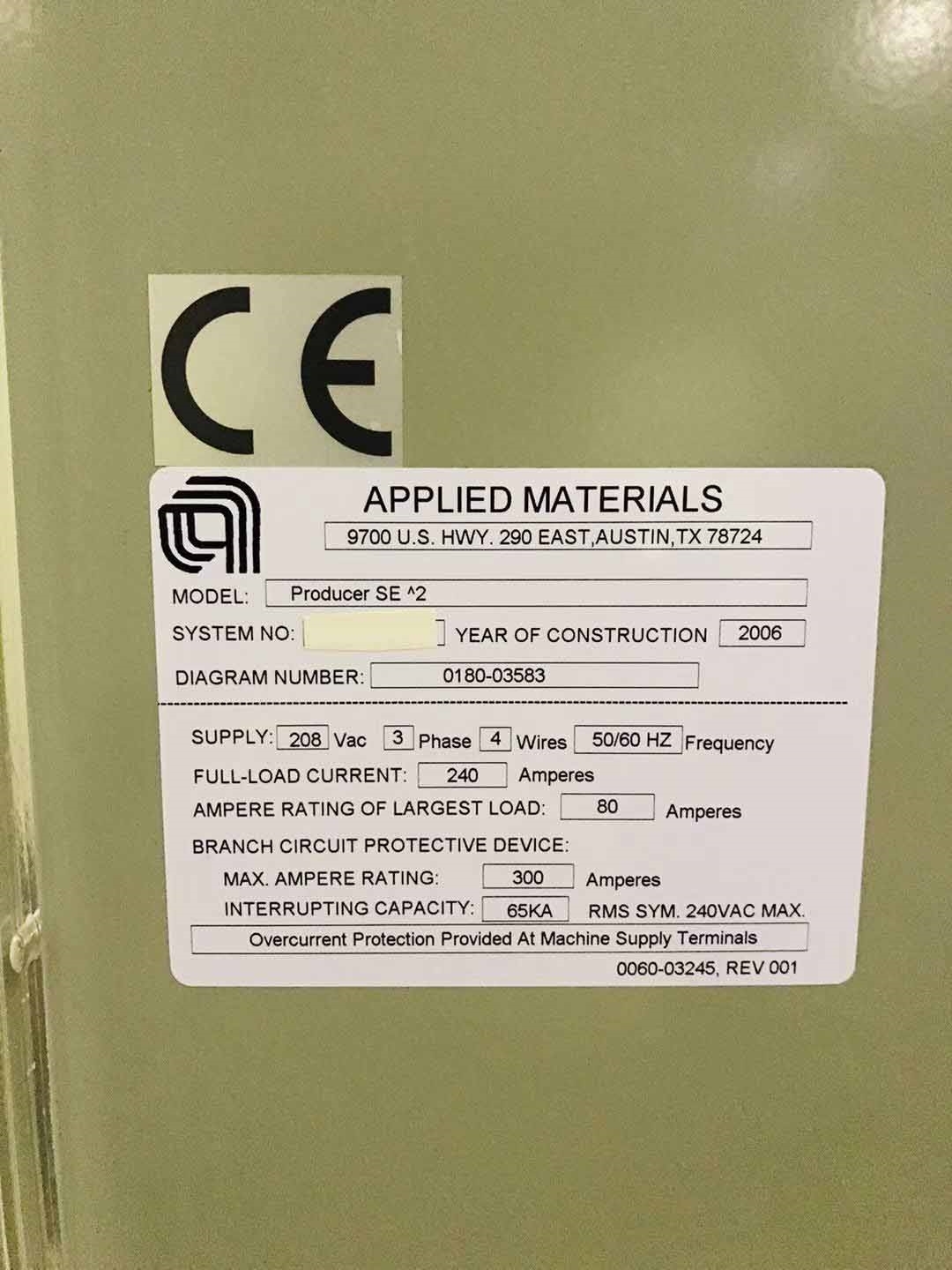

二手 AMAT / APPLIED MATERIALS Producer GT #9265758 待售

網址複製成功!

