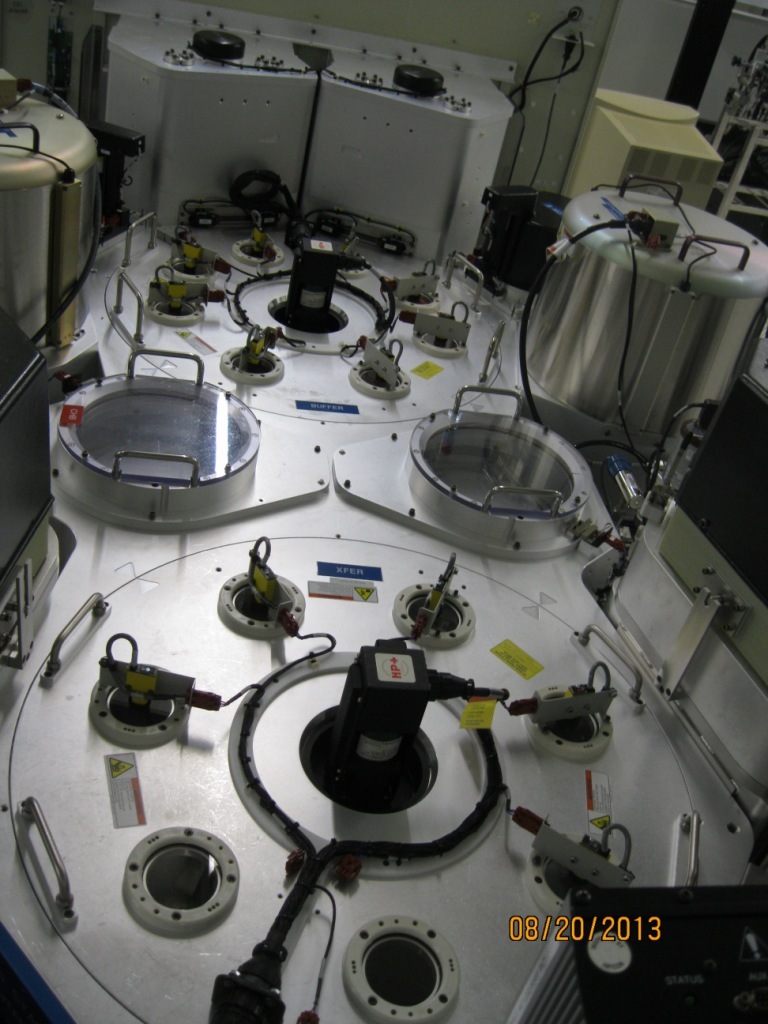

二手 AMAT / APPLIED MATERIALS Endura 5500 #9036092 待售

看起來這件物品已經賣了。檢查下面的類似產品或與我們聯系,我們經驗豐富的團隊將為您找到它。

單擊可縮放

已售出

ID: 9036092

PVD System, 8"

Wafer handling: SMIF

Front panel type: wide body

Software version: B88810

Single board computer in controller: Yes

Ion gauges: Yes

Robots (standard, HP, HP+, VHP, etc):

Buffer robot: HP+

Transfer robot:HP+

Blade material: Metal

Blade material: Metal

Load Lock: Wide Body

Narrow Body: tilt-out

Index handler type:

Loadlock vents: N2 vent

Basic Chamber setup: (PC II, Cooldown, O/D, pass through, CVD, other - w/o details)

A: Cool down

B: Cool down

C: Pre clean II

D: Pre clean II

E: Orient / Enhanced degas

F: Orient / Enhanced degas

Process: VECTRA IMP Ti

Platform: Endura

RF coil power supply: Advance Energy HFV 8000

Chamber temperature: Heater 100°C - Bake 30%

Pump Type: CTI 8F Enhanced Fast Regen Low Vib

MFC #1: Argon Heater

MFC #1 type / size: Stec SEC-4400M 50 Sccm

MFC #2: Argon Final

MFC #2 type / size: Stec SEC-4400M 100 Sccm

Source type: Vectra IMP

Target type / vendor: D-Bond 0.25" - Honeywell

Target part # 7VX00236

Coil part # 7VX20266

Magnet type / part number: Type RH-2 P/N 0010-21676

Ar Psi: 20 PSI

Power supply: MDX 12KW

Shutter: Linkage

Heater: Original 4F

Process Kit (type/desc): IMP Process Kit Version 4.5

Upper Shield Part No: 0020-22498

Lower Shield Part No: 0020-22499

Shield Clamp Kit Part No: 0240-25440

DC Bias Hardware Kit PN: 0240-20021

Process: CVD TiN

Platform: ENDURA

Chamber temperature: 400°C

Chamber type: TxZ HP+

Heater: AMAT P/N 0010-03244

Pump Type: ALCATEL 602 P

HX: AMAT 1

HX temperature: 60°C

MFC #1: Argon Edge Purge

MFC #1 type / size: Stec SEC-4400M 3000 Sccm

MFC #2: Argon BTPur

MFC #2 type / size: Stec SEC-4400M 2000 Sccm

MFC #3: He Carrier

MFC #3 type / size: Stec SEC-4400M 500 Sccm

MFC #4: N2 Dil

MFC #4 type / size: Stec SEC-4400M 1000 Sccm

MFC #5: He Dil

MFC #5 type / size: Stec SEC-4400M 1000 Sccm

MFC #6: N2

MFC #6 type / size: Stec SEC-4400M 1000 Sccm

RF Power supply: ADVANCE ENERGY PDX 900-2V

HE carrier pressure: 18 PSI

HE DIL pressure: 30 PSI

Ampole temperature: 50°C

Gas line temperature: 60°C

Hot Box: 70°C

CVD Ion gauge: Absent

Process Kit (type/desc)

