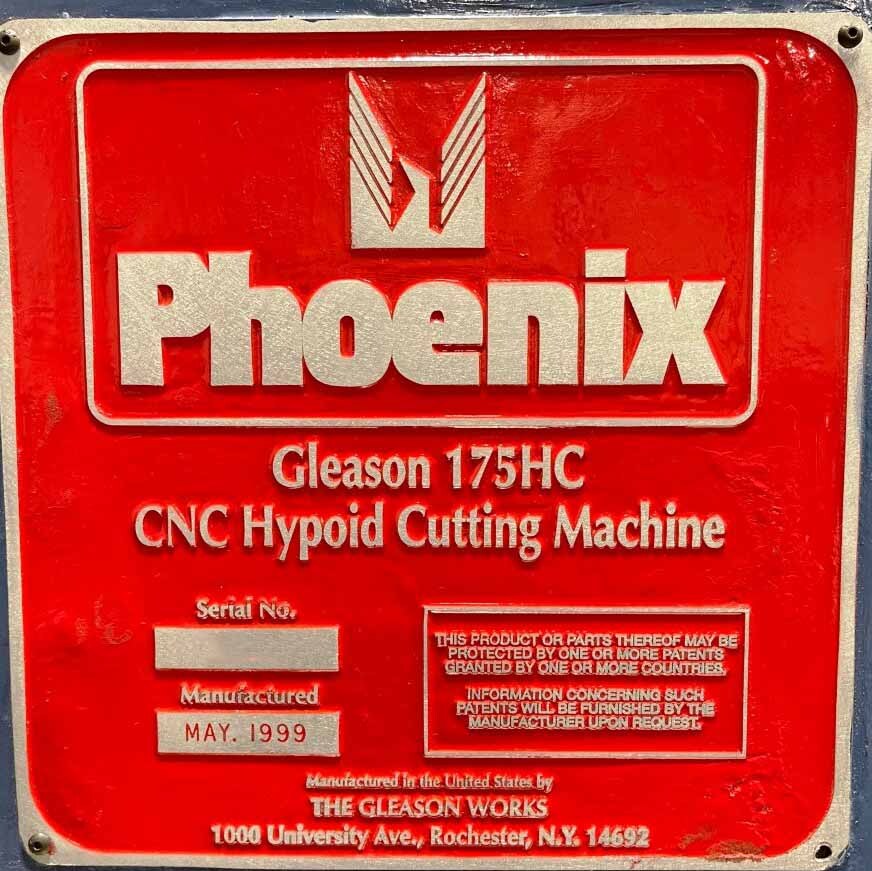

二手 GLEASON Phoenix 175 HC #9410228 待售

網址複製成功!

