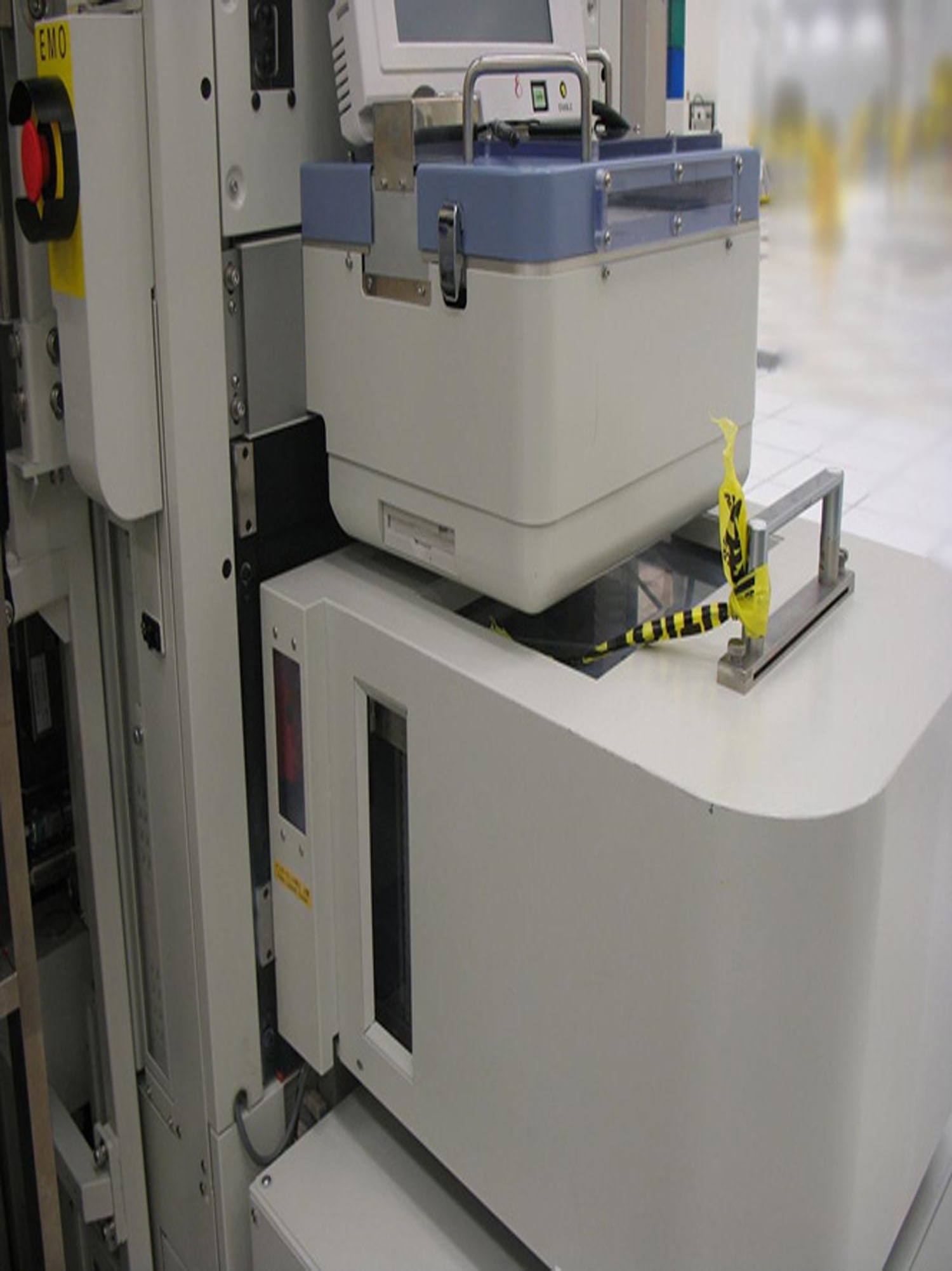

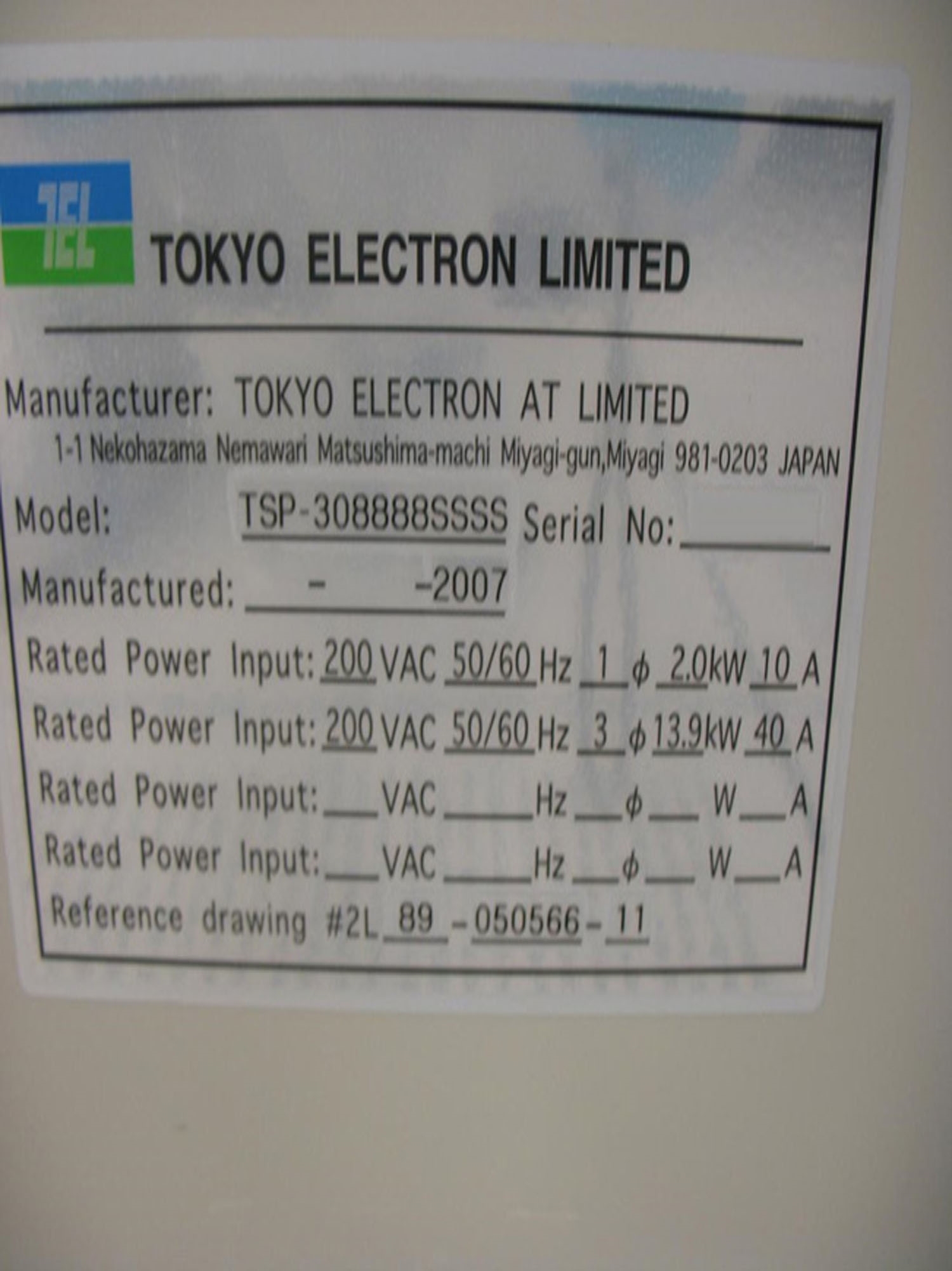

二手 TEL / TOKYO ELECTRON Telius SP 308QS #9213296 待售

網址複製成功!

