二手 TEL / TOKYO ELECTRON Indy-B-L #293637436 待售

網址複製成功!

單擊可縮放

ID: 293637436

晶圓大小: 12"

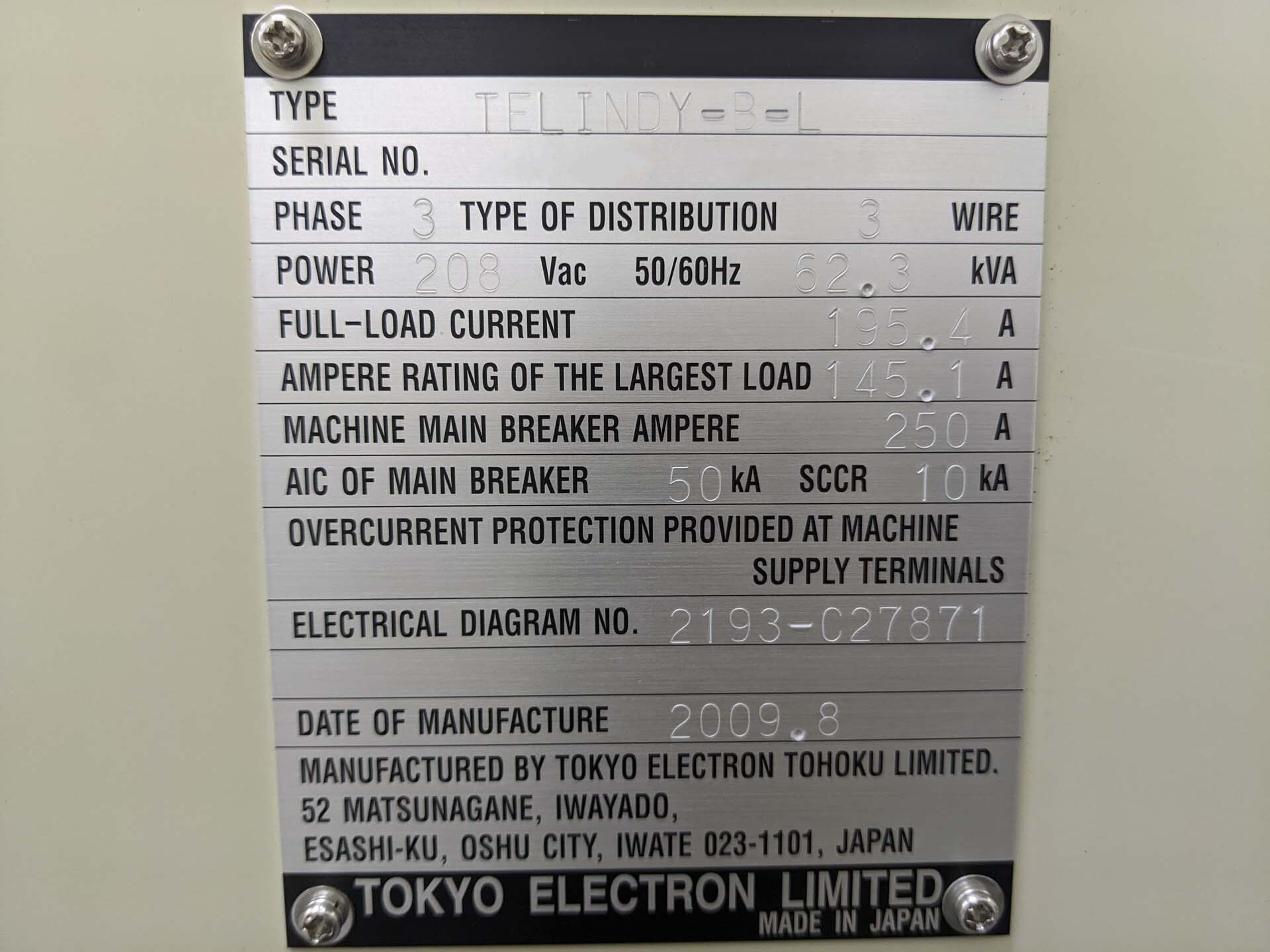

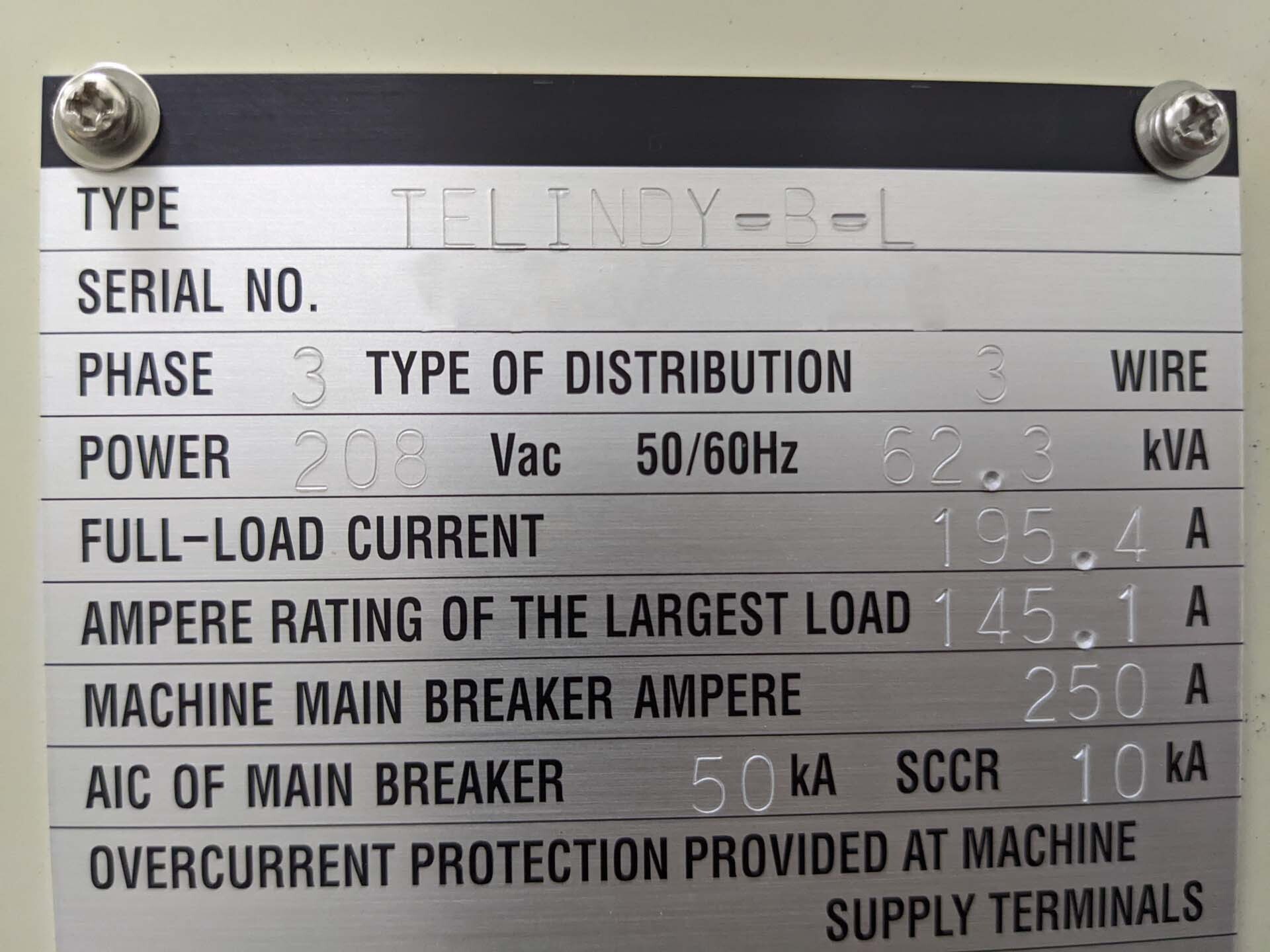

優質的: 2009

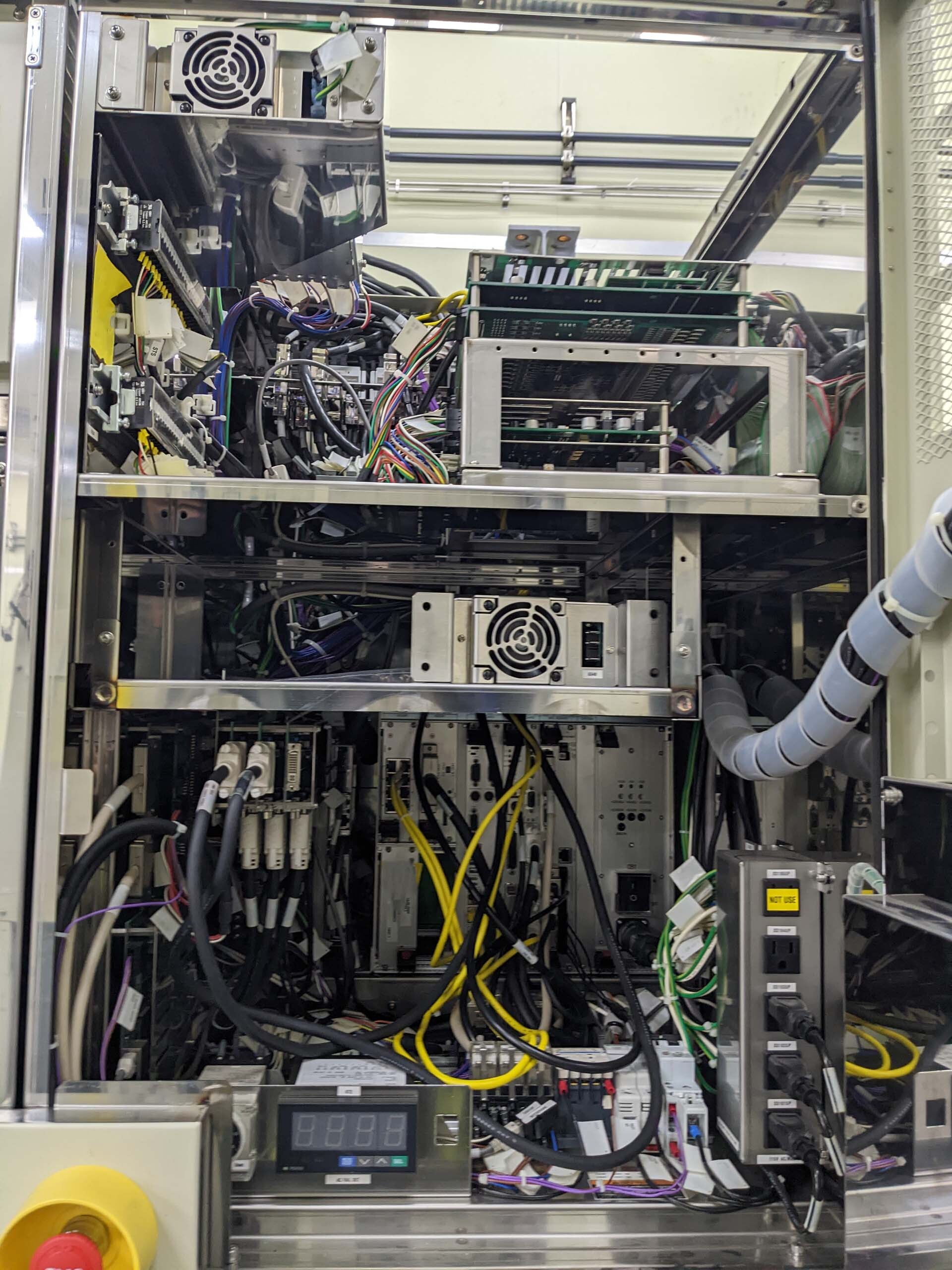

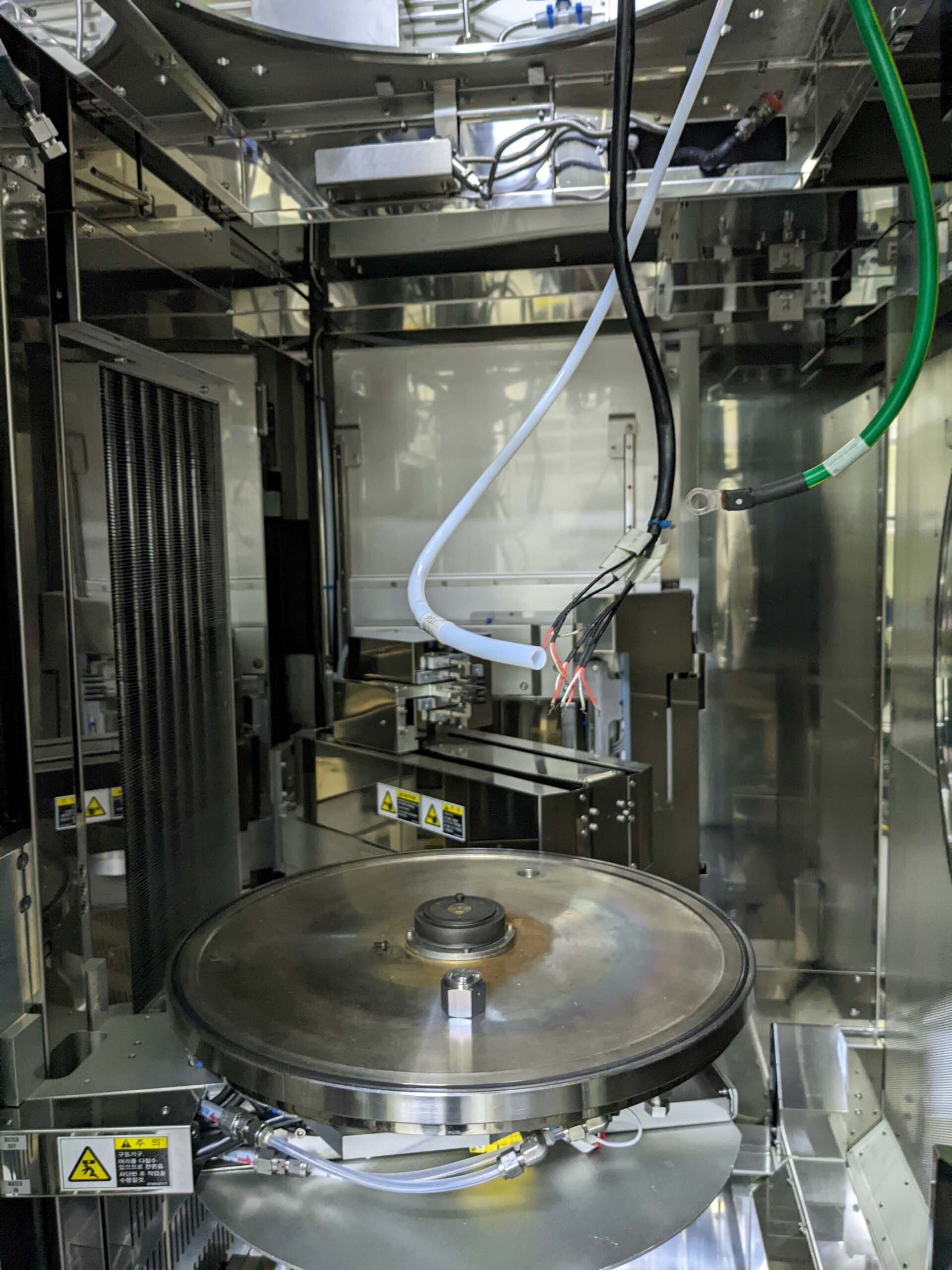

LPCVD Furnace, 12"

Wafer type: Si semi STD Notch

