二手 AMAT / APPLIED MATERIALS P5000 #9236969 待售

網址複製成功!

單擊可縮放

ID: 9236969

晶圓大小: 8"

優質的: 1998

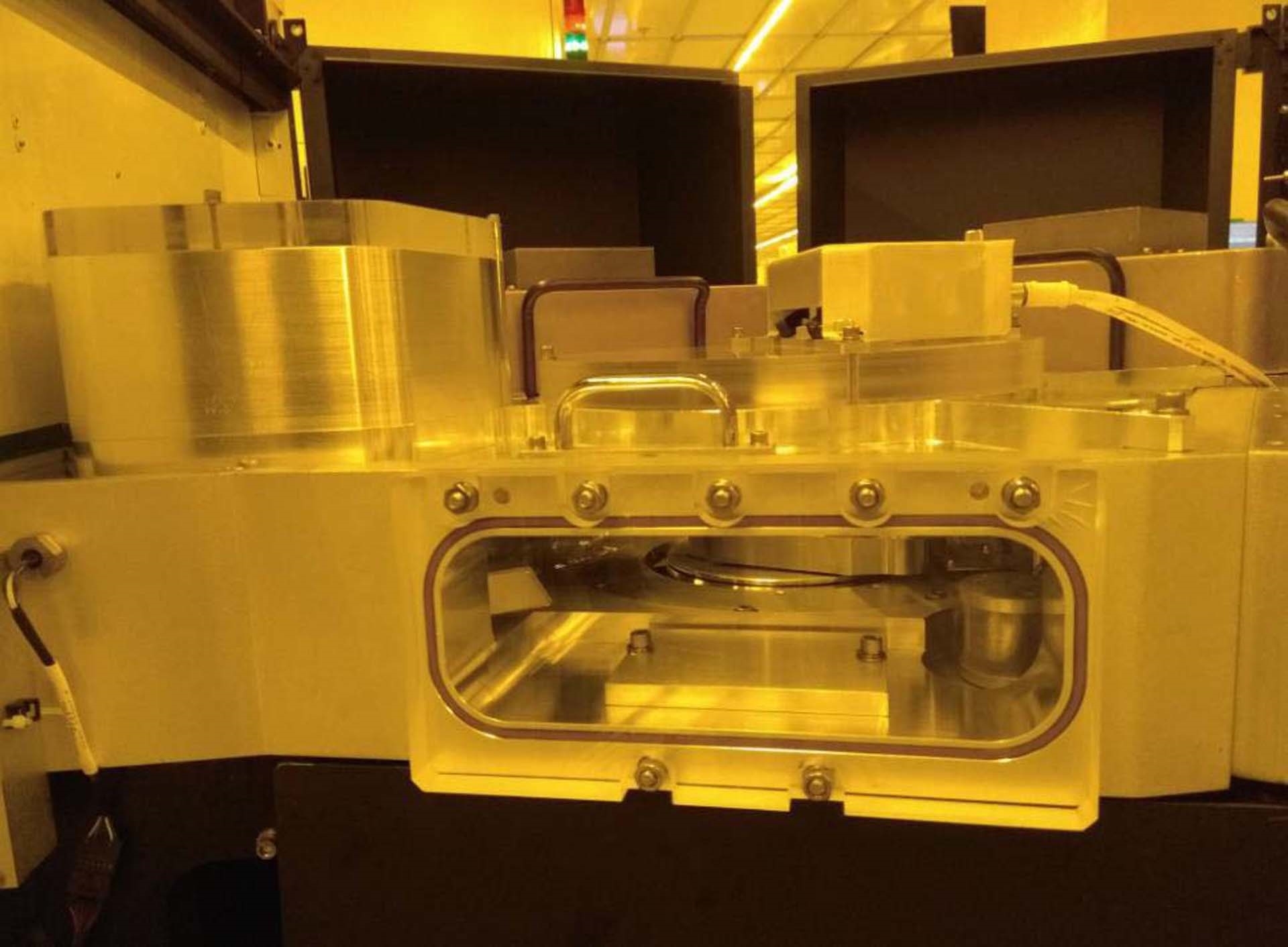

PECVD System, 8"

