二手 VEECO / EMCORE D125 #9212026 待售

網址複製成功!

單擊可縮放

ID: 9212026

優質的: 2003

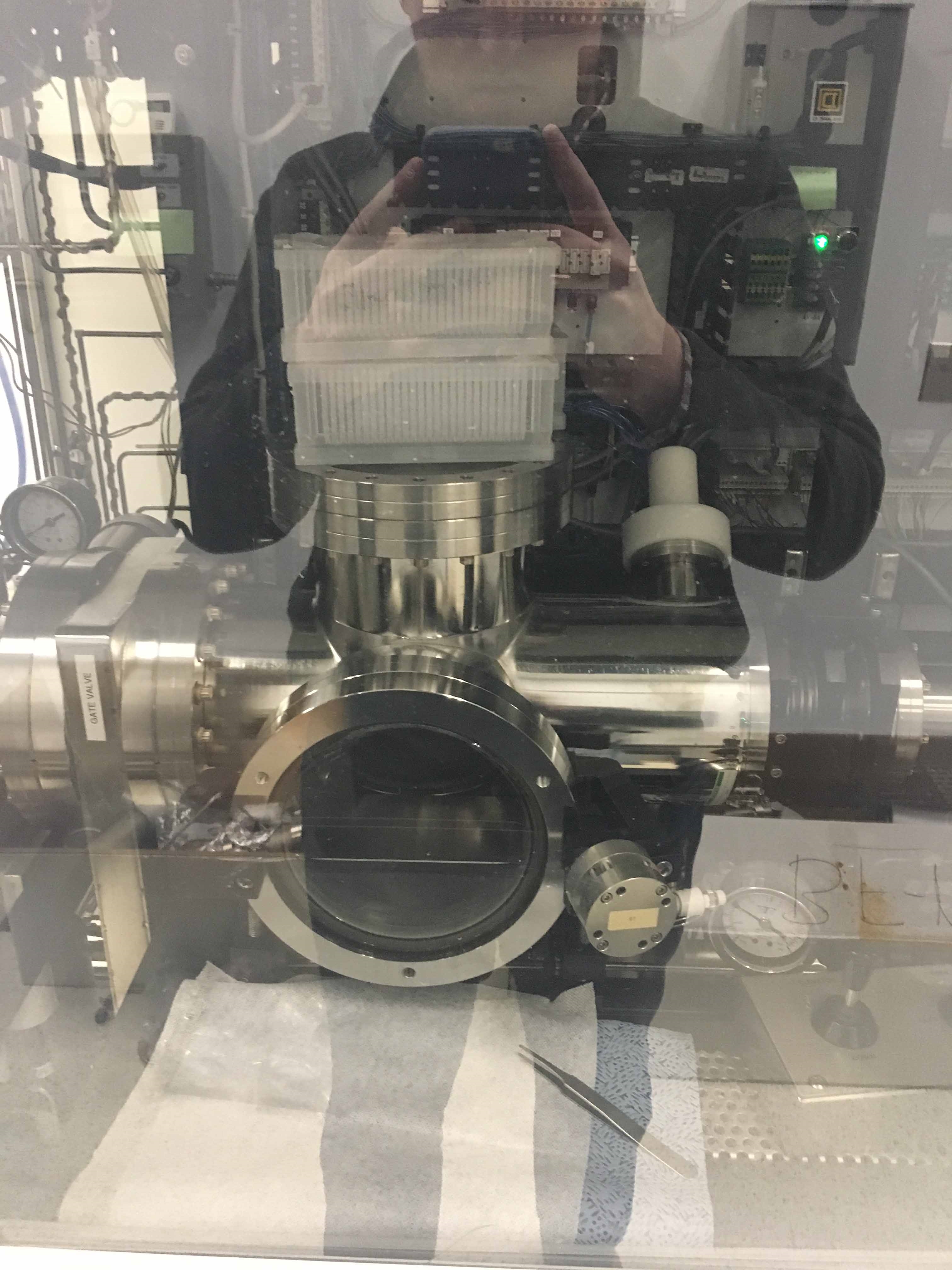

