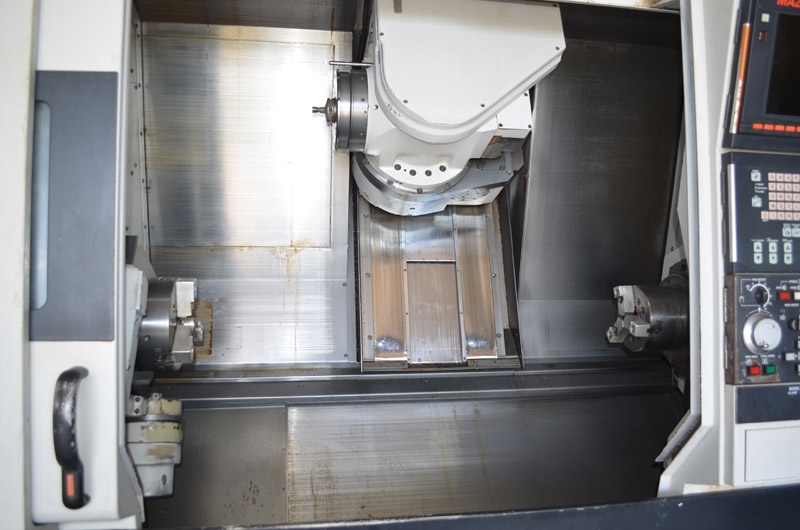

二手 MAZAK Integrex 200-IIIS #9296620 待售

網址複製成功!

單擊可縮放

ID: 9296620

優質的: 2004

Multi-Axis CNC turning center

With sub-spindle & Y-Axis

Specifications:

Maximum swing: 26"

Maximum swing over carriage: 19.7"-26"

Maximum cutting diameter: Chucking, 26"

Maximum cutting length: 40"

Maximum distance between standard chuck faces: 41.14"

Main spindle specifications (L):

Spindle nose: A2-6

Spindle bore: 2.99"

Maximum bar work: 2"

Spindle speed / Ranges: 35 - 5,000 RPM / 2

Spindle index (Programmable): 0.0001°

Spindle horsepower (Cont./30 Mins.): 20/30 H.P. (A.C.)

Spindle torque: 258.1 ft-lbs

Second spindle specifications (R):

Spindle nose: A2-6

Spindle bore: 2.99"

Maximum bar work: 2"

Spindle speed / Ranges: 35 - 5,000 RPM / 2

Spindle index (Programmable): 0.0001° C-Axis

Spindle horsepower (Cont./30 min): 20/25 HP (A.C.)

Spindle torque: 241 ft-lbs

Turret and tooling specifications:

Type of turret: 1 Position, with ATC

Tool shank height: 1.0"

Tool size (Boring bar max. dia.): 1.5"

Magazine capacity: 40 Tools

Tool selection method: Random

Tool to tool ATC Time: 1.3 Sec.

Max. tool diameter with all pockets full: 3.54"

Max. tool diameter with adjacent pockets empty. 4.92"

Max. tool length (From gauge-line): 11.8"

ATC Tool shank: KM

Rotary tool spindle speed / Ranges: 12,000 RPM / 1

Rotary tool spindle horsepower (20% ED). 25 H.P. (A.C.)

Rotary tool torque (20% ED): 88.2 ft-lbs

Maximum face mill: 4"

Maximum end mill: 1.25"

Maximum drill: 1.18"

Maximum tap: 1-8 UNC

Axis travels:

B-Axis: 225° (0.001° Increments)

Y-Axis: +/- 3.15"

X-Axis: 22.83"

Z-Axis: 41.1"

Second headstock W-Axis: 41.34"

Axis rapid rates:

Y-Axis: 1023 IPM

X-Axis: 1496 IPM

Z-Axis: 1496 IPM

Second headstock W-Axis: 1181 IPM

C-Axis: 400 RPM

General specifications:

Floor space (W x L x H): 87.1" x 150.39" x 102.24"

Machine weight: 21340 lbs

Equipped with:

MAZATROL Fusion 640MT PRO Control

PCMCIA I/F (2-Slots, card bus)

Network interface (For LAN and MODEM)

Y-Axis control

Coolant through milling head

Flood coolant: 213 PSI Through

C-Axis: 0.0001° (1st Spindle)

2nd Spindle C-axis: 0.001°

Tool magazine: 40 KM

B-Axis: 0.0001° Increment N/A contouring

B-Axis: Index 5° (Coupling clamp)

Chip conveyor side disposal (Consep)

Automatic tool eye

Auto chuck jaws open / Close (1 and 2 Spindle)

Chuck open / Close confirm (1 and 2 Spindle)

Auto power ON / OFF + Warm up

Coolant temperature control

Shower coolant: 38 PSI / 16 Gal

Through hole chuck B-208A615 (1st Spindle) through hole cyl S1552, 8"

Chuck B-208 2nd spindle with non-through hole cyl. Y-1225, 8"

2004 vintage.

MAZAK Integrex 200-IIIS是一種多任務、多軸機床,在單個設置中提供各種CNC車削、銑削和鉆孔功能。它利用強大的控制設備,提供足夠的自動化級別,非常適合中型和大型加工作業。Integrex 200-IIIS采用緊湊的床與大主軸和子主軸。它提供了3個主軸,總共有20個刀具工作站,這些工作站使用大孔條進紙器和幫式刀具更換器啟用。它允許同時進行銑削和車削操作,使用戶能夠快速且更精確地生產復雜的元件。機器由運行最新版本12軟件的可靠的MAZATROL 640MT Pro CNC控制系統驅動。控制單元由8.4英寸單色液晶屏幕和雙語鍵盤組成,便於手動輸入數據。它包含用於快速作業設置的內存格式以及用於高效加工的預編程加工循環庫。該機器可以使用會話編程、EIA/ISO和MAZAK專有的DNC Parallel Linker軟件進行編程。MAZAK Integrex 200-IIIS還具有強大的交流伺服驅動馬達,可提供平滑、穩定的切割和高的定位精度。它還配備了Fanuc的Absolute Position Detection機,以提高精度和更高的可靠性。整體軸驅動技術有助於減少振動並提供一致、準確的切割。除了性能外,Integrex 200-IIIS還考慮了用戶安全。它配有剛性箱道(斜床)切削區和電子互鎖安全門,防止加工時進入切削區。它還有一個操作員友好的手動模式,允許訓練有素的人員進入機器,而不必擔心中斷。MAZAK Integrex 200-IIIS是為多功能性和可靠性而設計的高效、精確的機床。其廣泛的切割功能和可靠的操作使其適合各種加工操作,包括石油、天然氣、汽車和航空航天應用。機器的自動化特性及其易於操作,使其成為需要精確精度和快速生產時間的應用程序的理想選擇。

還沒有評論