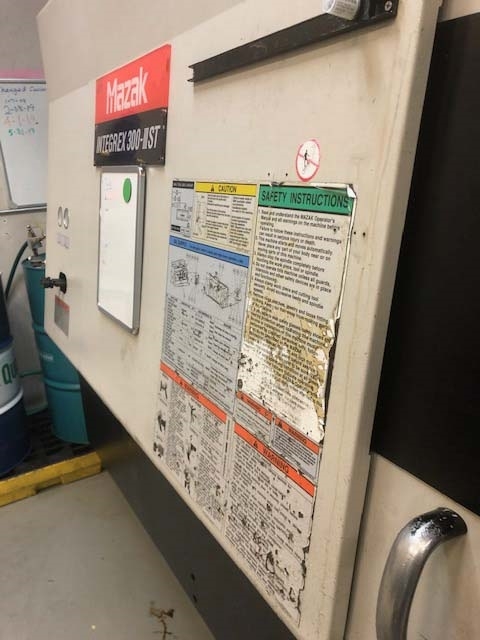

二手 MAZAK INTEGREX 300-3ST #9277147 待售

網址複製成功!

單擊可縮放

ID: 9277147

優質的: 2005

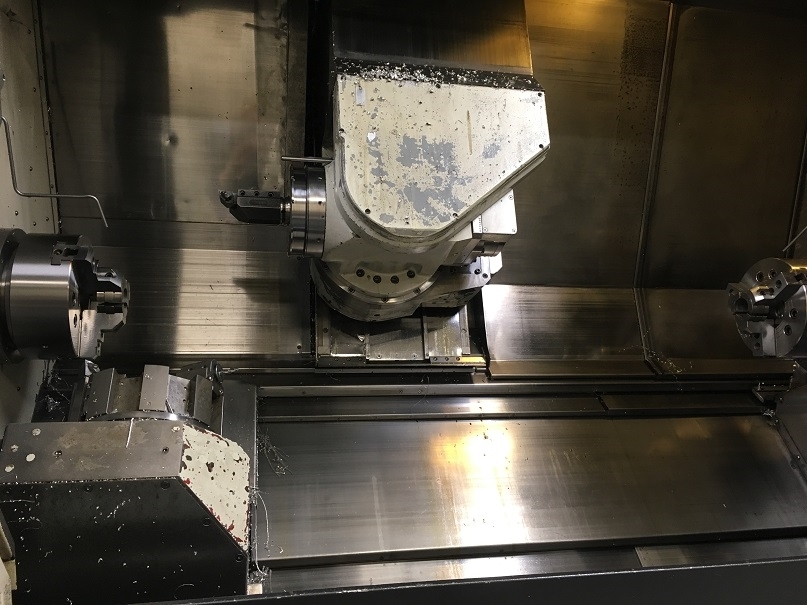

Multi-axis CNC turning center

MAZATROL Fusion 640MT PRO CNC

Floppy Disc Drive (FDD): RS-232 C / 3.5"

PCMCIA I/F (2-Slots, card bus)

Network interface (For LAN and MODEM)

Coolant thru milling head

Flood coolant: 213 PSI Thru (Upper Turret)

Flood coolant: 14.2 PSI / 1KG (Lower turret)

C-Axis: 0.0001° (1st Spindle)

2nd Spindle position: 0.001° without C-axis

Tool magazine: 40 KM

B-Axis: 0.0001° N/A contouring

B-Axis: Index 5° (Coupling clamp)

Lower 9-positions drum turret

Chip conveyor (Side, consep): 1500U (60")

Automatic tool eye

Auto chuck jaws open / Close (1 and 2 Spindle)

Chuck open / Close confirm (1 and 2 Spindle)

Chuck air blast (1st Spindle)

(2) KITAGAWA Chucks, 10"

Maximum swing: 33.5"

Maximum swing using Y-Axis: 26"-33.5"

Maximum swing over cross slide: 33.5"

Maximum swing over lower turret:16.5"

Without boring bar holder on turret

Maximum cutting diameter: Chucking, 30" (Upper)

Maximum cutting diameter: Chucking, 16.5" (Lower)

Maximum cutting length: 60"

Maximum distance between chuck faces: 60"

Main spindle (L):

