二手 AMAT / APPLIED MATERIALS ECP SlimCell #9031142 待售

看起來這件物品已經賣了。檢查下面的類似產品或與我們聯系,我們經驗豐富的團隊將為您找到它。

單擊可縮放

已售出

ID: 9031142

System, 12"

Factory interface: 3 FOUP stage

Anneal module: Anneal – A

SRD module: SRD – B

SLIM CELL module: CELL – B, CELL – D

IBC module: IBC – B

(16) Units:

1. EFEM

2. Buffer Unit

3. Annel Unit

4. Main System

5. Chemical Supplier #1

6. Chemical Supplier #2

7. Chemical Drain Unit

8. Chiller

9. Monitor Stand #1

10. Monitor Stand #2

11. Parts Box #1

12. Parts Box #2

13. Parts Box #3,

14. Parts Box #4

15. Lifter #1

16. Lifter #2

System Configuration:

Mainframe:

- Wafer Transfer Robot with two Blades x 1

- SLIM CELL TM Module x 2 (Cell - B, Cell - D)

- SRD (Spin Rinse Dry) x 1 (SRD - B),

- IBC (Integrated Bevel Cleaner) x 1 (IBC - B)

- In-Station (Pass Stage) under SRD x 4

- Independent Plating-solution Circulation System x 4

(for Anode and Cathode in each SLIM CELL TM Module)

- Mixing Unit for Plating-solution and Cleaning Fluid

- Fan Filter Unit (FFU)

Factory Interface (FI):

- Two Blade Robot

- FOUP Stage (ADO) x 3

- Aligner

- Fan Filter Unit

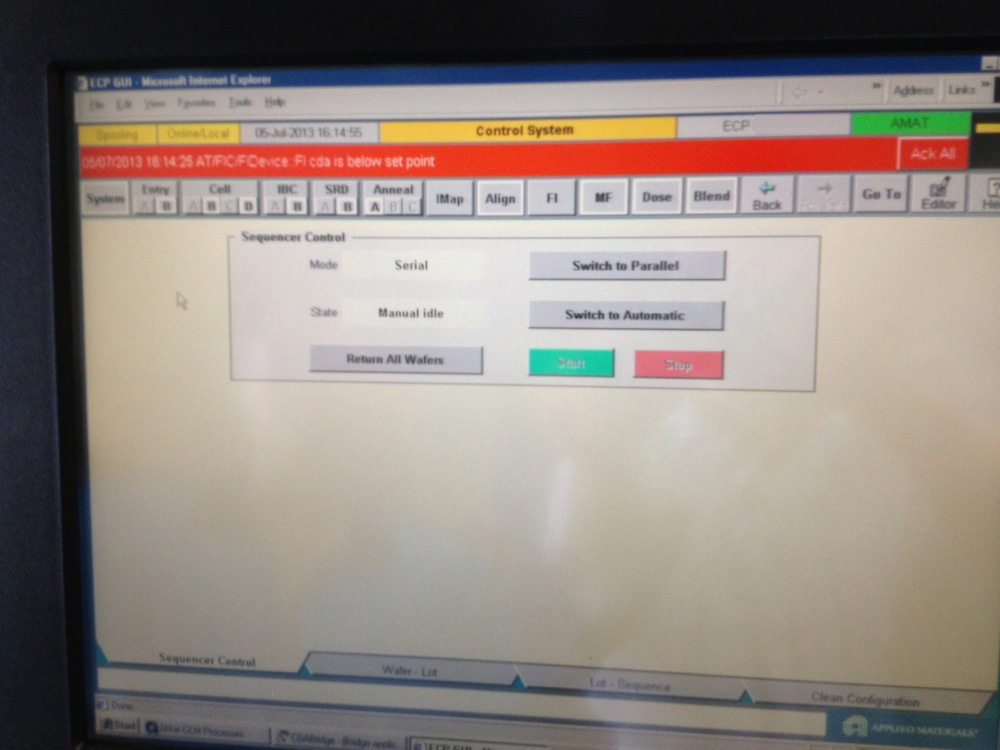

- GUI Computer controlling FI and Mainframe control systems

Heater / Chiller

Operator Interface x 2 (Main & Sub)

Anneal Chamber Module:

- Anneal Chamber x 1 (Anneal - A)

