二手 MATTSON EpiPro 3000 #9003702 待售

網址複製成功!

單擊可縮放

ID: 9003702

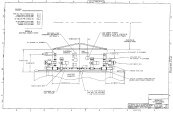

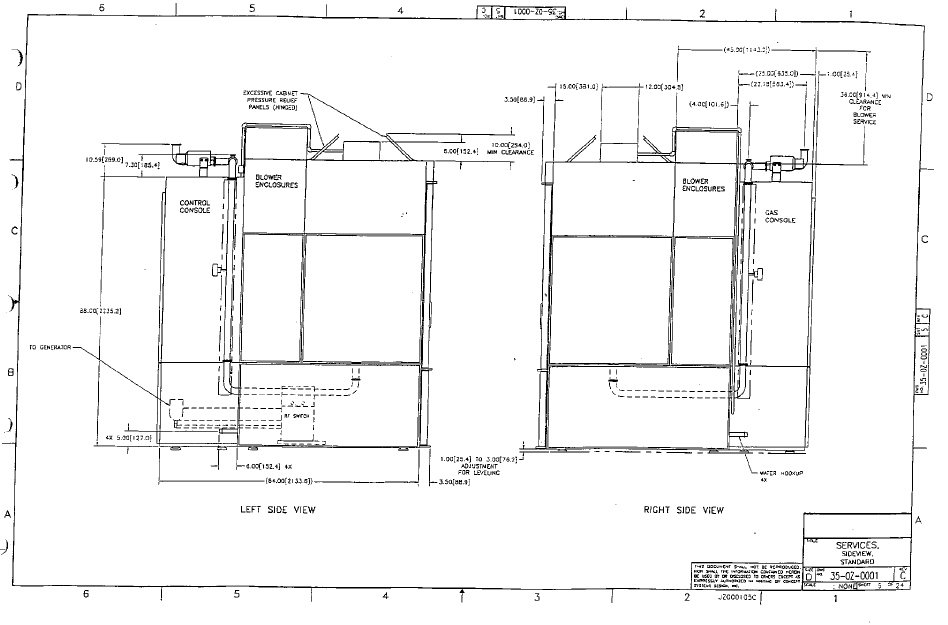

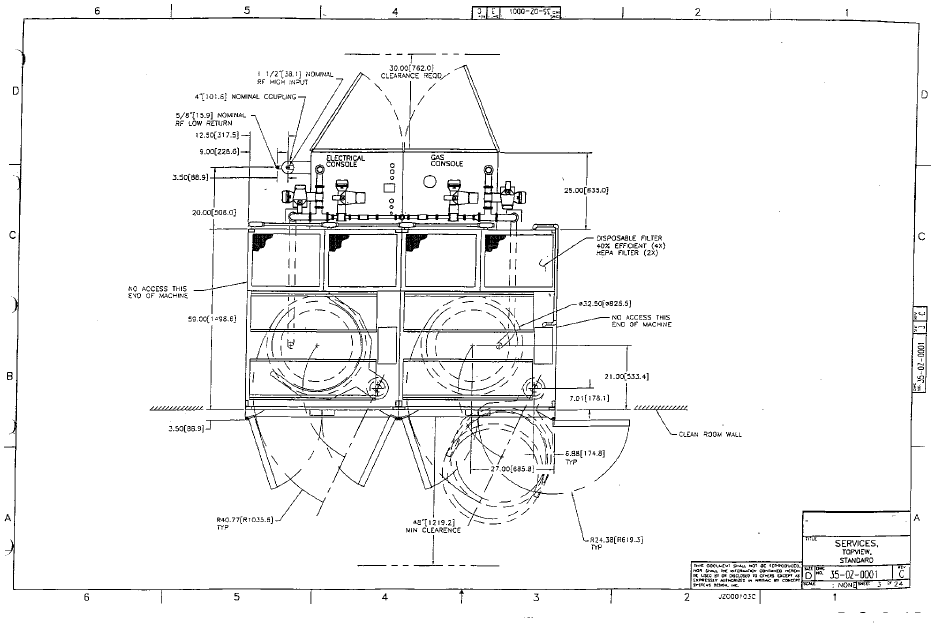

Reactors

Dual station

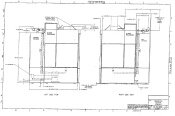

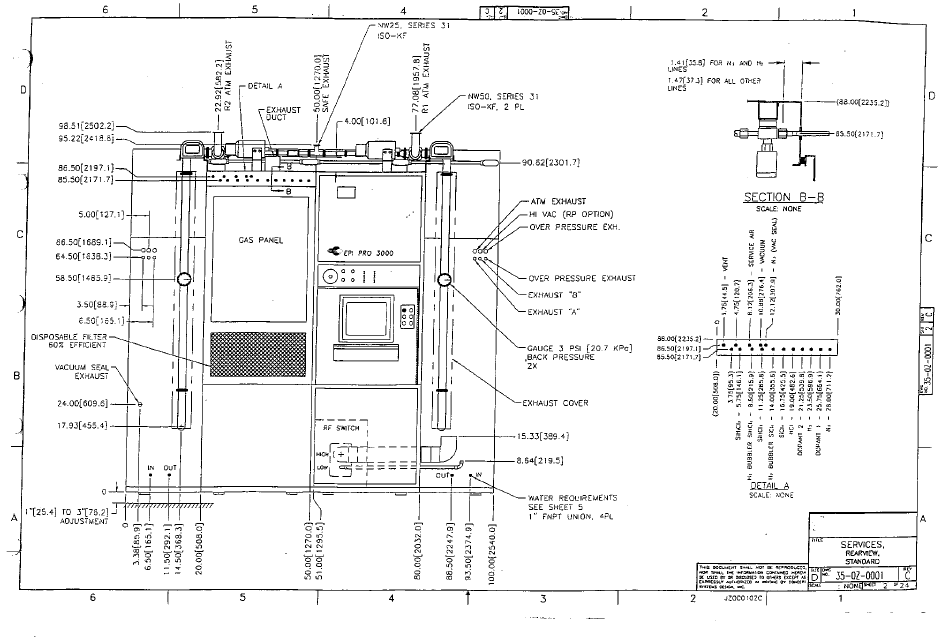

