二手 AMAT / APPLIED MATERIALS Centura DPS II #9189888 待售

網址複製成功!

單擊可縮放

ID: 9189888

晶圓大小: 12"

優質的: 2006

Metal etcher, 12"

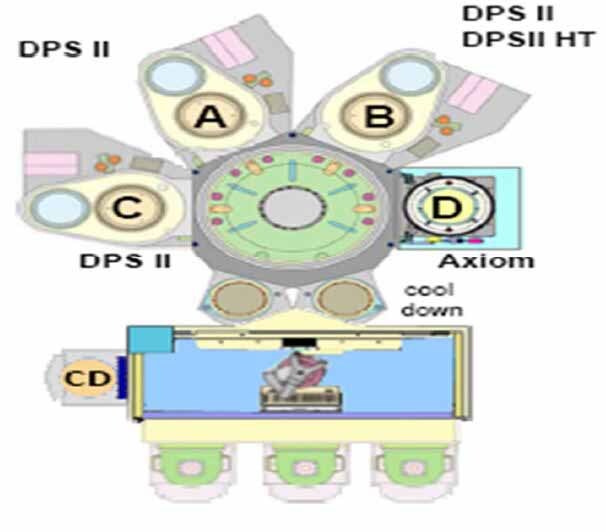

Chamber configuration:

(3) DPS II

Axiom

Chamber configuration:

Chamber A:

Chamber model: DPS II

Bias generator: AE APEX 1513, 13.56 MHz, maximum 1500 W

Bias match: AE 13.56 MHz,3 kV navigat

Source generator: AE APEX 3013, 13.56 MHz, maximum 3000 W

Source match: AE 13.56 MHz,6 kV navigat

Lid: Ceramic lid, Single gas nozzle

Turbo pump: STP-A2503PV

Throttle valve: VAT Pendulum valve DN-250

ESC: Dual zone ceramic ESC

Endpoint type: Monochromator

Cathode chiller: SMC POU

Wall chiller: SMC INR-496-016C

Process kits coating: Anodize coating

Cooling: HT 200 / FC 40

Chamber B:

Cathode chiller: SMC POU

Chamber C:

Cathode chiller: SMC POU

Wall chiller: SMC INR-496-016C

Mainframe configuration:

IPUP Type: ALCATEL A100L

Gas panel type: NextGen

VHP Robot: Dual blade

MF PC Type: CPCI

Factory interface configuration:

Frontend PC type: 306 Server

FIC PC type: 306 Server

(3) Load ports

Atmospheric robot: Yaskawa track robot

Side storage: Right side

MFC Configuration:

Chamber A:

Gas line Gas name Max flow MFC Type

Gas 1 BCL3 200 ARGD40W1

Gas 2 C2H4/HE 400 AAPGD40W1

Gas 3 NF3 200 AAPGD40W1

Gas 4 CL2 400 SC-24

Gas 5 N2_50 50 AAMGD40W1

Gas 6 N2_300 300 AAPGD40W1

Gas 7 CF4 100 AAPGD40W1

Gas 8 O2 1000 AASGD40W1

Gas 9 SF6 100 AAPGD40W1

Gas 10 CHF3 50 AANGD40W1

Gas 12 AR 400 AAPGD40W1

Chamber B:

Gas line Gas name Max flow MFC Type

Gas 1 BCL3 200 AARGD40W1

Gas 2 C2H4/HE 400 AAPGD40W1

Gas 3 NF3 200 AAPGD40W1

Gas 4 CL2 400 AARGD40W1

Gas 5 N2_50 50 AAMGD40W1

Gas 6 N2_300 300 AAPGD40W1

Gas 7 CF4 100 AAPGD40W1

Gas 8 O2 1000 AASGD40W1

Gas 9 SF6 100 AAPGD40W1

Gas 10 CHF3 50 AANGD40W1

Gas 12 AR 400 AAPGD40W1

Chamber C:

Gas line Gas name Max flow MFC Type

Gas 1 BCL3 200 AARGD40W1

Gas 2 C2H4/HE 400 AAPGD40W1

Gas 3 NF3 200 AAPGD40W1

Gas 4 CL2 400 AARGD40W1

Gas 5 N2_50 50 AAMGD40W1

Gas 6 N2_300 300 AAPGD40W1

Gas 7 CF4 100 AAPGD40W1

Gas 8 O2 1000 AASGD40W1

Gas 9 SF6 100 AAPGD40W1

Gas 10 CHF3 50 AANGD40W1

Gas 12 AR 400 AAPGD40W1

2006 vintage.

AMAT/APPLIED MATERIALS Centura DPS II是專為半導體器件制造而設計的高能、高通量等離子體蝕刻反應器。AMAT Centura DPS II的蝕刻速率是市場上可獲得的最高之一。此功能使制造商能夠縮短周期時間並提高生產吞吐量。反應堆還可以降低蝕刻過程中底物的溫度,從而有助於保持半導體器件的結構完整性。APPLICED MATERIALS CENTURA DPS+II采用AMAT高密度等離子體(HDP)技術,在整個基板表面提供卓越的均勻性和出色的蝕刻選擇性。這種對等離子體生成物種的優越控制也降低了底物上的缺陷密度。反應堆的HDP源具有低功率、脈沖電子源和多個感應耦合等離子體源以及集成氣體控制系統,在底物蝕刻過程中提供了很大的靈活性。Centura DPS II的最大基板尺寸為200 mmx200mm。它還提供可變壓力控制、真空排氣和可調工藝溫度,允許微調等離子體處理條件。此外,還可以對反應堆進行調整,以優化淺溝槽、窄細胞和其他需要低電離或激光蝕刻損傷的具有挑戰性的特征。閉環墨盒式平臺設計有助於保持工藝氣體的清潔,進一步幫助減少缺陷的形成。其大型PDLT電池和低離子室設計也使加工時間最小化,生產吞吐量最大化。最後,APPLIED MATERIALS一套過程監控和優化軟件有助於實現可靠和可重復的過程結果,滿足最嚴格的行業標準。

還沒有評論