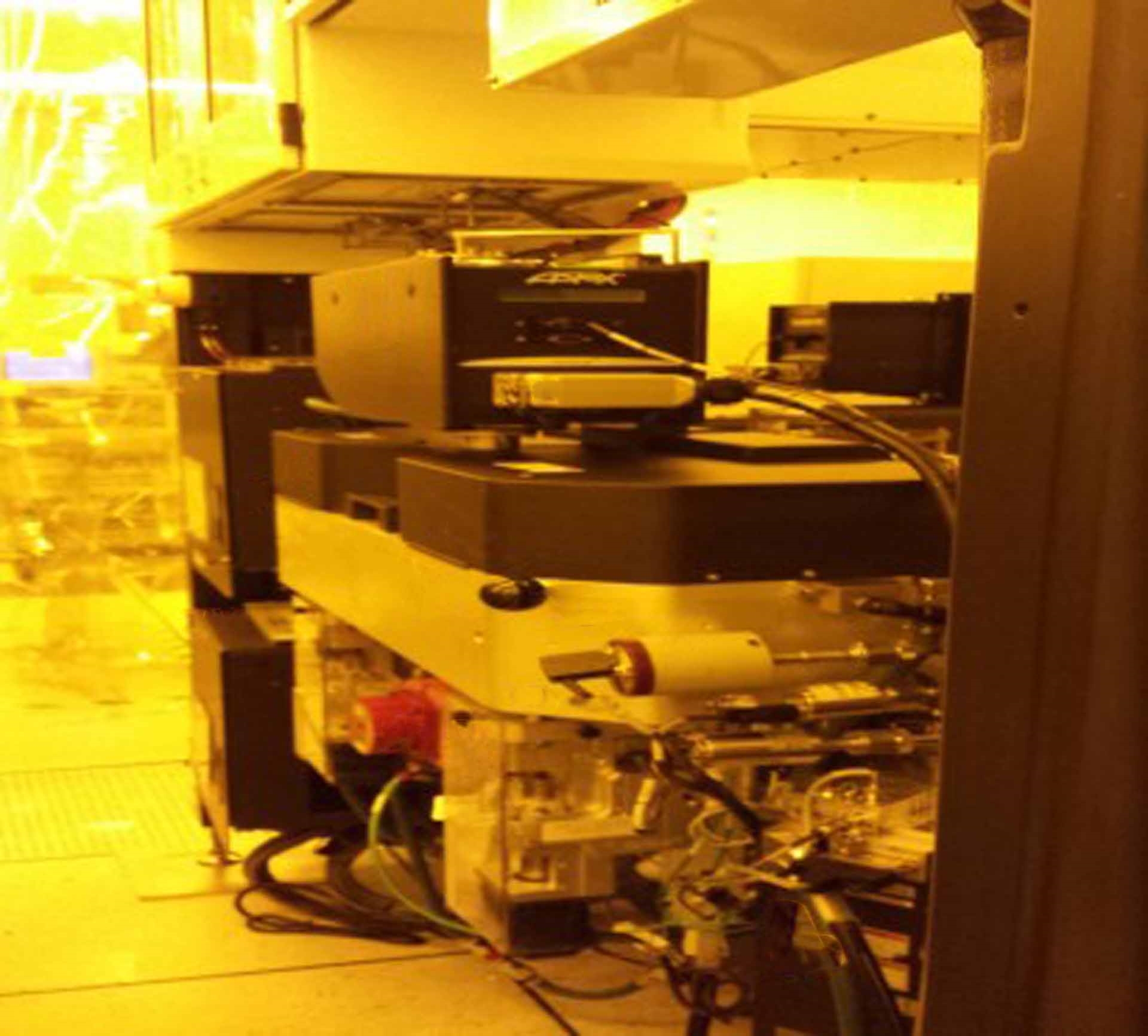

二手 AMAT / APPLIED MATERIALS Producer III #9223648 待售

網址複製成功!