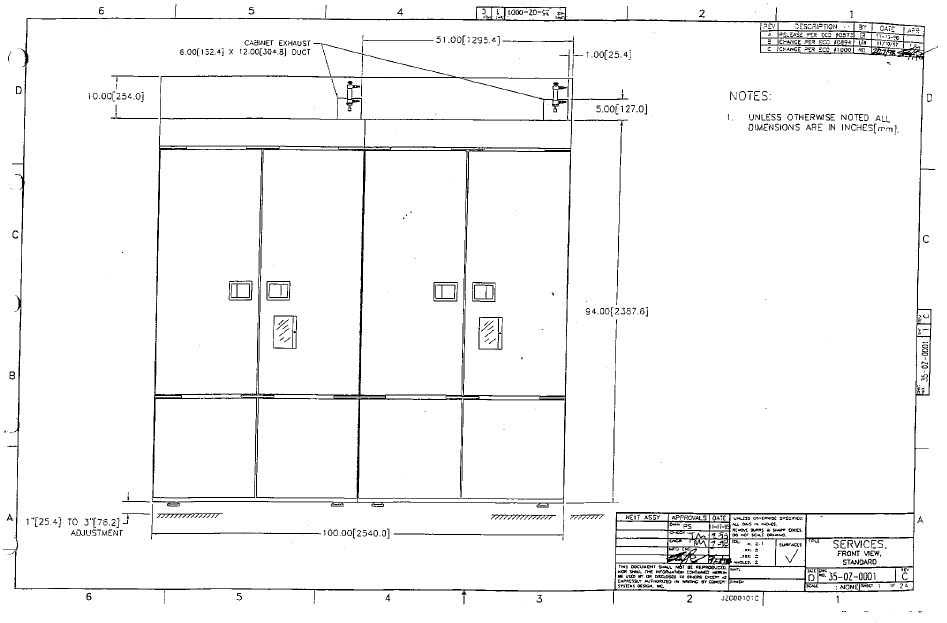

Chamber: 94" x 50" x 62"

R2 Reactor chamber: 94" x 50" x 62"

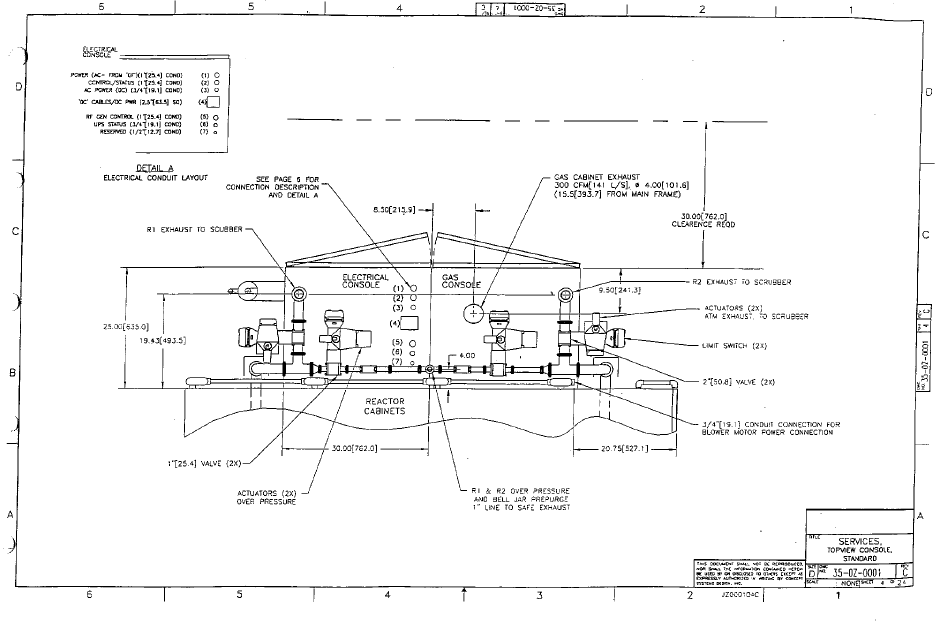

Electrical console

AC Power module

Remote interface module

UPS Module

Pillar vacuum tube oscillator RF generators, 125 kW

Generator pump module: (Pillar only)

