二手 AIXTRON G3 #9074580 待售

看起來這件物品已經賣了。檢查下面的類似產品或與我們聯系,我們經驗豐富的團隊將為您找到它。

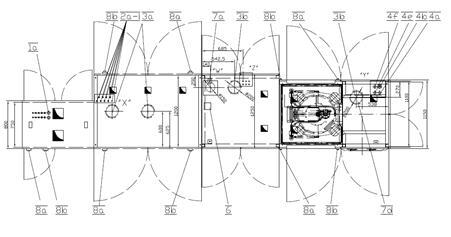

單擊可縮放

已售出

ID: 9074580

GaN systems

Dopants: Cp2Mg, SiH4

Transfer: load lock only

Wafer loading capabilities: (24) 2” or (8) 4”

CACE software

EpiTune (in-situ monitoring)

Facility requirements:

Gas specification:

N2 – 4VCRF – 4.0 ~ 7.0 bar

H2 – 4VCRF – 4.0 ~ 7.0 bar

NH3 – 4VCRF – 3.0 ~ 3.5 bar

SiH4/H2(200ppm) – 4VCRF – 3.0 ~ 3.5 bar

HCL – 4VCRF – 3.0 ~ 3.5 bar

GN2(N2 tech) – 4VCRF – 7.0 ~ 8.5 bar

Wafer specification:

System:

Inlet – 6.5 bar (maximum) 1" Swagelok bulkhead

Minimum total flow 63 l/m

Temp - 17°C ~ 25°C stability ± 1°C

Outlet – 2.5 bar (maximum) 1” Swagelok bulkhead pump loop

Minimum differential pressure 4 bar for required flow

Inlet – 6 bar(Maximum) 3/4” Swagelok bulkhead

Minimum total flow 50 l/m

Temp - 20°C stability ± 1°C

Outlet – 2 bar (maximum) 3/4” Swagelok bulkhead reactor loop

Minimum differential pressure 4 bar for required flow

Maximum temp – 40°C

RF generator:

Inlet – 6 bar (maximum) 3/4” Swagelok bulkhead

Minimum total flow 36 l/m

Outlet – 2 bar (maximum) 3/4” Swagelok bulkhead reactor loop

Minimum differential pressure 4 bar for required flow

Electrical requirements:

Voltage: System: 208 V, RF generator: 380 V

Current: System: 80A (customer 100A), RF generator 250A (customer 315A)

Frequency: 60 Hz

Wiring requirement: System: 3/N/PE, RF generator: 3/PE

Main power location: E-rack

UPS input location: internal to E-rack, provided as spare

Exhaust specifications:

Total cabinet exhaust requirement: GMS (750m3/h) (2ea) Reactor (500m3/h) (2ea)

TGA exhaust requirement:

- Process gas exhaust connected to scrubber DN40KF flange,

50~100mm below top of glovebox open line for continuous flow

HE-leak tight ≤ 10E-9 mbar l/s

Oxygen < 1ppm

Line pressure atm > p > atm – 20mbar

- Exhaust GB pump, 3/8” Swagelok

- Exhaust Forming gas, 3/8” Swagelok.

AIXTRON G3是一種先進的金屬有機化學氣相沈積(MOCVD)反應器,用於生產發光二極管(LED)芯片等半導體應用。AIXTRON G 3是一個健壯的平臺,使用壽命長,部分原因在於其專有的SplitFlow設計。SplitFlow是一種獲得專利的雙流量輸送系統,可幫助克服性能限制(如溫度和沈積均勻性),同時使用更少的源並降低運營成本。利用SplitFlow,氣體被分離並註入多個位置,從而縮短了到基板的流動路徑並縮短了化學接觸時間。這有助於提高流程的可重復性和效率。G3反應堆還能夠承受高達500毫巴的高腔室壓力,從而能夠快速形成薄膜和更厚的沈積,而不會影響均勻性。為確保均勻性,G3采用DualPlay,它通過兩個獨立編程的溫度控制器和兩個快門將氣體輸送和溫度控制管理結合在一起。這有助於在整個反應堆中創造一個一致的環境,這是晶體和薄膜層生長所必需的。AIXTRON G3具有三個單獨生長的、超穩定的線性電機級,用於精確的基板操作。這些臺階具有較低的熱漂移,具有較高的位置精度,最小間距為0.5微米。AIXTRON G3還具有Advanced Process Control Suite,一套智能算法,用於優化沈積配方的性能。G3反應堆是一種可靠的半導體反應堆,為高精度、精確度和可重復性而設計。它的SplitFlow設計允許更薄的薄膜、更好的均勻性和更高的效率,這要歸功於更短的流動路徑和更低的運營成本。它的高室壓力使得厚膜形成和溫度控制通過DualPlay管理,確保生長晶體和薄膜層的條件均勻。這三個線性階段提供了較高的位置精度,Advanced Process Control套件有助於微調整個過程。

還沒有評論