單擊可縮放

ID: 9223648

晶圓大小: 8"

優質的: 2004

Shrink system, 8"

Process: SILCU

CIM

(3) Twin chambers

Hardware configuration:

SMIF: (4) ASSYST Indexers

Handler system:

SMIF Front end robot

VHP Buffer robot

(3) Process chambers

Heat exchanger: Steelhead

High RF generator: (4) RFG 2000-2V

DPA RF Generator: ENI DPG-10

Platform type: Producer shrink

Chamber A & B & C:

Chamber body effective volume (Syscon):

Chamber A: 12980

Chamber B: 13275

Chamber C: 13300

SiH4_H: 1 SLM

SiH4-L: 300 Sccm

NH3 HI: 1 SLM

N2O HI: 3 SLM

N2O LO: 500 Sccm

N2: 10 SLM

NH3: 500 Sccm

Ar: 5 SLM

He: 10 SLM

Number of gas lines / Name: 10

RF1 & RF2 Generator (Max Power / Brand): 2000 W

Foreline pump (EBARA AAS 100WN): 10000 L/Min

Baratron off-set 626 MKS: 10 T

Lift pin type: Free drop

Lift pin speed (Timing of movement): 3580

Load lock: A & B

Configuration:

Pump capacity (EDWARDS BOC): IPX 100A

Difuser: ENTEGRIS 60 PSIG

Venting N2 flow rate: 10 SLM

Venting time: 57 Sec

Pump time: 65 Sec

Baratron Range / Brand / Off-Set: 325 Moducell MKS

Pressure set point for LL pumping switching: 45 Sec

Time delay for LL door open: 10 Sec

Transfer chamber:

Type of robot / Robot blade: Super blade

Robot speed with wafer / Runrate / Slope:

300000 / 210000

230000 / 120000

Robot speed without wafer (Ext/Rot):

200000 / 325000

230000 / 325000

MFC N2 Flow setting: 10 SLM

Chamber base pressure ( Actual / Alarm): 208 mTorr

Wafer transfer - chamber: 300 mTorr

Buffer pressure transfer chamber - wafer: 320 mTorr

Other periphere:

SiH4 HI: 29.6, 30, 36

NH3 HI 27.6, 27.8, 29

CDA Pressure: 85

HX Temperature / Flow rate: 75

N2 (P): 27

SiH4 LO

NH3 LO

N2O: 30

NF3

2004 vintage.

AMAT/APPLIED MATERIALS Producer III是制造半導體晶片的先進等離子體反應器。AMAT Producer III利用電子回旋共振(ECR)源創建了一個均勻、高密度的等離子體,這對於芯片生產中沈積多晶矽柵極電介質和銅互連等薄而精確的材料層至關重要。APPLIED MATERIALS Producer III設計允許對現有系統進行最佳的過程控制。其專利晶片密閉體積和低噪聲技術在晶片的每個區域保持極均勻的沈積。生產者III也極具能源效率,功耗降低,附帶熱量開發最小。所有這些組合使得AMAT/APPLIED MATERIALS Producer III能夠改善半導體制造商的芯片生產實踐。AMAT Producer III以以前的AMAT Producers I和II為基礎,增加了幾個關鍵功能。它提供了兩個獨立的射頻電源,可以從晶圓的底部和頂部獨立控制沈積,允許超過200層的生長。它還配備了專有的UHP(Ultra High Pressure)系統,保持超均勻氣體流過晶圓,更精確地調節工藝條件。應用材料生產商III也允許高度的靈活性沈積.它可以將統一的薄膜應用於整個晶片或根據應用程序選擇區域。每個區域都有可編程的參數,可以針對各個沈積過程進行調整,允許用戶自定義設計過程。它還具有高級診斷和數據日誌記錄功能,可以對進程進行脫機分析。生產者III是一種高度先進的等離子體反應器,旨在提供最精確和可重復的沈積結果。隨著工藝控制、靈活性和能效的提高,AMAT/APPLIED MATERIALS Producer III為芯片制造工藝提供了無與倫比的支持。

還沒有評論