INSERT LINER EXHAUST TXZ 200MM: 0021-02469

RING, LOWER, ISOLATOR: 0021-02155

RING, MIDDLE, ISOLATOR: 0021-02156

EDGE RING, PURGE HEATER, 200MM TXZ: 0021-03094

SCREW, CENTERING PURGE HEATER 200MM TXZ: 0021-07418

OUTER SHIELD W/O WINDOW, TXZ CHAMBER: 0021-03980

INNER SHIELD HP TXZ IMP. UNIF.: 0040-06127

PIN, LIFT, TXZ HEATER: 0200-01798

PLATE,BLOCKER,TXZ 200MM: 0021-35744

FACE PLATE, BKM3 TXZ 200MM: 0040-01878

CHAMBER INSERT 200MM TXZ CIP: 0200-00261

ISOLATOR, SIN, ENH, PUMPING LID, DXZ GECO: 0200-10163

TUBE GAS FEED: 0020-31425

LID LINER, HPTXZ: 0200-00689

Process: PVD TiN

Platform: ENDURA

Ch temp control: Without temp control

Chamber type: WB

Pump Type: CTI 8F Enhanced Fast Regen Low Vib

MFC #1: Argon

MFC #1 type / size: Stec SEC-4400M 100 Sccm

MFC #2: N2

MFC #2 type / size: Stec SEC-4400M 200 Sccm

Source type: G-12

Target type / vendor: D-Bond 0.35" - Praxair

Target part #: 7VX00135

Magnet type / part number: Type G-12 P/N 0010-20768

N2 Psi: 20 PSI

Ar Psi: 20 PSI

Power supply: MDX - L12M - 650

Shutter: Linkage

Heater: SST Pedestal Unclamped 101

Process Kit (type/desc): Shield Mounting G12 btn hd

Upper Shield Part No: 0020-25730

Lower Shield Part No: 0020-25077

Pedestal Part No: 0021-22028

Cover Ring Part No: 0020-24914

Process: Pre-clean

Pedestal type: Preclean II Pik1

Power supply 1: 400 KHz

Power supply 2: 13.56 MHz

Gasline fittings: VCR

Loadlock fittings: VCR

MFC type: Millipore / STEC

Paste chamber: NA

Chamber cryo pump type: CTI 8F Enhanced Fast Regen Low Vib

Umbilicals:

Mainframe to controller: ~25 ft

Mainframe to generator racks: ~25 ft

Mainframe to cryo compressor: ~25 ft

Main AC to system controller/sys. AC: ~25 ft

Syst cont/sys AC to primary Gen rack: ~25 ft

Main AC to primary generator rack: ~25 ft

Main AC to pump frame: ~25 ft

Main AC to Neslab heat exchanger: ~25 ft

Monitor cable: ~25 ft

Monitor2 cable: ~25 ft

Monitor3 cable: ~15 ft

EMO button guard ring: Yes

Water leak detector: yes

Buffer and transfer lid hoist: Yes

Support Equipment:

AMAT 0 Heat exchanger 0010-76467

Cryo compressors:

(2) CTI Cryo pump 1 8135900G001

Neslab with resistivity meter

Soft copy pdf manuals

Currently in a fab

2003 vintage.

AMAT/APPLIED MATERIALS/AKT Endura 5500反應堆是一種先進的、具有成本效益的多用途集群工具,為要求苛刻的晶圓制造工藝提供了改進的性能要求。該反應堆能夠在蝕刻和沈積過程中提供可靠和均勻的環境。AKT Endura 5500反應堆專為單室、雙室和多室操作而設計,采用先進的真空設備,具有優越的氣體分配和多種選擇。AMAT ENDURA 5500采用緊湊的設計,需要最小的空間,占用不到3立方米,使其能夠輕松融入任何生產過程。AKT ENDURA 5500允許在三維方向上輕松定位,使其設置和運行更加高效和方便。APPLIED MATERIALS Endura 5500還具有獨特的冷卻系統,可實現更快的吞吐量和運行之間的冷卻。這種多功能集群工具還為蝕刻和沈積過程提供了選項。Endura 5500包括模塊化蝕刻和沈積室設計,允許在同一空間進行蝕刻時進行沈積。這種多用途特性確保了在一個反應堆內能夠完成各種各樣的過程。Endura 5500Reactor提供低成本和低維護,並具有出色的性能和耐用性。其氣體輸送裝置有利於提高吞吐量和提高產品產量。AMAT/APPLIED MATERIALS/AKT ENDURA 5500的高真空能力提高了質量和可重復性,同時消除了晶圓邊緣效應。ENDURA 5500具有廣泛的控制選項,為蝕刻和沈積過程提供了高度的控制和準確性。反應堆既包括過程控制機,也包括操作員面板,以提高操作員的便利性。該控制工具可管理多個過程參數,流程開發速度快,性能高,精度高.APPLIED MATERIALS ENDURA 5500的高級功能和緊湊的設計使其成為許多應用程序的理想選擇。它具有靈活性和易於安裝,可將其集成到任何流程中,同時提供優化的結果和卓越的性能。反應堆可以處理從蝕刻到沈積的任何過程,成本低,重復性高,吞吐量提高。

還沒有評論