(100) Production wafers

Maximum operating temperature: 500-1000

N2 Load lock

Boat type handling position

O2 Density control for N2 Load lock

N2 Boat shower wafer cooling

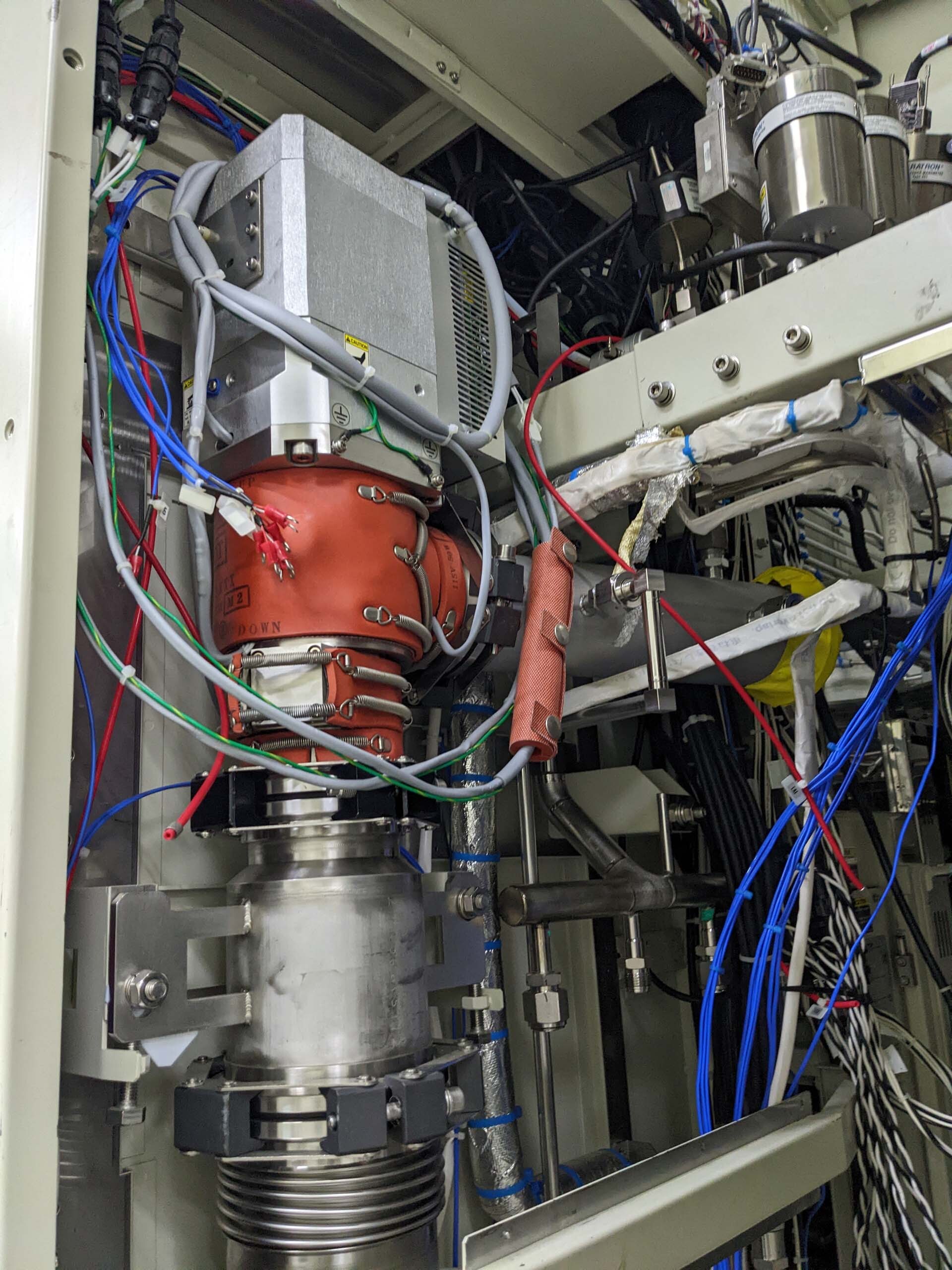

560A Furnace temperature controller

VMM-56-002 Heater

Wafer / Carrier handling:

(25) Carrier type: FOUP

ENTEGRIS A300

Carrier stage capacity: 16

Pin pad A, B

Fork material: Al203 and peek

W/T Type: 1+4 Edge grip

W/T Auto teaching

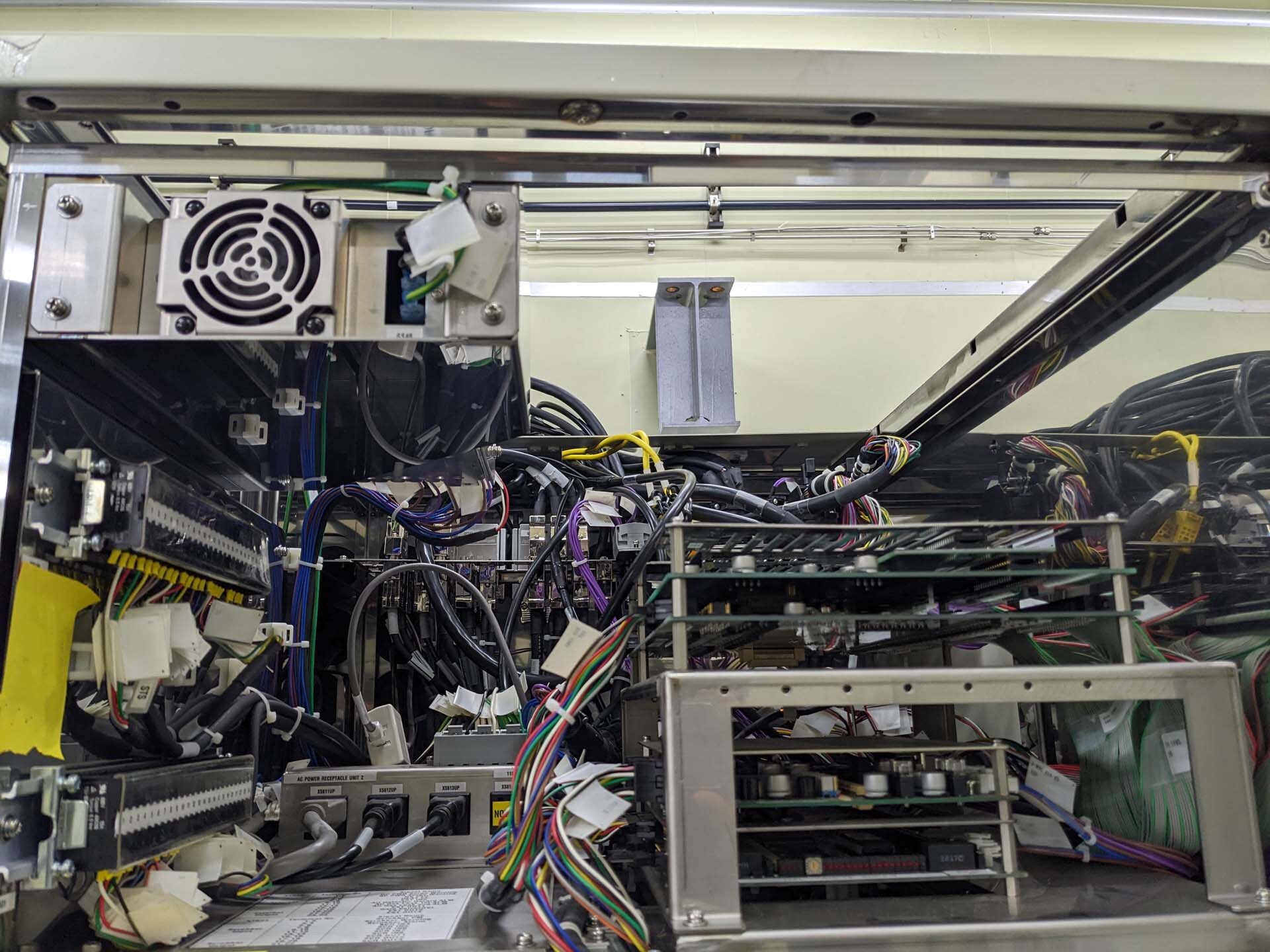

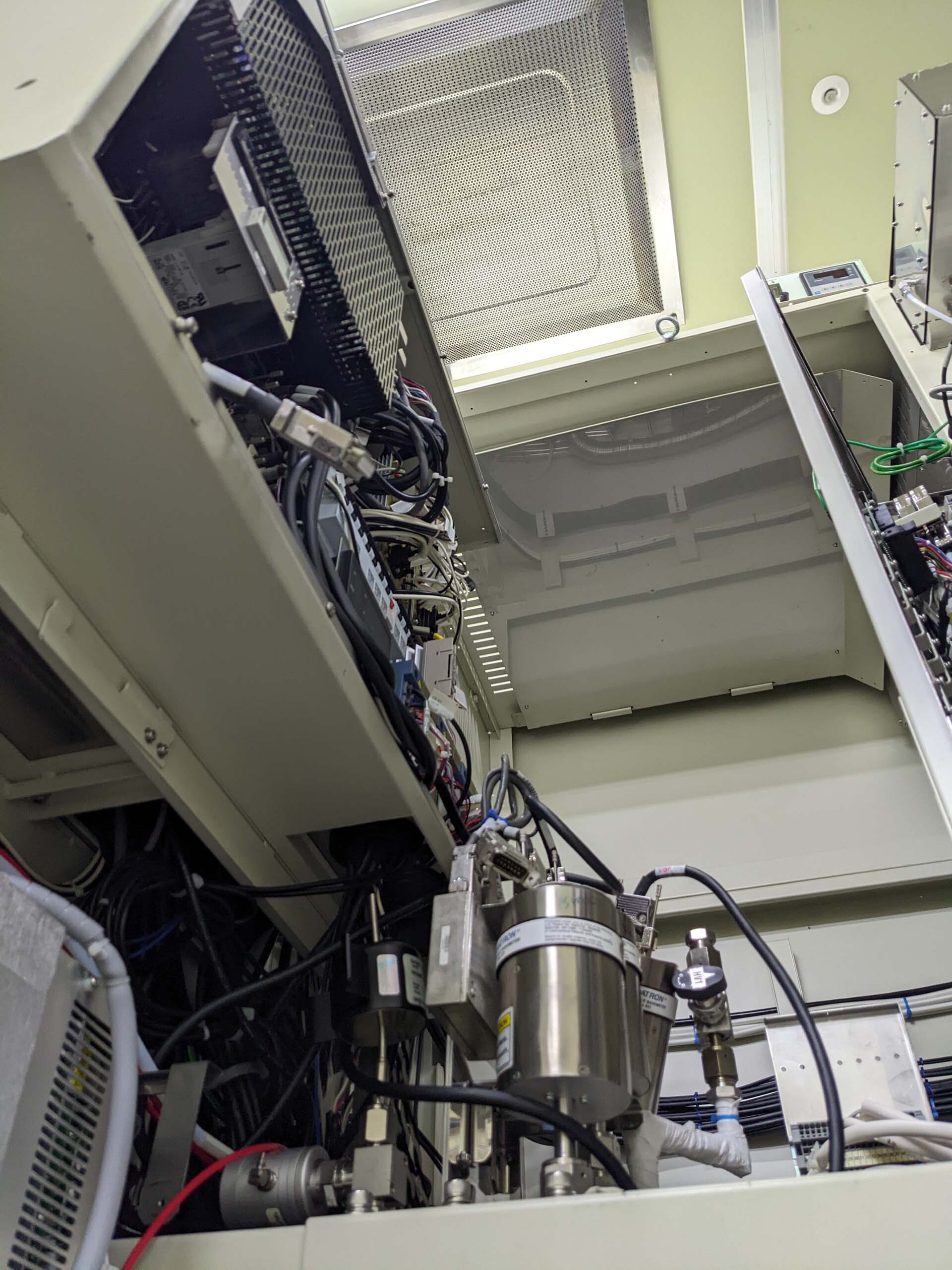

Furnace facilities:

Furnace exhaust connection point: Top connection

Cooling water connection point: Bottom connection

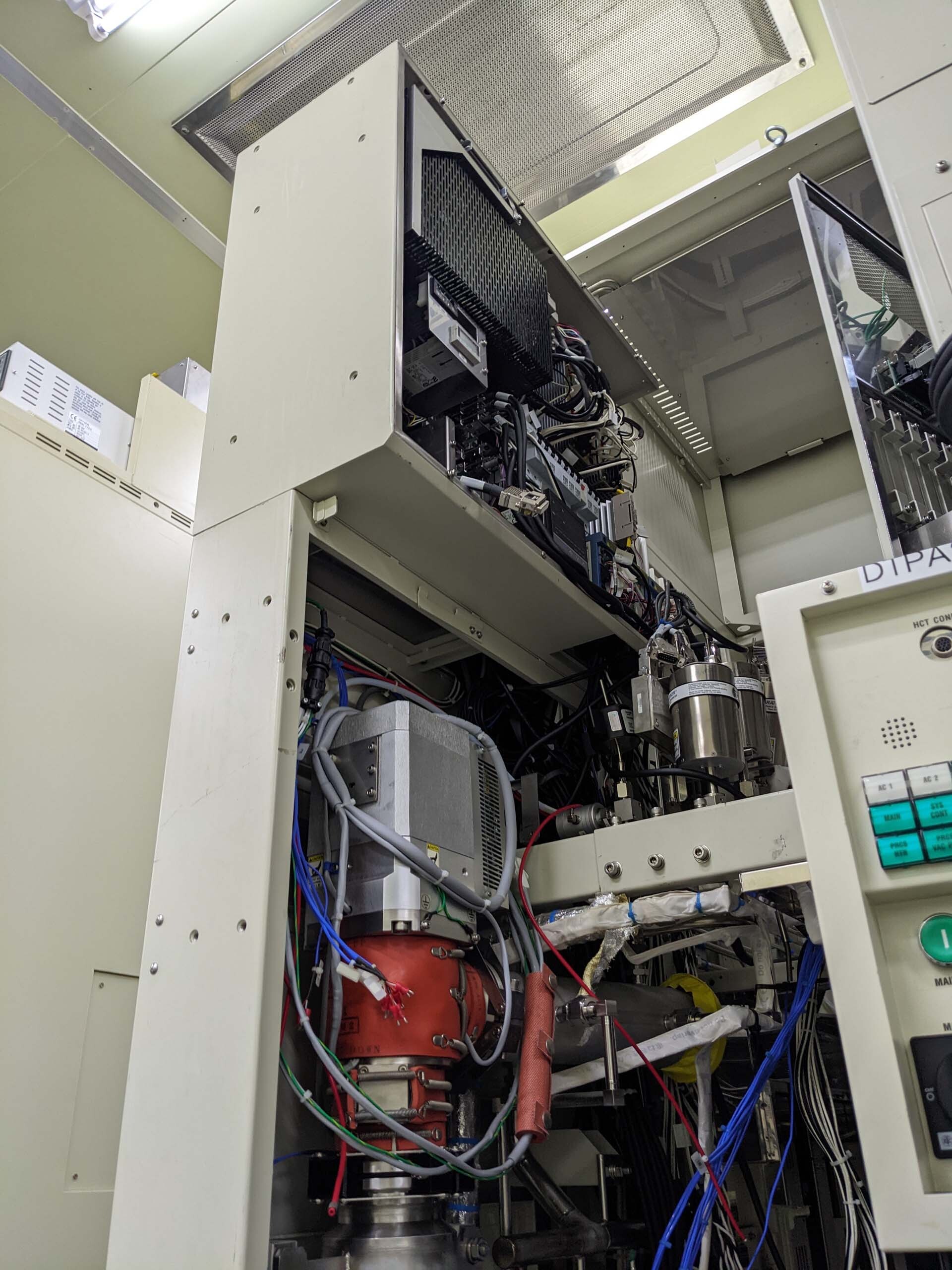

Gas specification:

IGS 1.5" W-seal rail-mount

FUJIKIN IGS

Tubing bend bend (Less than 90°)

HORIBA STEC

Incoming gas connection point: Bottom connection

Gas vent connection point: Bottom connection

Gas unit exhaust connection point: Bottom connection

Process gas exhaust connection point: Bottom connection

Exhaust specification:

MKS Vacuum gauge-press controller

MKS Vacuum gauge-press monitor

MKS Vacuum gauge-pump monitor

CKD-VEC Main valve

Condenser

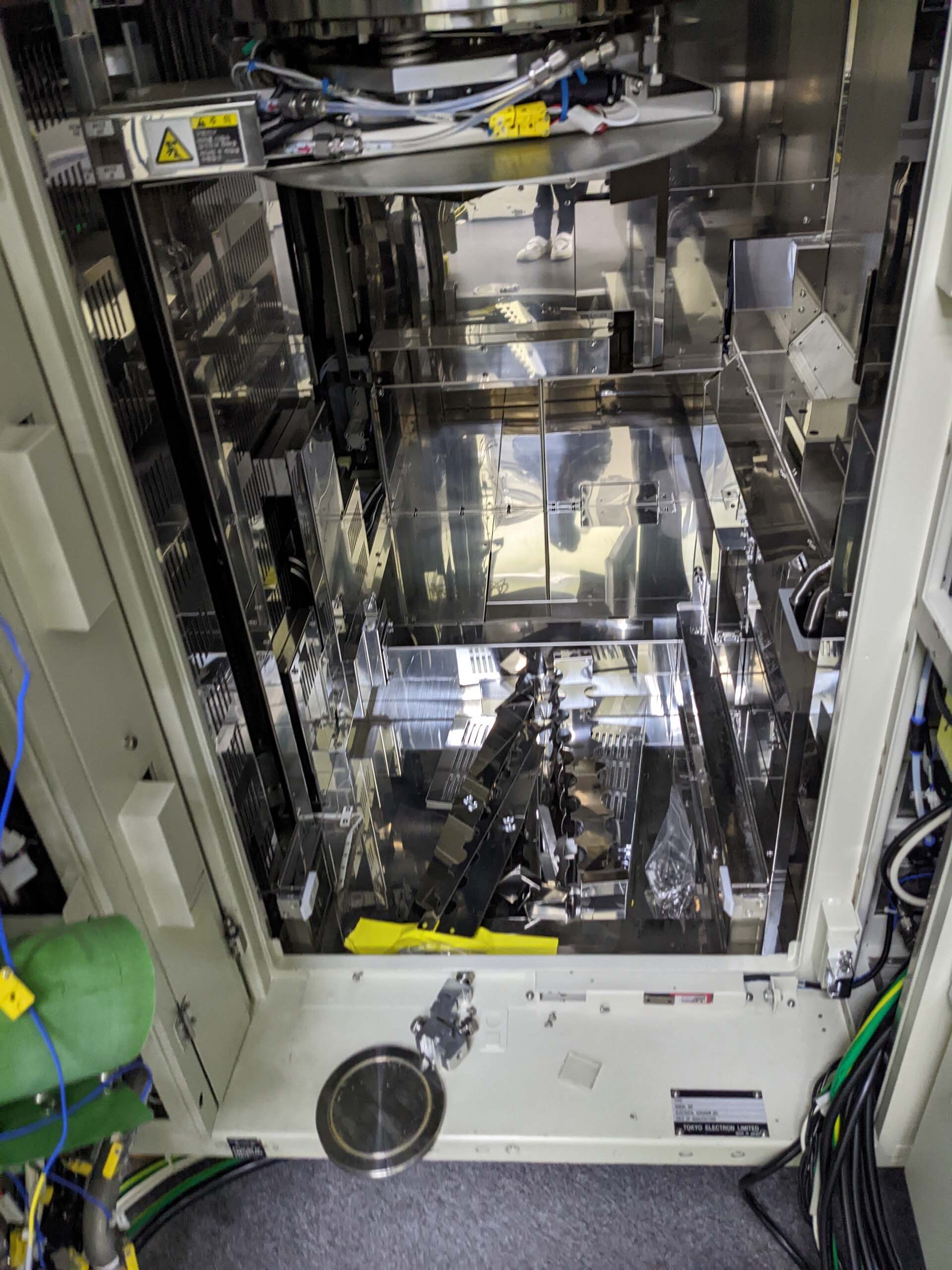

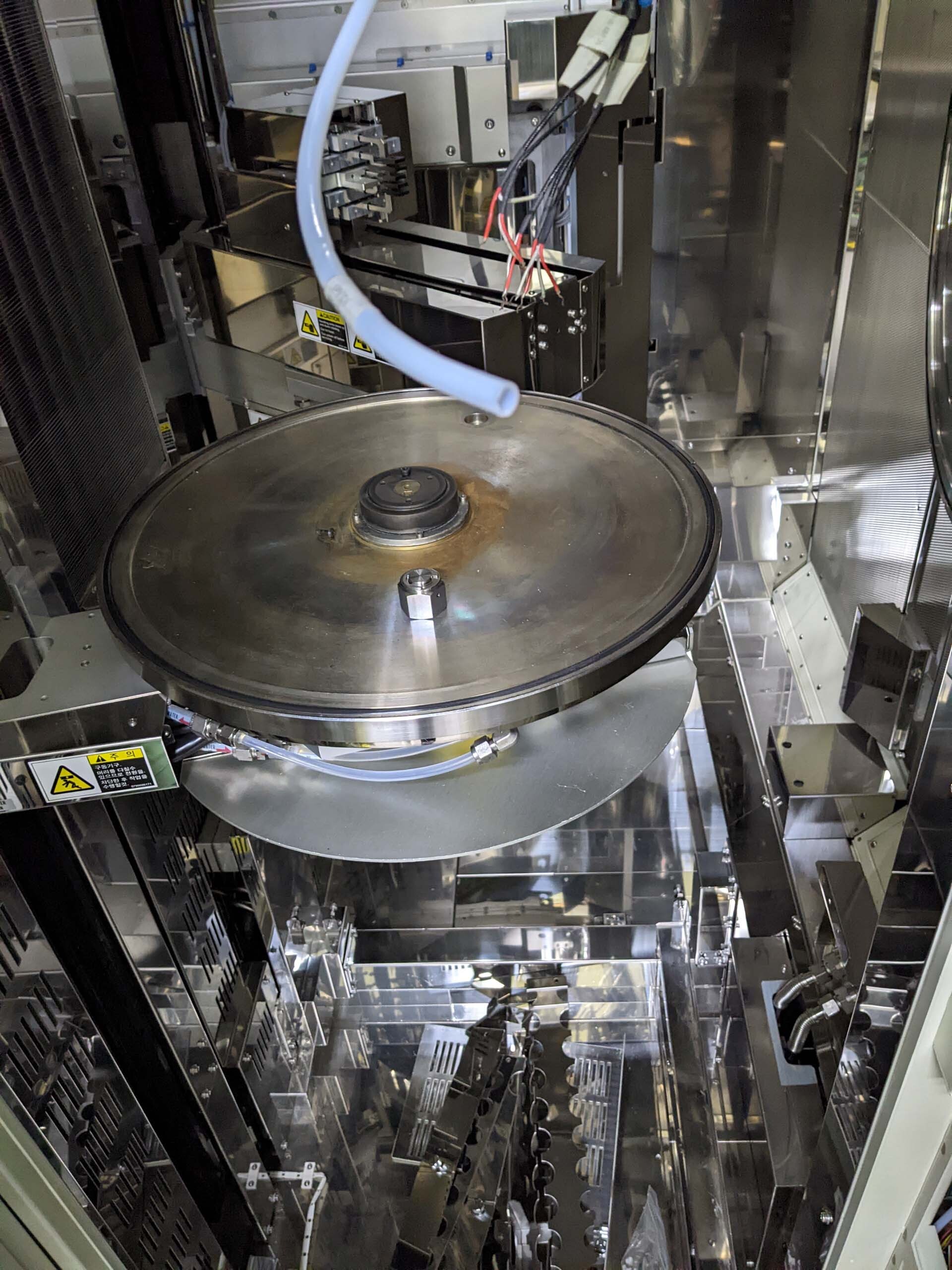

Reactor specification:

Tube material: Quartz (outter), quartz (inner)

Inner tube Type (LP): Straight

Inner T/C: Outer tube inferior (wall type)

Tube sealing: O Ring

Soft backfill injector

Boat type: (117) Slots, pitch, 8 mm

Boat rotation

Pedestal type: Quartz

No shutter purge type

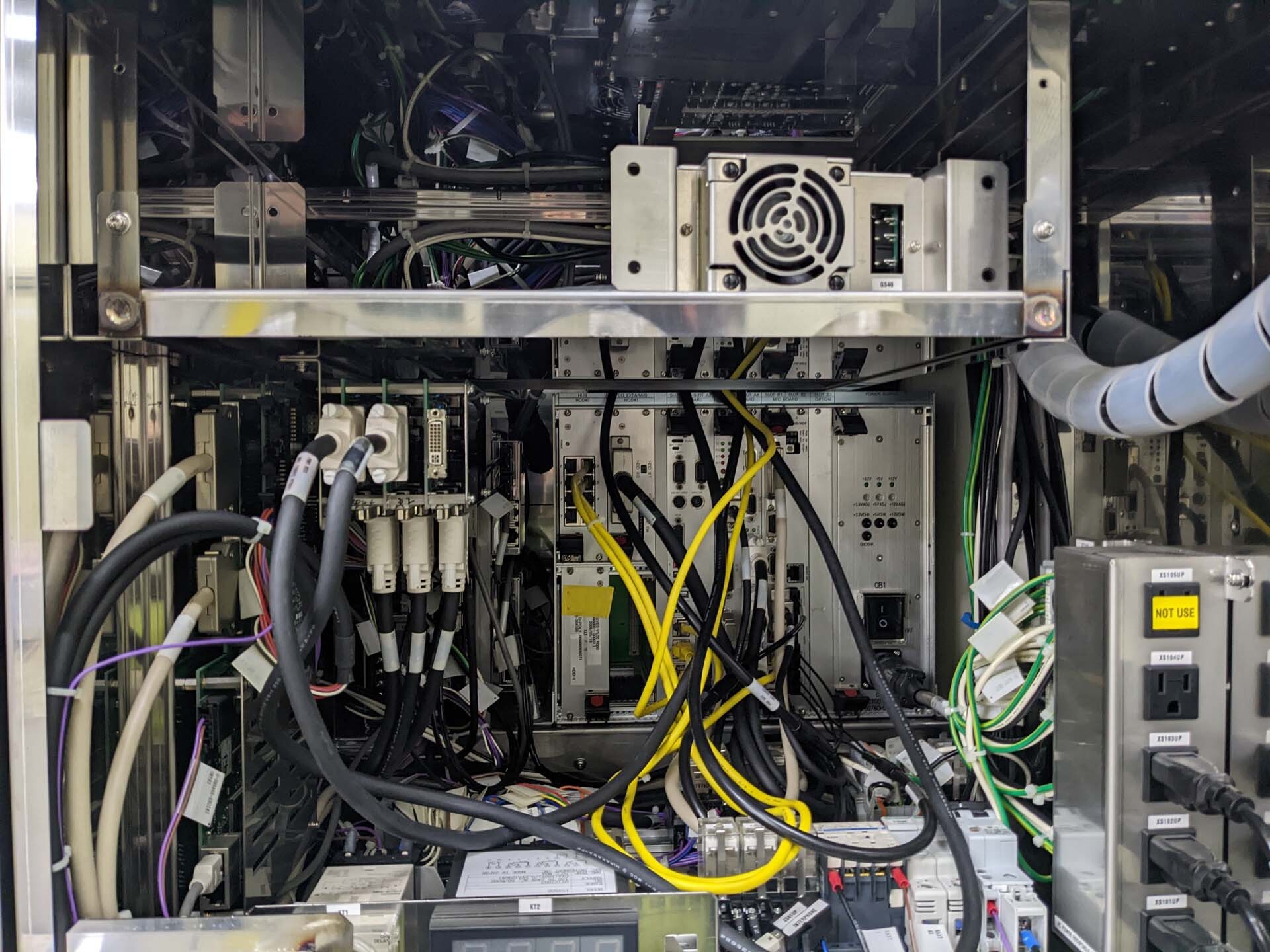

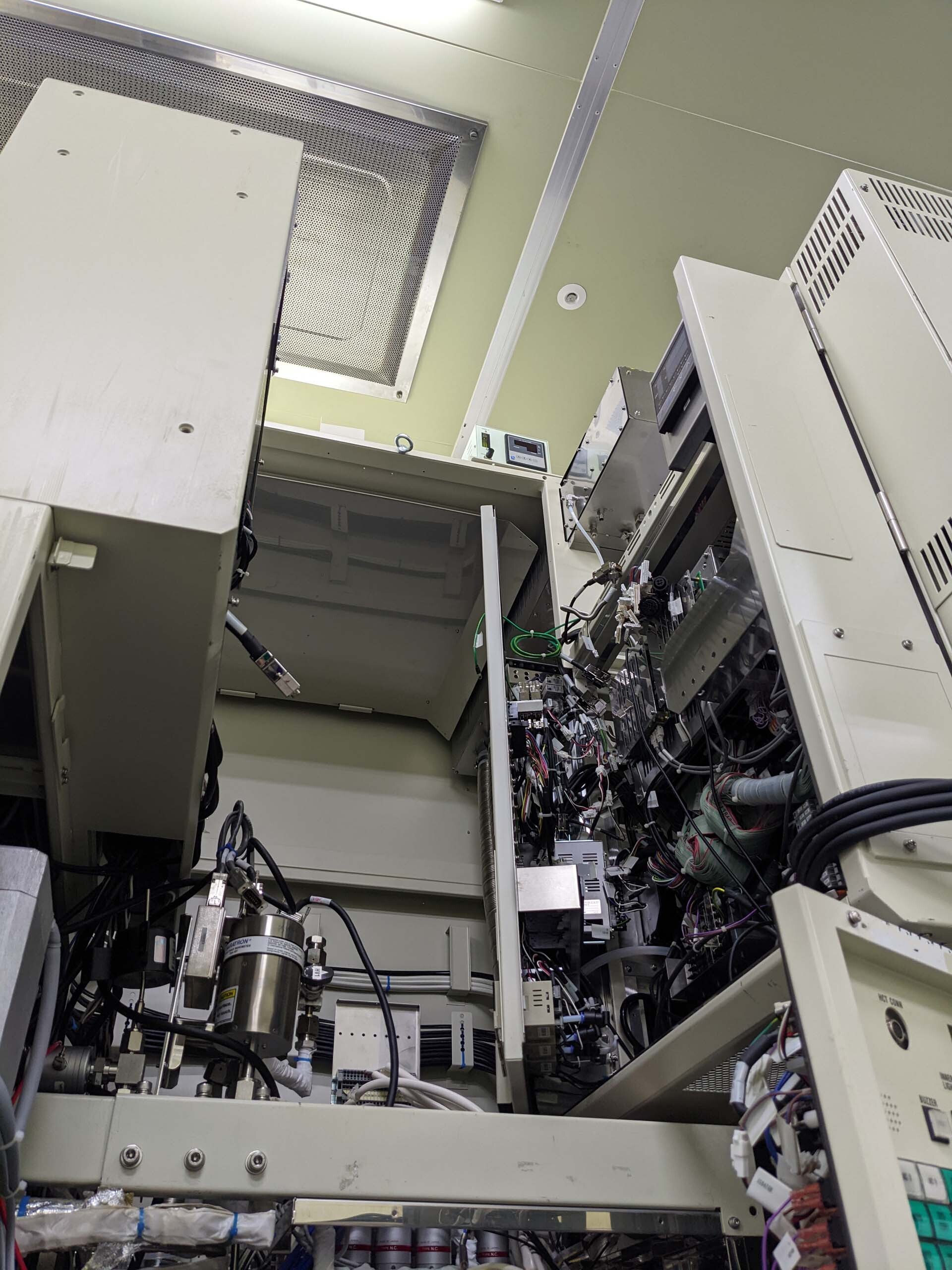

Interface specification:

Host communication: Comply with GJG

Equipment host I/F connection: Gas box top HSMS

Ingenio

OHT Capability

Load port operation: Upper

PIO I/F Location: FNC Top

HOKUYO DMS-HB1-Z PIO

RF Carrier ID reader writer type

CIDRW L/P: Read and write

ASYST ATR 9100 CIDRW

TEL CIDRW

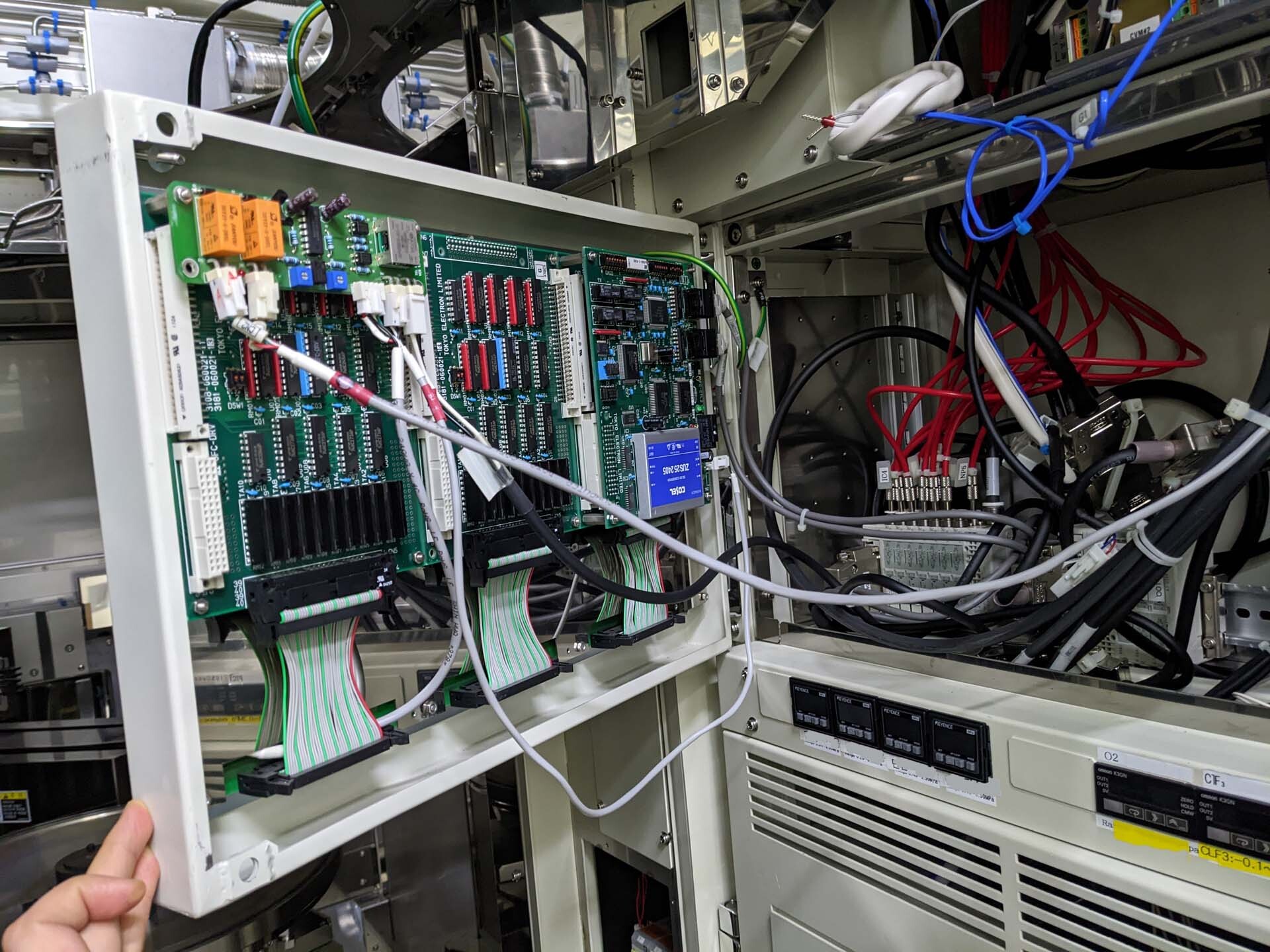

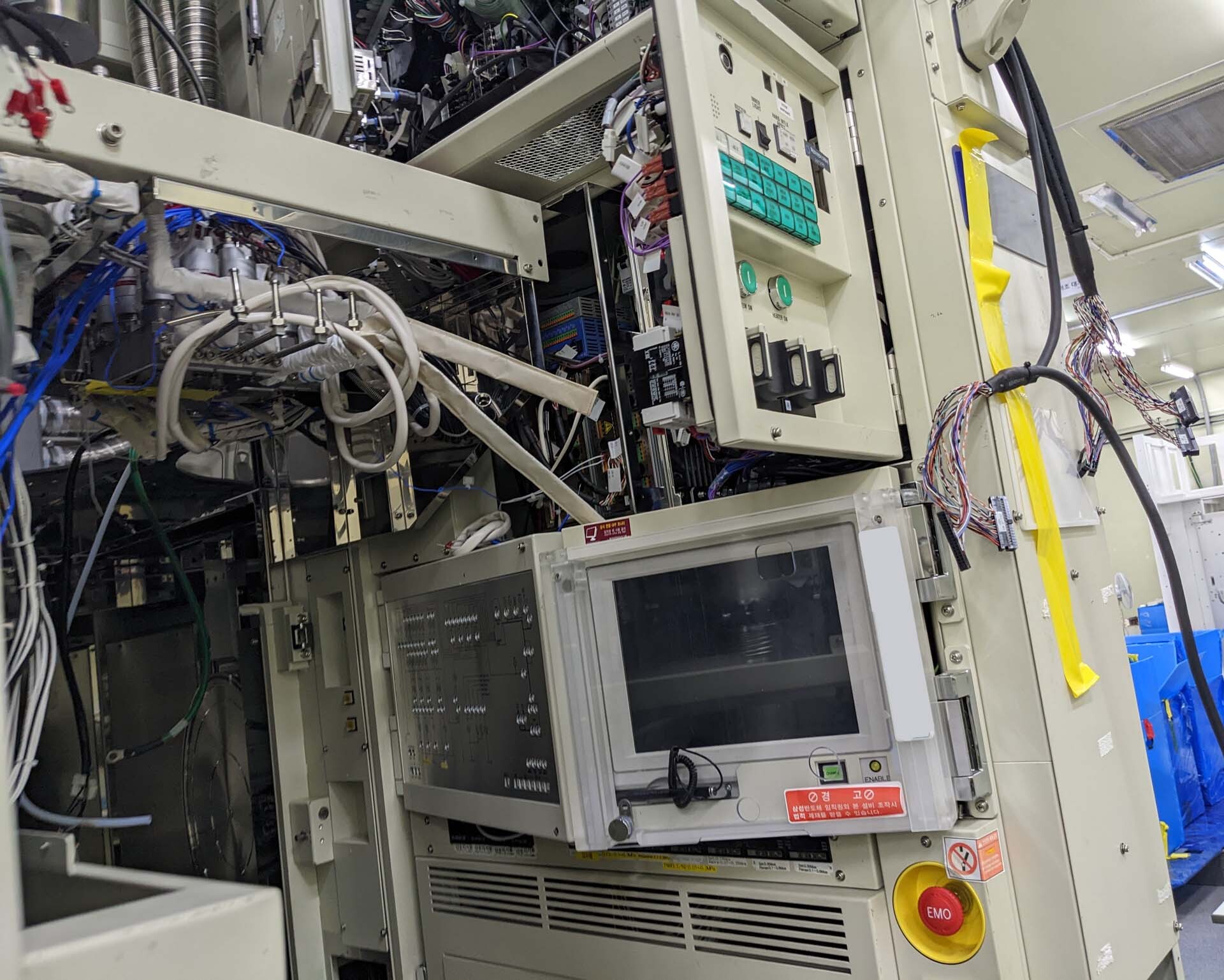

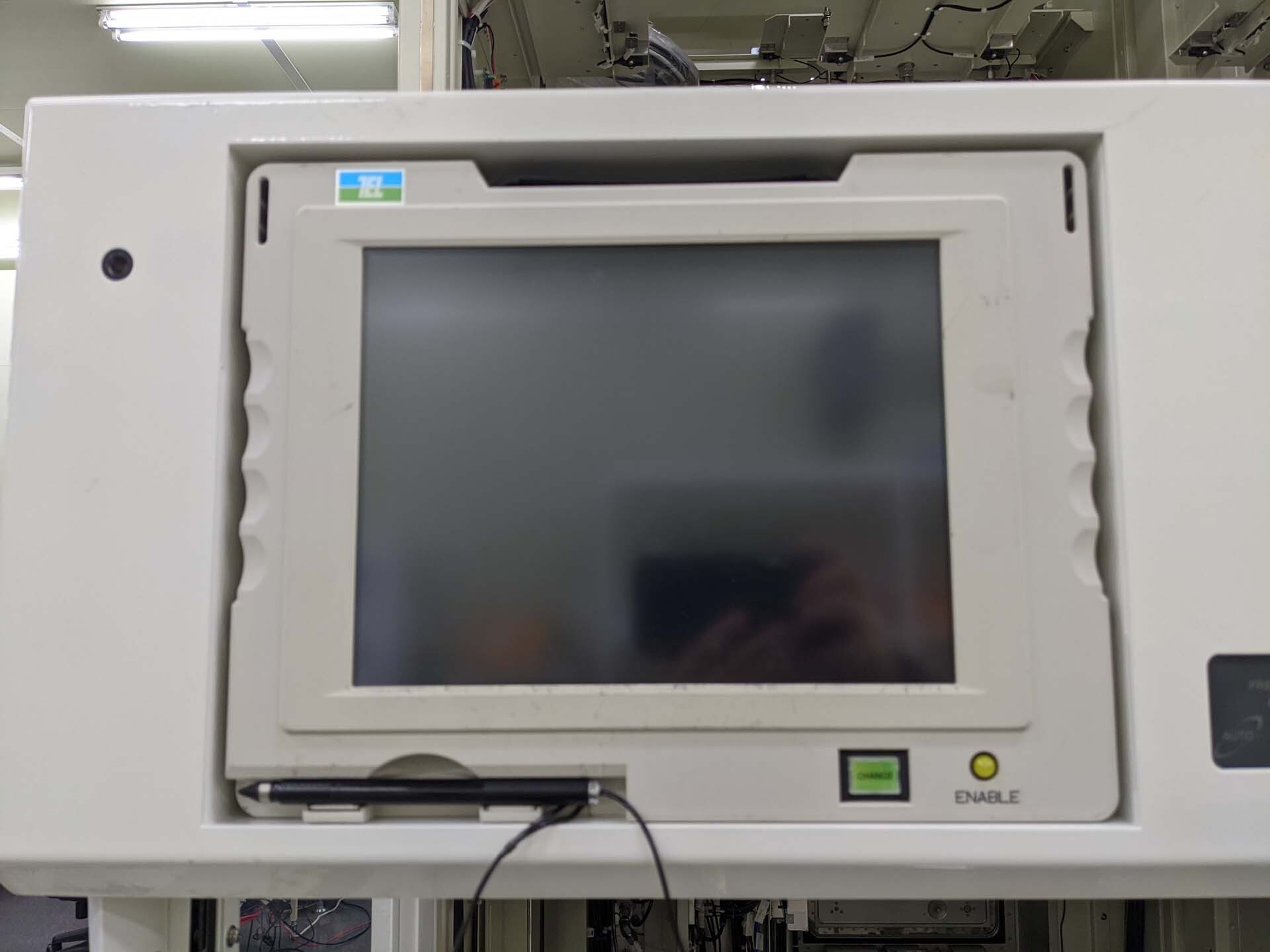

User interface

Signal tower model: Customized

Signal tower colors (From the Top): Red / Green / Yellow

Signal tower location: Front

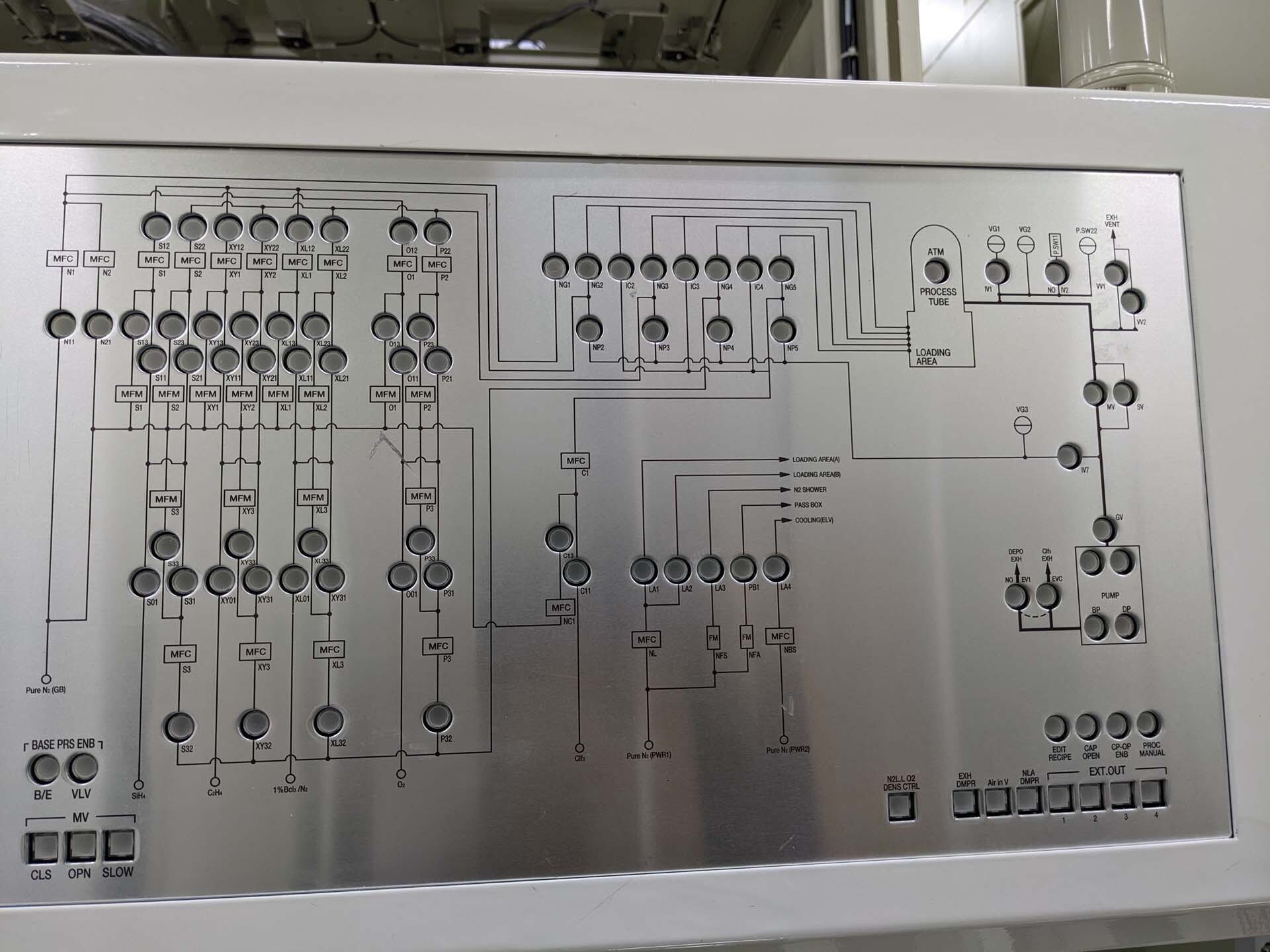

Front operation panel

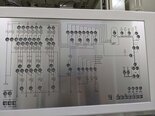

MMI and gas flow chart: Gas box and front operation panel installed

Indicator type: Superset

Operator switch: Operator access / orange

Pressure display unit (gas inlet / vacuum): Mpa / Pa

Cabinet exhaust pressure display unit: Pa

Gas leak detector:

Gas1 / SiH4

Gas2 / PH3

Gas3 / ClF3

Cable length:

FNC-Power box: 20 meter

Power box -refill system: 30 meter

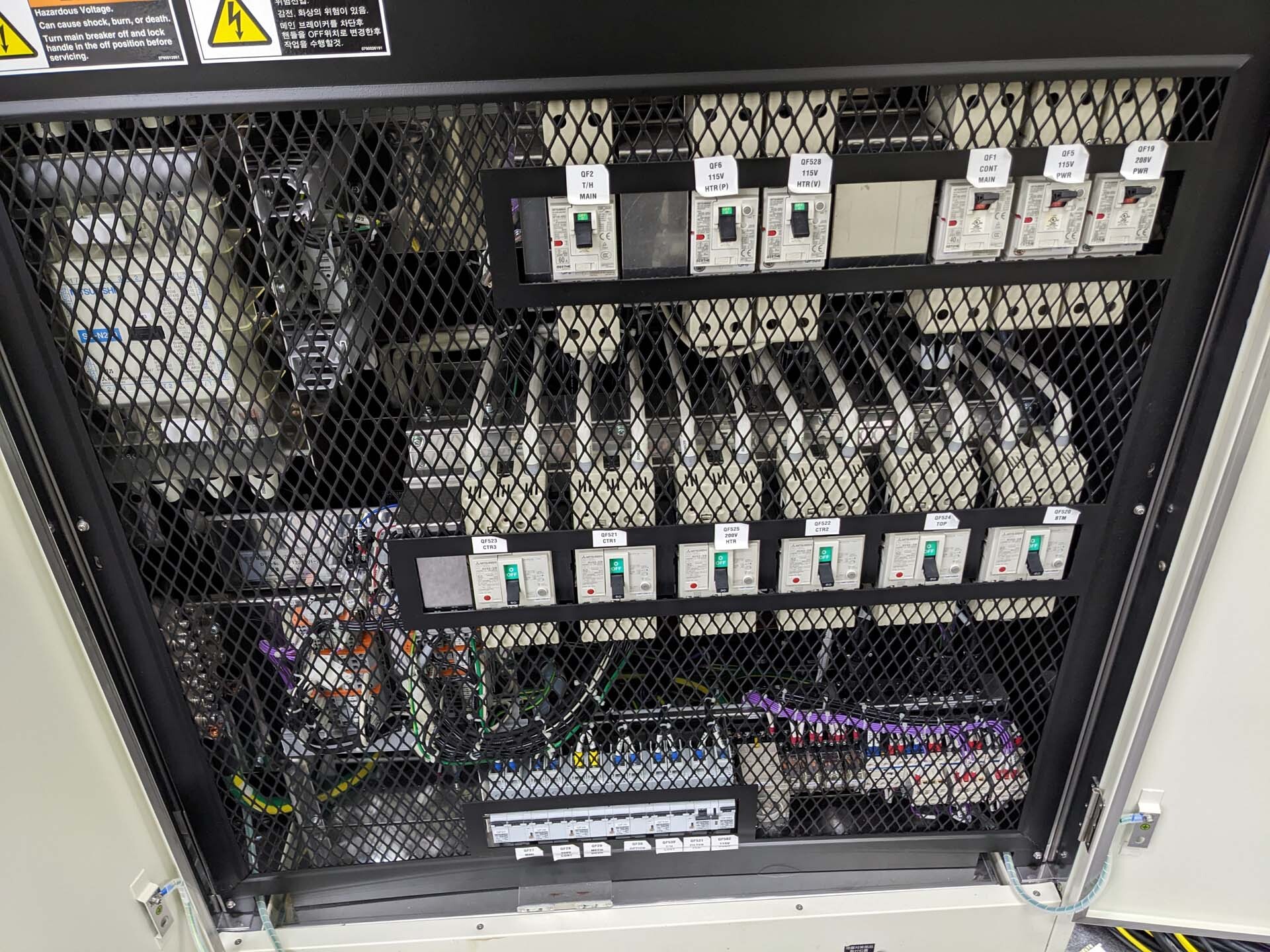

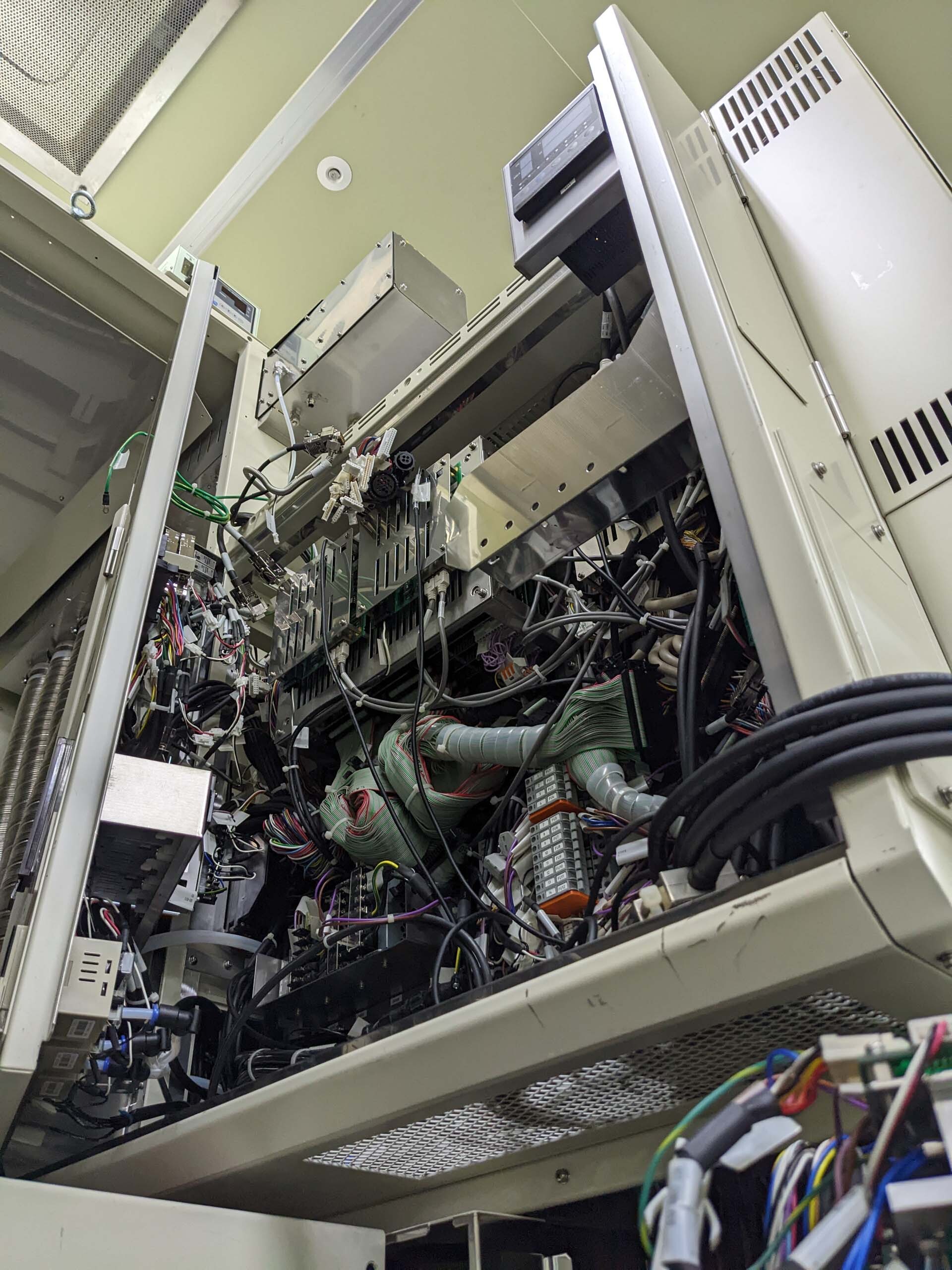

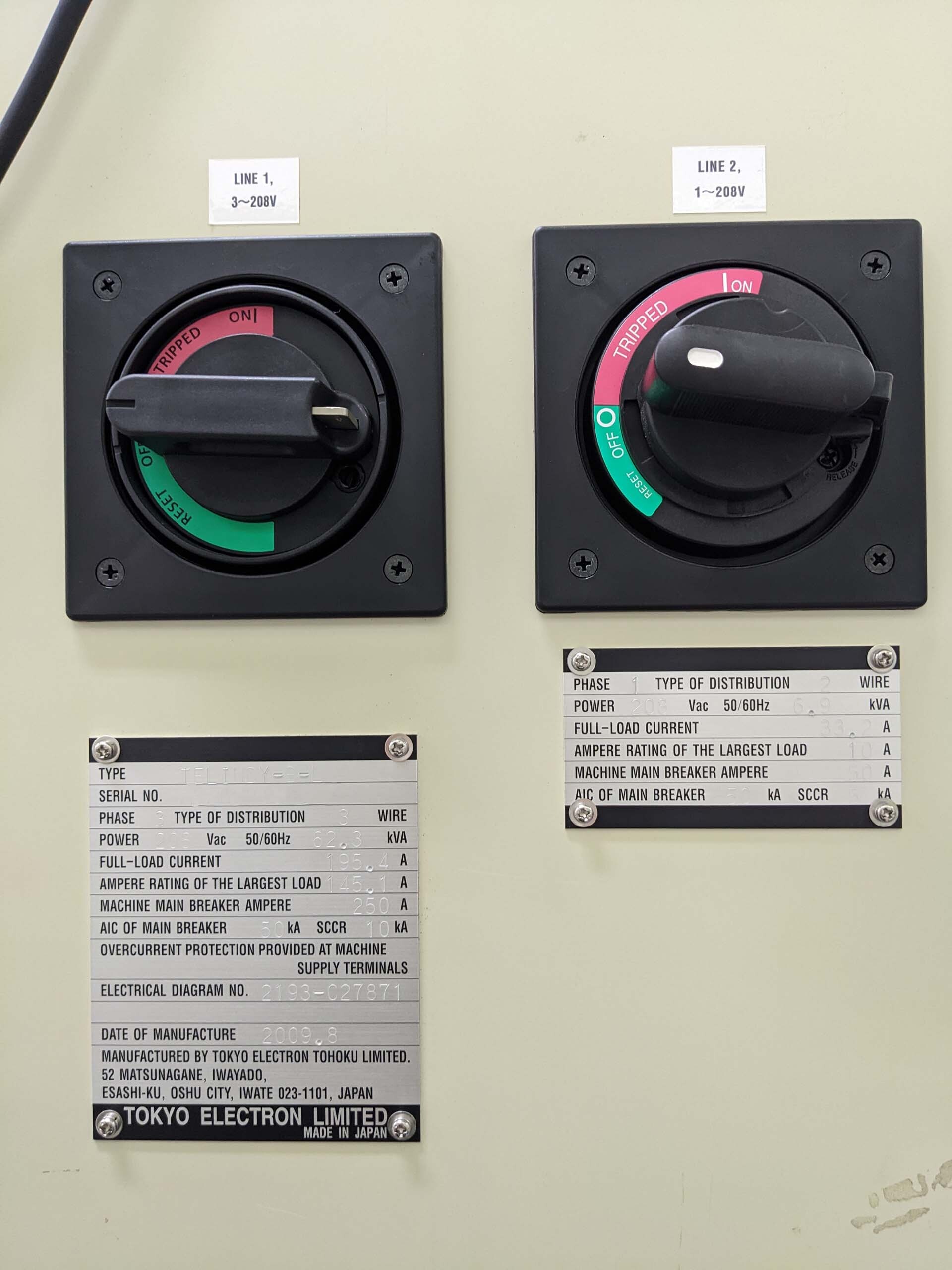

Power specification:

Voltage: 208 VAC, 3 Phase

Phase connection type: Star connection

Voltage single-phase: 120 VAC

Single-phase connection type: Grounded

Frequency: 60 Hz

Power cable input entrance location: Power box top

2009 vintage.