單擊可縮放

ID: 9213296

Deep trench silicon etchers

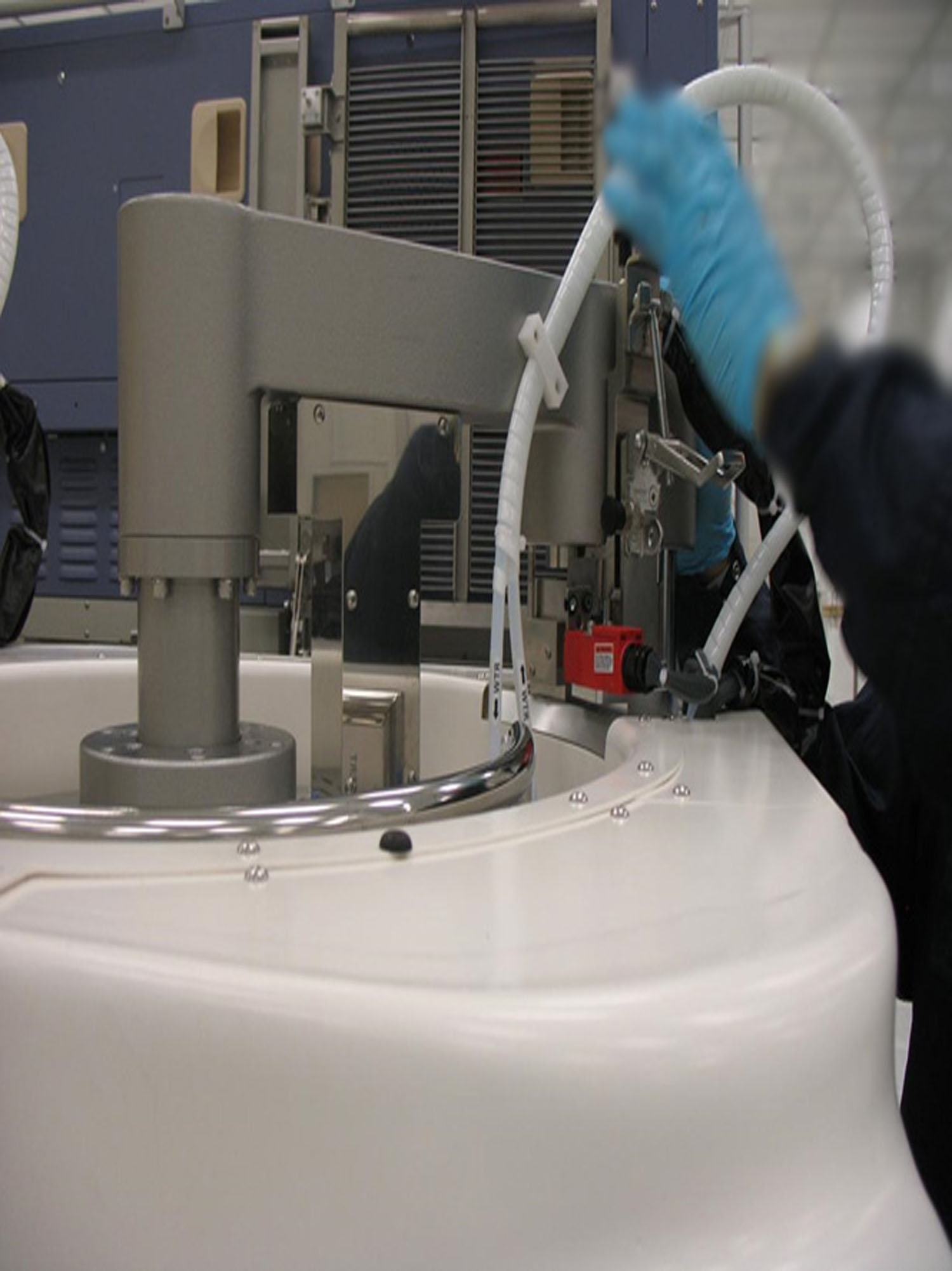

12" FOUP

(4) Chambers (SCCM)

