二手 APPLIED MATERIALS P 5000 Mark II #67130 待售

看起來這件物品已經賣了。檢查下面的類似產品或與我們聯系,我們經驗豐富的團隊將為您找到它。

單擊可縮放

已售出

ID: 67130

Metal etch system, 6"

Configuration details:

Precision 5000 Mark II MxP Etch system 6”

Mark II mainframe containing load lock chamber

Cassette to cassette wafer handling

VME system controller with hard disk and floppy disk storage

28 line compatible on-board gas panel

Bolt down load lock chamber lid and load lock purge system

Microprocessor controller including CRT display, self diagnostics, host computer interface via RS232 port SECS II protocol

Standard floppy and hard disc (170NMB) storage

Etch chambers include:

Temperature controlled pedestal

Magnet modules and cylinder lift mechanisms

Slit valve, gas distribution components

RF isolator, RF match

Capacitance manometer, throttle valve

Independent helium cooling

Integrated end point detector

Remote package including pumps, RF power supplies, heat exchanger, NESLAB recirculator, main AC box and other facilities

Fifty foot remote package cable length

Features:

(2) metal etch chambers and one strip chamber system

Chamber A: 6” clamped metal etch process kit

Chamber B: 6” clamped metal etch process kit

Chamber C & D: 6” advanced strip and passivation chamber

Including 1200 Watt generator process kit, hardware gas distribution plate and MFC controller gas line per chamber

6” metal etch process kit with:

AL etch ceramic fingered basic kit 0240-31587E

0.95” fingered ceramic focus ring 0240-09757E

Tapered head SiC DC Pick-ups 0240-31359

Unilid gas distribution plate - 119holes 0020-32259

6” advanced strip and passivation chamber process kit basket style wafer support

Gas panel A&B: BCL3, Cl2, CF4, N2, SF6 / C: O2, N2, H2O

Through the wall system

Heat Exchanger AMAT 1 and Heat Exchanger AMAT0

(1) NESLAB HX150 is missing

(1) etch chamber is leaking glycol (can be repaired but it is better to change the body chamber)

Second chamber has been repaired for the same problem

Machine was in production until Q3 2009

Currently installed in fab

Gases are purged and the machine is powered off

Can be inspected and powered on to see software only

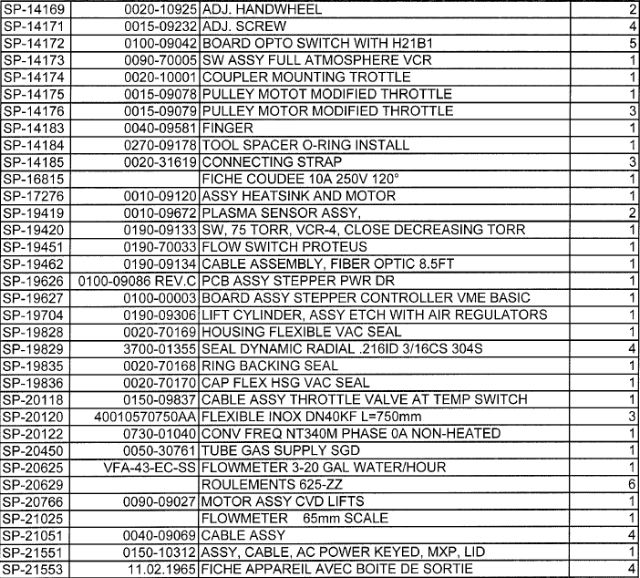

Spare parts available, list is shown in photos

1998 vintage.

APPLICED MATERIALS P 5000 Mark II是為多種材料的多級沈積過程而設計的高性能可配置並行處理反應器。它是市場上最先進的沈積設備,提供無與倫比的工藝靈活性和監控能力。APPLICED MATERIALS P5000 MARK II是一個大容量的生產過程反應堆,可容納5.5 x 4.0米大小的腔室,給它最多20個同時的腔室,總吞吐量超過8,400晶圓每小時。它能夠精確處理從75毫米到300毫米的各種晶圓尺寸,並且能夠在單個反應堆室內進行各種現場診斷、質量保證測試和電氣特性鑒定。該系統提供了業界領先的過程控制和一致性級別,具有自動劑量控制、腔室循環、結果報告、參數優化以及故障檢測和預防等功能。P 5000-MARK II還具有先進的可更換基座,專為快速過程維護和更換工具而設計。其晶片盒和高性能氣體輸送裝置確保了一致的過程重復性和均勻性。一個集成了多個真空泵和排氣口的真空機提供可靠的操作和盡量減少任何過程泄漏。APPLICED MATERIALS P 5000 MARK II是專為制造先進半導體材料而設計的,包括碳化矽、氮化氙、二乙烯化散銅的。它能夠執行一系列沈積過程,包括徑向等離子體、濺射、光照和原子層沈積(ALD)。其HMI軟件提供所有腔室參數的圖形監測和趨勢分析,以及全噴霧分析和優化。P 5000 MARK II是可靠、高通量、精度和靈活性最高的工藝反應堆的完美選擇。憑借其先進而集成的HMI,它為滿足最嚴格的生產要求提供了經濟高效的解決方案。其可靠、一致和自動化的流程重復性確保了最高的產量、質量和吞吐量。

還沒有評論