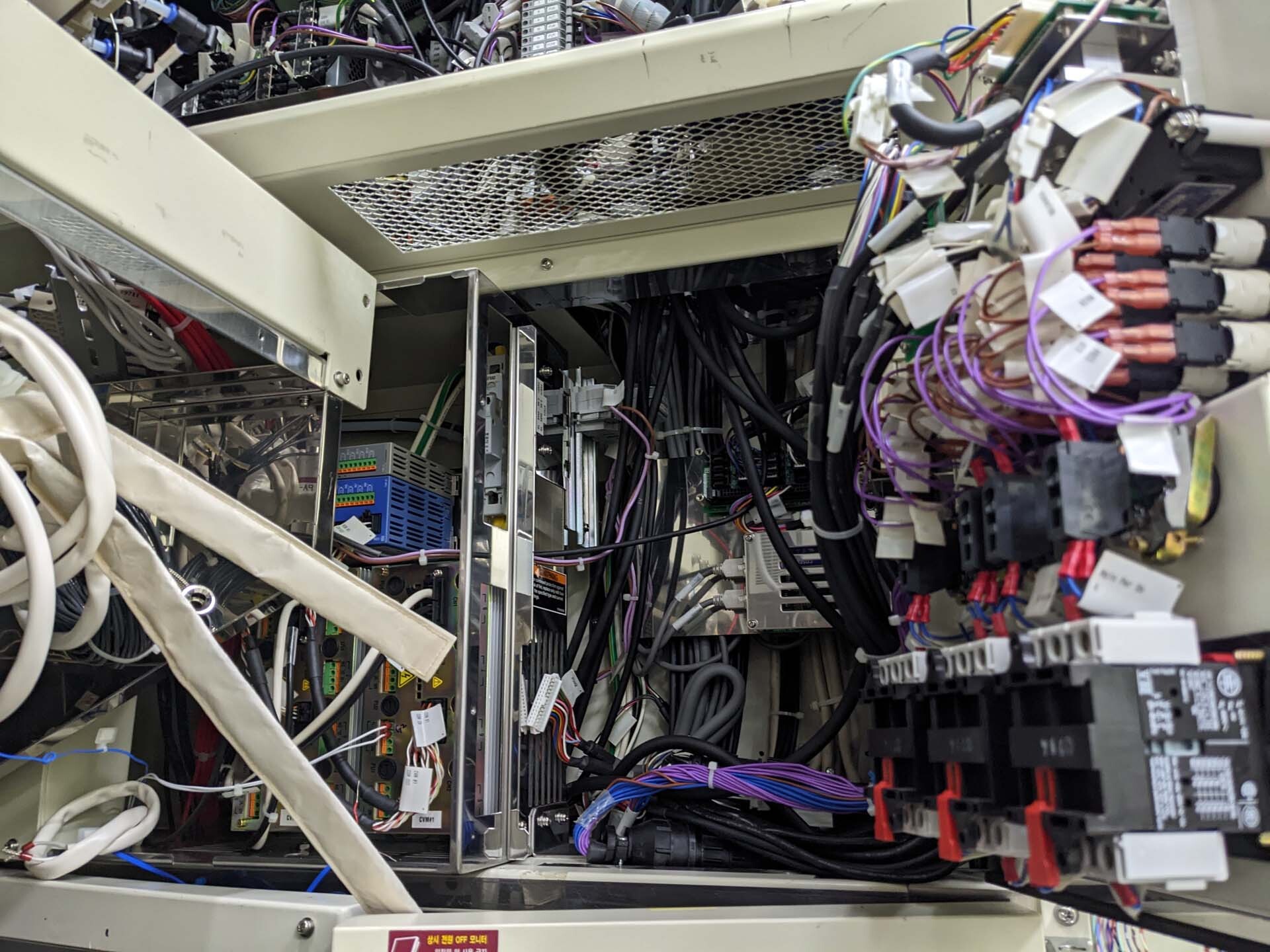

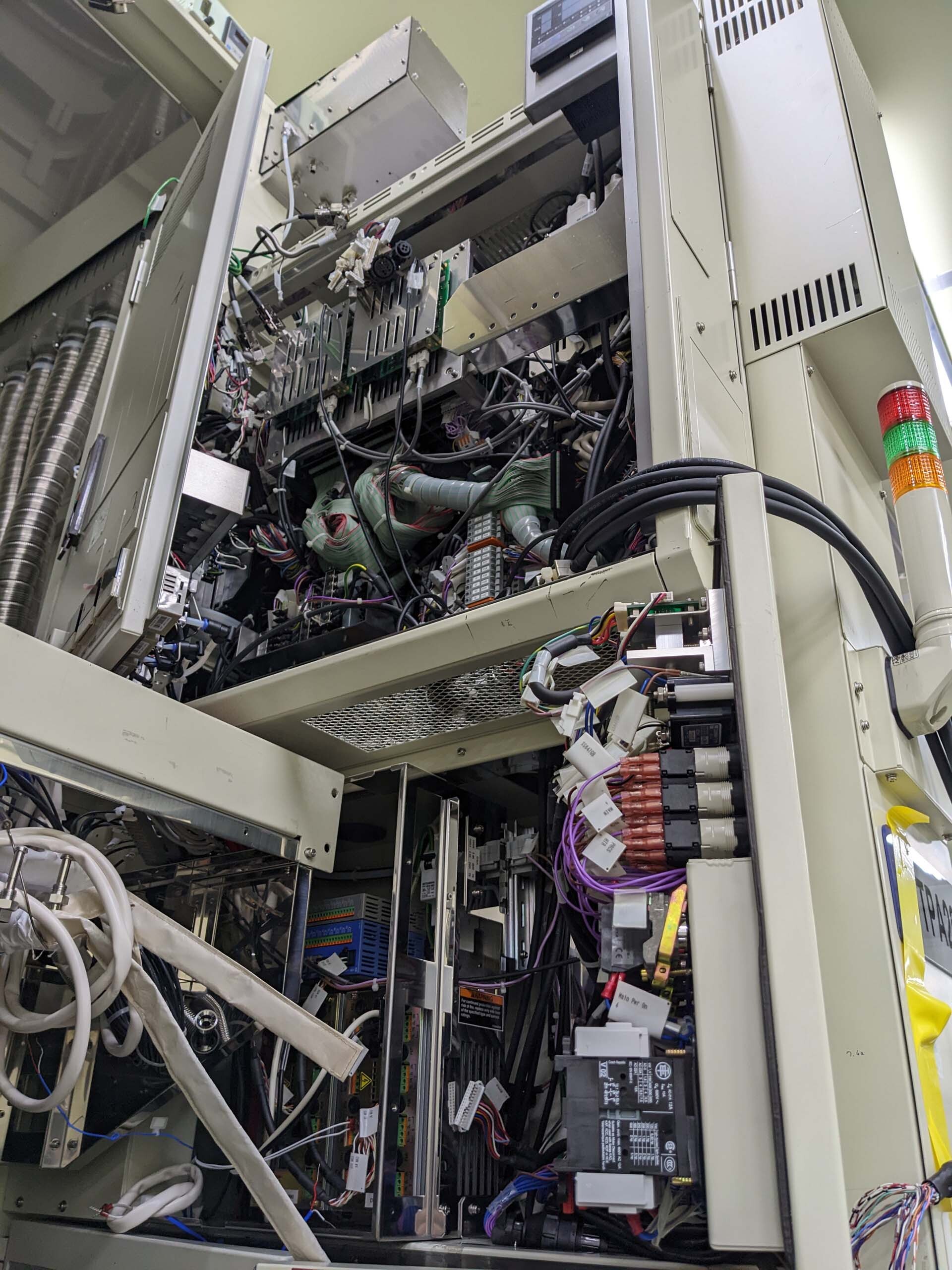

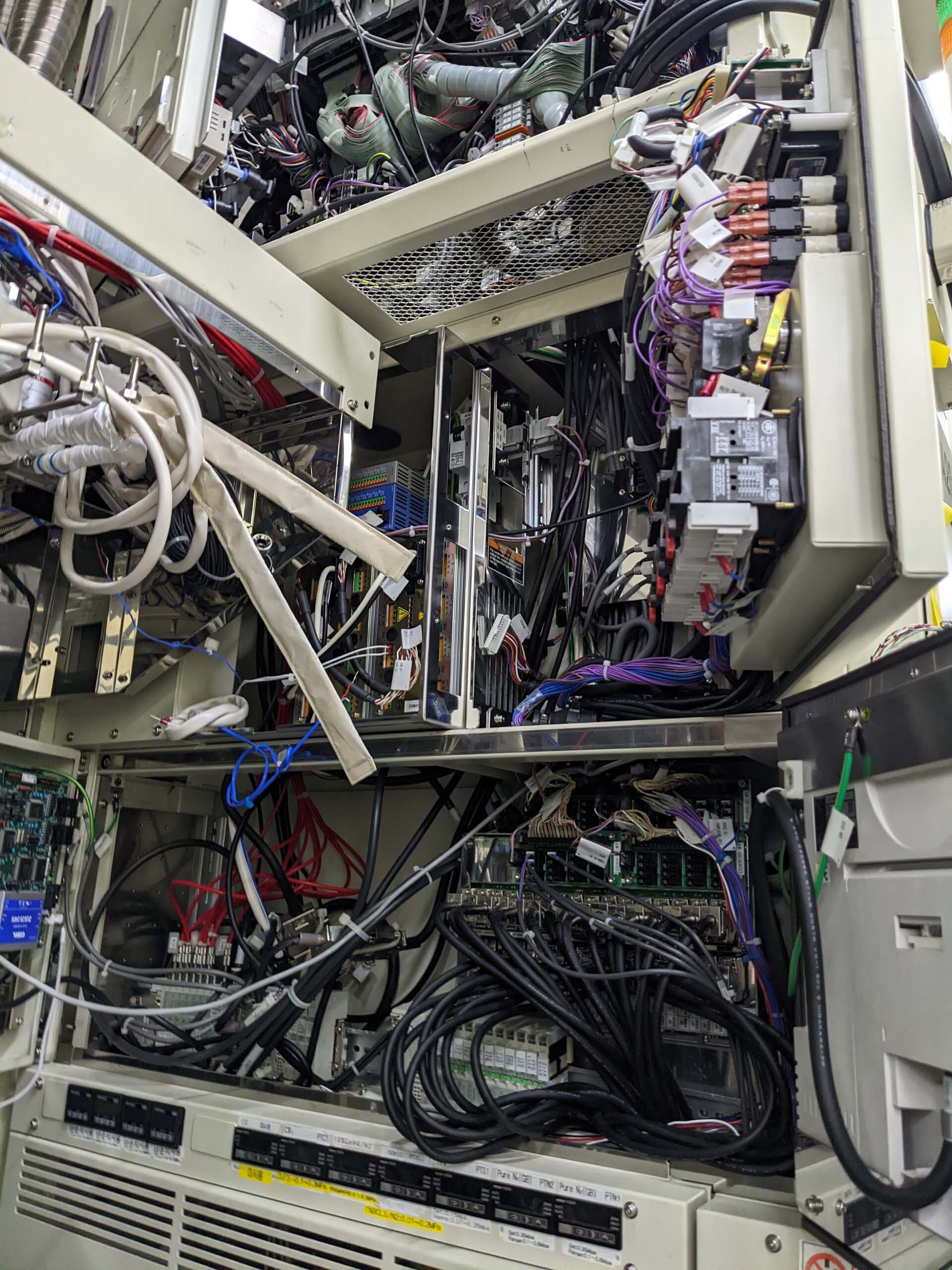

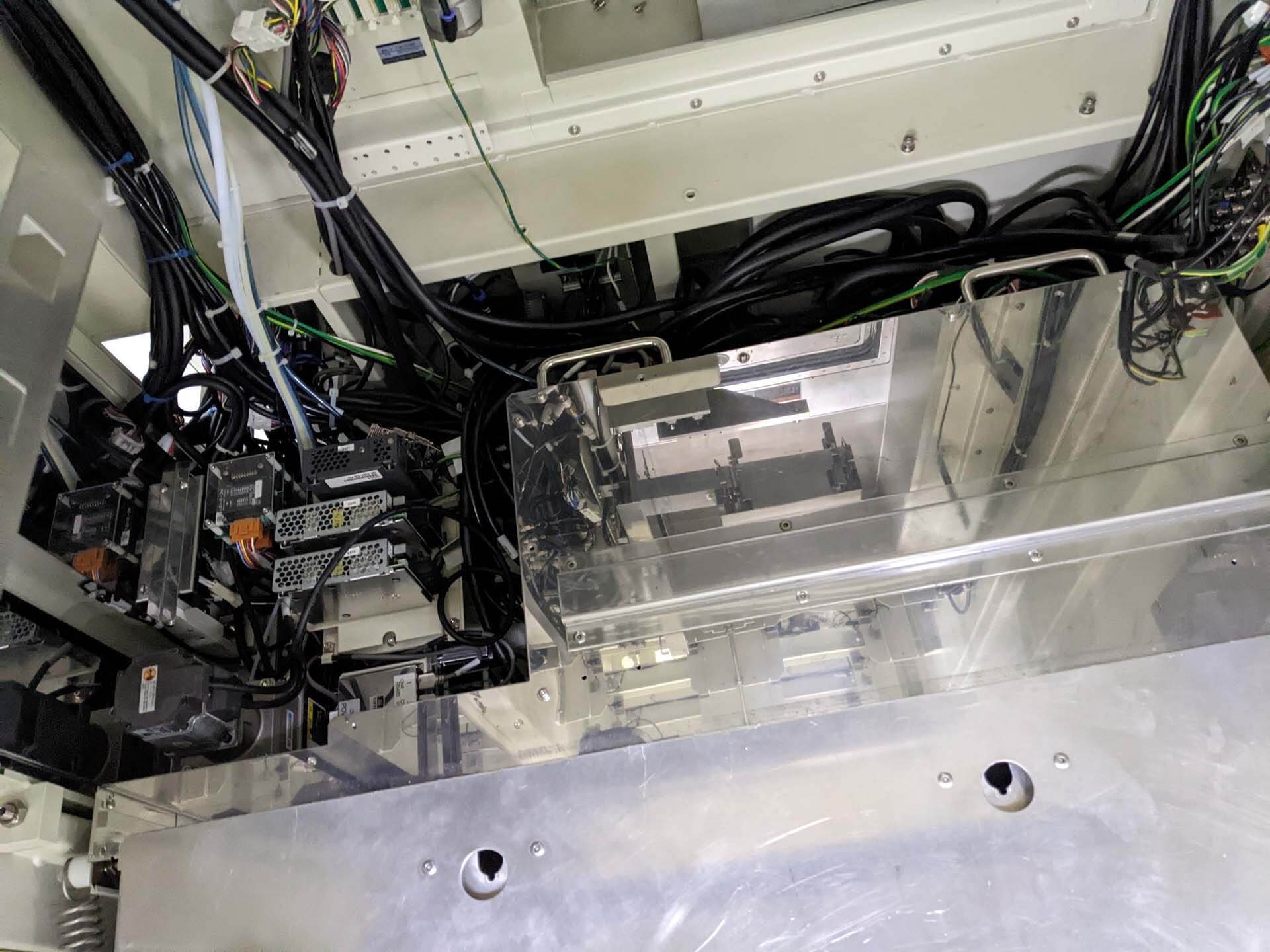

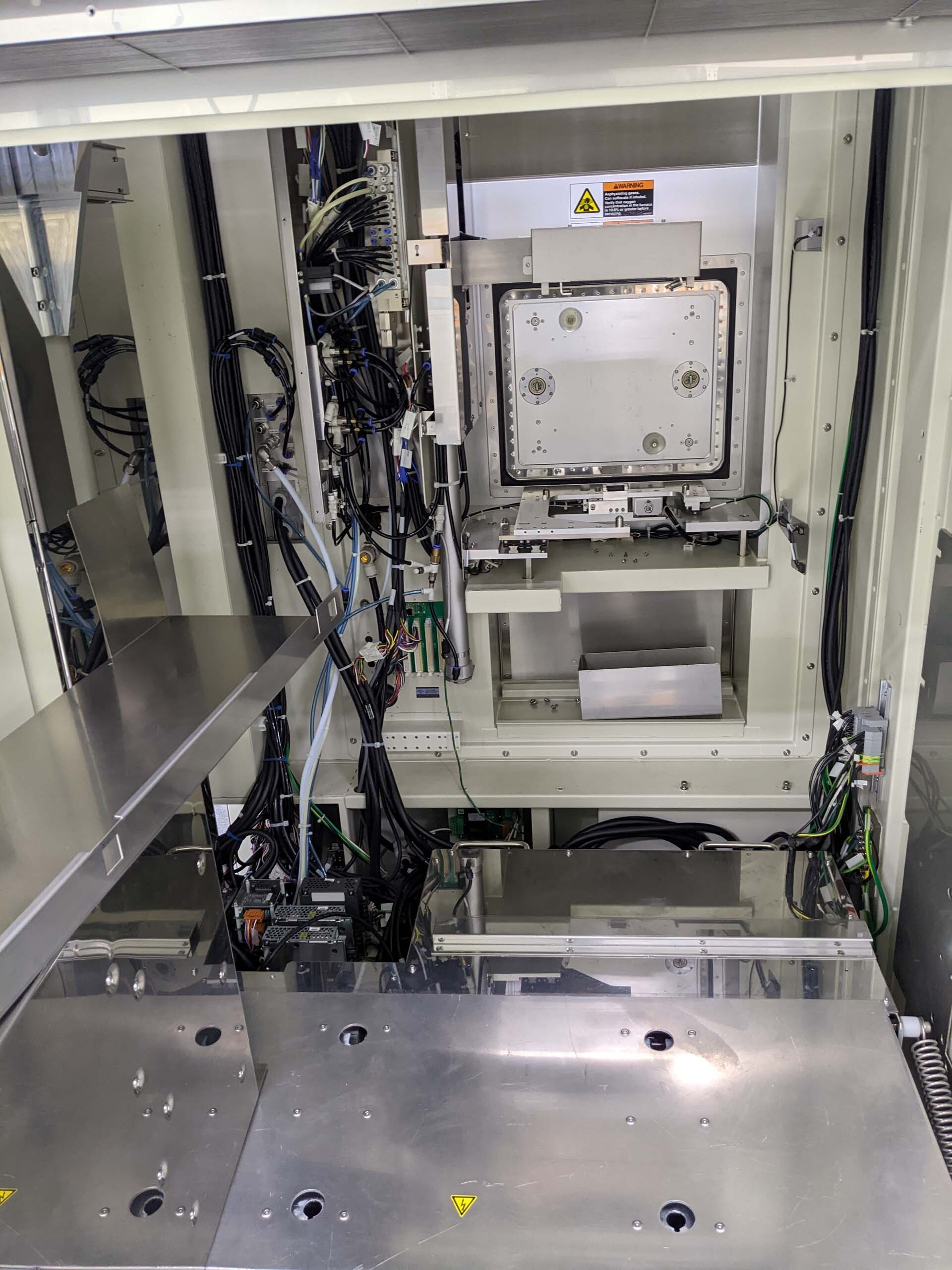

TEL/TOKYO ELECTRON Indy-B-L是一種室內晶圓蝕刻器/asher,在半導體晶圓上產生氧化薄膜。它是一種高性能、中通量、單室幹蝕刻設備。該系統采用操作員界面實現完全自動化,為用戶提供用戶友好的過程控制和優化。TEL INDY B L單元能夠為CoO、AlOx、ITO等多種應用執行蝕刻和灰化過程。TOKYO ELECTRON INDY B-L內部有5層石英室、可調壓力管和4個獨立控制的噴射N2吹掃出口。壓力由控制架內的組件監控;傳感器在腔室內外發送讀數。蝕刻器/灰化器中的N2清除出口和參數設置使無渣晶片的反應氣體能夠精確、完整地排出。