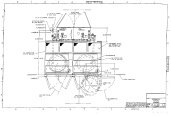

(2) Bell jars

RF Coils assy and quartz

Heat exchanger: Water to water

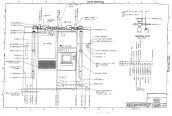

Gas inlet requirements:

Gas / Inlet pressure / Tubing diameter x wall thickness

N2 / 50-100 PSIG (1) / 3/8" x 0.035"

H2 / 50-80 PSIG (2) / 3/8" x 0.035"

HCL / 15 PSIG Regulated (3) / 1/4" x 0.035"

Dopants / 35 PSIG Regulated / 1/4" x 0.035"

SiCl4 / 20 PSIG Regulated / 3/8" x 0.035"

SiHCl3 / 20 PSIG Regulated / 3/8" x 0.035"

SiH2Cl2 / 7 PSIG Minimum / 3/8" x 0.035"

Pneumatic Air/N2 / 90-100 PSIG Regulated / 3/8" x 0.035"

N2 (Vacuum seal) / 80-100 PSIG (3) / 1/4" x 0.035"(1)

Gas purity:

H2: Greater than 99.95% minimum assay

Oxygen content must be less than 2 ppm

Water content must be less than 2 ppm

HCl: Greater than 99.99% (semiconductor grade)

Silicon sources – Greater than 100 ohm/cm intrinsic

Dopants: Greater than 99.99% H2 free basis

Maximum gas flows and volumes:

System / H2 / N2 / H2 / N2

Mainstream / 300 / 70 (2) / 300 / 70

High flow bypass (Fixed) / 200 / 100 (1) / 200 / 100 (1)

SiCl4 / SiHCl3 Carrier / 30 / - / - / -

Dopants dilution / 30 / - / - / -

RF Coil / Lower reactor purges / 30 / 10 / 30 / 10

Gas panel purges (Fixed) / 12 / 4 / - / -

Rotation purges (Fixed) / 10 / 2 / 10 / 2

Total N2/H2 flows / 612 / 186 / 540 / 182 (1) N2 flow rate during pre-post purge

Quartz cleaning facility:

Pedestal / 30-0R-281 / 4 1/2" diameter x 12" long

Support rod / 30-0R-139 / 1" diameter x 5" long

Coil cover / 30-0Z-000 / 25" diameter x 2" thick

Insulator, high Side / 30-0Z-857 / 3" diameter x 6" long

Insulator, bottom / 30-0Z-766 / 4 1/2" diameter x 1/4" thick

Insulator, top / 30-0Z-791 / 4 1/2" diameter x 1/4" thick

Insulator, high side / 30-0Z-793 / 5" x 4"

Insulator, middle / 30-0Z-794 / 5" x 4"

Inject tube / 30-0Z-758 / 1/2" diameter x 11" long

Tube cover / 30-0Z-1037 / 1/2" diameter x 9" long

Rod, fiber optic / 30-0Z-1037 / 1/4" diameter x 13"

Power requirements:

RF Generator: 480 VAC, 400 A, 3-Phase, +GND

Water system: 480 VAC, 30 A, 3-Phase, +GND

Electrical service: 10 KVA at 200-240 VAC, 50 amps, 50/60 Hz, single phase, 3 wire (6 ga) plus ground.

MATTSON EpiPro 3000是為大面積外延和沈積而設計的先進半導體沈積反應器。該反應堆提供可靠的生產,降低擁有成本。它具有高達500毫米晶圓的高溫和高精度操作功能,可提供可重復的工藝一致性,同時大大降低了擁有成本。EpiPro 3000利用先進的設計和功能來確保每個半導體沈積過程的可重復性和準確性。它具有低振動無碰撞氣源,允許真正統一的處理結果。晶片級由超精確的運動控制設備驅動,提供最大的穩定性和可重復性。通過采用高效金屬陶瓷包覆絕緣材料,優化了該反應堆的高溫運行。專利封閉式電極驅動系統消除了振動和漂移補償的需要,確保了精確的電極正時和最大的穩定性。MATTSON EpiPro 3000提供了多種性能增強功能,如可編程配方管理、現場分析和監控以及分布式聯網。這些功能為用戶提供了對每個沈積過程更大的控制和更高的準確性。反應堆的用戶友好性因其集成控制單元而得到進一步增強,該單元需要最少的操作員幹預。此外,EpiPro 3000還提供了一整套環保功能,例如氣體清除和洗滌器。這確保了反應堆符合區域安全標準。該反應堆的建造考慮到安全性和可靠性,並配備了有效的預防性維護機器,以最大限度地提高運行時間和過程穩定性。MATTSON EpiPro 3000是一種先進、高性能的沈積反應器,具有卓越的工藝重復性和準確性。其低擁有成本和用戶友好的設計使其成為涉及大面積半導體沈積工藝的廣泛應用的理想選擇。

還沒有評論