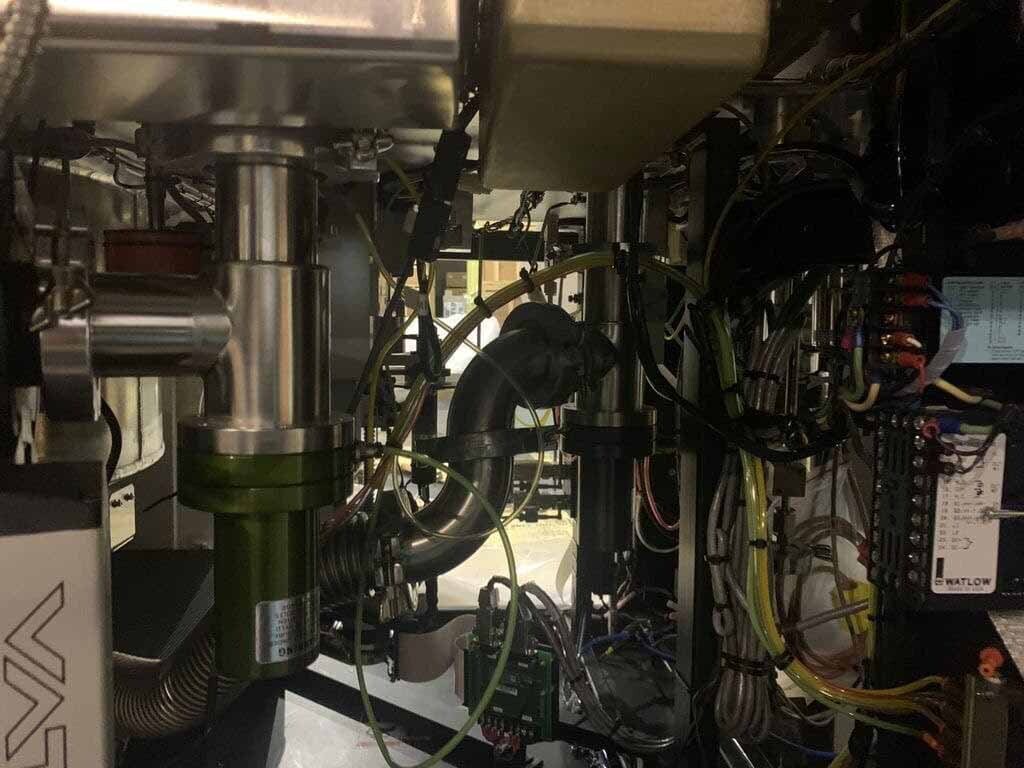

Transfer robot:

Main robot: 3-Axis robot with flex cable

Robot arm: (4) Adjustable paddles with standard arm

Slit door

Wafer sensors: Paddles, front and rear cassettes

Shuttle: 26"