TEL Indy-B-L的腔室最大尺寸為200毫米至8英寸,最高溫度處理最高可達400 °C。高密度的ECR等離子體是由磁共振子產生的,磁共振子可以單獨調節,以達到高質量的結果,低負載水平,在旋轉軸上具有優異的匹配特性。與傳統電弧源相比,ECR源等離子體具有更高的蝕刻速率和更好的選擇性,提高了活動性層蝕刻的均勻性。INDY B-L還配備了自動變色的吸收性濾光片,以指示汙染程度。此功能對於在批處理和單個晶圓過程中保持一致的質量非常有用。吸收劑會吸收和收集蝕刻或灰化過程中的塵埃顆粒,防止其進入機器,汙染晶片。包含在TEL/TOKYO ELECTRON INDY B L的可編程晶圓處理機器人和傳輸臂允許進行批處理和單晶圓處理。它還為單個操作員提供了一個簡單、安全的晶圓處理。此外,還有一個晶片檢測激光工具,確保機器人在轉移和蝕刻晶片時保持校準並達到最佳位置。TEL INDY B-L以其ECR等離子體源和精確的烤箱設置,提供可重復的蝕刻/接線,具有低均勻性誤差,良好的工藝控制和較低的維護成本。它是一種高度可靠的資產,具有簡單直觀的用戶界面控制和警報功能,非常適合批處理和單晶圓處理應用。

還沒有評論