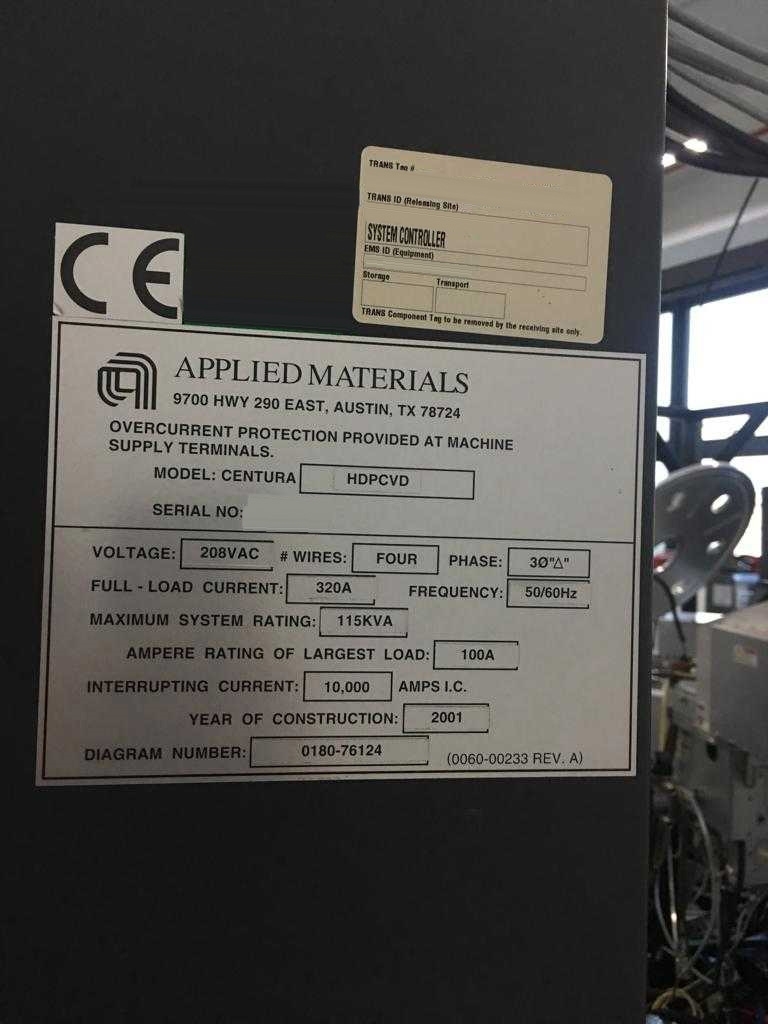

二手 AMAT / APPLIED MATERIALS Centura Ultima HDP #9223731 待售

網址複製成功!

單擊可縮放

ID: 9223731

晶圓大小: 8"

優質的: 2001

CVD System, 8"

System general:

Mainframe: Centura 5200 DCVD

Wafer type: Notch

Chamber position A, B, C: HDP Ultima plus chamber, 8"

