二手 YES / GLEN R3 #9251749 待售

網址複製成功!

單擊可縮放

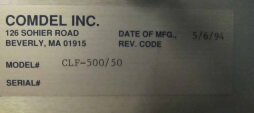

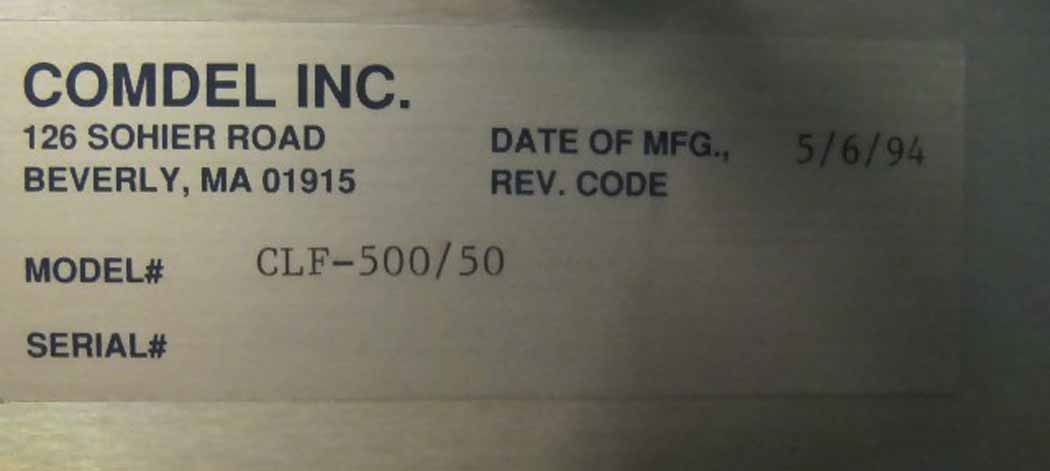

ID: 9251749

優質的: 1994

Plasma cleaner

Low frequency

Mass Flow Controller (MFC)

N2 Flow rate: 1.7 SCFM

Process gas flow rate: 20-50 SCCM

Chamber material: 6061-T6 Aluminum

RF Plasma power: 0 - 500 W at 550 VAC

Nitrogen consumption: 0 SCFM idle, 1.7 SCF

Reactant gas consumption: 0 SCFM Idle, 150 SCC

KF 40 Vacuum plumbing

Clean room capability: Class 10

Compliance: SEMI S2

Touch screen interface

Analog MFC control and monitoring

Thermocouple monitoring for etch uniformity

Safety factors: Integral RF and pressure interlocks

TCP/IP Port

Self-diagnostic program

Constant real-time display

Audible and visual cycle complete indicators

Audible and visual indication of incorrect process with diagnostics display

Vacuum sensor: 0-1000 Torr

With (2) trip points

Load capacity:

Up to 4 active plasma areas: 15.13" x 15.39"

Operational modes:

RIE

Downstream electron-free

Active ion trap

Grounded ion trap

Measurements:

Interior chamber dimensions: 450 x 450 x 300 mm

Chamber process area: 931 in² or 233 in²

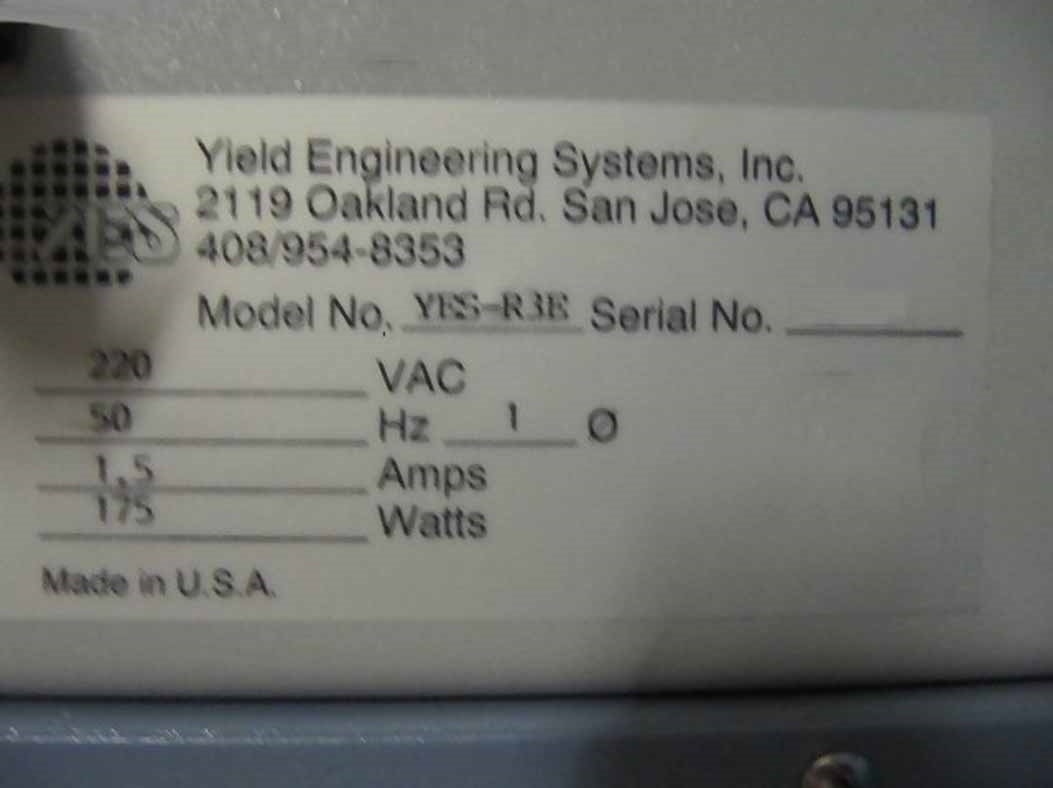

Power supply: 230 V, 20 Amps, 50/60 Hz, Single phase

1994 vintage.

YES/GLEN R3是一種通過蝕刻和長寬比測量來提高矽效率的蝕刻器/asher。其設計容量可處理15mm x 15mm,最多可處理8英寸晶圓。該設備有一個精密紡紗片模具(PSTD)和一個自動精密彈射系統。這種雙源流程有助於提高流程能力和可變性。封閉的4英寸真空外殼保持了工藝的重復性,並與傳統的Multi-Boron Plant Plus (MBI+)單元配合,提供樣品輸送和執行蝕刻。PDT通過其自動掃描頭提供單面平面場和多點測量功能。它采用了獨特的不銹鋼刀口口和定制卡盤,以提供非常低的失真和準確性。PSTD還針對隔離蝕刻和長寬比測量進行了優化。它具有組合的雙晶圓溫度控制機、氣體分配和氣體提升控制.這與高級工藝控制以及用於監視和操作蝕刻參數的軟件相輔相成,從而產生高工藝可重復性、可重復的殘留物和長寬比測量。YES R 3還具有無損和破壞性陣列蝕刻測量技術的組合。提供了雙面平場分析(DSFP)和多點分析(MPP)功能,並輔以廣泛的可變蝕刻速率和最小洗滌時間。DSFP和MPP測量極易重復,可提供快速可靠的過程信息,以幫助優化和故障排除工作。這種蝕刻器是一種可靠可靠的工具,設計時改進了工藝參數,提高了工藝吞吐量,提高了通量穩定性,提高了生產率。

還沒有評論