單擊可縮放

ID: 9265758

晶圓大小: 12"

優質的: 2006

CVD System, 12"

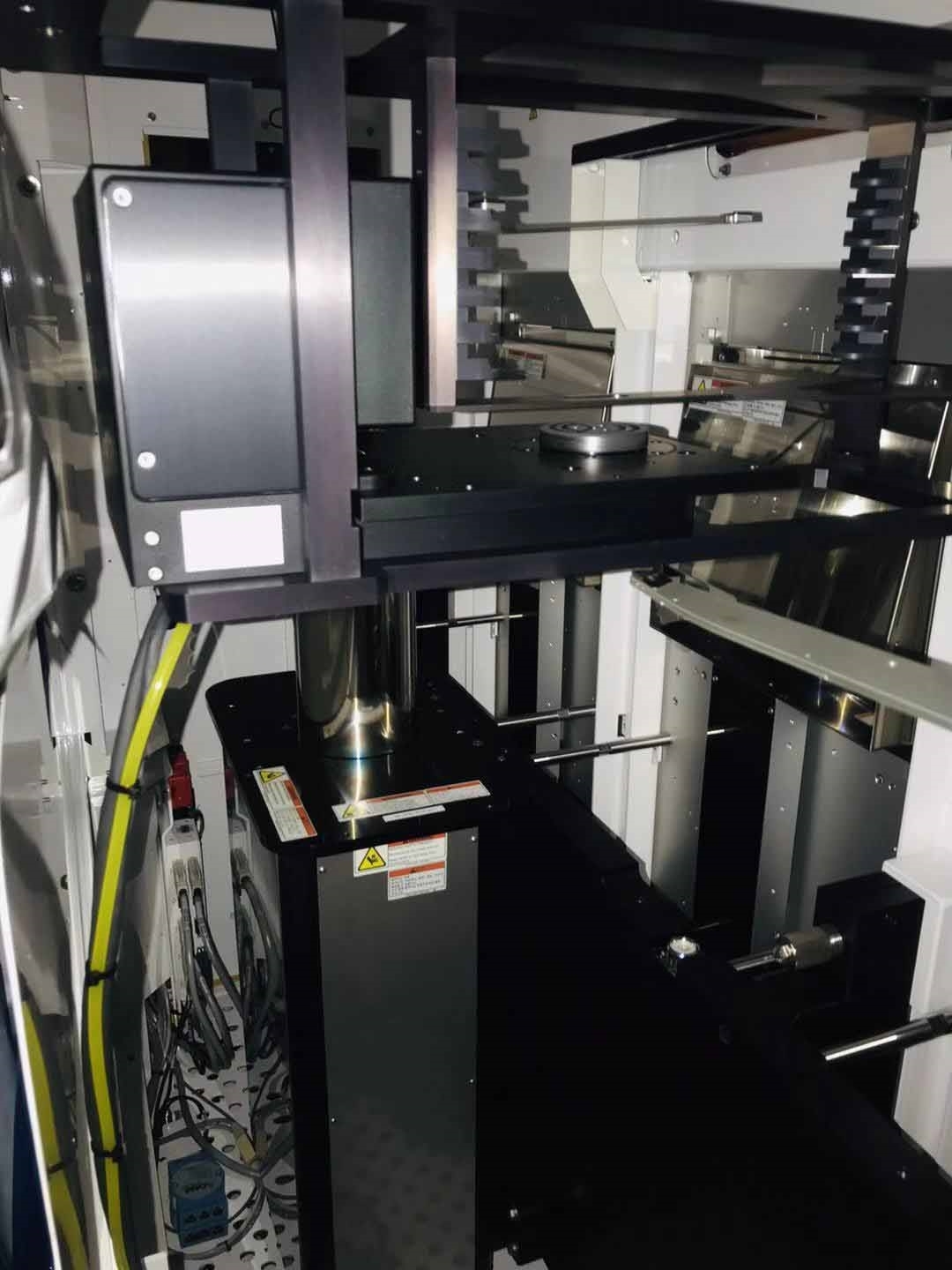

EFEM

Transfer module

AC Rack

NPP Rack

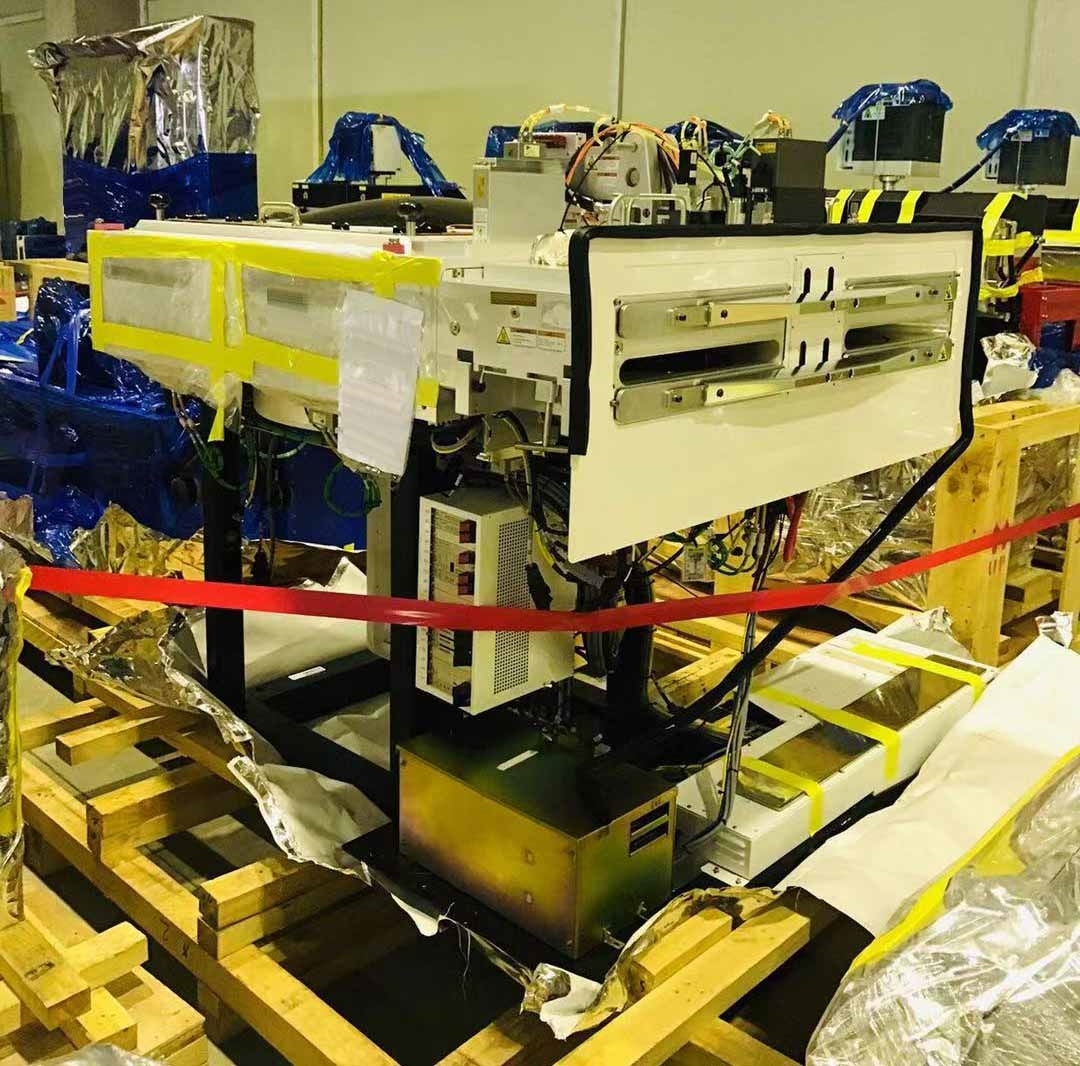

WIP Delivery type: OHT

Pre-alignment and centering: Single axis aligner

Wafer pass thru and storage: 7 Slots wafer pass thru

KAWASAKI 3NS510B Atmospheric robots

(4) Load ports

E84 Sensors and cables

OMRON With RF

Light curtain

Carrier ID host interface

Light towers

UPS Interface

Chamber process: HARP USG

Process chamber type:

Chamber A, B and C Twin: HT-ACL

Local center finder

Robot blade and type: FX Dual deck ceramic

Chamber A, B and C:

Frequency: Single

APEX 3000 RF Generator

Heater: HA12 Dual zone heater

Single source with RF cap

Manometer: 10 / 100 Torr / 70 Trip

Clean type (RPS): Single (NPR804L)

No NDTR endpoint

No DPA

Foreline, 2"

ISO: MKS 99D0654

TV: MKS 683B-26033

Monitors:

Stand alone

TTW With keyboard

Gas delivery - APF GP:

MFC:

UNIT 125

GF 125

No regulated gas panel

Gas feed: Bottom

Gas panel cabinet exhaust: Bottom exhaust

No interlock indicator

No transducers

No display gas pallet

No liquid source

Gas pallet configuration:

Chamber A:

Gas / Size / Model

AR / 4000 / Unit 125

O2 / 15000 / Unit 125

C3H6 / 3000 / GF 125

HE / 5000 / Unit 125

N2 / 10000 / Unit 125

C3H6 / 3000 / Unit 125

O2 / 10000 / Unit 125

AR / 10000 / Unit 125

NF3 / 5000 / Unit 125

Chamber B and C:

Gas / Size / Model

AR / 4000 / Unit 125

O2 / 15000 / Unit 125

C3H6 / 3000 / Unit 125

HE / 5000 / Unit 125

N2 / 10000 / Unit 125

C3H6 / 3000 / Unit 125

O2 / 10000 / Unit 125

AR / 10000 / Unit 125

NF3 / 5000 / Unit 125

Missing parts:

A1 RF Signal cable

L/L EUROTHERM controller

(2) PIRANI Gauges

Chamber C: (2) Heaters

(2) L/L Lift LM guides

Upper L/L foreline

(3) Chamber AC box kits

Mainframe box

Driver box kit

Power supply: 208 V, 50/60 Hz

2006 vintage.

AMAT(應用材料)AMAT/APPLIED MATERIALS PRODUCER GT是一種高溫化學氣相沈積(CVD)反應器,旨在滿足半導體工業的需求。該反應器可實現氧化、氮化和碳化等多種過程。AMAT Producer GT提供單一晶片配置或批處理配置,旨在實現長期穩定性和可靠性。反應堆采用經過驗證的強制流動氣體輸送設備,能夠在反應堆室內產生均勻的溫度和濃度分布。這確保了一致的薄膜質量和非常均勻的摻雜輪廓。該反應堆配有堅固的風冷加熱器和最先進的溫度控制系統,以提高工藝的均勻性。反應器中的加熱元件使用有源水套,以確保晶圓表面的溫度均勻性。這樣可以防止晶片過熱並確保更均勻的沈積。反應堆由不銹鋼構成,設有真空室、分批板、氣體輸送單元和感應發生器。該反應器采用高容量渦旋泵進行高真空和快速控制,循環壓力水平。腔室用石英或石墨絕緣,以減少熱負荷損失。應用材料生產商GT利用高容量、低功率射頻發電機和射頻輸電機進行可靠可靠的等離子體發電。溫度控制工具的精度和精確度很高,能夠在很大的流量、溫度和壓力範圍內實現高質量、均勻的沈積速率。該反應堆包括各種材料和應用的廣泛工藝配方,以及對流動路線和閥門選擇的定制。它還提供了一個可選的配方庫和計算機控制包,用於操作多個反應堆的套件。綜上所述,Producer GT是一種高度可靠和高效的CVD反應器,旨在提供一致的薄膜質量和均勻的摻雜輪廓。其堅固的風冷加熱器和優越的溫度控制資產確保了均勻的薄膜性能和性能,而其廣泛的工藝配方使其能夠用於通用應用。

還沒有評論