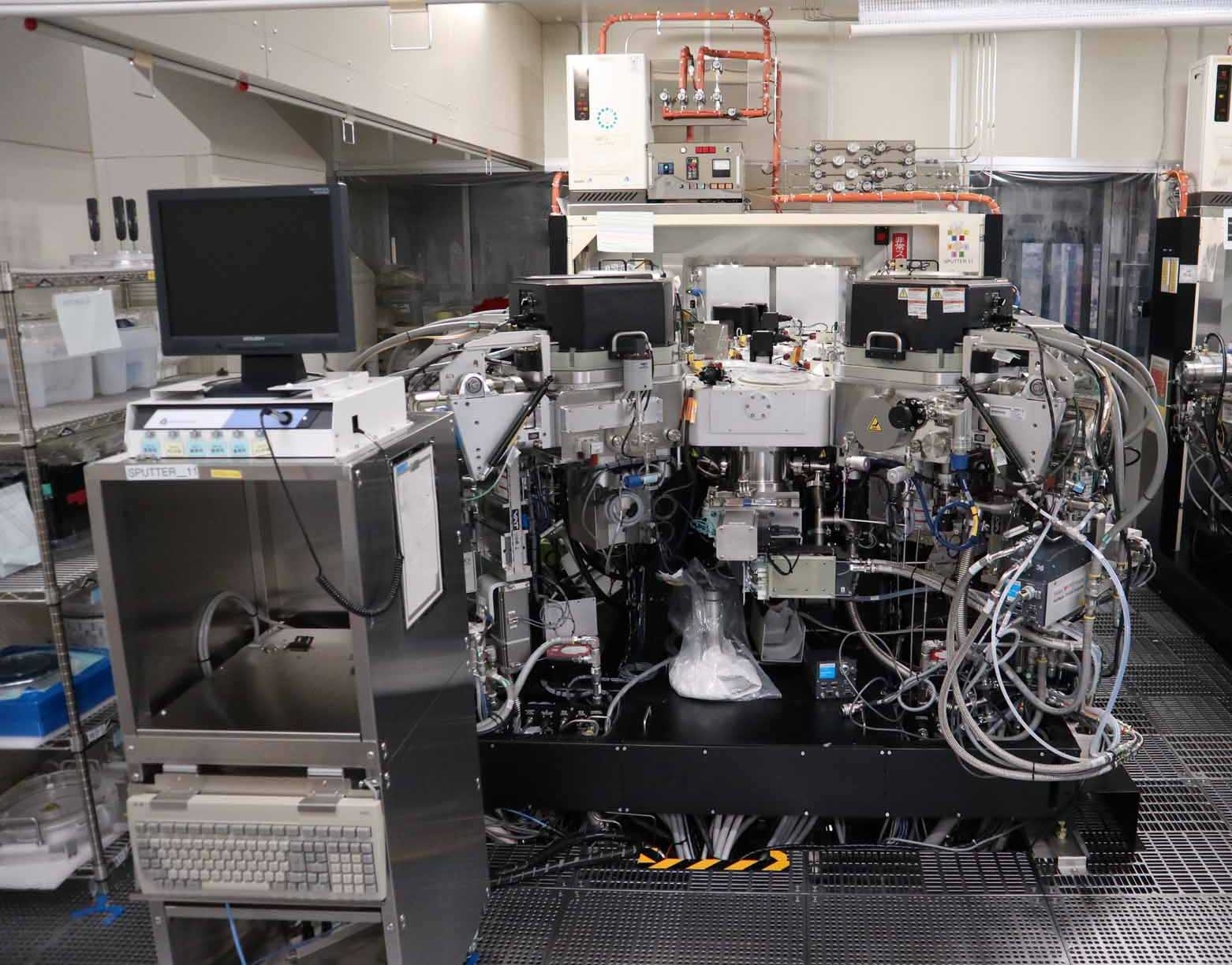

二手 AMAT / APPLIED MATERIALS Endura 5500 #9219406 待售

看起來這件物品已經賣了。檢查下面的類似產品或與我們聯系,我們經驗豐富的團隊將為您找到它。

單擊可縮放

已售出

ID: 9219406

晶圓大小: 8"

