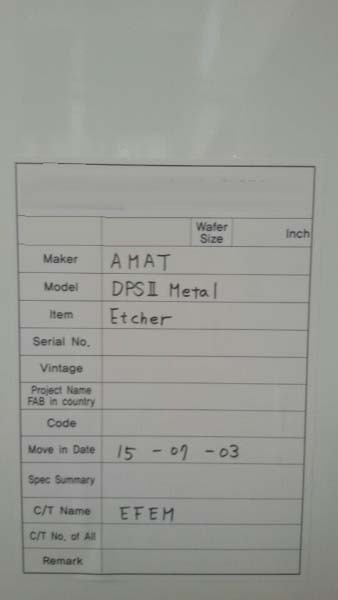

二手 AMAT / APPLIED MATERIALS Centura DPS II #9189076 待售

網址複製成功!

單擊可縮放

ID: 9189076

晶圓大小: 8"

優質的: 2002

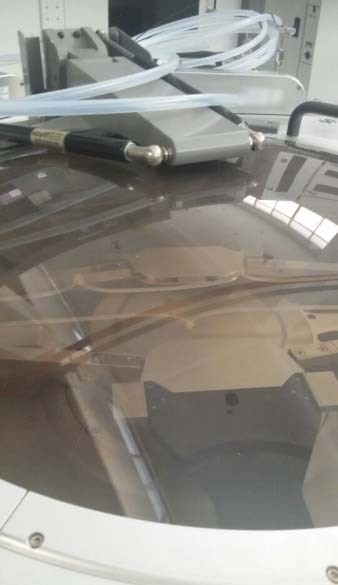

Metal etcher, 8"

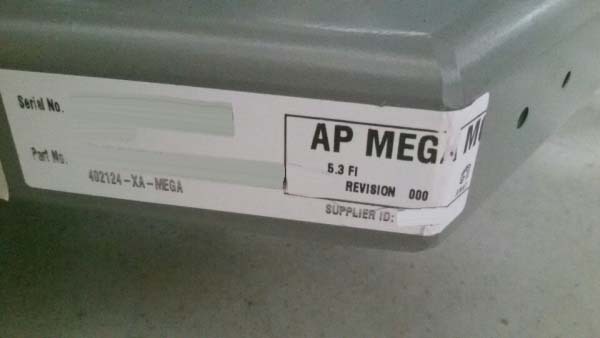

Platform type: Centura AP

Chamber configuration:

Chamber A & B: DPS II Metal bridge chamber, 8"

Chamber C: ASP II Chamber

Process chamber:

Process kits:

DPS II Metal parts / Chamber

Ceramic Lid

ESC Type: DPS II STD CESC, 8"

ESC Power supply: DPS II STD

Control type:

APPLIED MATERIALS STD (VAT)

Chamber A: 65048-PH52-AFS1 / 0583 A-664028

Chamber B: 65048-PH52-AFS1 / 0546 A-626798

EOP Type: Monochromator

Transfer chamber:

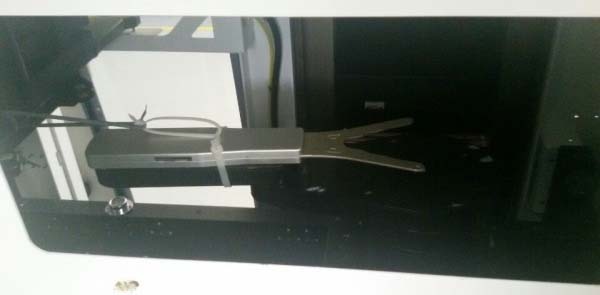

Robot type: VHP+ Dual blade

APPLIED MATERIALS STD LCF Detector

Loadlock chamber:

SWLL Body: (2) SWLL Chambers

EFEM:

(2) Loadports

ASYST Versaport 2200

Air intake system: APPLIED MATERIALS STD Intake

FI Robot: APPLIED MATERIALS Kawasaki

Wafer align: APPLIED MATERIALS STD

Wafer out of position detection: APPLIED MATERIALS STD

Remote interface:

Components interface:

Dry pump (Transfer chamber): IPUP Pump, ALCATEL A100L

Chiller

System monitor: Monitor 1 & Monitor 2

Flat panel with keyboard on stand

Components:

Turbo molecular pump: APPLIED MATERIALS STD BOC EDWARDS

RF Power system:

Source RF generator:

APPLIED MATERIALS STD / APEX 3013

Frequency / Max power: 13.56MHz / 3KW

Bias RF generator:

APPLIED MATERIALS STD / APEX 1513

Frequency / Max power: 13.56MHz / 1.5KW

RF Match box:

Source: Navigator 3013

Chamber A & B: 0190-15168

Bias: Navigator 1513

Chamber A: 0190-23623

Chamber B: 0190-15167

Utility specification:

Gas panel type: STD

Gas panel exhaust: Top center exhaust

(12) Gas lines

Gas line tape heater (for liquid gas): BCL3

MFC Configuration:

MFC type: Digital type

MFC Maker / Model (All Chamber): UNIT MFC

Gas information:

Gas Size

BCL3 200

CL2 200

NF3 100

HCL 100

NF3 20

N2 50

HE 100

O2 1L

SF6 400

CHF3 25

CF4 50

AR 400

Axiom + chamber:

Gas Size

NH3 1000

O2 10000

CF4 750

N2 1L

Independent helium control: APPLIED MATERIALS STD MKS 649A

Electricity:

AC Rack: APPLIED MATERIALS STD AC Rack

Power supply: 3 φ, 208 V, 400 A, 50/60 Hz

System controller:

FES: FEPC

FIS: Flex3

MF SBC: Flex3

CCM SBC: 166 MHz

MF Controller:

Mainframe devicenet I/O:

Cardcage and backplane board

2002 vintage.

AMAT/APPLIED MATERIALS Centura DPS II是一種雙區快速熱反應器,設計用於各種應用的先進材料處理。它具有強大的射頻發生器,可產生高功率,並具有精確的溫度控制,可精確處理薄膜、多層結構和設備堆棧。AMAT Centura DPS II的主要功能是以精確精確的方式將不同材料的多層沈積到基板上。這是利用雙區域快速熱處理器的雙區域配置完成的。這兩個區域是獨立的,可以在每個區域中創建精確的溫度輪廓。這是通過單獨控制加熱器,並由先進的計算機控制系統進行監控來完成的。在APPLIED MATERIALS CENTURA DPS+II中的雙區域配置允許均勻的熱量分布和精確的溫度控制。這是通過將兩個區域加熱到不同的溫度來完成的,這將由用戶定義的參數來確定。RTP反應器還具有包含和限制不同成分和濃度的氣體混合物的能力,用於精確的成分控制反應。Centura DPS II使用主動冷卻在每個區域達到所需溫度後快速冷卻,以實現精確和一致的沈積。這種多區RTP配置還為每個區提供了精確的斜坡上升和斜坡下降速率,這對於薄膜和厚膜沈積的研究至關重要。應用材料Centura DPS II還具有先進的診斷功能,使工程師和科學家能夠精確監控和測量RTP反應堆中處理的材料。這種監測在需要精確層特性的多層和堆棧設備實驗中特別有用。CENTURA DPS+II因其精確的溫度控制、精確的沈積速率和精確的監測能力,是先進材料加工行業科學家和工程師的寶貴工具。該反應器被用於許多應用,從半導體器件制造、薄膜沈積等等。AMAT CENTURA DPS+II的集中供暖、制冷和監測能力使其成為研究和工業生產方面的寶貴工具。

還沒有評論