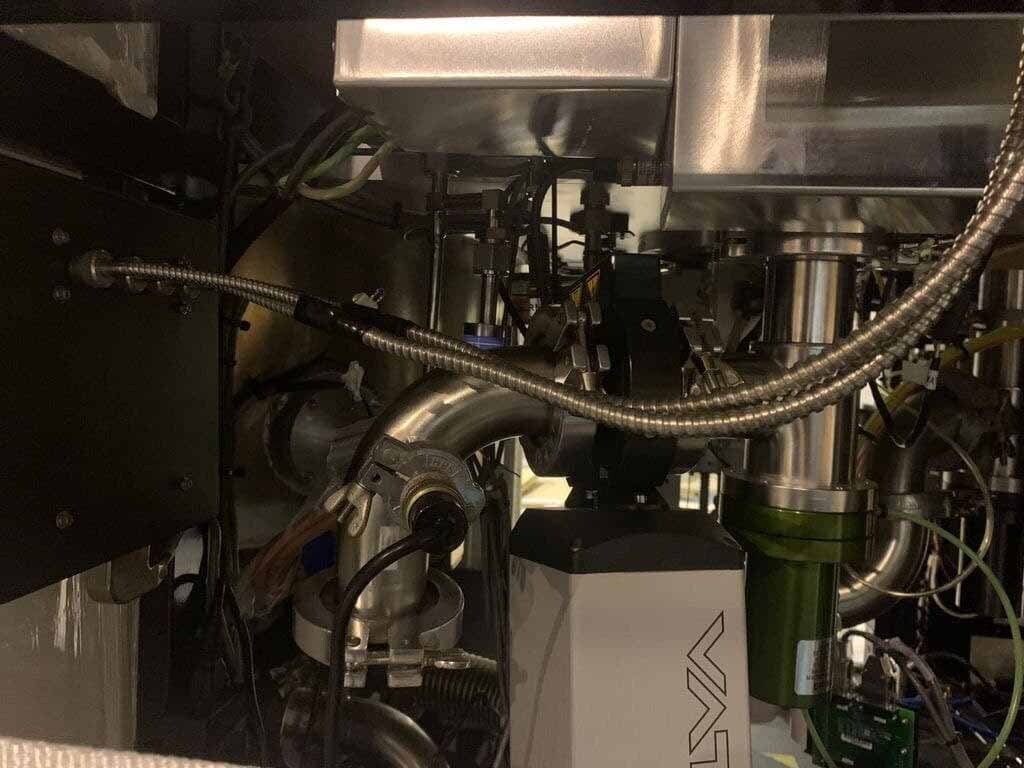

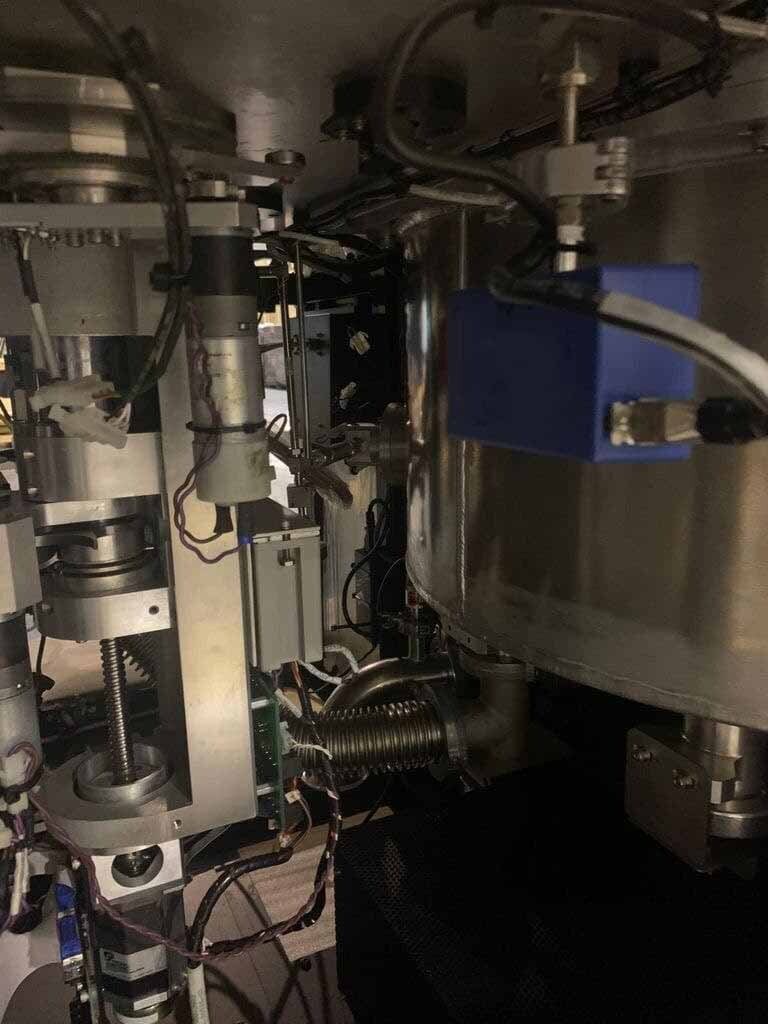

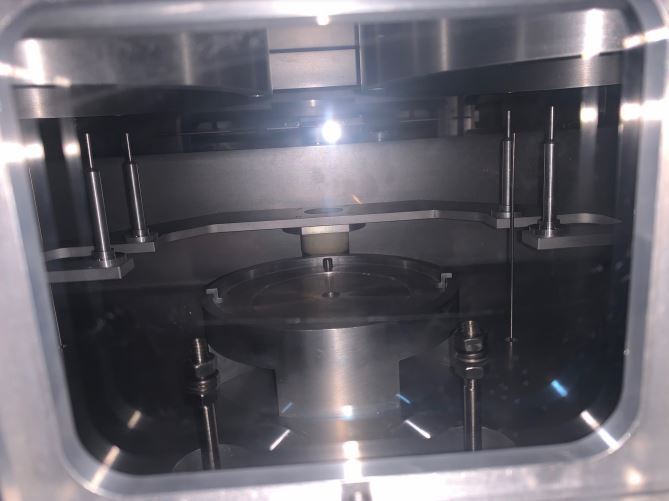

Process module:

Chamber right and back:

Tube type: Quartz tube

Standard process window

ICP Chamber O-ring type: Flurosilicon

Temperature controller: WATLOW 988 / EZ Zone

Thermal couples: Spring loaded TC

Lift pin assembly

Grids / Guide rings: Extended guide ring

Electrical feed through

Manifold and ceramic parts

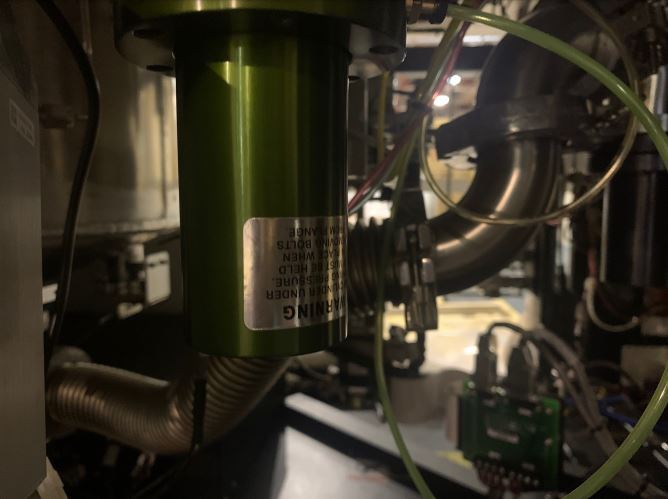

Isolation valve

Top plate

Load lock

Chamber

Pressure controller:

VAT Valve pressure controller

Chamber manometer: 10 Torr

Load lock manometer: 100 Torr

Shuttle manometer: 1000 Torr

RF / MW System:

RF System: Top RF 13.56 MHz

(3) RFPP10 RF Generators: (2) Power cables missing

TRAZER AMU 10D-2 RF Top match, P/N: 914-92003-00: (2) Vacuum capacitors missing

Re-silvered RF coils

(125) RF Vacuum caps: 100PF

AC Box: 2-3 Phase generators with safety cover

DC Box

Gas system:

Gas VCR gasket: Stainless steel and Nickel

Gas line / Gas / Range

Gas 1 / O2 / 1000 SCCM

Gas 2 / N2 / 1000 SCCM

Gas 3 / N2/H2 (4%) / 2000 SCCM

Gas 4 / CF4 / 100 SCCM

Side:

Gas 1 / O2 / 5 SLM

Gas 2 / N2 / 1 SLM

Gas 3 / CF4 / 200 SCCM

Gas 4 / O2 / 1 SLM

Rear:

Gas 1 / O2 / 10 SLM

Gas 2 / N2 / 1 SLM

Gas 3 / CF4 / 200 SCCM

Gas 4 / O2 / 1 SLM.

MATTSON Aspen II是一款先進的蝕刻設備,提供高吞吐量、低擁有成本的精密蝕刻。它旨在提高生產率,同時提供高度的靈活性和對蝕刻參數的控制。Aspen II用於需要蝕刻各種材料的多種類型的應用和研究項目。適用於蝕刻矽、石英、鉬和不銹鋼等多種基材。該系統具有可調節的臺階,可輕松蝕刻大或小基板,包括角、邊和臺階。大蝕刻室允許一次蝕刻多個晶片,以加快生產速度。MATTSON Aspen II很好地配備了超精密機器人X、Y、Z驅動器,最大速度為11毫米/秒。它還具有基於視覺的高速對準和自動聚焦功能。該單元還具有一個冷卻器,以最佳冷卻基板,以穩定蝕刻過程。蝕刻速率非常穩定,提供靈活的蝕刻條件,具有重復高性能結果的能力。該機裝有真空泵,能夠創造低真空環境,腔室壓力為5 mTorr。該工具還有一個內置的預室除氣資產,允許原始蝕刻條件。Aspen II還能夠在沿垂直軸的蝕刻速率高於沿水平軸的蝕刻速率的情況下進行各向異性蝕刻。MATTSON Aspen II具有廣泛的蝕刻化學,包括氧氣、氯氣、六氟化硫和氟基。為了確保可重現的結果,該模型還具有對電力、溫度和離子源等關鍵參數的遠程控制功能。此外,這些設備可以很容易地集成到現有的半導體工藝中。Aspen II是高性能、高通量蝕刻的絕佳選擇。其堅固的結構和精密的性能使其成為許多不同蝕刻應用的理想選擇。

還沒有評論