優質的: 2001

System, 8"

Wafer shape: SNNF

MF Facilities: Bottom

Chamber 1: STD WC Body

Process 1: ESC AL

Chamber 2: Wide body

Process 2: TTN

Chamber 3: Wide body

Process 3: TTN

Chamber 4: Wide body

Process 4: Ti

Chamber A: Pass through

Chamber B: Cooldown

Chamber C/D: PCII

Process C/D: Oxide etch

Chamber F: O/D With temp

Heat exchanger 1: NESLAB I

Loadlock pump type: iL600

Transfer robot type: HP+

Transfer robot blade: Metal

Buffer robot type: HP+

Buffer robot blade: Metal

Wafer sensor: Mini beam

Loadlock type: Narrow BD without tilt out

System umbilical: 50 ft

EMOs: Turn to release

Hard drive: SCSI

(2) CRTs

GEM: No

OTF: No

No Facility power (UPS)

No loadlock pump

Loadlock slit valve O-rings: Viton (Black)

Heat exchanger 1: NESLAB

Heat exchanger 2: M-Pack

Main AC box: 480 V, Wide type

Chamber A:

Chamber type: Pass through

Chamber lid: STD Lid

Lift hoop & finger

Pedestal type: Standard

Chamber B:

Chamber type: Cooldown

Gas valves: Fujakin

Heater / Cathode cooling: PCW

Chamber lid: STD Lid

Pedestal type: Standard without TC option

Chamber C:

Chamber type: PCII

Manometer config: Single

Manometer 1: 100mTorr

No shutter option

Chamber process: Oxide etch

Lid type: RF Resonator

RF Gen / DC supply 1: COMDEL CPS-1001S

RF Gen / DC supply 2: RFPP LF10A

RF Match: 13.56 MHz

No endpoint system

Process kit type: PIK-I

Chamber pump: EDWARD iL70

Turbo pump: LEYBOLD

No heated valve stack

Gas MFC Size MFC Type MFC Number Gas stick

N2 20 SCCM STEC 4400 MFC9 (2) Manifolds

N2 300 SCCM MC-3102E-NC MFC10 (2) Manifolds

Chamber D:

Chamber type: PCII

Manometer config: Single

Manometer 1: 100mTorr

No shutter option

Chamber process: Oxide etch

Lid type: RF Resonator

RF Gen / DC supply 1: COMDEL CPS-1001S

RF Gen / DC supply 2: RFPP LF10A

RF Match: 13.56 MHz

No endpoint system

Process kit type: PIK-I

Chamber pump: EDWARD iL70

No heated valve stack

Gas MFC Size MFC Type MFC Number Gas stick

N2 20 SCCM STEC 4400 MFC12 (2) Manifolds

N2 300 SCCM MC-3102E-NC MFC13 (2) Manifolds

Chamber 1:

Chamber type: STD WC Body

Manometer config: Single

Manometer 1: 100mTorr

No shutter option

Chamber process: ESC AL

Lid type: 12.9"

RF Gen / DC Supply 1/2: AE MDX-L12M

Susceptor / Pedestal: MCA ESC

Heater / Cathode cooling: NESELAB I

No endpoint system

Gate valve position: 3 POS

Process kit type: ESC AL

Chamber pump: Cryo pump (OB8F-3 Phase)

No heated valve stack

Gas MFC Size MFC Type MFC Number Gas stick

N2 100 SCCM STEC 4400 MFC18 (2) Manifolds

N2 20 SCCM STEC 4400 MFC9 (2) Manifolds

Chamber 2:

Chamber type: Wide body

Manometer config: Single

Manometer 1: 100mTorr

No shutter option

Chamber process: TTN

Lid type: 12.9"