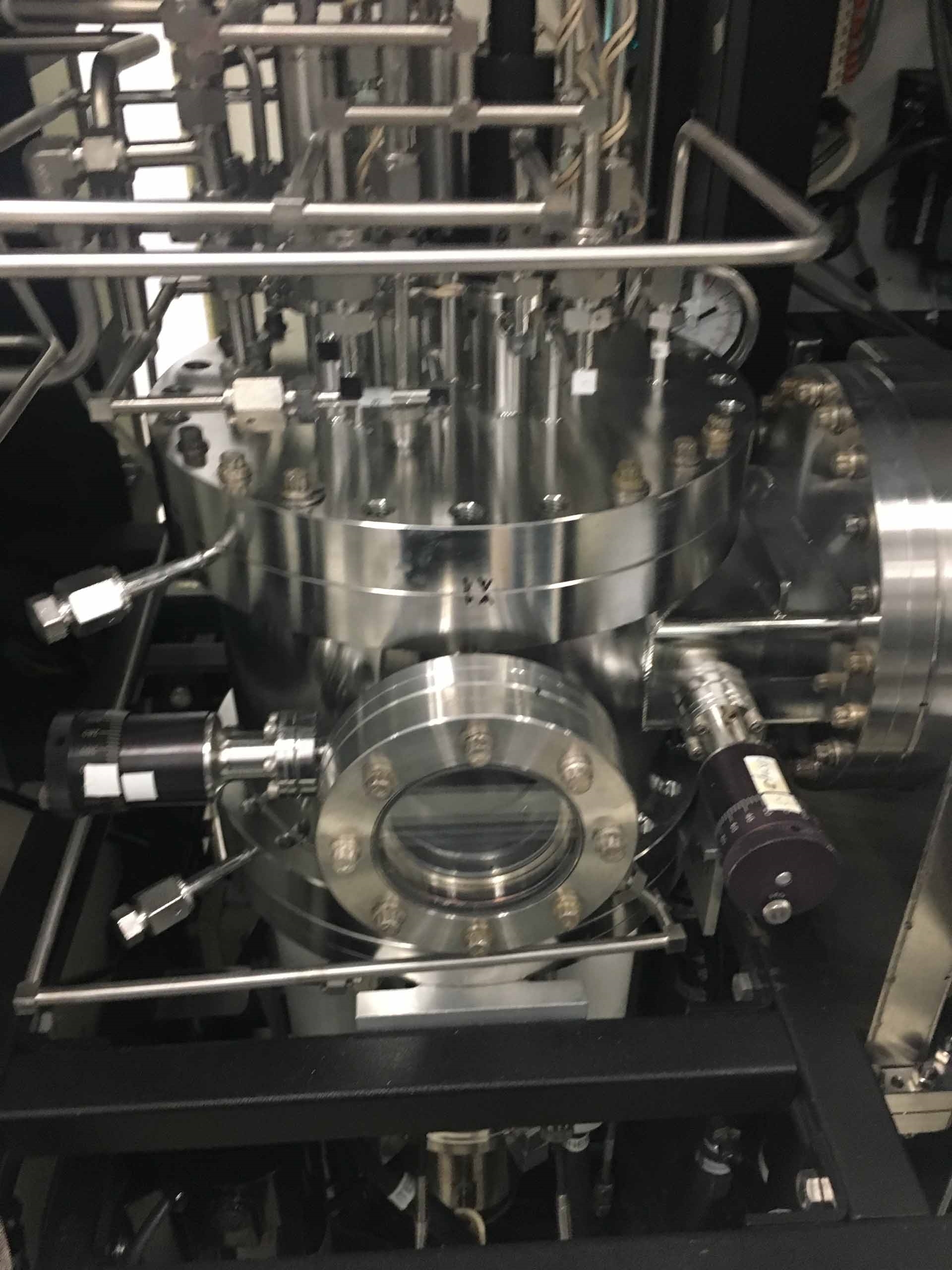

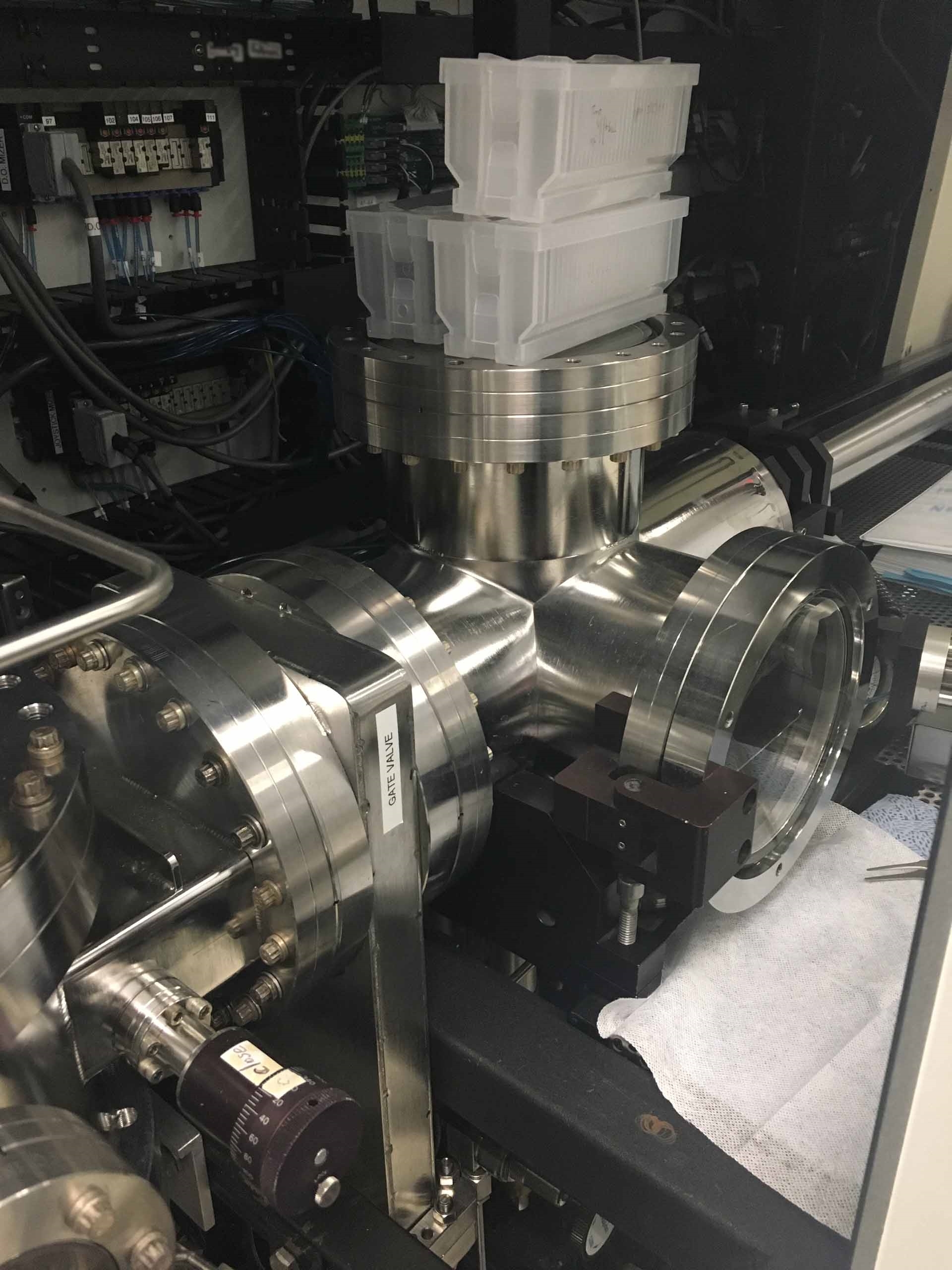