單擊可縮放

ID: 9410228

優質的: 1999

CNC Hypoid cutting machine

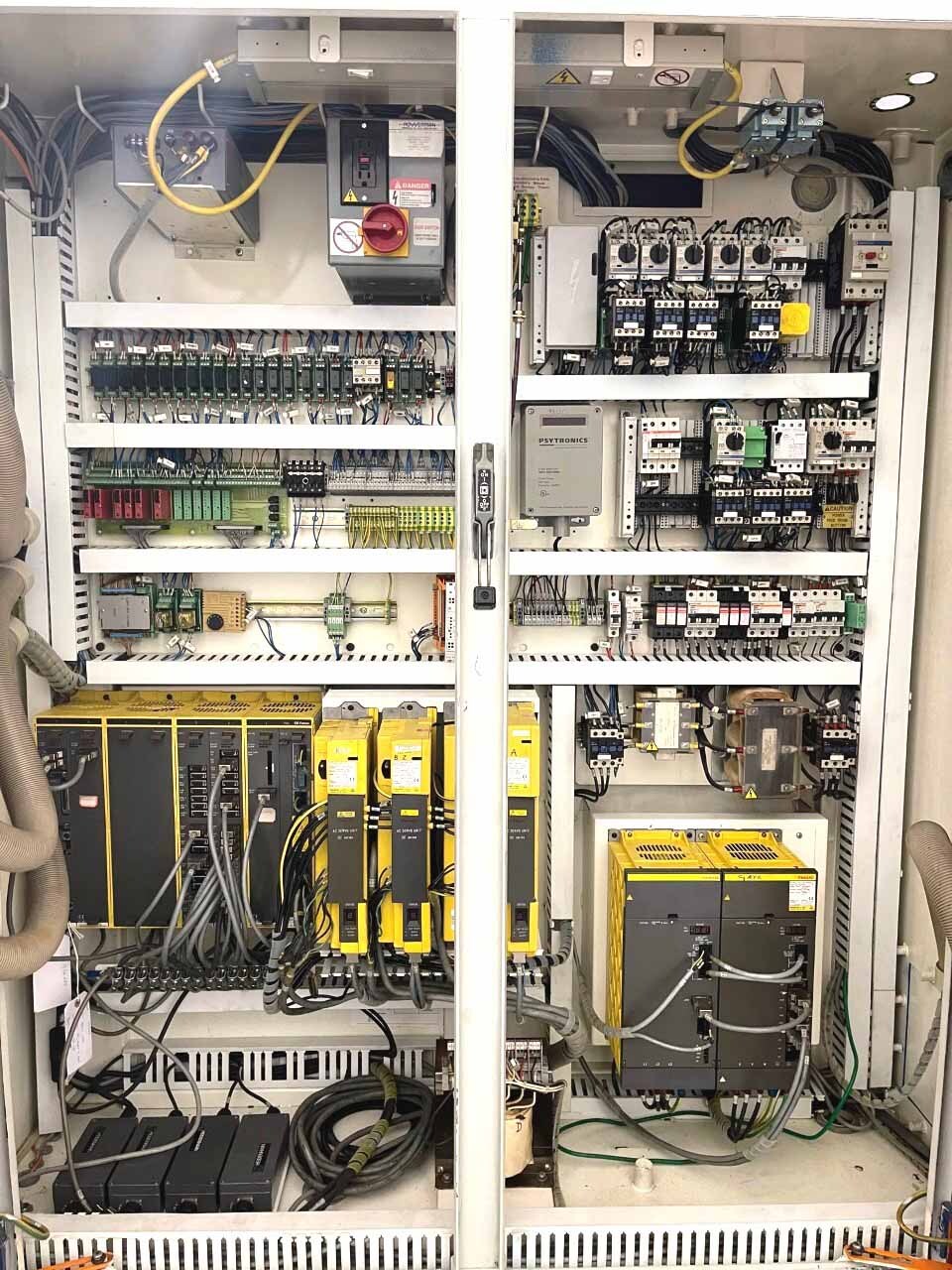

GE-FANUC 150 MB CNC Controller

High speed for dry cutting

Cyclovac air assist chip removal system

FANUC 60i Computer control

Face milling: 216 mm

Face hobbing: 190 mm

Magnetic chip conveyor

LCD Flat color display, 10.4"

Cycle fault monitoring

Production and sharpen-cutter count display

Hydraulic work-piece chuck (With draw-rod and nut)

Work spindle bore: 3-29/32

Work-head ratio gears: 5:1

Single-cycle gear finishing arrangement

Work chamber lighting

Foot switch for hydraulic chucking of work-piece

Power forced lubrication system

Self contained coolant system (Pump tank and piping)

Magnetic chip separator: Chip exit height, 24"

Control circuit: 115 VAC, 24 VDC (Input / Output)

PHOENIX NFPA 79-1987

Storage capacity for (100) Parts

Security key for control of set-up

Wiring and hydraulic diagram

Extreme ratio: 10:1

Root angle range (B-Axis): -5° to 90°

Equivalent root angle range: -5° to 90°

Maximum gear pitch diameter: Face hobbing

Spiral: 30°

TRI-AC Cutter, 6" with (13) blade groups

Maximum pitch diameter:

1:1: 6.000"

2:1: 7.500"

5:1: 7.500"

Maximum full depth: 0.550"

Maximum face width: 1.600"

Maximum gear pitch diameter: Face milling

Spiral: 35°

Diameter cutter, 7.5"