Spindle nose: A2-8

Spindle bore: 3.46"

Maximum bar work: 3.0" Dia

Spindle speed: 4,000 RPM

Spindle index (Programmable): 0.0001°

Spindle horsepower (Cont/30 Mins): 30/35 HP (AC)

Spindle torque: 442.5 ft-lbs

Second spindle (R):

Spindle nose: A2-8

Spindle bore: 3.46"

Maximum bar work (Non-thru): 3.0" Diameter

Spindle speed: 4,000 RPM

Spindle index (Programmable): 0.001°

Spindle horsepower (Cont./30 Min.): 30/35 HP (AC)

Spindle torque: 368.8 ft-lbs

Upper turret and tooling:

Turret position with ATC

Tool shank height: 1"

Tool size (Boring bar Maximum diameter): 1.5"

Magazine capacity: 40 Tools (KM)

Tool selection method: Random

Tool to tool ATC time: 1.3 Sec

Maximum tool diameter with all pockets full: 3.54"

Maximum tool diameter with adjacent pockets empty: 4.92"

Maximum tool length (From gage-line): 15.75"

Rotary tool spindle speed: 12,000 RPM

Rotary tool spindle horsepower (20%ED): 24.8 HP (AC)

Rotary tool torque (20%ED): 88.5 ft-lbs

Lower turret and tooling:

Turret: Drum

Tool shank height: 1.0" x 1.0" x 5"L

Tool size (Boring bar maximum diameter): 1.25"

(9) Tools

Tool selection method: Bi-Directional

Tool index time (1 Step): 0.14 Sec

Axis travels:

Y-Axis: +/- 4.53"

X-Axis: 24.8"

Z-Axis: 62.4"

X2 Axis lower: 9.06"

Z2 Axis lower: 60.2"

Second headstock W-axis: 60.24"

Axis rapid rates:

Y-Axis: 1023 IPM

X/X2 Axis: 1496 IPM

Z/Z2 Axis: 1496 IPM

Second headstock W-axis: 1181 IPM

C-Axis: 400 RPM

B-Axis: 10 RPM

2005 vintage.

MAZAK INTEGREX 300-3ST是一種多任務機床,非常適合制造復雜的元件,其復雜的特性要求高精度和高精度。它配備了一個「托盤池」功能,允許方便和高效的托盤交換載入/載出。這增加了生產靈活性,因為可以快速卸載元件並裝載新托盤,所有這些都不會中斷加工操作。該機包括三個獨立的主軸-主軸、旋轉刀具主軸和計數器主軸.主軸具有高達2200 rpm的高功率切割能力和42千瓦的高扭矩切割能力。這樣可以提高加工困難材料時的切削速度。旋轉刀具主軸也可達到2200 rpm的轉速,非常適合銑削和表面加工操作。計數器主軸可達到6000 rpm的轉速,還具有高達14 kW的高扭矩切割能力,可為小型工件提供可重復性和精度。該機還配備了強大的數控設備,能夠同時處理多項任務。這允許復雜的元件加工和更短的循環時間。CNC控件還可以處理與元件程序相關的數據,如尺寸、公差和切割條件等,準確度很高。該機還配備了強大的12軸系統,可同時進行三次操作。這包括用於精度和精度的3個伺服驅動軸、用於運動控制的3個軸、用於與加工同時進行運動控制的2個軸以及用於復雜零件加工的4個軸。12軸單元提高了生產效率,因為它可以減少設置時間並縮短加工周期時間。INTEGREX 300-3ST還具有多種冷卻劑輸送系統,如高壓機器、間歇工具和油霧資產。這樣可以有效地冷卻切削區域並改進芯片控制,這在加工高強度材料時尤為重要。該機還包括一個可存儲多達40個刀具的自動刀具彈匣,允許快速高效的刀具更換。這有助於減少周期時間並提高機器利用率。總體而言,MAZAK INTEGREX 300-3ST是一款功能強大且高效的機床,非常適合制造具有復雜功能的復雜組件。配備了強大的電機主軸、高性能數控模型、三次同步運行的12軸設備以及多種冷卻劑輸送系統。此外,它還具有一個可存儲多達40個工具的自動工具庫,從而實現了高效的刀具變更和提高了生產效率。

還沒有評論