二手 REAL 30 #9124168 待售

網址複製成功!

單擊可縮放

ID: 9124168

High rate thermal cycle and TriAx 6 DoF vibration stress/test system,

Features:

Rapid thermal ramp rate (70 degree C per minute typical)

Tri-Axial, repetitive shock vibration system (30” x 30” table, up to 60 GRMS)

Advanced insulation for thermal efficiency and sound deadening

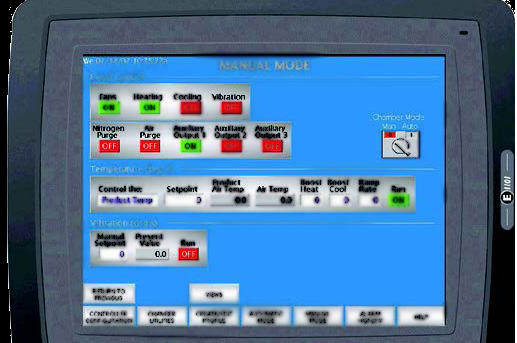

REAL chambers color touch-screen controller provides easy operation and programming for the user

State of the art PLC controls for all chamber operations

Technical Features:

Capable of monitoring up to 36 auxiliary thermocouples and 40 accelerometer inputs

Standard vacuum jacketed LN2 control system provides efficient frost free LN2 use along with reduced profile transition lagtime

Optional software for chamber operation and data logging from a PC with web based control

System Specifications:

Temperature range: +200°C to -100°C (+392°F to -148°F)

Thermal ramp rate : 70o C per minute typical

Vibration range : 1 - 60 GRMS on table, measured from 5Hz to 5 KHz

Cooling : vacuum insulated liquid nitrogen system, including proportional control valve and redundant safety. direct nitrogen atomization in plenum

Vibration table: 30" x 30" surface with 3/8-16" mounting inserts on 4" centers

Heaters : 24 kW open nichrome heater wire; baffled to prevent direct radiation to test specimens

Exciters : eight pneumatically actuated hammers, each with adjustable ball valves, which gener- ate six degrees of freedom, non-coherent, broad band excitation

Vibration table max payload: 600 lbs

Doors: one in front & one in back, open to 95° for easy access

Door Interlocks : Inhibit thermal and vibration systems when any door is ajar

Windows: 24" x 24" multi-pane viewing on each door

Access port : Two 6" x 8" ports with phenolic covers

Controller : PLC based controls with color touch-screen interface

Channels : Temp: plenum temp, product temp, (2) auxiliaries (standard)

Vibration: table control, (3) auxiliaries (standard)

Software programs (optional): REAL SCADA package allows operating the chamber and logging data from a PC

Interior workspace dimensions: 36” w x 36” d x 31” h. (91w x 91d x 79h cm)

Exterior dimensions : 77” w x 51” d x 96” h. (196w x 130d x 244h cm)

Weight : 2,350 lbs. (1066kg)

Power requirements : 460 VAC, 3 phase, 65A service (contact REAL for other voltages)

Main power disconnect switch: rated at 50,000 AIC at 480 VAC, with lock-out capability.

Compressed air: 3/4” FPT supply, 100 psig, 70 CFM, 6.9 barg, 2 m3/minute.

Exhaust: 6"/15.2 cm port

LN2 connection: 1/2" female dissimilar metal bayonet

REAL 30是一款多功能、高精度的機床,用於工業制造操作。它被認為是同級中最先進的機床之一,具有優越的技術特性和卓越的精確度。它由一個剛性的基礎框架組成,該框架設計用來承受重載,具有集成的主軸和運動控制系統。主軸能夠以高達40,000rpm的速度高速旋轉,並具有小於5微米的耗盡(公差)。它的總行程長度為1000 mm,加工範圍為700 × 600 × 500 mm, X、Y和Z軸的行程分別為630、500和600 mm。30的載重量可達500公斤,采用雙T型槽和導軸的床設計,以達到最大剛度和精度。它配置了多種工業級伺服電動機和交流伺服電動機,用於動態和精確的運動控制。將強大的數控ME109控制器集成到機器中,為復雜的輪廓和形狀提供快速的數據傳輸。數控控制器配備了可自動調整切削力的特殊運動控制系統,實現了最佳切削性能。除了強大的電機和數控控制器,REAL 30還擁有一系列先進的傳感技術來監控機器,提高安全性。它采用集成激光探頭自動檢測準直和定位點,而三重氣隙反饋傳感器則保證了主軸的平穩動態性能和精確定位。集成了一個編碼器來測量主軸轉速,並以極高的精度控制其旋轉。30的強大構建,加上強大的自動化能力、先進的感官能力和卓越的精確度,使其成為各種工業制造過程的理想選擇。廣泛用於各種加工功能,如銑削、鉆孔、車削、敲擊和磨削。該機也適用於EDM(放電加工)和多軸加工,非常適合在多種材料中生產復雜復雜的零件和結構。

還沒有評論