二手 SEHO GoSelective-2 #9208023 待售

網址複製成功!

單擊可縮放

ID: 9208023

Selective solder machine

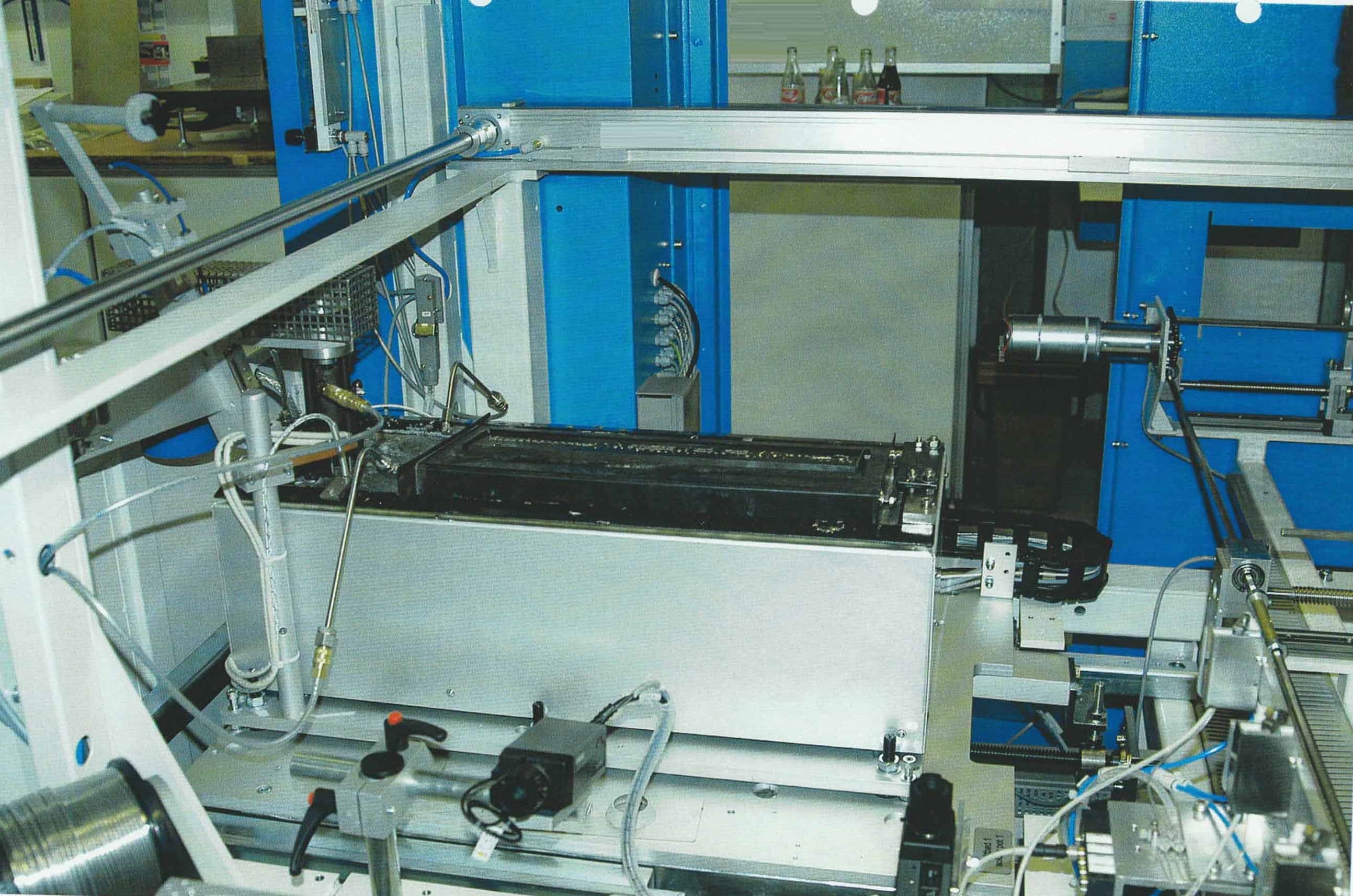

Conveyor system:

Loading

Unloading

Parameter:

Roller conveyor: (2) Driven segments

Motor controller: DC

Speed: 0.5 to 2.0 m/min

Width: 80 mm to 400 mm

Width adjustment: Electrical / Programmable options

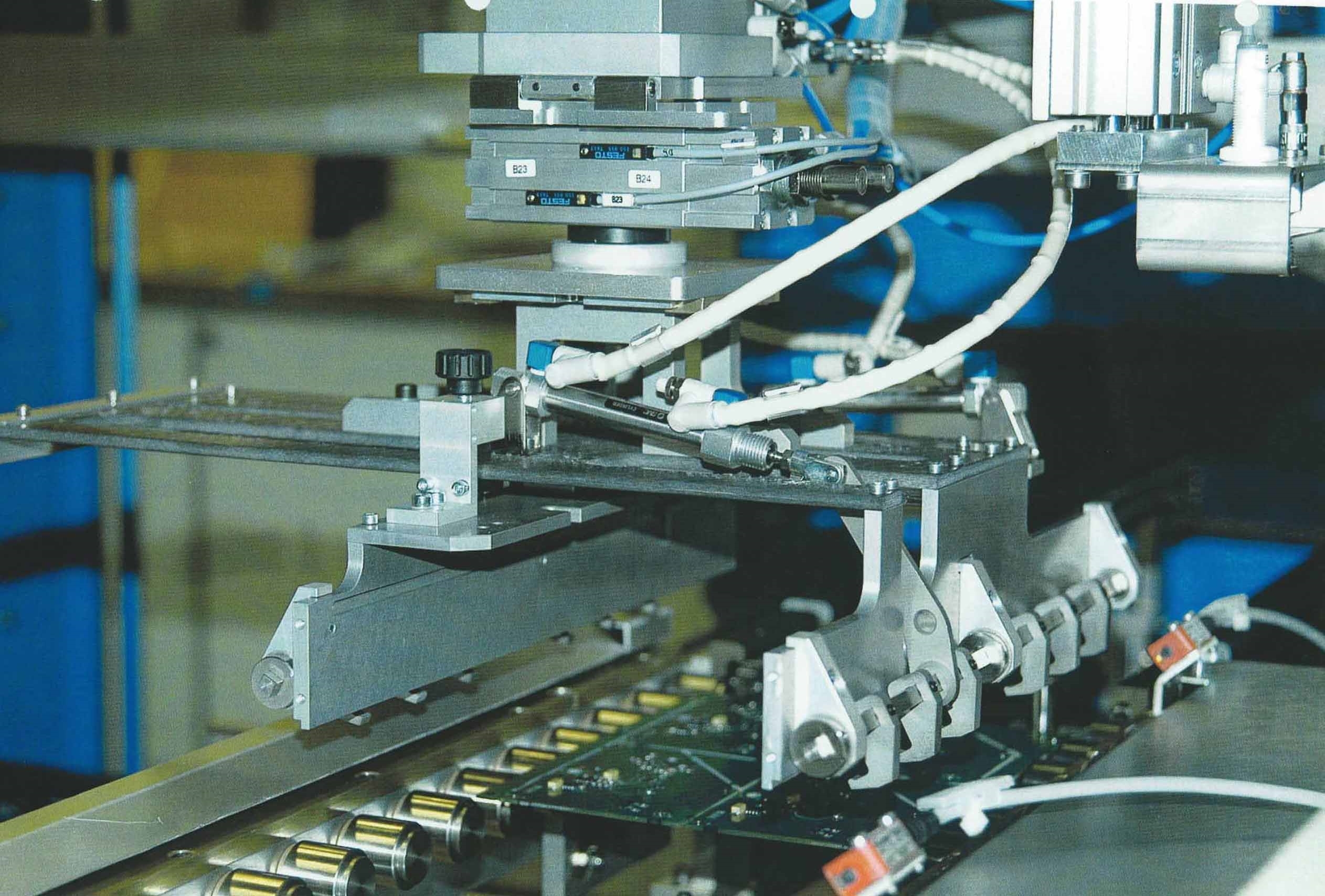

Gripper head:

Parameter

Angle direction A: 7° C

Angle direction B: 7° C

Pneumatic turn: 90° C

Gripper tool carrier:

Parameter

Length: 350 mm

Width: 300 mm

Component height top side: 50 mm

Component height bottom side: 30 mm

Gripper tool bare board:

Parameter:

Length: 80 to 400 mm

Width: 80 to 350 mm adjustable

Component height top side: 30mm

Component height bottom side: 30mm

Preheat station:

Parameter

Heating elements: Quartz

Power per heating element: 1.0 KVA

(6) Heating elements

Total power: 6.0 KVA

Preheat control: Time and power rate

Pyrometer control: Option

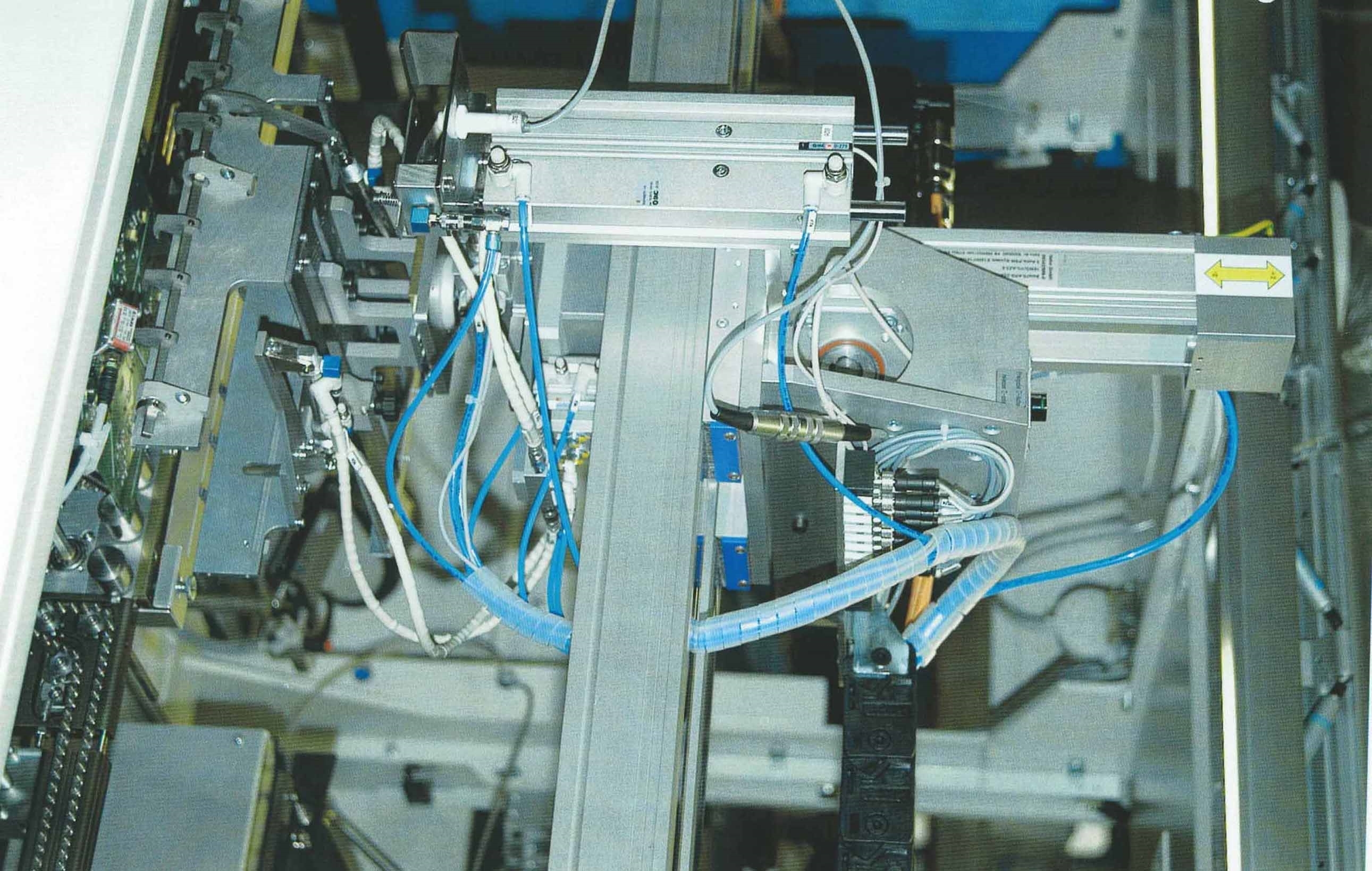

Fluxing system:

Parameter:

Dropjet-nozzle diameter range dropjet: 1 -4 mm

Dropjet quantity control: Fluxing time

Level control of the flux container

Flux container: 10I Stainless steel container

Flux supply: AC Pump

Additional nozzle heads: Option

Additional dropjet nozzles:

(2) Row connectors process: Option

Flux types:

Alcohol / Water based fluxes

With a solids content: Up to 5%

Coordinate fluxing unit as a separate module: Option

Dropjet spray control: Option

Automatic solder wire feeder:

Parameter:

Dimensions (DIN 46399): Drawina

Weight of soider wheel: 4k

Diameter of wire: 3mm

Alarm if feeder is empty

Drive system: Pneumatic

Control system:

Parameter:

Colour touch screen display, 10": Standard

CAN Field bus: Standard

Real time CNC controller: Standard

Modular: Standard

Multi language: Standard

Teach process:

Parameter:

Graphical teach editor: Standard

User friendly programming system: Standard

Online teaching with laser pointer: Standard

Offline teaching with any PC: Option.

