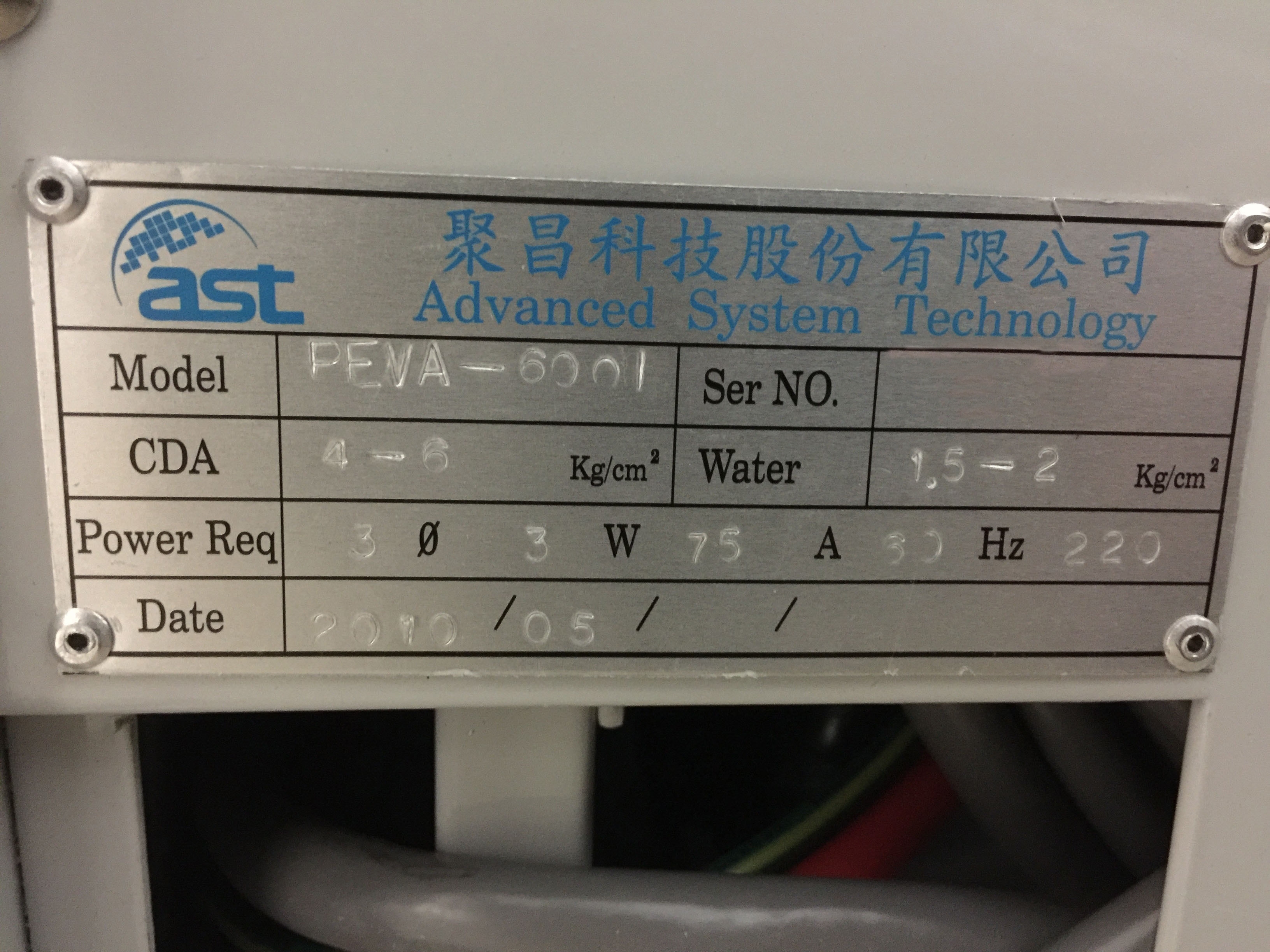

二手 AST / ADVANCED SYSTEM TECHNOLOGY Peva-600I #9263379 待售

網址複製成功!