(5) Loader ports

Load locker modules

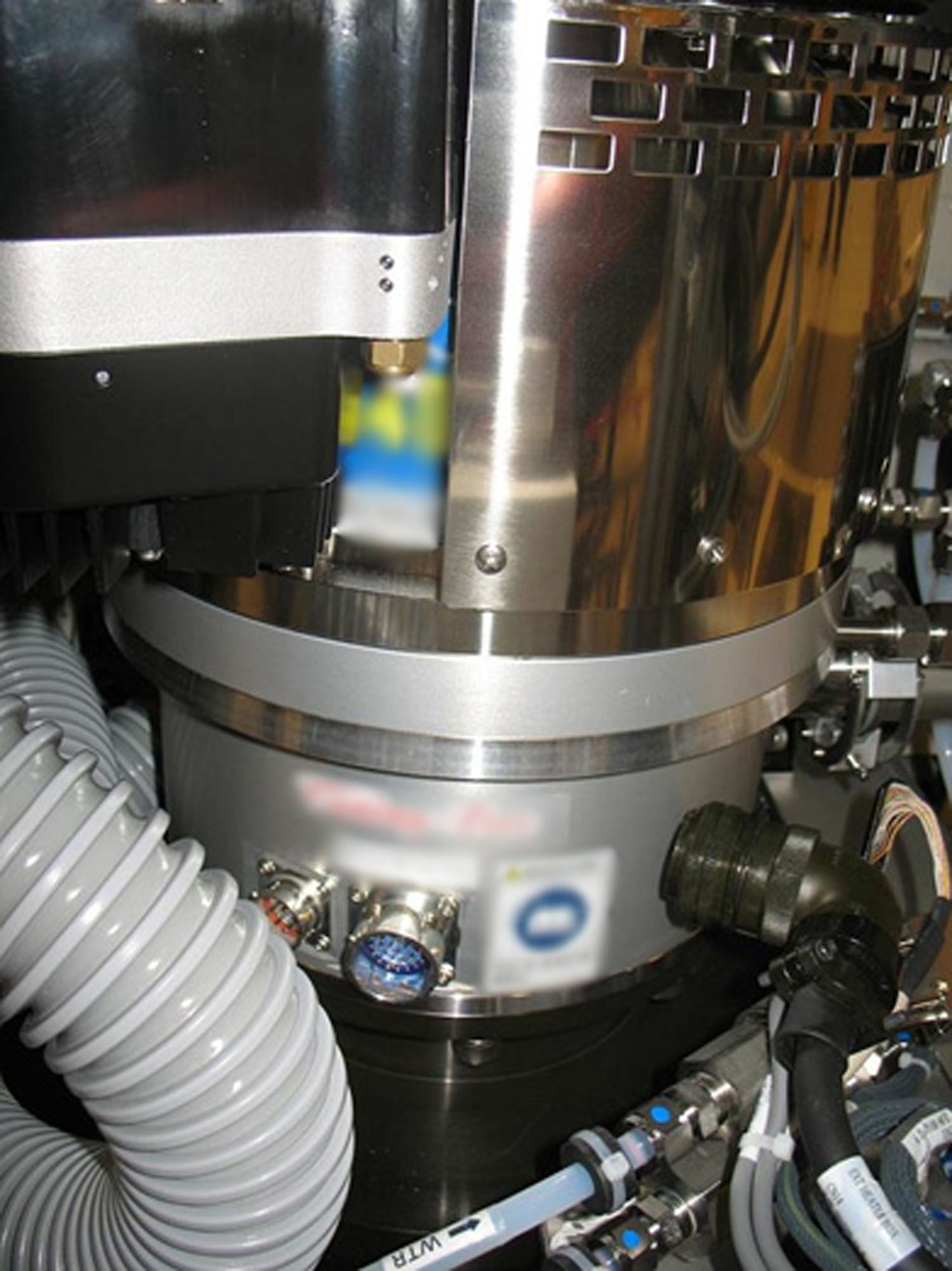

GEW3040 and NOVA50A 40MHz and 3.2MHz dual frequency source

ESD Chuck

Temperature control

RF Application method

Process: 80um deep 90nm wide via silicon etch