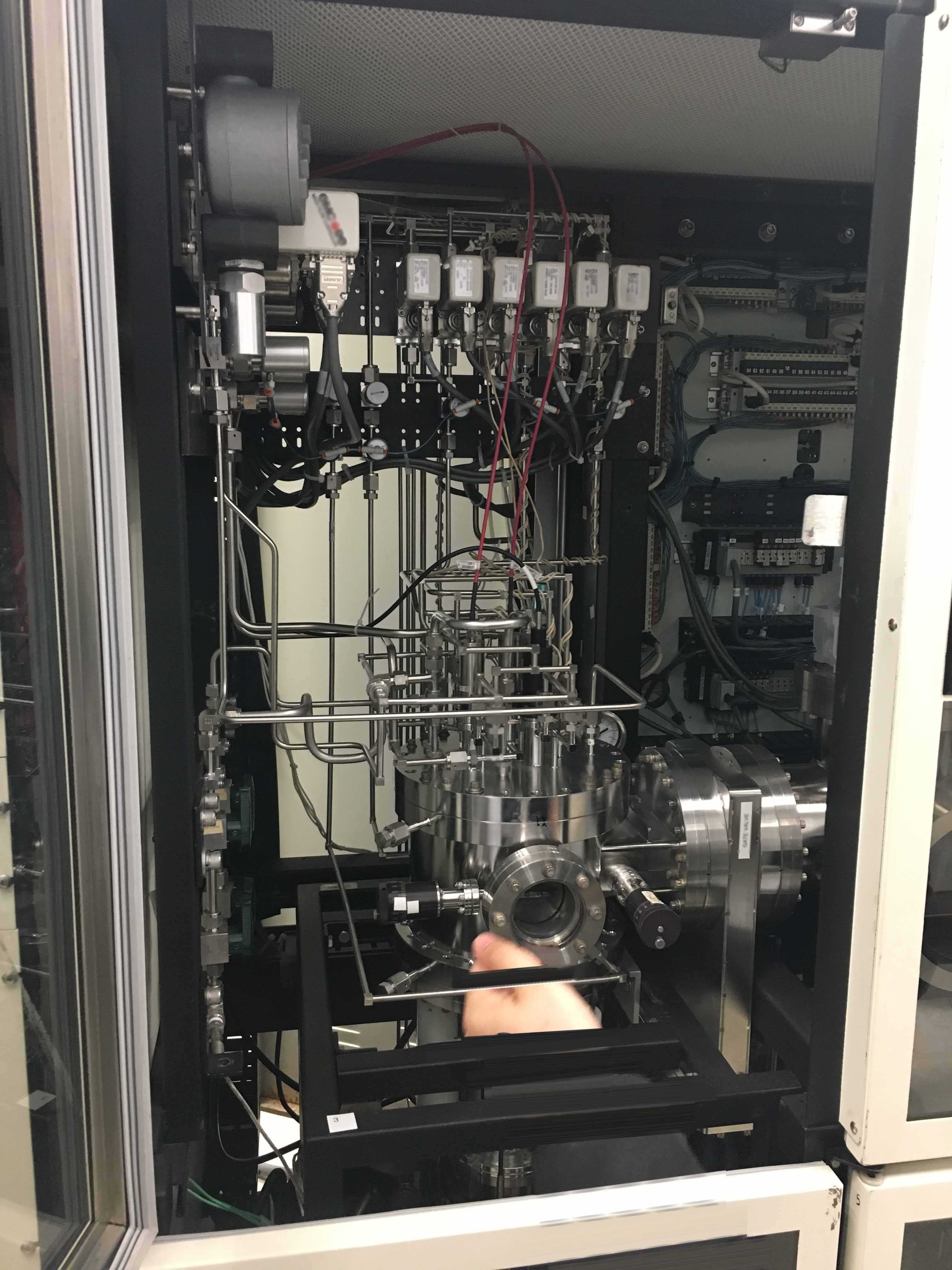

