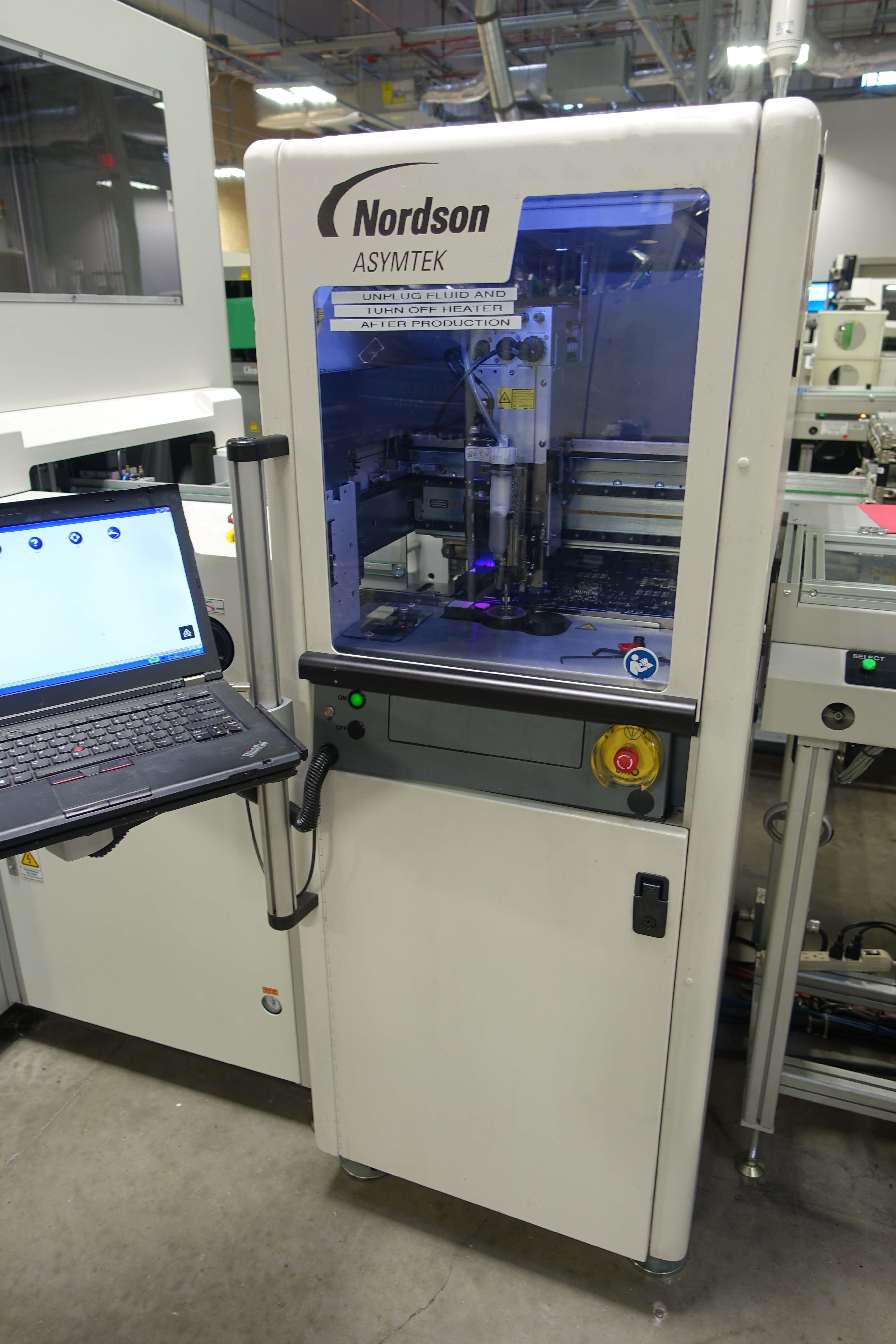

二手 NORDSON / ASYMTEK S-922N #9354584 待售

網址複製成功!