- Movement and Temperature Control, Gas Box

* Mainframes consist of 1) Mainframe, 2) FI and 5) Anneal Chamber Module

* Anneal Chamber is middle of Anneal Chamber Module and Anneal - A is above

the Anneal Chamber

Mainframe Details:

Frame

Fan Filter Unit: ULPA Filter (>0.12 μm, >99.999%)

Plating-solution Supply Unit

SLIM CELLTM Module

- Plating Head: 5 RPM to 400 RPM

- Plating Cell

- Plating-solution circulation system

Filter (Millipore, 0.05 μ, 20")

Temperature Control ± 1.5 deg C

SRD (Spin Rinse Dry): 50 ~ 2500 RPM

- Lower Cleaning Nozzle (one for DI and Chemical)

- Upper Cleaning Nozzle (one for DI)

IBC (Integrated Bevel Cleaner): 50 ~ 2500 RPM ± 20%

- Lower Cleaning Nozzle (three for each DI and Chemical)

- Upper Cleaning Nozzle (one for each DI and Chemical)I)

LBDU (Liquid Blend Dose Unit): ± 5 %

AC Box

- 208 VAC, 3 Phase, 175 A

Mainframe ROBOT

- Dual Arm Robot made by Roze, RS-485 (Ethernet) serial interface

Factory Interface (FI) Details:

FOUP Stage (ADO: Auto Door Opener)

- TDK for AMAT Specification

Link Tunnel

- Dual Blade Robot made by Yaskawa

Align Stage detecting Wafer Notch

Fan Filter unit: (>0.12 μm, >99.999%)

FI / Mainframe Control Unit with UPS (Window NT 4.0)

GUI (Graphic-User-Interface) Computer with UPS (Window NT 4.0)

Chiller Details

- Daiken for AMAT Specification

- Temperature Control Range: 5 ~ 22 deg C

Operator Interface Details

- LCD Touch Panel, Keyboard with Track Ball

- Desk Type or Roll-Around or Wall Mount Type

Anneal Chamber Module Details:

Anneal Chamber

- Gas Box: Mixing and Control of N2 96 %, H2 4% Process Gases

MFC, Flow Switch

- Heater (150 ~ 300 deg C), Cooler Plate, Arm

MTBF

1) MTBF Target : 250 hr

2) MTBF Target for each Unit

- Slim Cell 3400 hr

- IBC 3400 hr

- SRD 4000 hr

- Anneal 4500 hr

- MF Robot 6800 hr

- FI 5000 hr.

AMAT/APPLIED MATERIALS ECP SlimCell是利用電子回旋共振(ECR)沈積介電和導電膜的反應器。反應堆包括一個功能齊全的帶有ECR微波源的工藝室、氣體偏置輸送框架、額外的氣體輸入、燃燒輔助清潔、工藝控制器、水循環和冷卻系統以及精心設計的安全設備。反應堆的腔室為單殼透明石英和不銹鋼結構。它是為高性能的重新激活離子蝕刻,等離子體消融和沈積操作而設計的。ECR微波源是一種高頻發生器,它產生微波使室內的氣體混合物電離。氣體偏置輸送框架位於腔室的下部,從而可以精確控制離子的強度。額外的氣體輸入連接到腔室頂部,將惰性或腐蝕性氣體輸送到工藝腔室。燃燒輔助清潔系統是一個新的特點,其中受控的化學反應有助於保持一個清潔的腔室。它不需要同時進行復雜的真空清洗。它還減少了工藝後維護時間。該過程控制單元基於與Windows傳輸體系結構相連接的分布式設備機器。它旨在同時處理多個應用程序和配方,並與所有外圍設備處理組件一起操作。該工具還能夠對所有工藝參數進行實時反饋控制。水循環和冷卻系統旨在為反應室的所有關鍵部件提供均勻的溫度控制冷卻。在反應器中采用鈍化板設計,以最大限度地提高水速和散熱。AMAT ECP SlimCell反應堆的安全資產包括各種安全功能,以防止事故和保護人員免受過度輻射和/或過熱。APPLICED MATERIALS ECP SlimCell為沈積過程提供了出色的一致性和可擴展性,而其卓越的安全系統使其非常適合用於關鍵操作。全面的維護過程有助於使設備保持良好的工作狀態,並確保性能一致。采用現代、集成的控制模型可以方便、精確地進行過程控制,使其成為研究和生產的最佳選擇。

還沒有評論