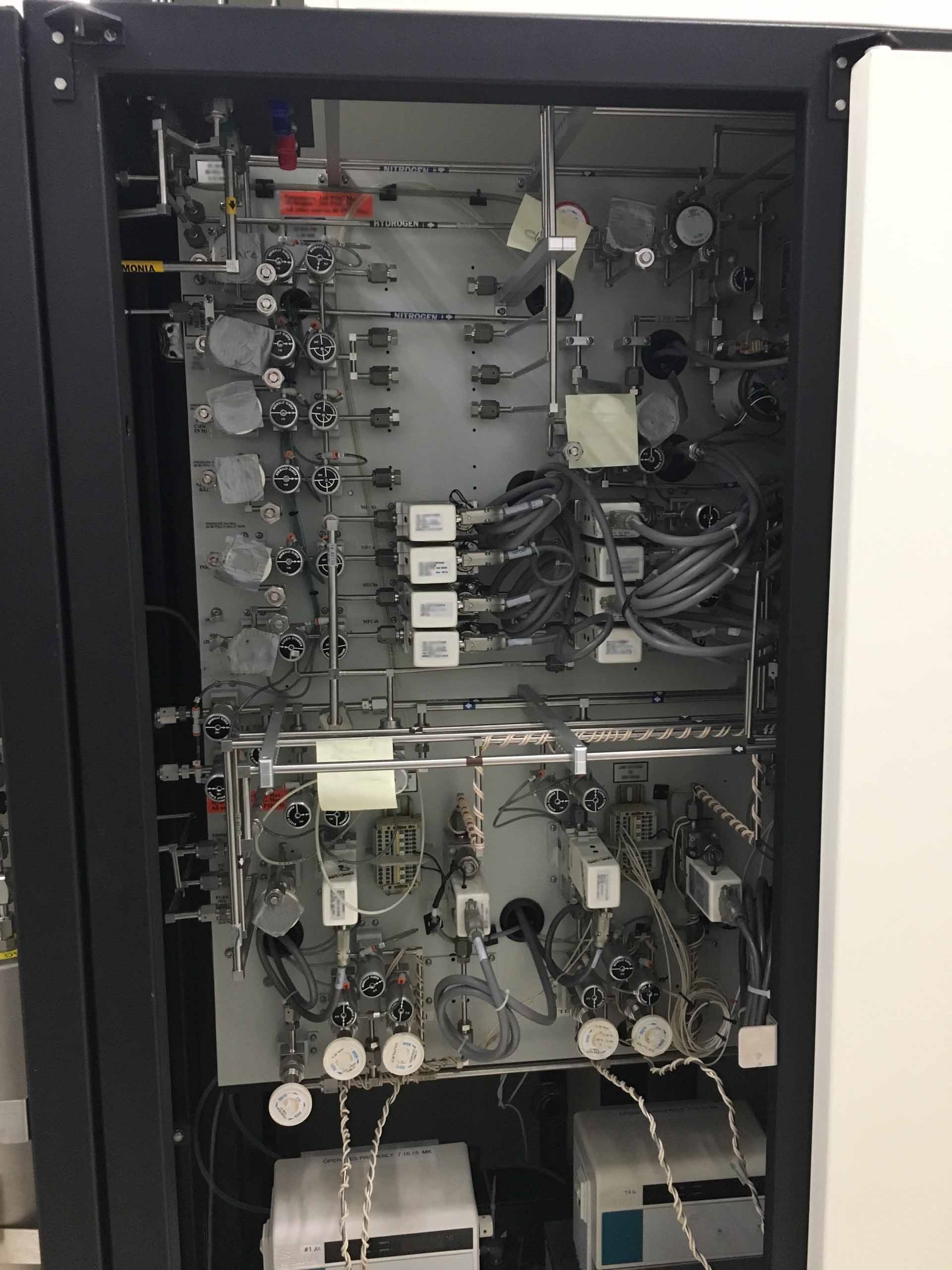

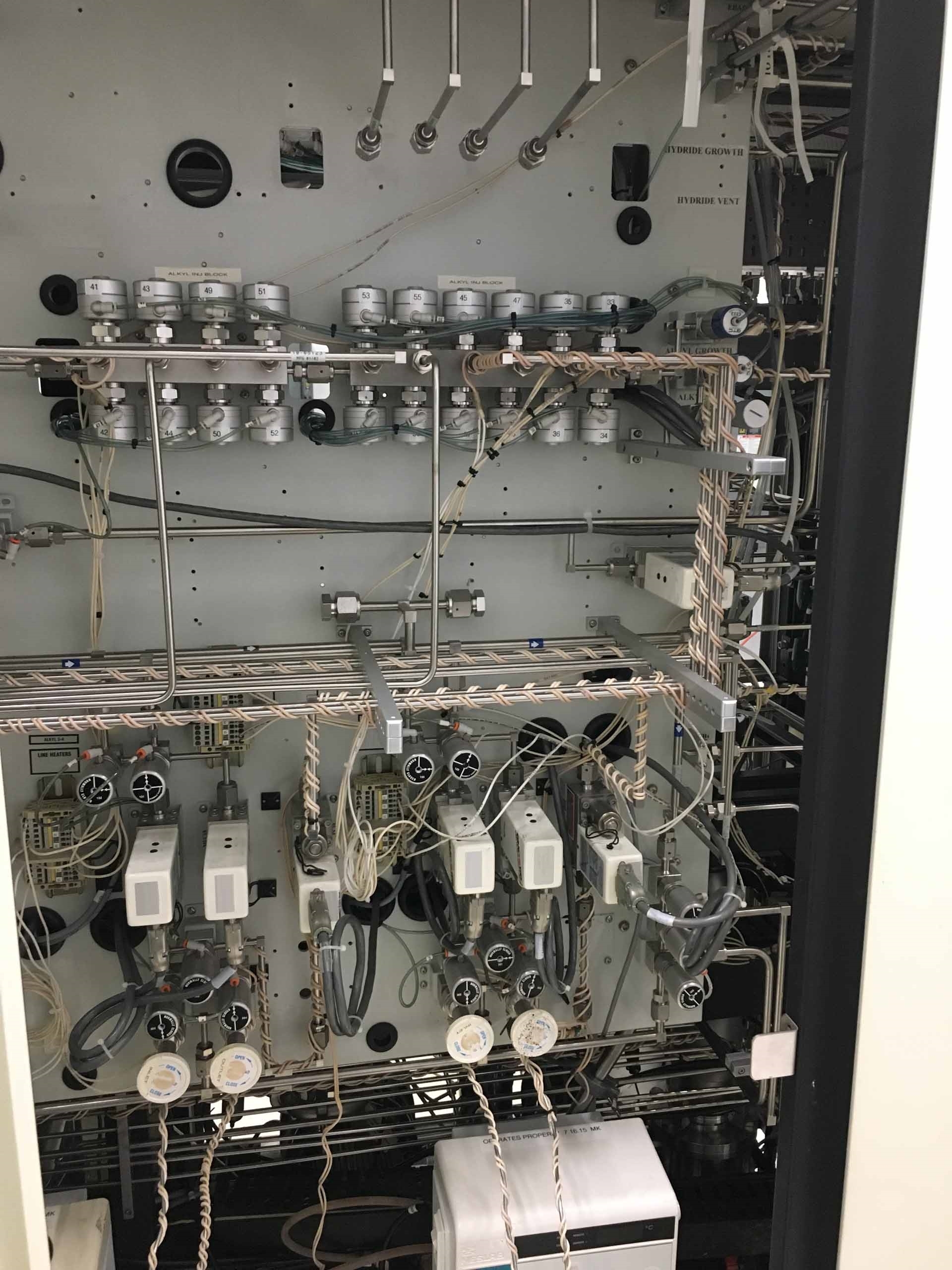