單擊可縮放

ID: 9354584

優質的: 2013

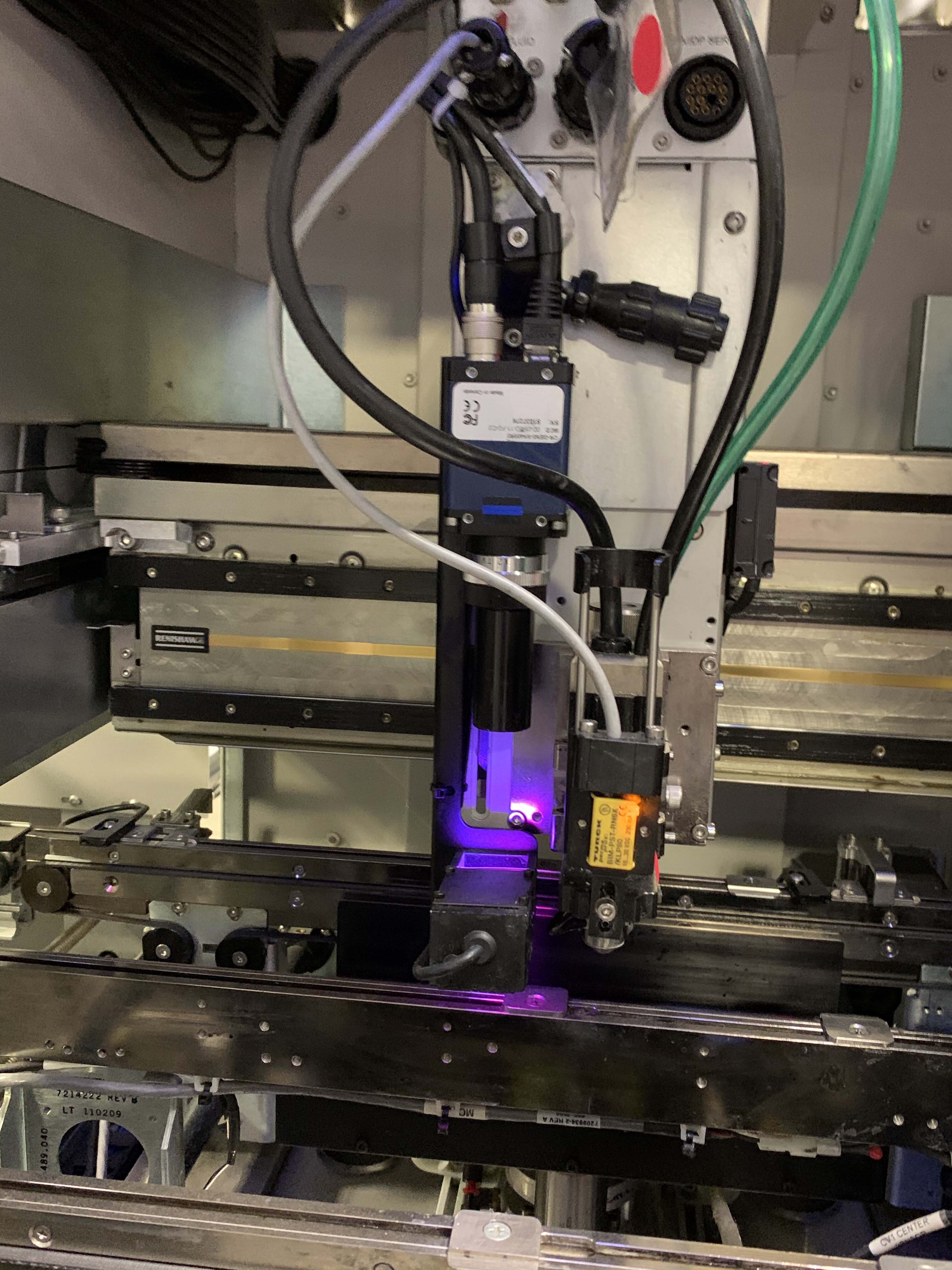

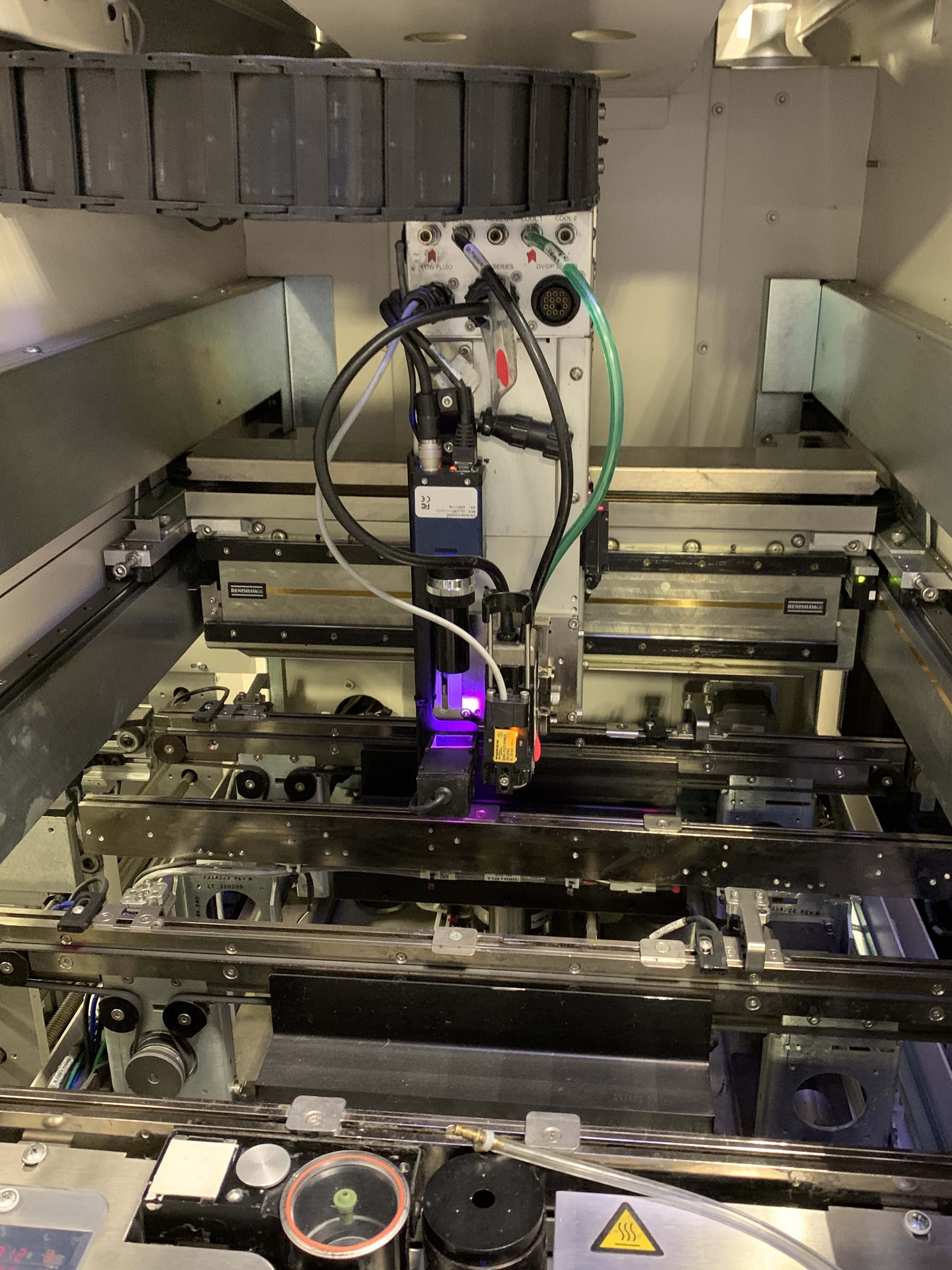

Automated fluid dispenser

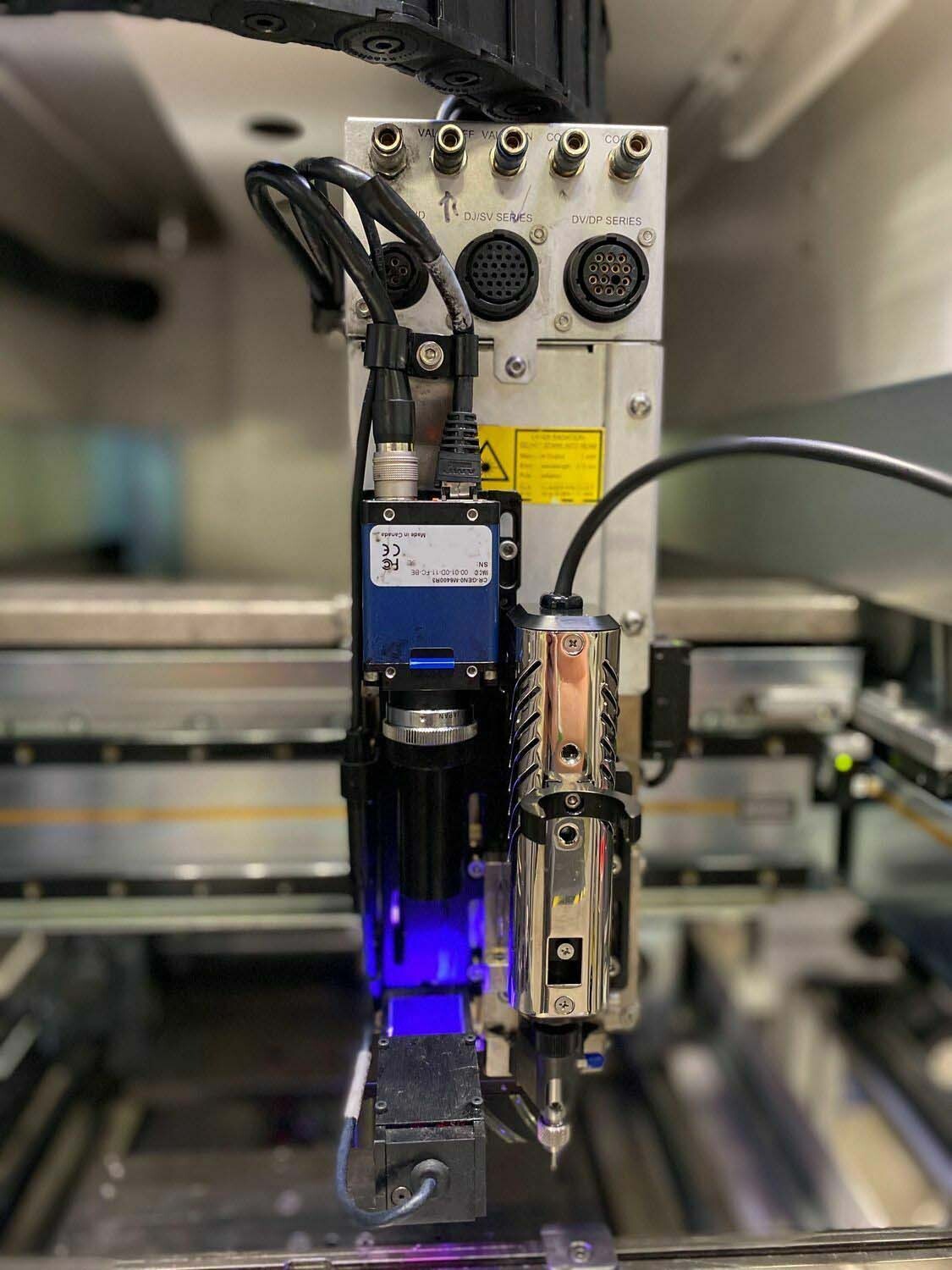

Motion system:

X-Y Placement accuracy: ±0.050 mm, 3 σ

Z Accuracy: ±0.025 mm, 3 σ

X-Y Repeatability: ±0.025 mm, 3 σ

X-Y Acceleration: 1 g Peak

X-Y Velocity: 1 m/s Peak (40 in./s)

Vision and lighting:

Camera resolution: 640 x 480 Pixels

Field of view: 7.0 x 5.0 mm (0.28 x 0.20 in.)

Lighting: Red / Blue LED

With 255 independent light levels for each color

Computer:

Laptop with windows operating system

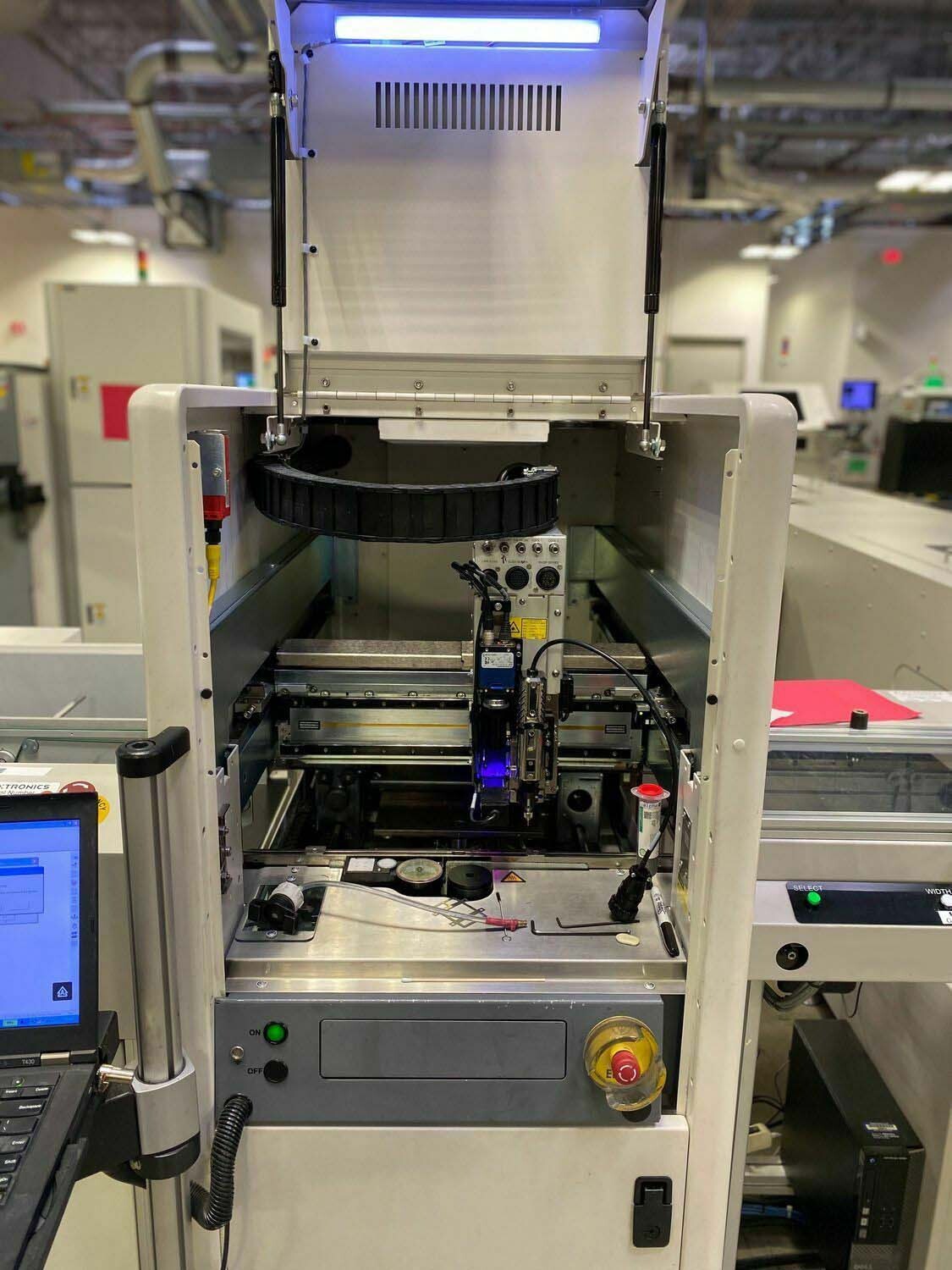

Dispense area (X-Y):

339 x 410 mm (13.3 x 16.1 in.)

Conveyor:

Maximum board / Carrier length:

One station: 340 mm (13.4 in.)

Three stations: 320 mm (12.6 in.)

Minimum board / Carrier length: 25 mm (1.0 in.)

Maximum board / Carrier width:

Single lane: 535 mm (21.1 in.)

Dual lane: Up to 228 mm (9.0 in.)

Minimum board / Carrier width: 34 mm (1.3 in.)

Maximum board / Carrier thickness: 12 mm (0.5 in.)

Maximum overboard clearance: 30 mm (1.2 in.)

Under board clearance: 2.75 mm (0.11 in.)

Maximum load capacity: 2 kg (4.4 lbs.)

Operation modes:

Automatic (SMEMA)

Manual

Pass-through

Belt types:

ESD O-ring

ESD High-temp 6-mm flat belt

ESD High-temp 4-mm flat belt

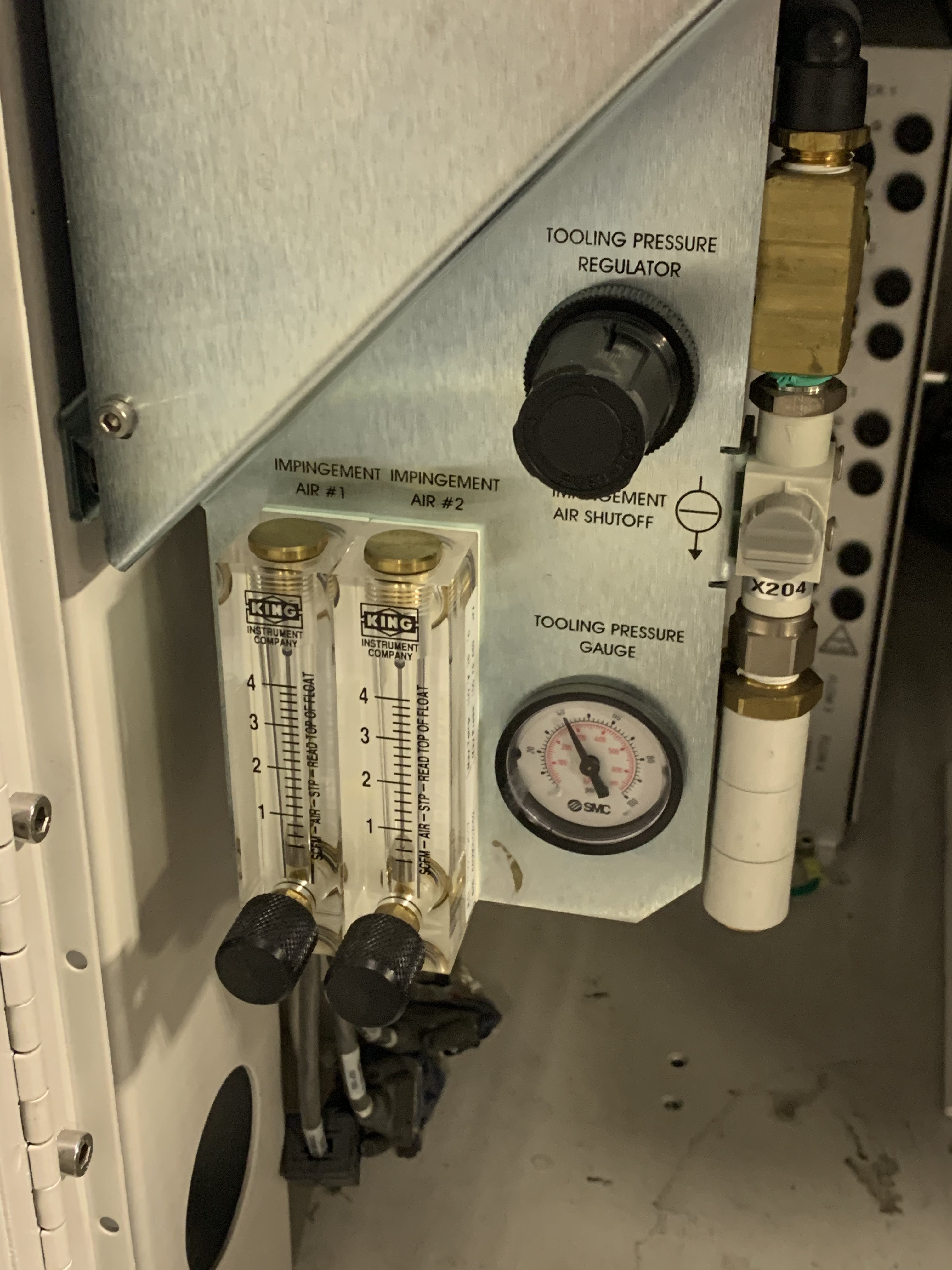

Facilities requirements:

System footprint: 600 mm wide x 1321 mm deep (23.6 x 52.0 in.)

Two heat stations: 850 x 1321 mm (33.5 x 52.0 in.)

Three heat stations: 1100 x 1321 mm (43.3 x 52.0 in.)

Air supply: 689 kPa (6.8 atm, 100 psi)

Power supply: 200-240 VAC, 47-63 Hz, Single phase, 30 A

2013 vintage.