Chamber E position: Multi-slot cool down chamber

Chamber F position: Wafer orienter chamber

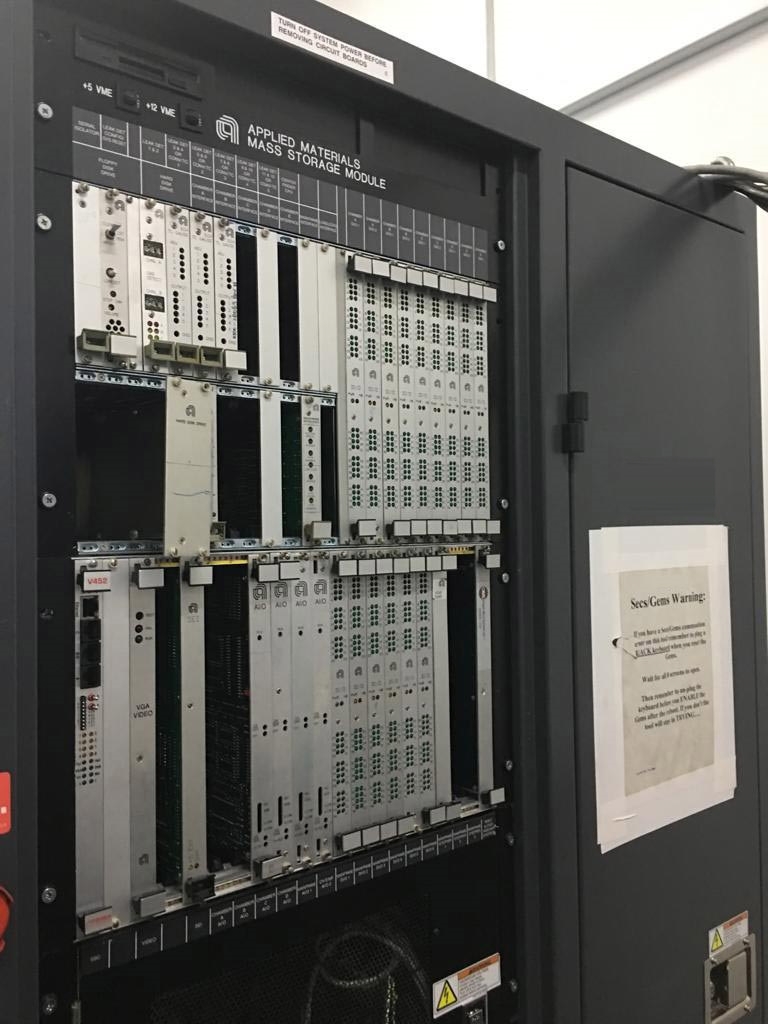

System controllers:

SBC V452 Board

VGA Board

P3 Board

Facility and safety configurations:

EMO Switch type: Turn to release EMO

EMO Guard ring

EMO Shunt trip

Bracket standoff adapter

Water and smoke detect output: Alarm

Facility power indicator

System water leak detector

Main frame:

Facilities type: Phase II

System placement: Stand alone

Front panel: Steel white polymer finish

Facilities connection: VCR

Facilities orientation: Mainframe facilities bottom connection

Facilities water: Phase II water

Controller IO interface option: I/O Expansion base card with seriplex gas panel card

Interface: GEM Interface

Load lock chamber type: Narrow body

Transfer chamber:

Transfer chamber manual lid lift

Transfer chamber sensor

Process chamber slit valve A, B, C: Bonded door with KALREZ O'ring

Robot type: HP+ Robot (Dual speed)

Basic wafer on blade detector

N2 Purge MFC type: Unit instrument (UFC-1661) 1L

Buffer purge slow vent flow: 500 sccm

Dedicated transfer rough pump: EDWARDS Pump interface

Mainframe inert gas lines:

Chamber N2 supply

Chambers N2 surface finish: 10 Ra

Mainframe N2 supply

Mainframes N2 surface finish: 10 Ra

Chamber A configuration:

Type: HDP Ultima plus chamber

Frequency type: Top, side and bias RF

Heater type: 0190-46458

Thermalogic board

Manometer type: DUAL 10/100 TORR MKS

Throttle valve: Turbo throttle valve plus rough throttle valve

Gate valve type: 3870-04276, Pendulum ISO250 (Actuator 52.3)

Turbo pump type: EBARA ET1600W

Turbo pump controller: 1604W

Turbo pump ring type:

0010-11762, CTR Ring assy, HDP-CVD Ultima plus

Chamber O'ring type: KALREZ 9100

Clean method: RPS

0190-26744, MKS Astroni AX7670

Clean gas: NF3

Chamber A process kit:

0010-03090 ESC Cathode (WTM Type)

0040-18219 ESC (WTM Type)

0190-18430 WTM Probe

0200-18109 Collar

0200-18081 Cover ceramic

0200-01009 Top nozzle

0200-18093 Side nozzle

0200-01006 Dome

0040-04650 Gas ring with (24) nozzles

0200-40156 Lift pin ceramic

Chamber B configuration:

Type: HDP Ultima plus chamber

Frequency type: Top, side and bias RF

Heater type: 0190-46458 Thermalogic board

Manometer type: Dual 10/100 TORR MKS

Throttle valve: Turbo throttle valve plus rough throttle valve

Gate valve type

3870-04276, Pendulum ISO250 Actuator 52.3

Turbo pump type: EBARA ET1600W

Turbo pump controller: 1606W TF

Turbo pump ring type:

0010-11762, CTR Ring assy, HDP-CVD Ultima plus

Chamber o ring type: KALREZ 9100

Clean method: RPS

0190-26744RPS, MKS Astroni AX7670

Clean gas: NF3

EDWARDS Rough pump interface

0010-03090 ESC Cathode (WTM Type)