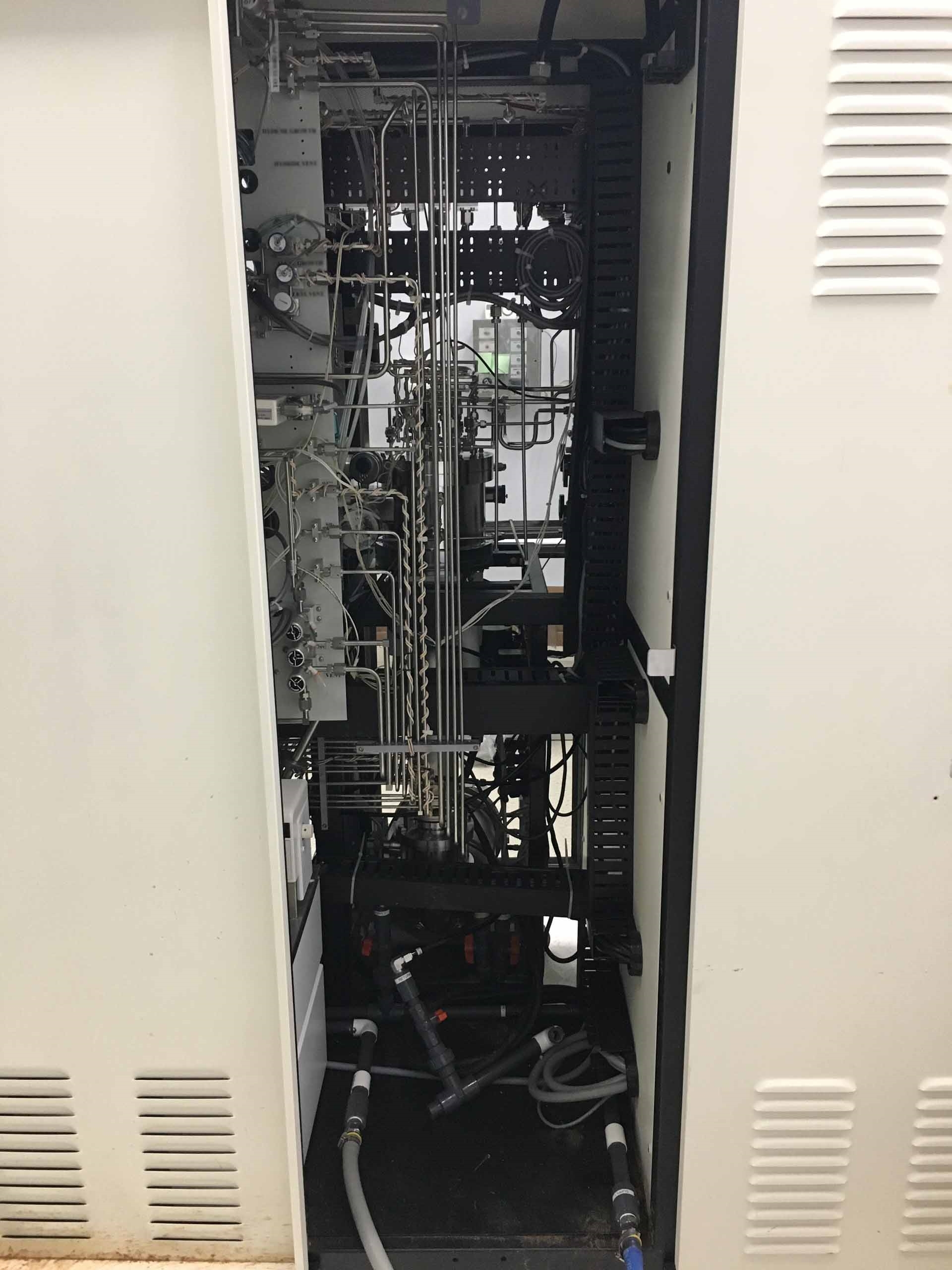