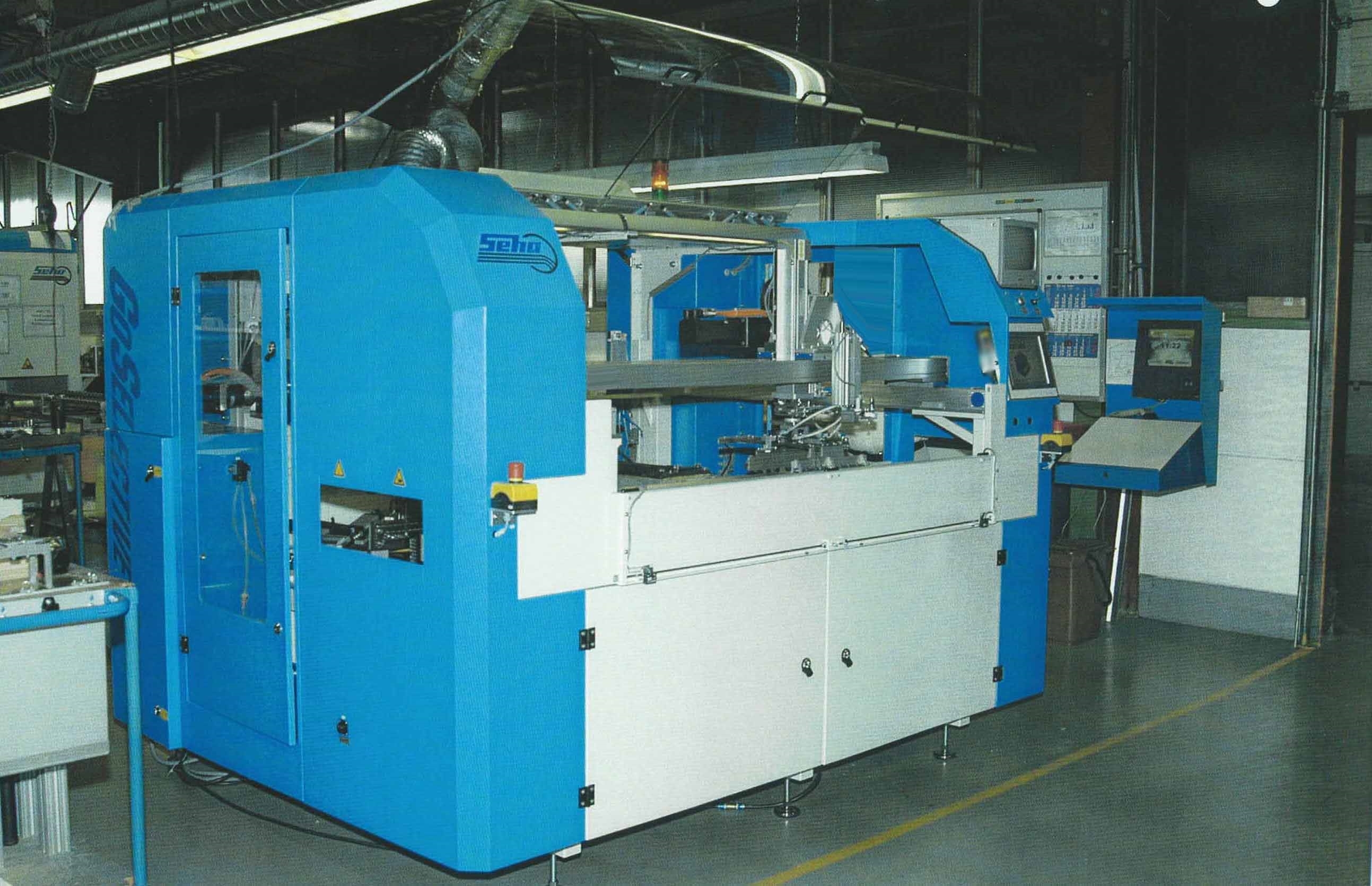

SEHO GoSelective-2是由德國著名制造商SEHO打造的半自動pcb焊機。它旨在為中型到大型生產運行中的無鉛、選擇性和波浪焊接應用提供精確、可靠的結果。GoSelective-2有一個專利,可調節的雙面傳送帶。這使得輸送機能夠輕松地在不同的板尺寸之間切換,而不會犧牲板的對準精度。它配備了智能溫度測量控制,有助於在傳送帶的所有表面上保持穩定、均勻的溫度。這臺pcb焊機采用高效、低維護的PLC控制設備。它提供模塊化規格,例如預熱和冷卻、裝配、多板焊接和自動測試。該機能夠精確控制沈積焊膏的速度、位置和角度,使其能夠構建最復雜的電路板。為了安全操作,SEHO GoSelective-2配備了安全門和各種安全功能。它被封閉在密封的金屬外殼中,以保護其免受灰塵、濕度和其他有害元素的侵害。該機器還得益於涵蓋所有主要組件和部件的全面現場保修。GoSelective-2增加了可選的雙波焊接功能,進一步提高了可靠性。它還具有熱空氣噴嘴系統,具有優質的陶瓷加熱元件和可調節的速度控制風扇。這些功能協同工作,以匹配每批的完美焊接條件。SEHO GoSelective-2利用富士開發的X-Y龍門在焊接過程中精確定位機頭。它還具有專門為高質量波焊接設計的輸送裝置。可選的快速更改機(QCS)使小批量的電路板設置非常快速輕松。GoSelective-2是印刷電路板制造商尋求可靠、準確和經濟高效的結果而又不犧牲性能的理想選擇。它提供精確、可重復的焊接,允許快速、方便地生產高質量的電路板。

還沒有評論