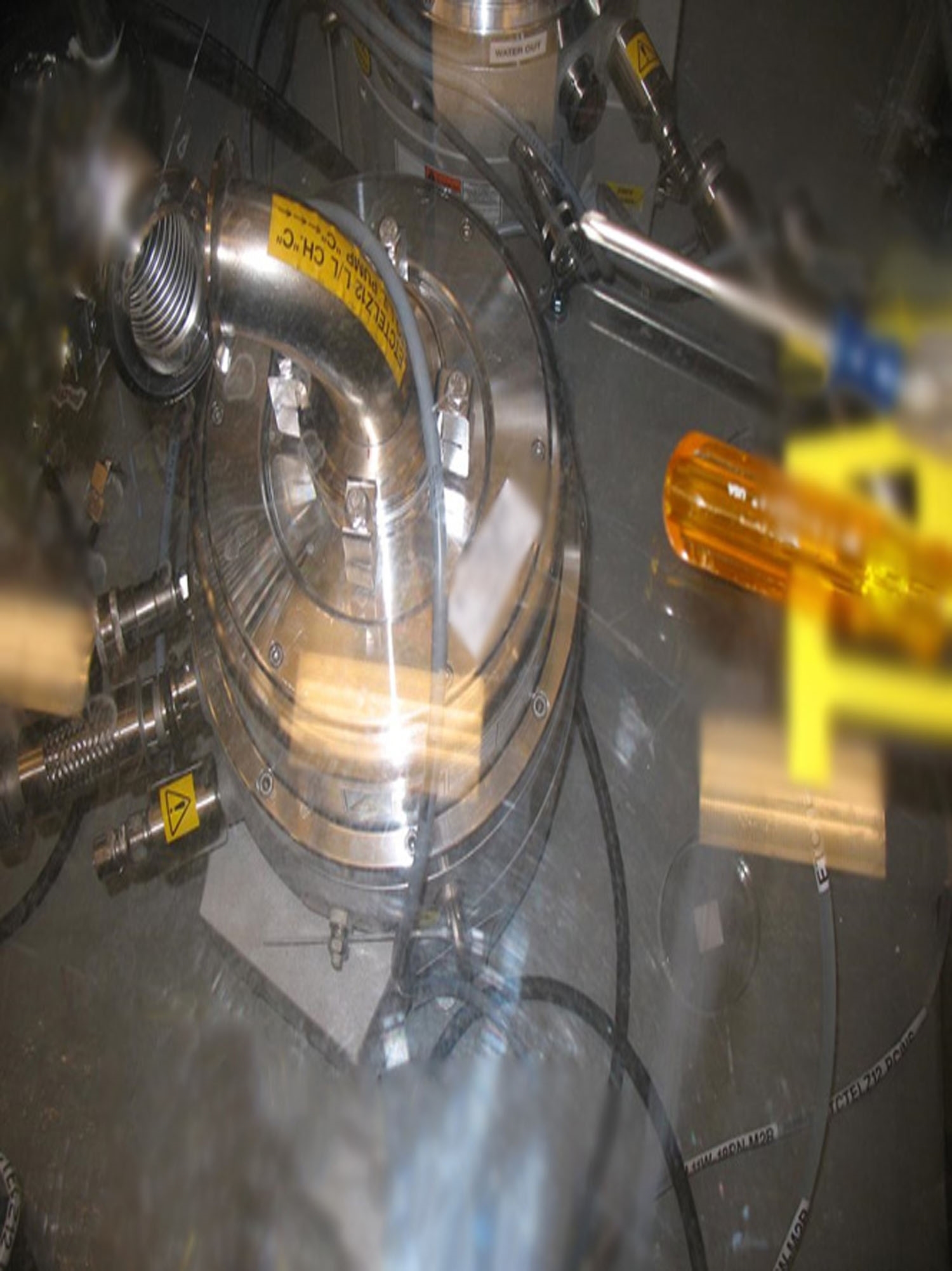

Chamber:

Aluminum alloy chamber

Material: Aluminum alloy (A6061)

Surface finishing: Hard sulfuric acid anodizing

RF Application method: Apply upper RF to lower electrode

Discharge method: SCCM Type

Temperature control:

Upper electrode: Temperature control by heater and cooling water

Lower electrode: Temperature control by circulating coolant

Side wall: Temperature control by heater

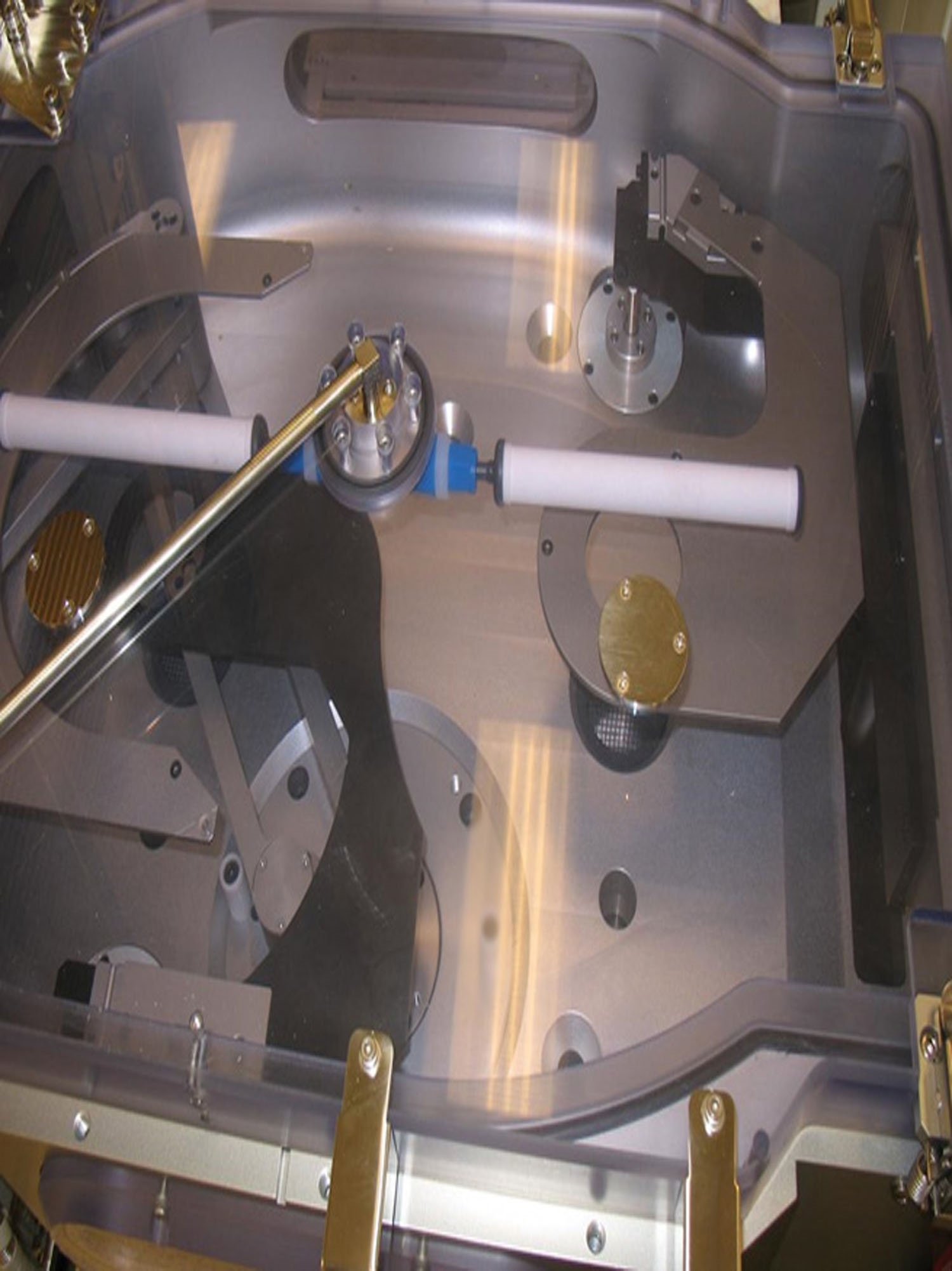

Upper electrode:

Quartz cover or aluminum alloy (A6061) with hard sulfuric acid anodizing

Shield ring

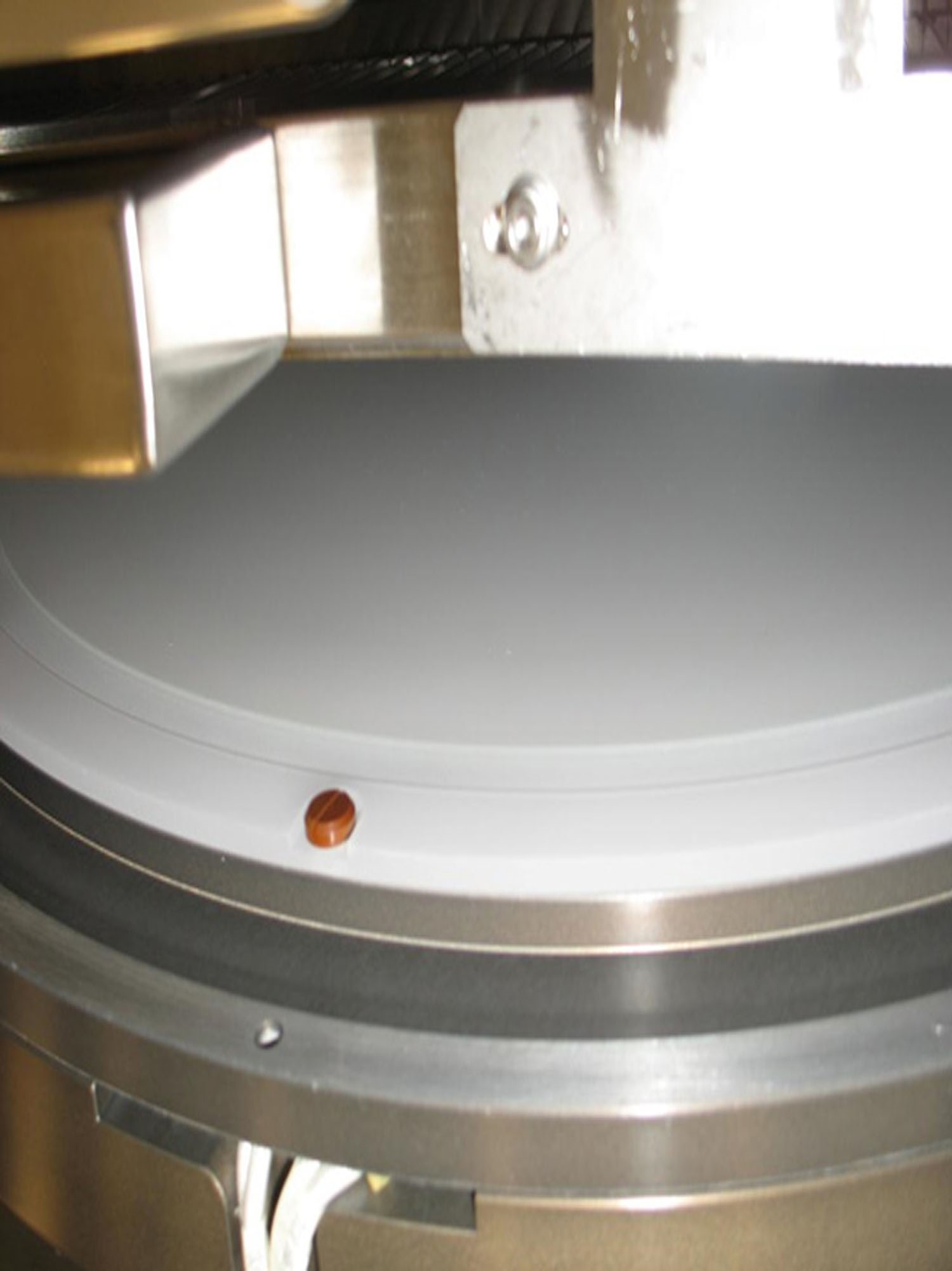

Lower electrode:

Ceramics electro static chuck

Thermometer

Wafer holding method: Electrostatic chuck(φ300) mechanism

Lifter: Resin

Focus ring: Qz

Exhaust plate: Aluminum alloy with hard sulfuric acid anodizing

Insulation ring: Quartz cover or aluminum alloy (A6061) with hard sulfuric acid anodizing

Distance between electrodes: 30~35 mm

Magnet:

Intensity: 170G (center)