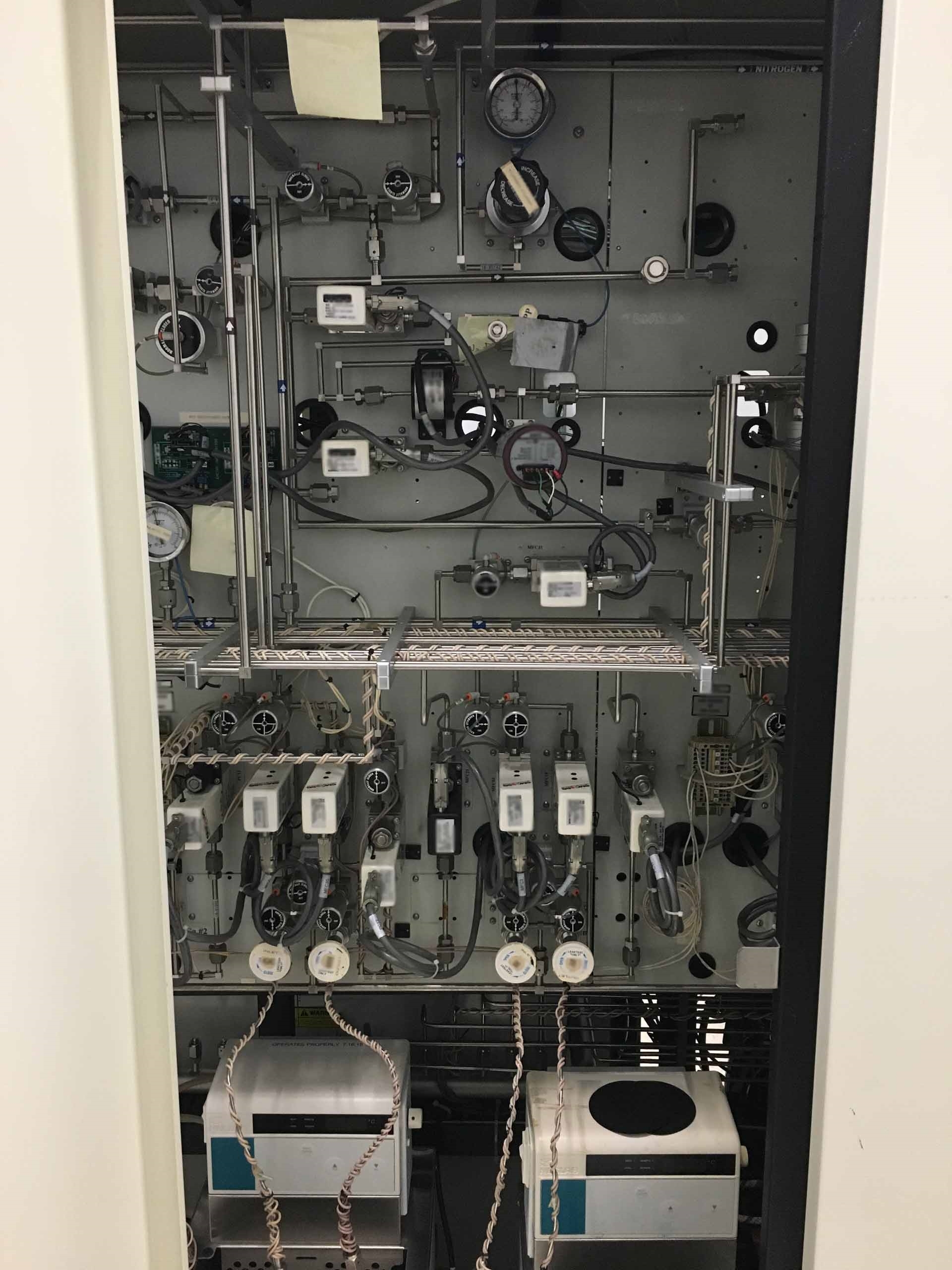

MOCVD System

