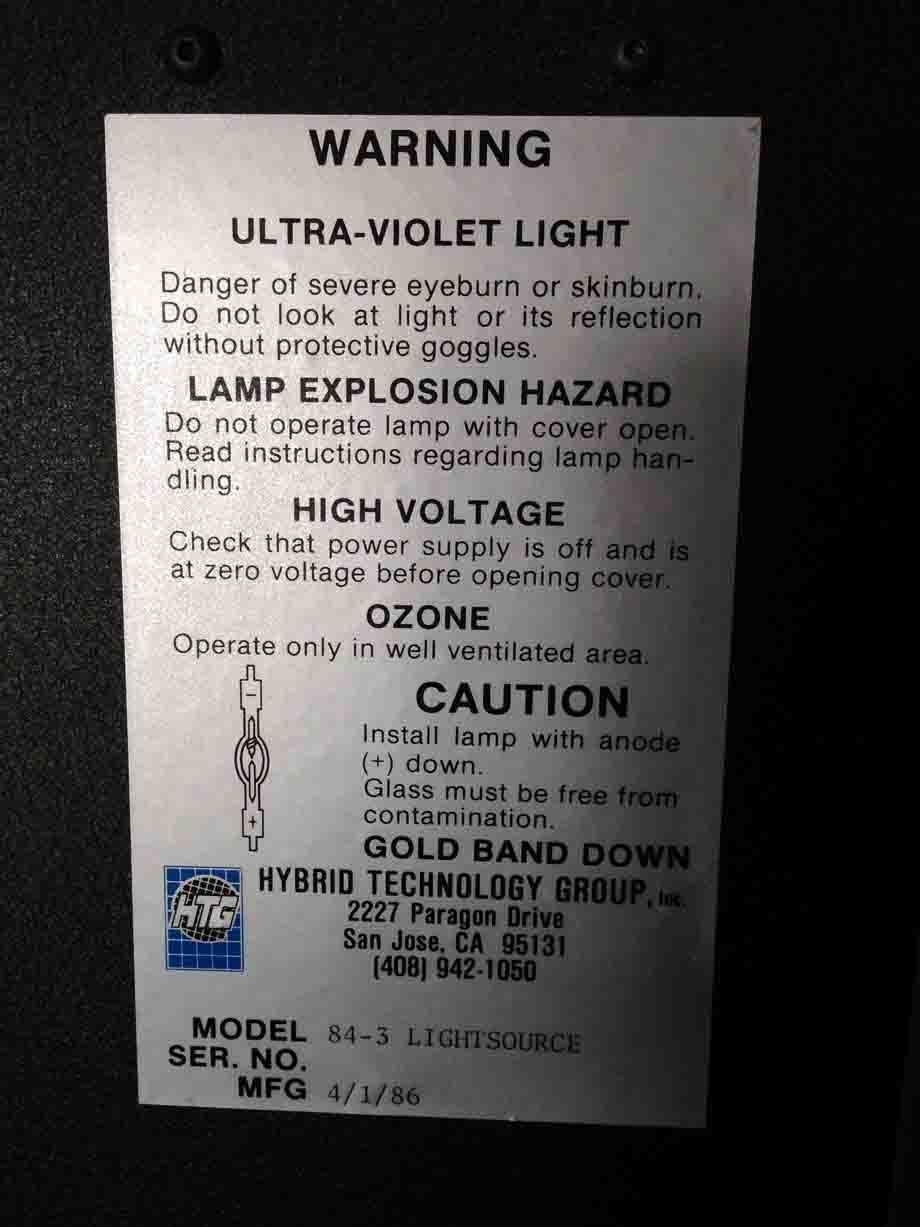

二手 HTG 84-3 #9198923 待售

網址複製成功!