Rotation: 20± 1rpm

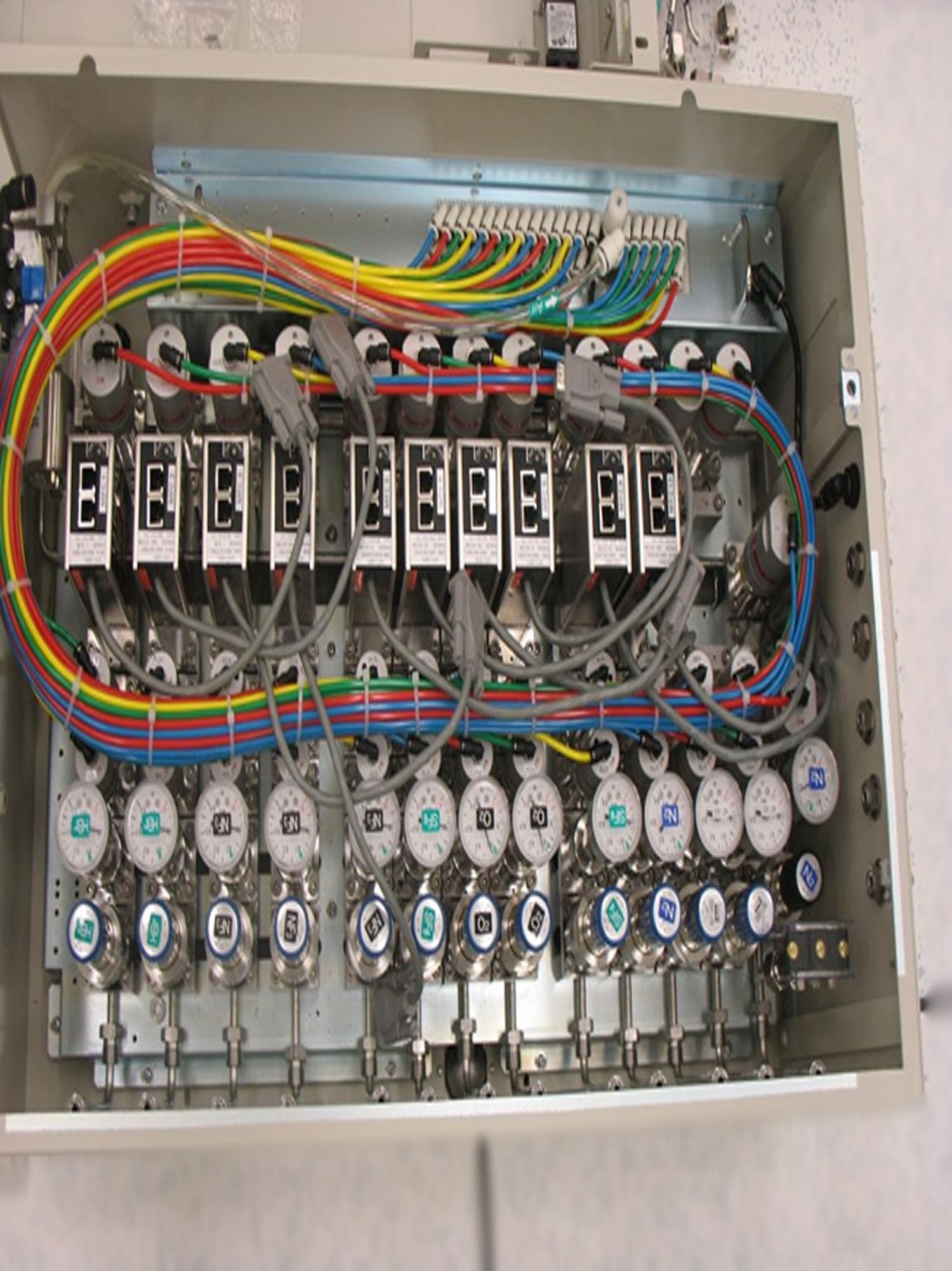

Pressure monitor: (3) Types

He B.P unit: Cooling gas for wafer back

Pressure switch: PCV (STEC)

Number of line: (2) Lines

Control range of pressure:

(Center / Edge): 0~7980Pa(0~60Torr)

He monitor: Leakage monitor

Detection of valve open / close: Valve ON/OFF sensor

End point detection: SE2000

Confirmation of luminescence

Window: Orifice (Quartz)

Deposition shield: Removable depo-shield

Material: Quartz

Shutter:

Plate: Aluminium alloy with hard sulfuric anodizing

Drive: Air cylinder

Final valve: Diaphragm type mega-one (Fujikin)

Manifold: Aluminium alloy with hard sulfuric anodizing

O-ring for chamber: Chemratz

Specifications for performance:

Ultimate vacuum: 0.0133 Pa (7.5*10-2 mTorr) or less

Leak back: 0.133 Pa/min (1 mTorr/min) or less

2007 vintage.

TEL/TOKYO ELECTRON TELIUS SP 308QS是一款高精度的蝕刻器/asher,設計用於實現精確的薄膜厚度控制和快速的基板處理。該機利用多種先進技術,在提供卓越吞吐量速度的同時,達到高質量的效果。TEL Telius SP 308QS具有直觀的圖形用戶界面,使蝕刻過程簡單明了。蝕刻室的設計考慮了靈活性和人體工程學,適合各種蝕刻應用。它擁有先進的四激光幹涉測量設備,用於精確控制薄膜厚度。該系統能夠測量和測量從0.2 nm到70 mm的薄膜厚度。它還具有自動i-LINE模式,用於高精度蝕刻和簡單的一鍵操作。該單元附帶一個圖形模式編輯器,您可以根據高級應用程序要求輕松編輯蝕刻模式。蝕刻過程在熱控超高真空蝕刻室中進行。該真空室能夠達到高達10-7 Torr的真空水平。它具有自動優化功能,可用於自動調整蝕刻條件,以實現更高的蝕刻速率和更低的蝕刻選擇性。自動優化功能還可用於微調蝕刻條件,以實現更精確的工藝控制。TOKYO ELECTRON TELIUS SP 308QS配備了先進的流程監控和數據記錄功能,能夠進行流程產量分析。它具有高精度的離子監控器,可確保一致且可重復的蝕刻過程。蝕刻器還具有先進的圖形處理器單元,在吞吐量過程中允許更高的性能,同時還提供高質量的數據輸出。Telius SP 308QS是一款高度先進的蝕刻機,可提供可靠、可重復的蝕刻結果,並具有顯著的吞吐量速度。其創新的設計和先進的技術使其成為各種蝕刻應用的理想解決方案。

還沒有評論