二手 AMAT / APPLIED MATERIALS Endura 5500 #9304004 待售

網址複製成功!

單擊可縮放

ID: 9304004

晶圓大小: 6"

優質的: 1997

System, 6"

MF Facilities: Rear

Heat exchanger: NESLAB I

Buffer robot type: HP

Transfer robot type: HP

Hard Disk Drive (HDD): SCSI

Buff robot blade: Ceramic

Wafer sensor: Mini beam

Loadlock type: Narrow body without tilt out

Transfer robot blade: Metal

Signal tower: 3 Color

System umbilicals: 25 ft

EMO

No GEM

No OTF

Controller

Generator rack

(2) CTI-CRYOGENICS 9600 Compressors

CTI-CRYOGENICS Motor controller: 3 Phase

EBARA A07V Pump

Main AC box

Transformer: 200 VAC,3 Phase, 50/60 Hz

MF Enclousure cover installed

MF Gas box

Laser assy

OB- 8F Cryo pump: Enhanced type

Process lift: Motorize type

SBC BD Type: V452

Buffer / Transfer: VHP Conversion possible type

MF Facility box

UPS: Interface type

Chamber A:

Type: PC-II

ADVANCED ENERGY LF10A RF Generator

COMDEL CPS1001S RF Generator

Gas valves: Nupro

Manometer: 100m Torr

LEYBOLD Turbovac 361C Pump

Lid: Resonator

Match box, 6"

LEYBOLD Turbotronic 150 / 360 Turbo controller

EBARA A07V Pump

Gasses:

LEYBOLD Turbo pump

MFC Size / Gas name / MFC Type

300 / Ar / Stec 4400

20 / Ar / Stec 4400

Chamber B:

Type: Cool down

Gas valves: Nupro

Heater / Cathode cooling: PCW

Lid modified to Quartz lid

Chamber 1:

Process: TTN

Type: STD Body

Manometer configuration: Single

Manometer: 100m Torr

No shutter option

Lid type: 11.3"

ADVANCED ENERGY MDX-L12-650 DC Power supply

Susceptor / Pedestal: 101

3-Position gate valve

OB-8F Pump: 3 Phase

Ion gauge: Nude type

Lift type: Basic motorize type

Gasses:

Gas / MFC Size / Gas name / MFC Type / Qty / Gas stick configuration

Gas 1 / 200 SCCM / N2 / Stec 4400 / (2) / Manifolds

Gas 2 / 100 SCCM / Ar / Stec 4400 / (2) / Manifolds

Gas 3 / 200 SCCM / N2 / Stec 4400 / (2) / Manifolds

Chamber 2:

Process: AL

Type: STD Body

Manometer configuration: Single

Manometer: 100m Torr

No shutter option

Lid type: 11.3"

ADVANCED ENERGY MDX-L12M Power supply

ADVANCED ENERGY MDX-L12 Power supply

Susceptor / Pedestal: 4F

Heater / Cathode cooling: NESLAB I

3-Position gate valve

OB-8F Pump: 3 Phase

MKS Residual gas analyzer installed

Lift type: Basic motorize type

Gasses:

Gas / MFC Size / Gas name / MFC Type / Gas stick configuration

Gas 1 / 100 SCCM / Ar / Stec 4400 / Standard

Gas 2 / 100 SCCM / Ar / Stec 4400 / Standard

Chamber 3:

Process: Ti

Type: STD Body

Manometer configuration: Single

Manometer: 100m Torr

No shutter option

Lid type: 11.3"

ADVANCED ENERGY MDX-10K DC Power supply

Susceptor / Pedestal: 101

3-Position gate valve

OB-8F Pump: 3 Phase

Lift type: Basic motorize type

Gasses:

Gas / MFC Size / Gas name / MFC Type / Qty / Gas stick configuration

Gas 1 / 200 SCCM / N2 / Stec 4400 / (2) / Manifolds

Gas 2 / 100 SCCM / Ar / Stec 4400 / (2) / Manifolds

Gas 3 / 200 SCCM / N2 / Stec 4400 / (2) / Manifolds

Chamber 4:

Process: TTN

Type: STD Body

Manometer configuration: Single

Manometer: 100m Torr

No shutter option

Lid type: 11.3"

ADVANCED ENERGY MDX-650 HiZ DC Power supply

Susceptor / Pedestal: 101

3-Position gate valve

OB-8F Pump: 3 Phase

Lift type: Basic motorize type

Gasses:

Gas / MFC Size / Gas name / MFC Type / Qty / Gas stick configuration

Gas 1 / 200 SCCM / N2 / Stec 4400 / (2) / Manifolds

Gas 2 / 100 SCCM / Ar / Stec 4400 / (2) / Manifolds

Gas 3 / 20 SCCM / Ar / Stec 4400 / (2) / Manifolds

Missing parts for chamber 1:

Drive: 2 Phase

Motor

Gear box

Gear box mount

Belt

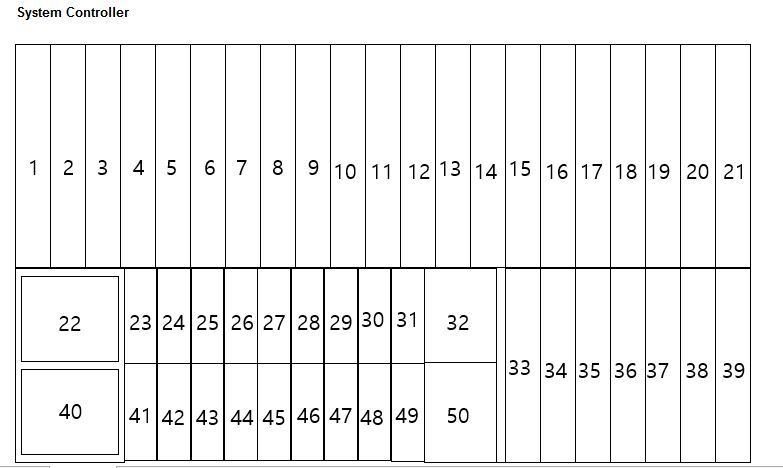

Slot / Top rack boards:

1 / SBC Board

2 / Videl board

3 / OMS Board

4 / DI/O Board

5 / DI/O Board

6 / DI/O Board

7 / DI/O Board

8 / DI/O Board

9 / DI/O Board

10 / SEI Board

11 / No 486C

12 / No seriplex

13 / No DI/O board

14 / No AO board

15 / Stepper board

16 / No spare

17 / No spare

18 / Stepper board

19 / AI Board

20 / AO Board

21 / AO Board

22 / Hard Disk Drive (HDD)

23 / No grounding JAC

24 / Convectron board

25 / Convectron board

26 / Convectron board

27 / Convectron board

28 / No TC

29 / No TC

30 / ION Gauge board

31 / ION Gauge board

32 / No spare

33 / DI/O Board

34 / DI/O Board

35 / DI/O Board

36 / DI/O Board

37 / DI/O Board

38 / No DI/O board

39 / No DI/O board

40 / Floppy Disk Drive (FDD)

41 / No spare

42 / Cryo temp

43 / AI Mux

44 / AI Mux

45 / No AI Mux

46 / No spare

47 / Opto detect board

48 / Opto detect board

49 / Opto detect board

50 / No spare

UPS: 200 VAC, 3 Phase, 50/60 Hz, 350 A

1997 vintage.

AMAT/APPLIED MATERIALS/AKT Endura 5500是一種高通量、功能齊全的外延反應器,設計用於半導體生產。AKT Endura 5500具有全自動裝載機/卸載機和多個處理室,可實現快速的過程設置和優化的過程一致性。AMAT ENDURA 5500旨在為小直徑和大直徑外延晶片提供高通量。AMAT Endura 5500支持多種工藝化學方法,包括化學氣相沈積(CVD)和分子束外延(MBE),用於各種材料的生長,包括矽、矽、碳摻雜矽和其他化合物。這種靈活性適應了多種產品的生產,包括傳統邏輯器件、MEMS(微機電系統)、高級邏輯和光電元件。該系統具有獨特的單源遙控器,簡化了流程設置,並允許對最多三個APPLIED MATERIALS ENDURA 5500系統進行全面遠程監控。這包括實時訪問多個工藝參數,如溫度、增長率和工藝壓力,此外還允許用戶直接公司工藝室。這些數據對於快速查找和排除流程問題非常寶貴。ENDURA 5500提供了多種工藝室配置、受限制的木筏和箱體尺寸,允許快速、高效的晶圓循環和大批量生產。受約束的木筏具有增強的均勻性控制功能,允許以梯田方式鋪設晶片,以確保整個晶片的熱均勻性一致。使用高度集成的攝像頭系統,可以使用四、六、八和十二英寸晶片進行自動晶片對準,從而確保晶片處理和處理的一致性和準確性。APPLIED MATERIALS Endura 5500還擁有一個完全自動化的晶圓處理模塊,消除了耗時的手動晶圓處理和加載。這包括Endura 5500的簽名旋轉卡帶傳輸系統,允許連續自動裝卸多達十個晶圓卡帶,不間斷生產。總體而言,AKT ENDURA 5500是一種頂級的、功能齊全的外延反應堆,專為快速、大容量的晶圓生產而設計。該裝置配備了最新的工藝室性能和自動晶片加載,以及遠程監控和優化的均勻性控制,所有這些都確保了一致、可靠的生產。

還沒有評論