0040-18219 ESC (WTM Type)

0190-18430 WTM Probe

0200-18109 Collar

0200-18081 Cover ceramic

0200-01009 Top nozzle

0200-18093 Side nozzle

0200-01006 Dome

0040-04650 Gas ring with (24) nozzles

0200-40156 Lift pin ceramic

Gas panel configurations:

Gas panel type: HP 10 Ra

Cabinet exhaust: Top exhaust

Gas panel door

Gas feed: Single-line drop (Bottom feed)

Valve type: FUJIKIN 5 Ra max

Filter: MILLIPORE Ni 10 ra max

Fitting: VCR

MFC: SEC-4400 MC (D-Sub 9 pins)

Veriflo Regulator

MKS Transducer with display unit

Gas line configuration chamber A, B, C:

Gas pallet: HDP Ultima plus

Gas feed: Single-line drop (Bottom feed)

Automatic gas line purging capability

Gas 1: SiH4, 200 sccm

Gas 2: NF3, 2000 sccm

Gas 3: SiH4 Top, 20 sccm

Gas 4: SIF4, 20 sccm

Gas 5: AR Top, 50 sccm

Gas 6: AR, 300 sccm

Gas 7: HE, 200 sccm

Gas 8: SIF4, 100 sccm

Gas 9: O2, 400 sccm

Gas 10: AR-MW, 2000 sccm

System controller:

Controller Type: Phase I Controller

Controller GFCI: 30MA GFCI

Controller UPS: Facilities ups interface

Controller electrical interface: Top feed AC cables

Controller exhaust: Top exhaust

Cursor type: Blinking cursor

Heat exchanger type:

SMC Themo chiller, INR-498-001D

Heat exchanger water fittings: Stainless steel

Generator rack:

Chamber A, B, and C top RF generator: ENI NOVA-50A

Chamber A, B and C side RF generator: ENI NOVA-50A

Chamber A, B and C bias RF generator: ENI GHW-50A

Power: 200/208 VAC, 50 Hz, 400 A

2001 vintage.

AMAT/APPLIED MATERIALS Centura Ultima HDP Reactor是幹式就地蝕刻和保形塗層領域的先進工具。該設備的設計使制造商能夠以最小的努力和最小的復雜性實現高精度。HDP代表高密度等離子體,這是一種最新的等離子體技術,旨在對各種過程提供最高級別的性能和周期控制。AMAT Centura Ultima HDP反應堆滿足了全球半導體制造商日益復雜的需求。該系統的高級功能和模塊化體系結構為各種應用程序提供了快速實施、靈活性和可擴展性。這包括了纖薄的保形塗層、深反應性離子蝕刻(DRIE)、電鍍銅升空(ECLO)等應用。應用材料CENTURA ULTIMA+HDP反應堆通過優化的吞吐量和周期控制提供了高水平的生產率。其多頻射頻等離子體源和水冷陰極可實現較小的特征尺寸控制和較低的薄膜應力,而線性質量流控制器則可實現對過程氣體的精確控制。它的模塊化體系結構使它能夠以最小的幹擾重新配置,並配置在多個機房中,從而能夠快速、準確地並行處理眾多部件。HDP反應堆采用等離子體源技術的最新進展,以優化蝕刻和保形塗層工藝。其全新設計的等離子體源和腔室允許高長寬比蝕刻和塗層。HDP反應堆的高級過程控制功能有助於實現嚴格的過程分布,從而減少了操作員手動調整的需要。該單位的實時過程監控允許快速決策和快速糾正行動。該機集成了智能診斷功能,可實現快速錯誤反饋和最小停機時間。它的在線模擬功能使用戶能夠快速調整配方並進行必要的更改,而無需長時間設置。此外,其數據輸出可用於記錄相關流程細節和提高流程監控能力。AMAT/APPLIED MATERIALS CENTURA ULTIMA+HDP Reactor是世界上最新型、最先進的幹版蝕刻和保形塗層工具。該工具專為尋求具有高精度和重復性的可靠高效資產的半導體制造商而設計。它的高級功能和模塊化體系結構實現了快速的實施和可擴展性,使其能夠以最小的中斷進行重新配置,並配置在多個機房中,以涵蓋各種應用程序。AMAT CENTURA ULTIMA+HDP Reactor提供了高水平的生產力,並配備了等離子源技術的最新進步,讓用戶達到復雜工藝所需的精度。

還沒有評論