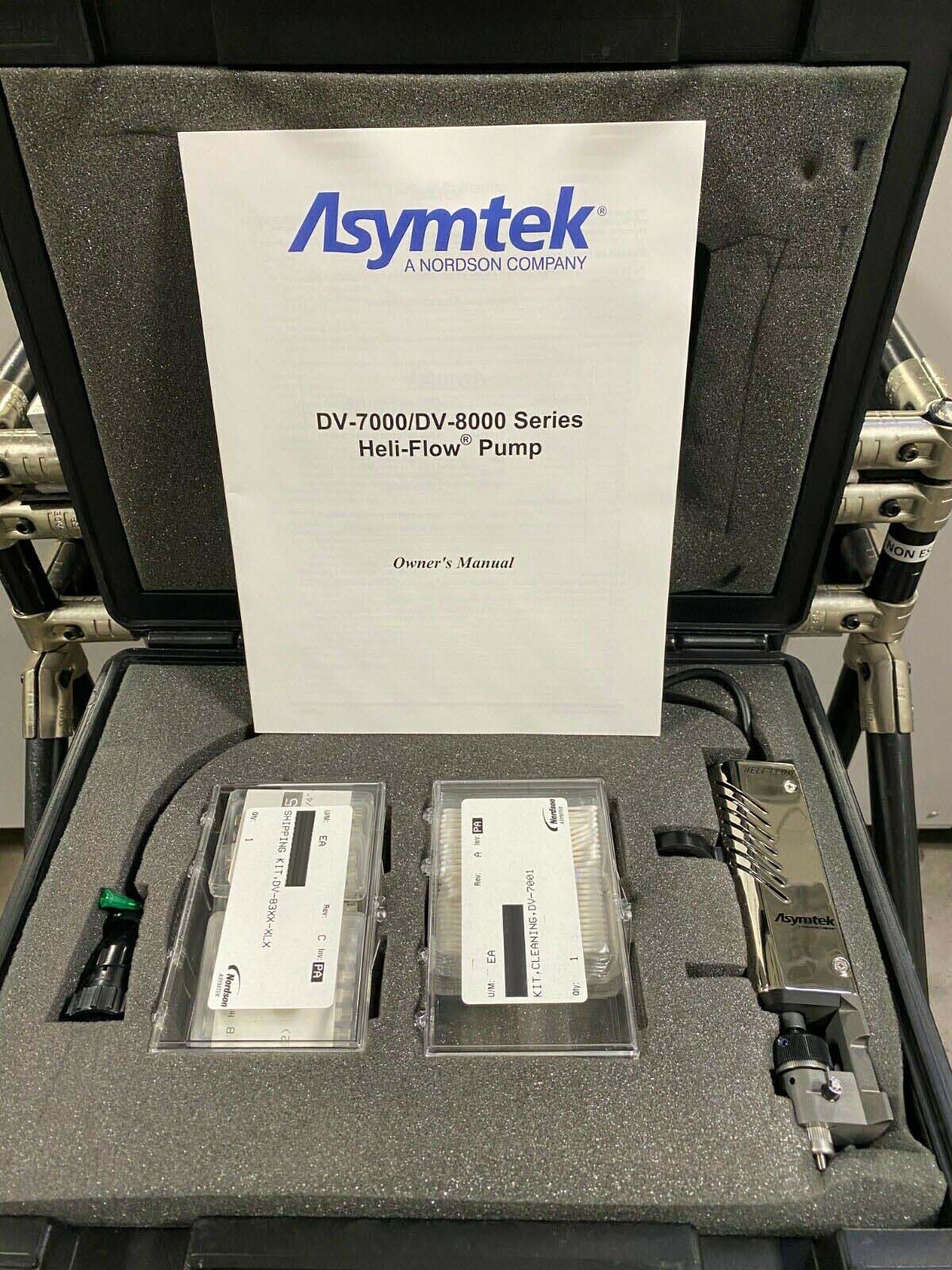

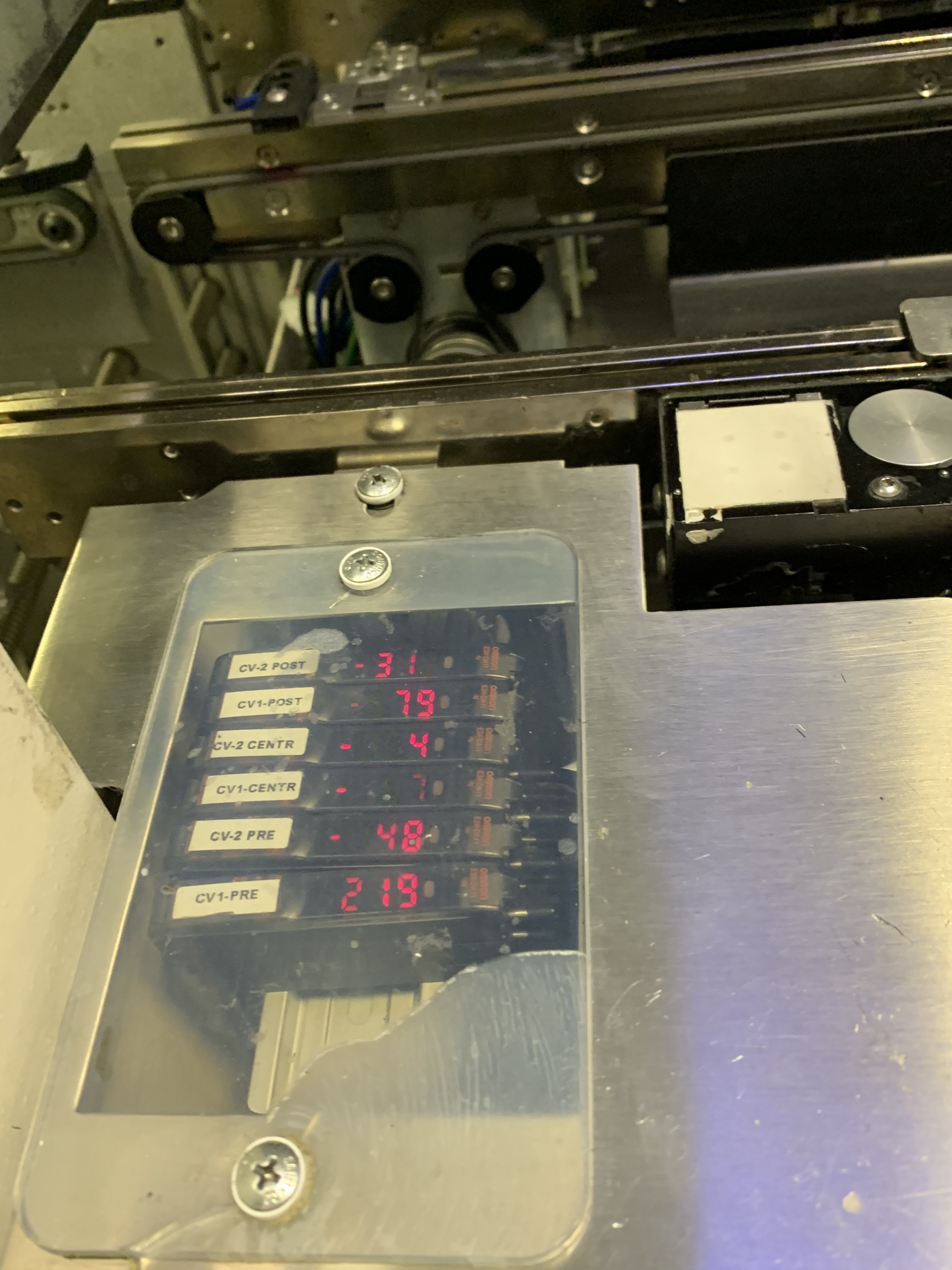

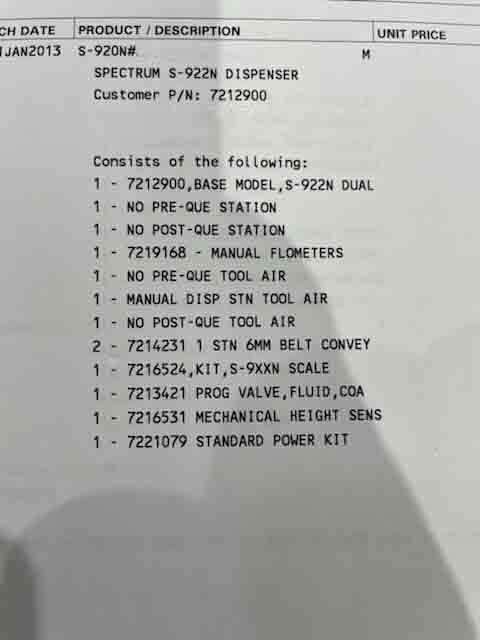

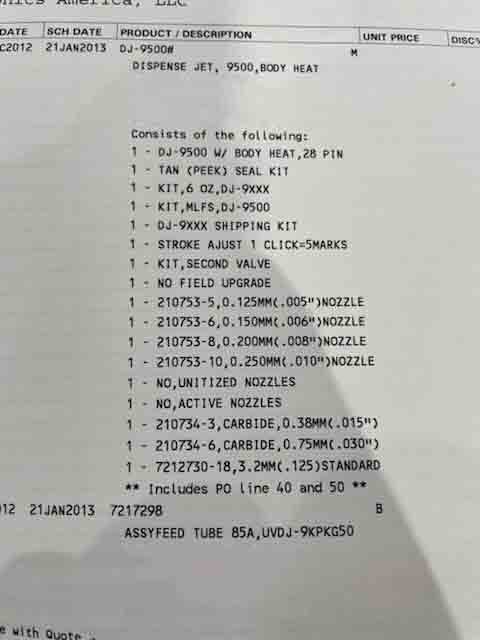

NORDSON/ASYMTEK S-922N是一種全自動、多站、pc板裝配和制造設備,旨在生產高質量的SMT和浸入式PC板裝配。先進的設計允許在單個平臺中集成多個工藝技術和站點配置。NORDSON S-922N具有多項先進技術,如封閉式、零件追蹤式、雙軌傳送帶、高速數字網絡分發器、雙車道SMT饋送元件放置系統,以及在線AOI視覺和元件存在檢測元件。它還為每個組件提供A1類檢查技術,以及自動組件分類功能。ASYMTEK S-922N在一個高級控制系統上運作,具有若幹自動化操作功能以及交互式診斷。該單元可以配置兩個、四個和六個階段的線性元件傳輸和放置,每個階段都具有自己獨立控制的線性電動機,以確保最佳放置精度。S-922N還具有改進的機械設計,以實現最高的可靠性和效率,包括可擴展的帶有多個噴嘴選項的索引頭,以及氣動組件,以便在各級之間進行平穩和精確的移動。NORDSON/ASYMTEK S-922N的高級制造軟件實現了即時作業設置、序列化以及實時作業管理。NORDSON S-922N旨在滿足高質量的生產標準,並提供多種定制選項,包括元件驗證、開腔、焊接、元件標記和線材尺寸。此外,ASYMTEK S-922N還提供多種電源選項來滿足任何電源需求,包括單相、三相、交流或直流以及雙電壓選項。S-922N旨在為PC板裝配和制造提供高性能、經濟高效的解決方案。先進的技術、控制機和多種定制選項確保了刀具能夠輕松滿足最苛刻的生產需求。

還沒有評論