二手 NOVELLUS CONCEPT 2 Dual Sequel #9092631 待售

網址複製成功!

單擊可縮放

ID: 9092631

晶圓大小: 6"

CVD system, 6"

Software: C2.SEQ_4.92B15

Operating system: QNX4

SECS GEM: Yes

Free cable length: 75 Ft

RF Cable length: 84 Ft

Indexer firmware: 2.0_G

Transfer robot: Brooks Mag 7

Chamber location: Left

Chamber model: C2-CVDD-S SEQX

EPD: Verity dual wavelength

Shower head: Al 6061 8" 16-033931-00

Handling wafer size: 6"

Heater block: No slot Sequel STN 1 pin 19-00154-04

Spindle speed: Standard

Fork assembly: Ceramic anti-deflect

15-101482-00

15-101482-01

15-00700-00

Fork type: Min Contact

15-053394-02

Spindle feed through: Ferro fluidic

Primary process gauge: 10T

Gate & throttle valve: Heated / Internal

02-260348-00

16210-0403QS-002HJR

MFC Type: Brooks GF100

IOC Software version: 4.2

RF Switching option: Yes

RPC (Remote plasma clean): No

HF RF Generator: AE Apex 5513

LF RF Generator: AE PDX 1400

RF Match AE mercury: 3013

Foreline heated: No

2.0 MFC C Open

MFC B N2 (10000 sccm)

MFC A N2O (20000 sccm)

MFC 9 NF3 (5000 sccm)

MFC 8 O2 (20000 sccm)

MFC 7 Open

MFC 6 NH3 (10000 sccm)

MFC 5 Open

MFC 4 Open

MFC 3 Open

MFC 2 N2 (5000 sccm)

MFC 1 SiH4 (1000 sccm)

Chamber location: Rear

Chamber model: C2-CVDD-S SEQX

EPD: Verity dual wavelength

Shower head: Al 6061 8" 16-033931-00

Handling wafer size: 6"

Heater block: No slot Sequel STN 1 pin 19-00154-04

Spindle speed: Standard

Fork assembly: Ceramic anti-deflect

15-101482-00

15-101482-01

15-00700-00

Fork type: Min Contact

15-053394-02

Spindle feed through: Ferro fluidic

Primary process gauge: 10T

Gate & throttle valve: Heated / Internal

02-260348-00

16210-0403QS-002HJR

MFC Type: Brooks GF100

IOC Software version: 4.2

RF Switching option: Yes

RPC (Remote plasma clean): No

HF RF Generator: AE Apex 5513

LF RF Generator: AE PDX 1400

RF Match AE mercury: 3013

Foreline heated: No

2.0 MFC C Open

MFC B N2 (10000 sccm)

MFC A N2O (20000 sccm)

MFC 9 NF3 (5000 sccm)

MFC 8 O2 (20000 sccm)

MFC 7 Open

MFC 6 NH3 (10000 sccm)

MFC 5 Open

MFC 4 Open

MFC 3 Open

MFC 2 N2 (5000 sccm)

MFC 1 SiH4 (1000 sccm)

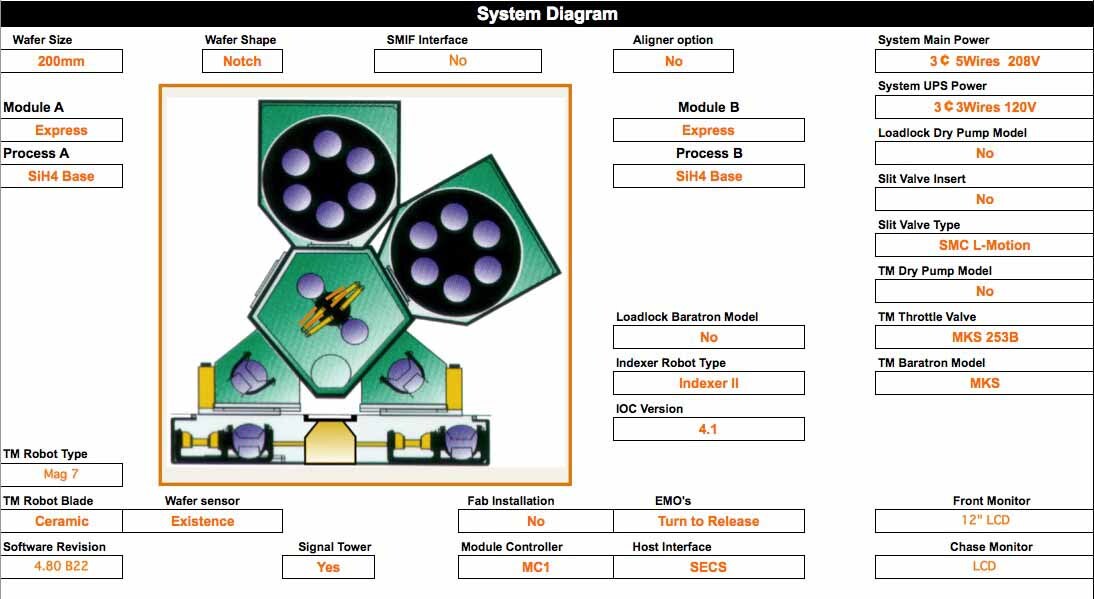

System main power: 3ϕ 5Wires 208V

System UPS power: 3ϕ 3Wires 120V

SMIF Interface: No

Aligner option: No

Loadlock dry pump model: No

Slit valve insert: No

Slit valve type: SMC L-Motion

TM Dry pump model: No

TM Throttle valve: MKS 253B

TM BARATRON model: MKS

Front monitor: 12" LCD

Chase monitor : LCD

Loadlock BARATRON model: No

Indexer robot type: Indexer II

IOC Version: 4.1

TM Robot type: Mag 7

TM Robot blade: Ceramic

Software revision: 4.80 B22

Signal tower: Yes

Module controller: MC1

Host interface: SECS

Module A: Express

Process A: SiH4 Base

Module B: Express

Process B: SiH4 Base

System and DLCM:

MC1 (P166 64M) System

DLCM Module controller

MSSD (2 Sequel configuration) power rack

Upgrade 4 cool station

SiH4 Base oxide process

Signal cables

RF Coaxial cables

MKS 253B throttle valve

651D Throttle valve controller

MAG 7 Transfer robot

Dual arm

Indexer robot

Animatics controller

Standard shuttle assy

Chase PC and table

Generator rack

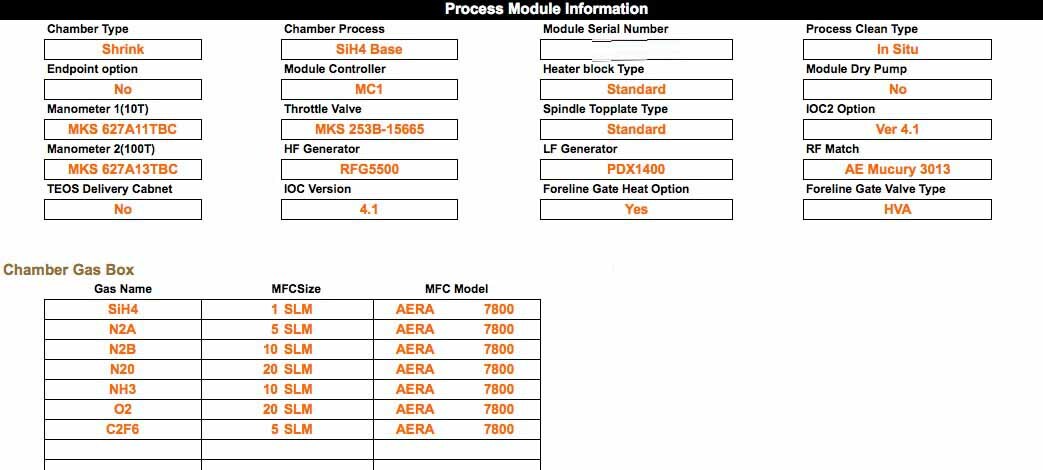

Process module:

Chamber type: Shrink

Chamber process: SiH4 base

Process clean type: In Situ

Endpoint option: No

Module controller: MC1

Heater block type: Standard

Module dry pump: No

Manometer 1(10T): MKS 627A11TBC

Throttle valve: MKS 253B-15665

Spindle topplate type: Standard

IOC2 option: Ver 4.1

Manometer 2(100T): MKS 627A13TBC

HF Generator: RFG5500

LF Generator: PDX1400

RF Match: AE Mercury 3013

TEOS Delivery cabinet: No

IOC Version: 4.1

Foreline gate heat option: Yes

Foreline gate valve type: HVA

Chamber gas box:

Gas name MFC Size MFC Model

SiH4 1 SLM AERA 7800

N2A 5 SLM AERA 7800

N2B 10 SLM AERA 7800

N20 20 SLM AERA 7800

NH3 10 SLM AERA 7800

O2 20 SLM AERA 7800

C2F6 5 SLM AERA 7800

Module A :

Gas filters

Gas box

HF and LF RF Generators

RF Matching network

Lower spindle assy

Ferrofluidic spindle Assy

Bottom and top plates

10Torr and 1000Torr manometer

Heated type HVA gate and MKS throttle valves

Throttle valve controller

Upgrade MC1 (P166 64M) module controller

Ceramic type spindle fork assy

O-Rings

Metal parts in chamber

Watlow temp controller

Window shappire

Heater ISO box

TC gauge

MFC's

Heater block (OPM)

Shower head

RF and heater feedthru

2000-2001 vintage.

NOVELLUS CONCEPT 2 Dual Sequel是由等離子體化學氣相沈積(CVD)系統的領先供應商NOVELLUS Systems, Inc.設計制造的反應堆。該反應堆用於制造亞微米和超微米尺寸的半導體器件,非常適合大批量生產這些部件。該反應堆包括獨特的雙室設計,利用兩個獨立的腔室將材料沈積到基板上。Dual Sequel反應堆利用高達10 Torr的腔室壓力進行沈積過程,範圍從很低到很高的薄膜厚度。它還包括一個用於不斷監測沈積過程的探測器單元。為了保持整個晶片的熱均勻性,反應堆包括晶片冷卻功能,旨在減少因壁溫度變化而產生的有害影響。此外,此功能還有助於消除過程中的雜質。Dual Sequel反應堆配有獨特的互鎖設備,通過共享真空線將工藝室相互連接。這種互鎖確保兩個會議廳協同工作,從而提供可靠和一致的性能。互鎖還有助於調節整個系統的壓力,使腔室壓力保持在預期範圍內。其他特點包括高效氣體輸送裝置,有助於盡量減少加工氣體的使用。機器還以特殊的「半開」模式運行,可以通過同時執行一系列過程來加快進程。此外,Dual Sequel也因為像緊急泵工具和安全聯鎖一樣具有先進的安全特性而提供了更高的安全級別。總體而言,CONCEPT 2 Dual Sequel反應堆是一種先進、高通量、可靠的CVD工具,非常適合大批量生產小型半導體元件。其獨特的雙室設計提供了更高水平的沈積和溫度控制,而它的互鎖資產允許一個更加統一和高效的過程。它還擁有一系列旨在提高安全性、最大限度地減少工藝氣體和提高吞吐量的功能。

還沒有評論