二手 AMAT / APPLIED MATERIALS Centura Ultima HDP CVD #9063643 待售

看起來這件物品已經賣了。檢查下面的類似產品或與我們聯系,我們經驗豐富的團隊將為您找到它。

單擊可縮放

已售出

ID: 9063643

晶圓大小: 8"

優質的: 2000

Etcher, 8"

(2) Ultima chamber

(1) Ultima plus chamber

Technology :IMD

Wafer Size : 8"

Wafer Shape : SNNF (Semi Notch No Flat)

Software Version : B4.3.14

CHAMBER TYPE AND LOCATION

Ch A : Ultima HDP-CVD

Ch B : Ultima HDP-CVD

Ch C : Ultima + HDP-CVD

Ch E : Multislot Cool Down

Ch F : Orientor

CHAMBER A,B Ultima HDP-CVD :

Nozzle : Long/Long Side

Clean Gas Distribution : Baffle

Turbo Pump : Ebara ET1600WS w/ HVA

Wafer Temperature Monitoring : Yes

Top Gas Feed : Without Top O2

Dual Independent He Control : Standard 10/10 TORR

Clean Method : Microwave

CHAMBER C - Ultima + HDP-CVD :

Nozzle : Long/Long Side

Clean Gas Distribution : Baffle

Turbo Pump : Ebara ET1600WS w/ HVA

Wafer Temperature Monitoring : Yes

Top Gas Feed : Without Top O2

Dual Independent He Control : Standard 10/10 TORR

Clean Method : Top Mount

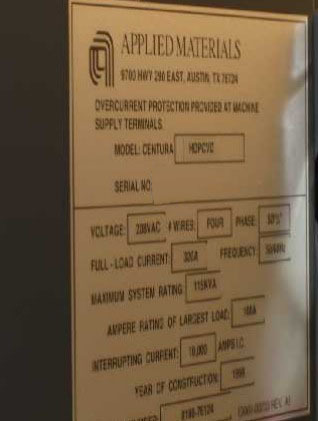

EXISTING ELECTRICAL REQUIREMENTS

Line Frequency : 60Hz

Line Voltage : 200/208V

Line Amperage : 600A Platform

EXISTING SAFETY EQUIPMENT :

EMO type : Turn to release EMO

EMO Guard Ring : Yes

System Labels : English w/Chinese Non-simplified

System Smoke Detector : Controller

EXISTING MAINFRAME :

Mainframe Type : Ultima HDP w/Multislot

Frame Type : Standard Frame

System Placement : Through the Wall

Mainframe Skins : No

Mainframe Exhaust Duct : No

Mainframe Facilities Connection : Back

Robot Type : HP Robot

Robot Blade : Ceramic

Loadlock Cassette : Narrow Body

Narrow body Loadlocks : Cassette Present Sensor

Loadlock Wafer Mapping : Basic

N2 Purge Type : STEC 4400MC 10 Ra Max

EXISTING GAS DELIVERY :

Gas Panel Surface Finish : Standard Gas Panel

MFC Type : STEC 4400MC 10 Ra Max

Valves : Fujikin 5 Ra Max

Filters : Pall Ni 10 Ra Max

Transducers : MKS w/ Display

Regulators : Veriflo

System Cabinet Exhaust : Top

Gas Panel Gas/Flow Direction Labels : Yes

APC Seriplex Cover : Yes

Gas Panel Doors : Solid

Gas Pallet Configuration :

Chamber A, B, C

Gas Stick/Process Gas/MFC size/Regulator/Transducer

#1 SiF4 100 Y Y

#2 O2 400 Y Y

#3 SiH4 200 Y Y

#4 Ar 300 Y Y

#5 SiH4 20 Y Y

#6 Ar 50 Y Y

#7 NF3 2000 Y Y

#8 Ar 2000 Y Y

REMOTES :

RF Generator Rack - Ultima Gen. Rack

ASTEX 80S09mW (3)

Quantity : Two

Ultima Stand-Alone RF Generator Rack : Yes

Generator Rack Cooling - RF Gen Rack Manifold with Quick Disconnect Ultima Gen Rack H20 Connection - Barbed Brass

Existing Heat Exchanger : SMC Thermo

Umbilicals :

System Controller Signal Cable Length : 55ft

RF Gen Rack Cable Length : 50ft

Ultima Stand-Alone Generator Rack : 98 ft

HX Hose Length : 50ft

HX Cable Length : 50ft

Pump Cable : 50ft

Ultima Microwave Generator Cable Length : 50 ft

Ultima WTM Cable Length : 32.8 ft (10m)

Vacuum Pumps, Exhaust Scrubber not included in sale

Currently crated and stored

System Can be inspected

1999-2000 vintage.

AMAT/APPLIED MATERIALS Centura Ultima HDP CVD(高密度等離子體化學氣相沈積)反應器是一種模塊化、低成本、垂直的熔爐,專為尖端薄膜材料的高容量、高通量生產而設計。該反應堆采用了一種創新的專利設計,使用了大量的高密度等離子體,從而實現了更快的沈積速率和更高的產率。該技術還提供低寄生蟲和改進的沈積均勻性,使其成為太陽能電池、平板顯示器、光學塗層和先進半導體器件等應用的絕佳選擇。AMAT Centura Ultima HDP CVD反應堆使用RF驅動的高密度等離子體(HDP)在低溫下驅動反應,使其節能,非常適合生產高性能薄膜塗層。該技術還消除了傳統上與CVD工藝相關的許多昂貴的物料處理和清潔步驟,最大限度地降低了成本並提高了總體產量。該設備具有高度的可配置性,允許各種等離子體源和材料----包括金屬和介電靶標、介電化合物和氣體靶標----以可選擇的順序使用。SPLIED MATERIALS CENTURA Ultima HDP CVD反應堆的核心是子模塊或工作空間,它是一個完全封閉的腔室,具有單一等離子體源和集成氣體護理系統。該氣體護理裝置確保沈積過程中使用的氣體的連續流動始終處於最佳水平,以獲得準確的結果。一個中央安裝的目標支架確保被塗覆的基板由等離子體旋轉而不會受到任何阻塞,從而在沈積過程中達到最佳均勻性。高密度等離子體加上均勻的沈積,確保底物的溫度保持低且均勻,保持材料的特性,同時確保在整個表面有高質量、精確圖樣的沈積。機器的高級控制軟件提供了一個直觀的用戶界面,允許對過程參數進行精確控制,並允許有針對性地優化沈積過程。Centura Ultima HDP CVD反應堆是任何涉及尖端薄膜沈積的生產線的絕佳選擇。由於其創新和經濟高效的設計,高吞吐量的生產以低成本和最低開銷實現。這使得該工具成為尋求充分發揮薄膜沈積潛力和提高器件性能的工業制造商的一個有吸引力的選擇。

還沒有評論