RF Gen / DC Supply 1: AE MDX-L12M

Susceptor / Pedestal: 101

No endpoint system

Gate valve position: 3 Pos

Process kit type: (2) Ti/TiN

Chamber pump: Cryo pump (OB8F-3 Phase)

No heated valve stack

Gas MFC Size MFC Type MFC Number Gas stick

N2 300 SCCM STEC 7440 MFC9 (2) Manifolds

N2 100 SCCM STEC 4400 MFC10 (2) Manifolds

Chamber 3:

Chamber type: Wide body

Manometer config: Single

Manometer 1: 100mTorr

No shutter option

Chamber process: TTN

Lid type: 12.9"

RF Gen / DC Supply 1: AE MDX-L12M

Susceptor / Pedestal: 101

No endpoint system

Gate valve position: 3 Pos

Process kit type: (2) Ti/TiN

Chamber pump: Cryo pump (OB8F-3 Phase)

No heated valve stack

Gas MFC Size MFC Type MFC Number Gas stick

N2 100 SCCM STEC 4400 MFC2 (2) Manifolds

N2 300 SCCM STEC 4400 MFC3 (2) Manifolds

Chamber 4:

Chamber type: Wide body

Manometer config: Single

Manometer 1: 100mTorr

No shutter option

Chamber process: TTN

Lid type: 12.9"

RF Gen / DC Supply 1: AE MDX-L12M

Susceptor / Pedestal: MCA ESC

Heater / Cathode cooling: NESELAB I

No endpoint system

Gate valve position: 3 Pos

Process kit type: ESCAL

Chamber pump: Cryo pump (OB8F-3 Phase)

No heated valve stack

Gas MFC Size MFC Type MFC Number Gas stick

N2 20 SCCM STEC 4400 MFC4 Single

N2 100 SCCM STEC 4400 MFC5 (2) Manifolds

N2 200 SCCM STEC 4400 MFC6 (2) Manifolds

Missing ES chuck

System power: 200 VAC, 60 Hz, 3 phase, 343 A,150 kVA

2001 vintage.

AKT (AMAT) AMAT/APPLICED MATERIALS/AKT Endura 5500是為生產先進半導體而設計的高性能、獨立式反應堆。AKT Endura 5500能夠實現多種基材和材料的高吞吐量和低缺陷率。該設備采用可擴展的模塊化體系結構,支持最先進的半導體工藝和制造技術。AMAT ENDURA 5500配備了多種獨特的功能,可確保最佳的生產效率。它有一個高性能的晶圓處理系統,可以讓晶圓快速輕松地加載。APPLICED MATERIALS Endura 5500還具有自動晶圓映射單元,可確保晶圓加工的均勻性。此外,該機器還具有一個高級工藝控制工具,可連續監控工藝溫度和其他關鍵參數。AMAT Endura 5500旨在為大批量生產提供卓越的生產可靠性。它具有先進的冷卻資產,可確保高效運行並最大程度地減少停機時間。此外,Endura 5500還采用了空氣排氣過濾、真空控制和溫度調節等環保措施。這確保了在生產環境和實驗室環境中的安全運行。在美學方面,ENDURA 5500具有誘人、圓滑的設計。該模型設計為自成一體,具有易於學習和使用的直觀用戶界面。該設備還具有一系列可選功能,例如用於分析晶片的高級掃描儀,可以添加這些功能以進一步提高其性能。除了令人印象深刻的性能和美觀外,APPLIED MATERIALS ENDURA 5500還提供一系列提高生產力的功能。它專為高吞吐量和低缺陷率而設計,可滿足各種光學、晶圓和工藝要求。此外,系統的高級控制單元提供了有關流程參數的詳細數據,使用戶能夠根據需要調整流程。AKT ENDURA 5500是一種極可靠的反應堆,為用戶提供了高度的工藝靈活性。它是大容量半導體生產應用的理想解決方案,非常適合實驗室和生產環境。

還沒有評論