單擊可縮放

ID: 9198923

優質的: 1986

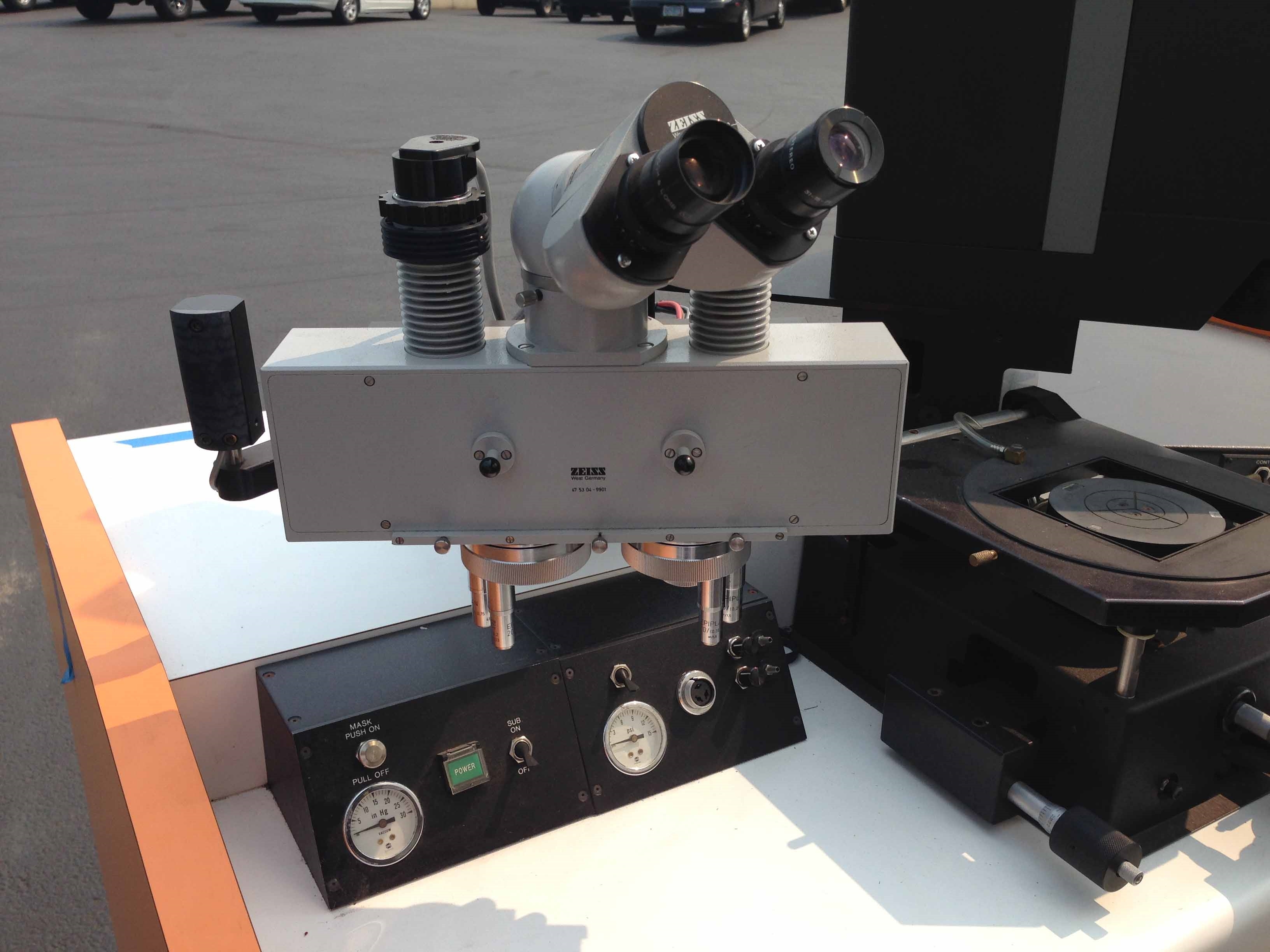

UV Mask aligner

With microscope

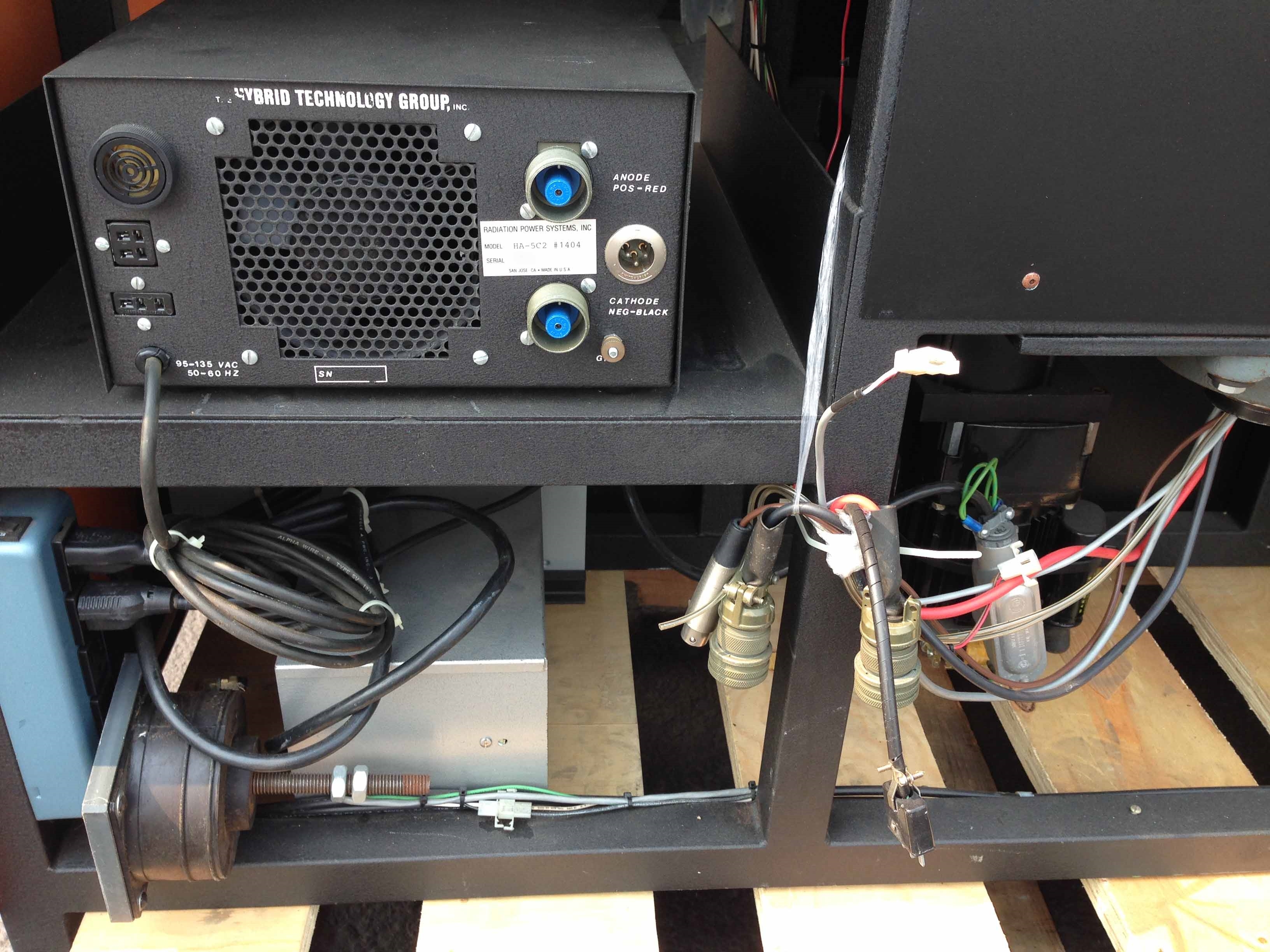

UV Lamp power supply

High resolution

Sub-micron printing

Contact and proximity exposures

Scale production alignment capability

Silicon, GaAs, LiNb, InP

Consistent printing:

Wafers

Rectangular substrates

Odd sized / Brittle materials

Single or split field viewing

Up to 600x magnification on the optics

Alignment accuracy: ±1 µm

Precise wafer to mask leveling

Highly collimated UV/deep UV exposure systems

Two channel intensity controlling power supply systems

Stationary alignment tooling

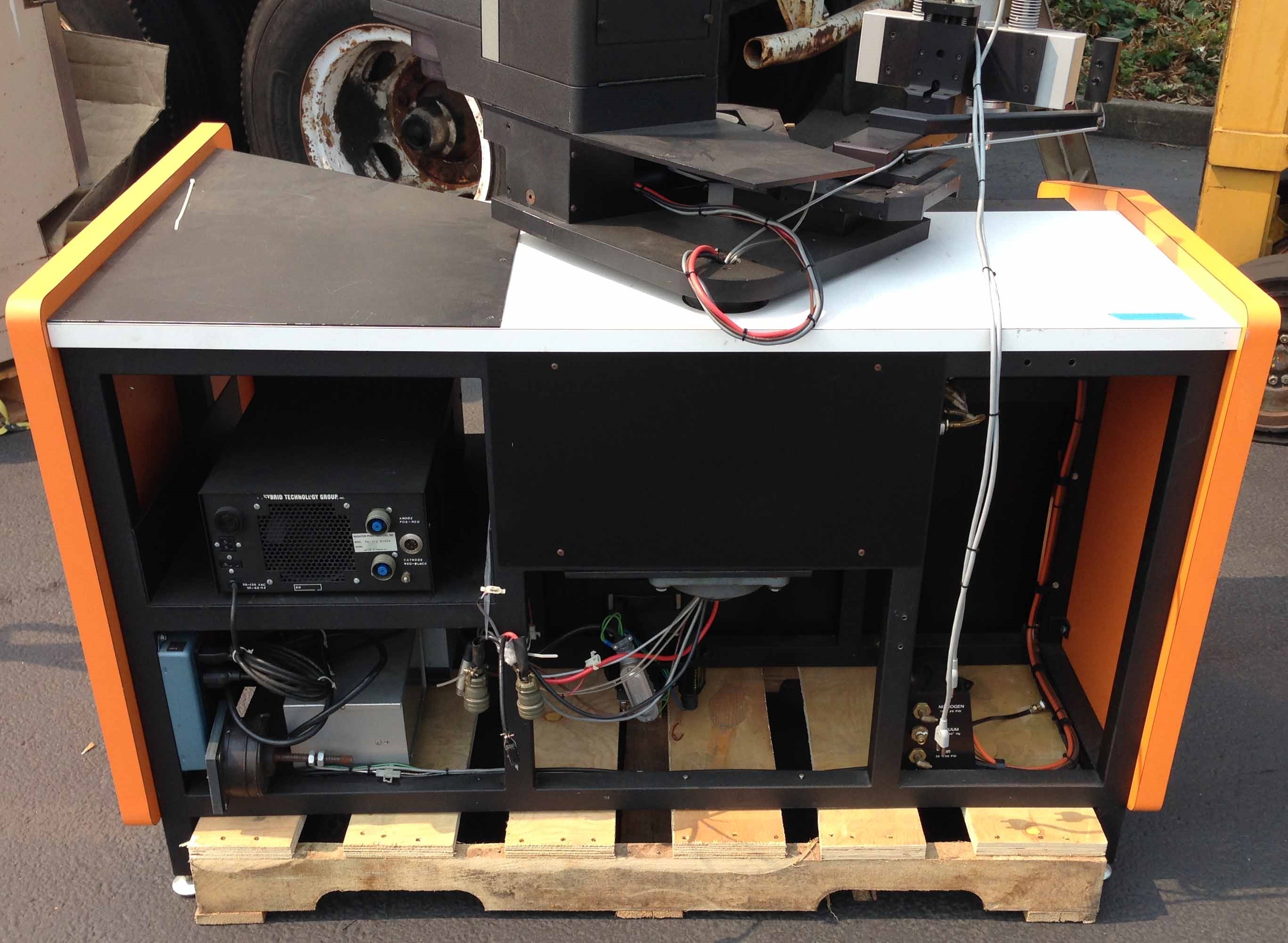

Vibration isolation console

Differential micrometers

Self planarizing chucks

Wafer chuck and mask holder included

Wafer chuck motions:

X, Y, Z and ø (direct drive)

Z-Axis adjustment: ±750µ

Air-bearing planarization system

Wafer / Substrate size: Up to 6.0" wafers / Square substrates

Mask rotation: 180°

Mask size: 7.0" x 7.0"

Vacuum mask clamp

Pneumatic mask assembly lift

Front side alignment accuracy: <0.5µ

Printing resolution:

Near UV: <0.8µ

Mid UV: <0.4µ

Deep UV: <0.3µ

Control functions:

Power

Test

Substrate vacuum

Mask vacuum

Contact vacuum

Expose

Cycle

Skip

Mask lift

N2 Purge

Timer:

000.1 to 999.9 sec

0.1 increments

Gauges:

System vacuum

Contact vacuum

N2

1986 vintage.

HTG 84-3是半導體器件制造過程中使用的掩模對齊器。它是一種先進的工具,能夠以最高的精度和精確度對半導體掩模進行對準和陣列化。84-3的主要部件包括一個掩模對準主單元、一個真空室和一個真空設備。掩模對準器主單元由X-Y級、激光對準系統、真空單元組成。掩模對準主單元負責將掩模、激光投影機和真空對準級移動到真空室內的適當位置。激光投影工具由激光源、準直儀和一系列將激光束投射到掩模和晶圓上對準的透鏡組成。激光源通常是氦-硼(He-Ne)激光器。準直器用於將激光束聚焦在掩模或晶圓的小直徑上。激光投影資產還包括一個檢查模型,用於檢測掩模和晶圓的位置和形狀的不規則性。檢查設備由一系列攝像機組成,這些攝像機能夠捕獲掩模和晶片的圖像,然後將圖像與預先編程的數據進行錯誤比較。真空室用於密封掩模和晶片,以便精確對準。該腔室包含一個真空系統,它可以防止壓力累積,從而幹擾對準過程的精度。真空裝置還保護掩模和晶片免受塵埃顆粒或其他碎片的汙染。HTG 84-3非常精確,能夠將掩模和晶片對準0.0025mm的精度。機器也很快,能夠在0.2秒內對準掩模和晶片,並且可以用於各種應用,如接觸和非接觸掩模。總體而言,84-3是一款用途廣泛且可靠的掩模對齊器,旨在提供卓越的性能和準確性。其精度和精確度使其成為半導體器件制造的寶貴工具。

還沒有評論