Process: Passivation

Chamber type: DLH

CIM Linked

Main frame

Load lock

SMIF System: ASYST ARM-2200 V111S

Handler system: Robot assembly

Process chamber:

(3) CVD Deposition chambers A, B & C

(3) Primary generators

(3) RF2 Generators & matches

(4) Ebara pumps

Heat exchanger

Mini SBC board

SBC Board

SEI Board

(2) AI Boards

(2) AO Boards

VGA Board

(4) Stepper driver boards

(2) Digital I/O boards

Buffer I/O board

(2) Optical sensor boards

(4) Chopper driver boards

(3) Baratrons

LAMDA Power supply

Hard Disk Drive (HDD)

Wiring distribution board

Pneumatic board

Loader interconnect board

(2) TC Gauge boards

+12V DC Power supply

+15V DC Power supply

-15V DC Power supply

AI MUX Board

(3) RF Generators

Controller distribution board

Encoder interface board

System electronic back plane

Robot blade assembly

Facility:

A10S Loadlock pump

A70W Process pump

Incoming power: 208 VAC

Heat exchanger temperature set point: 65

Buffer:

LPT / Indexer: ARM-2200 H112S

Center finder

Storage elevator: (8) Slots

LL Robot type: Metal

Load lock actuator: IO Door

Chamber actuator: 0010-70162

CDA Pressure for buffer: 60 psi

Process chamber:

RF 1 Generator: ENI OEM-12B

RF 2 Generator: RFPP 7520572050

RF Match: AMAT / APPLIED MATERIALS Automatch 0010-09750

Pressure manometer: MKS 10T (122BA-001000EB-S)

Throttle valve / PCV Model: VEXTA PX245-02AA-C4

TC Part number: 3310-01074

Chuck type: P-Chuck

Chuck part number: 0010-38437

Process temperature: 400°C

MFC Gases:

C2F6: 10 SLM

SIH4: 3000scc

NH3: 300scc

N2: 10 SLM

N20: 3000 SCC

N20 (G): 200 SCCM

PH3: 300 SCC

DPA Included

Endpoint: 0190-09472

CDA Pressure for chamber: 60 psi

1998 vintage.

AMAT/APPLIED MATERIALS P5000是一種用於制造半導體器件的反應堆。它利用先進的技術提供精確的熱控制和化學氣相沈積(CVD)的平臺。反應堆的設計目的是確保均勻的溫度,減少整個材料或裝置生長過程中的不均勻性。AMAT P-5000是一種單晶片反應器,它包含三個關鍵特征:均勻性、溫度控制和基板柔韌性。反應堆由幾個部件組成:石英室、感應座、控制設備、加熱元件和冷卻系統。石英室允許在受控條件下將膜氧化或沈積到基板上。磁感器安裝在處理過程中保持晶片,設計為提供均勻的溫度分布。該控制單元可實現精確的溫度控制和CVD平臺。加熱元件設計為通過整個晶片提供均勻的溫度。冷卻機用於降低基板溫度,使工藝穩定。APPLIED MATERIALS P 5000反應堆有著廣泛的優勢,如性能增強、重復性高、吞吐量提高、產量提高等。它還能夠在高溫下生產設備,具有極好的均勻性和可重復性。此外,P5000反應器是晶片鍵合的理想選擇,因為它可以確保非常均勻的溫度和更高的處理精度。最後,AMAT P5000反應器是半導體制造過程中的重要組成部分.它能夠提供均勻的溫度並減少材料或設備整個生長過程中的不均勻性,這使得它極為有用和具有成本效益。隨著技術的進步,預計P 5000反應堆將在生產半導體器件方面變得更加先進和高效。

還沒有評論