單擊可縮放

ID: 9263379

優質的: 2010

E-Gun evaporators

System frame with clad panels

Mounting frames

Rack cabinet for control units, 19"

Mains and safety elements with emergency shut-down

Deposition chamber

Single walled: 304L Stainless steel and electro-polished

Semi rectangular pipes dimension for cooling: 630 x 850 mm

Front opening / closing door

With automatic electro-magnetic lock / unlock

Viewport diameter front door, 4.0"

Optically reflector

Shielding parts

Baseplate:

6 Holes diameter, 1"

High voltage

Sweep signal

Crucible index drive

E-gun body cooling

Shutter drive feed through

Sidewall:

Rectangular flange for HV valve: 16" x 11"

KF 40 Flange for heating power feed through

(3) KF 25 Flanges for thermocouple feed through and ion gauge head

(3) KF 16 Flanges for venting valve and pirani gauge head

35 CF Flange

Top plate:

Fitting gas inlet feedthrough: 1 Hole 1" dia

Rotation drive and quartz sensor feedthroughs: 1 Hole 5" dia

Deposition chamber pumping system and vacuum measurement:

CTI-CRYOGENICS Torr-10 Pump, 10"

CTI-CRYOGENICS 9600 Liquid helium cryogenics water-cooled compressor

Auto-regeneration function for cryo pump

GP 307 Vacuum gauge controller: ATM ~5.0E-10 torr

GP 274 Ion gauge head: 1.0E-02 torr ~1.0E-09 torr

(2) GP 275 Pirani heads with tungsten filament: ATM ~5.0E-04 torr

Accessories for substrate stage:

Substrate carrier rotary driver

Substrate carriers

Substrate heating

Accessories of process sources:

JOEL JST-3F Electron beam evaporator

Type: JEBG-203UA

Source with deflection: 270°

Uniform energy distribution

High speed scanning

Water cooling feed through

X and Y Sweep signal feed through

Single crucible 20 cc

Remote control

Shutter drive

Gas inlet systems

Process controller / Layer thickness measurement:

MAXTEK MDC-360C Layer thickness

Rate and process control unit

Process control: RS-232 Interface

Multi-film and multi-process storage: Up to (99) materials

2010 vintage.

AST/ADVANCED Equipment TECHNOLOGY Peva-600I蒸發器是一種先進技術的工業蒸發器,其設計效率和性能最高。這種蒸發器設計用於各種需要高效蒸發的工業應用,如熱冷卻、蒸餾和冷凝。AST Peva-600I蒸發器在高壓閉環系統上運行,利用加熱和膨脹的蒸氣蒸發和冷凝工作流體。這樣可以確保最大效率和產品質量,同時顯著降低能耗。它的高壓能力使得它在比其他蒸發器高得多的壓力下運行。ADVANCED UNIT TECHNOLOGY PEVA 600I蒸發器由堅固的不銹鋼框架構成,具有多種定制功能,可根據客戶的要求進行設計。它包括一個高質量,耐腐蝕,密封機,以確保可靠的性能。為了確保蒸發器的最高效率,Peva-600I包括了一些創新功能。蒸發器配備了一個高質量的低壓調節閥,旨在優化進料液體的流動,以達到最大效率。它還包括一個可調壓力表,允許精確調整壓力,允許最佳速度和性能。易於操作的AST PEVA 600I蒸發器還包括高效熱交換器和高效冷凝工具,可使用內置控制資產輕松調節。可調板換熱器可用於在最高溫度下產生產品。PEVA 600I蒸發器設計方便操作和安裝,維護要求最低.維護僅限於對零部件進行定期清潔和潤滑,並定期更換任何磨損的部件。AST/ADVANCED MODEL TECHNOLOGY PEVA 600I蒸發器設計用於提供高效蒸發和冷凝流體的高性能工業溶液。非常適合實驗室、食品加工、蒸餾和冷卻應用。這款工業蒸發器以其卓越的設計結構和先進的特點,提供卓越的性能和可靠性,是一款經濟實惠的工業應用解決方案。

還沒有評論