Maximum pitch diameter:

1:1: 6.750"

2:1: 8.500"

5:1: 8.500"

Maximum full depth: 0.625"

Maximum face width: 1.600"

Maximum swinging base travel (B-Axis): 5° to 90°

Maximum vertical travel (Y-Axis): -4.00" to 7.00"

Maximum horizontal travel (X-Axis): -6.00" to 4.00"

Sliding base travel (Z-Axis): 2.00" to 12.00"

Machine center to work spindle face: 4.500"

Tooth number: 5 to 200

Cutter diameters:

Conventional face milling: 1.1" to 7.5"

HELIXACT

TRI-ACT

Fine pitch: 102-152 mm

Coarse pitch: 152 mm

Speed:

B-Axis swinging base (Degrees per second): 30°/Sec

A-Axis work spindle (Face milling): 240-960 RPM

A-Axis work spindle (Face hobbing): 240-960 RPM

C-Axis cutter spindle: 380-910 RPM

X-Axis horizontal: 4.92"/Sec

Y-Axis vertical: 4.92"/Sec

Z-Axis sliding base: 4.92"/Sec

Work spindle:

Diameter of taper at large end: 3-29"/32"

Taper per foot: 38"/64"

Depth of taper: 3"

Motors:

B-Axis swinging base: FANUC 5s/3000 Digital servo-drive, 2,000 RPM

A-Axis work spindle (Face milling): FANUC 30s/3000 Digital servo-drive, 20,000 RPM

A-Axis work spindle (Face hobbing): FANUC 30s/3000 Digital servo-drive, 20,000 RPM

X-Axis horizontal: FANUC 5s/3000 Digital servo-drive, 10,000 RPM

Y-Axis vertical: FANUC 5s/3000 Digital servo-drive, 10,000 RPM with brake

Z-Axis sliding base: FANUC 5s/3000 Digital servo-drive, 10,000 RPM

C-Axis cutter spindle: FANUC 1024 15P Digital servo-drive

Coolant: 3 HP

Hydraulic: 3HP

Chiller

Chip separator

Manuals included

Control circuit: 115 VAC with 24 VDC Input / Output

Power supply: 380-460 V, 50/60 Hz, 3-Phase

1999 vintage.

GLEASON Phoenix 175 HC是一種組合機床,設計用於圓柱和非圓柱工件的切割和成型產生磨削。Phoenix 175 HC是一款功能齊全、用途廣泛的機床,模塊化設計便於機器安裝,非常適合各種研磨和輪廓研磨應用。GLEASON Phoenix 175 HC的基機配備了高容量、直驅動、CNC控制的磨削主軸,最大切削速度為15.000rpm。主軸由強大的直線電機和保證精確定位和可靠切割速度的直驅伺服電機支撐。主軸可以在X軸和Z軸上進行調整,以獲得最高精度和表面光潔度質量。菲尼克斯175 HC的主軸驅動電動機是一種先進的5-HP三相交流電動機,沿著兩條平行的硬化和地面導軌直接驅動。主軸傳動包括低慣性、高扭矩、皮帶驅動的電動機,可實現精確的運動控制並確保一致的平滑切割。機器的磨頭配備了主動的前後定位器,可快速重復切割復雜的幾何形狀。定位器由四相無刷直流電機提供動力,即使是最復雜的形狀,也能實現高精度、低誤差的輪廓研磨。GLEASON Phoenix 175 HC配有由兩速交流電動機驅動的內置磨輪。主軸轉速是可調的,以適應不同的磨輪直徑,允許機器創建多個切割輪廓與單一設置。該機配備了具有撥入功能的標準GLEASON控制器、直觀的觸摸屏操作員界面和編碼器反饋,使所有機器功能都能輕松編程和執行。Phoenix 175 HC還采用工業級不銹鋼外殼,並具有耐用部件,包括精密級耐刮板和全覆蓋防護系統。GLEASON Phoenix 175 HC適用於多種行業的切割應用,包括航空航天、汽車、造船和軍事應用。

還沒有評論