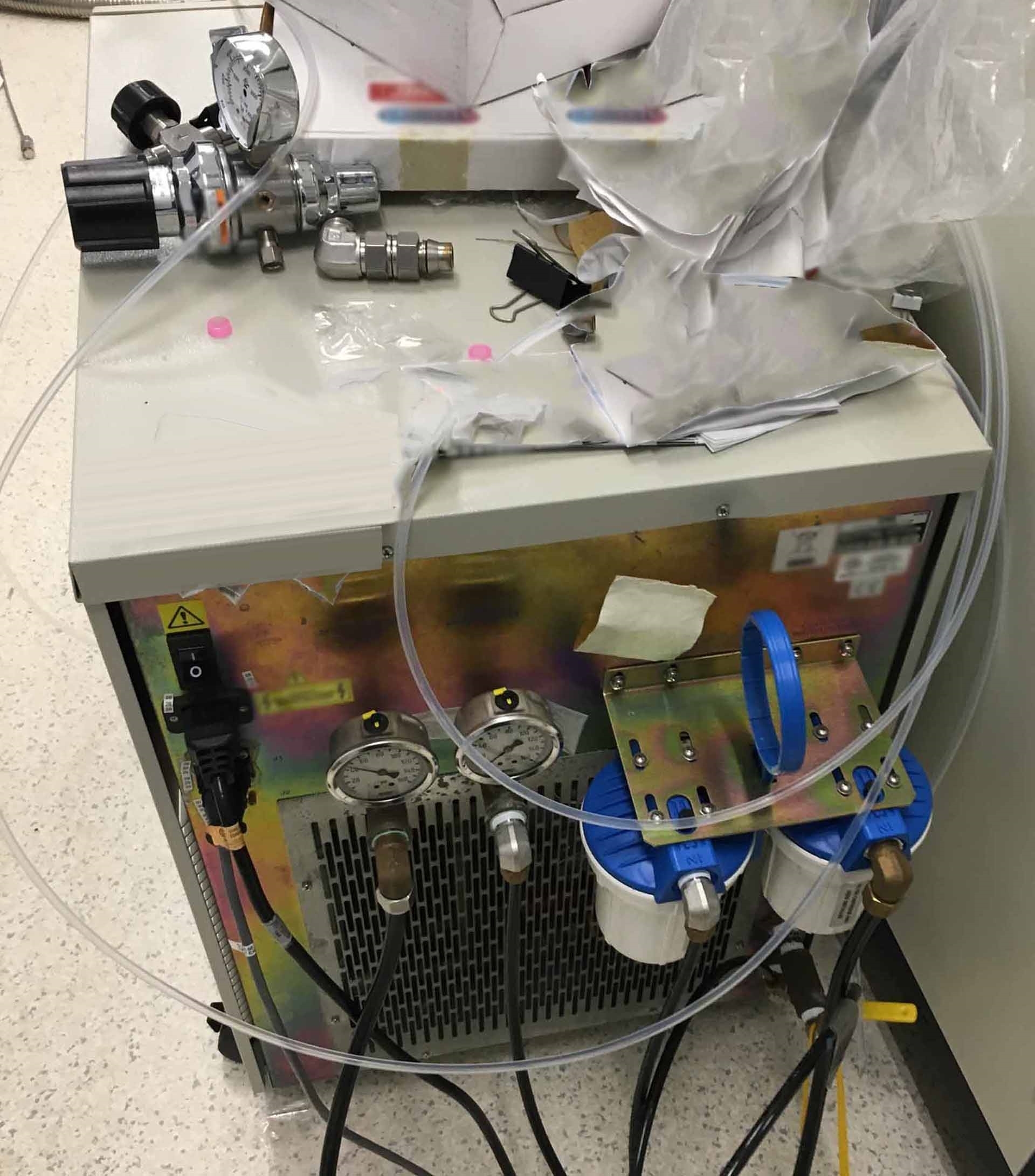

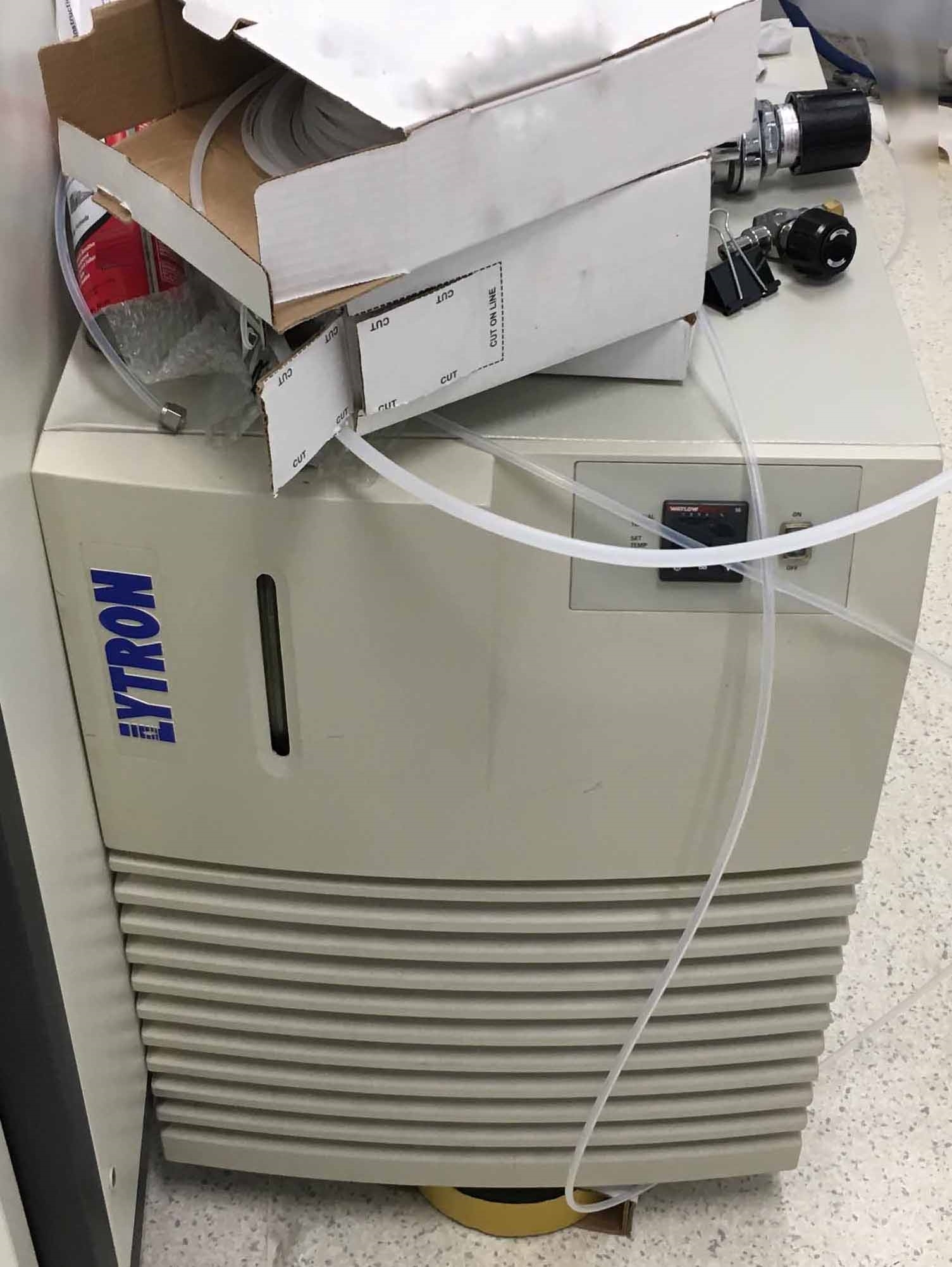

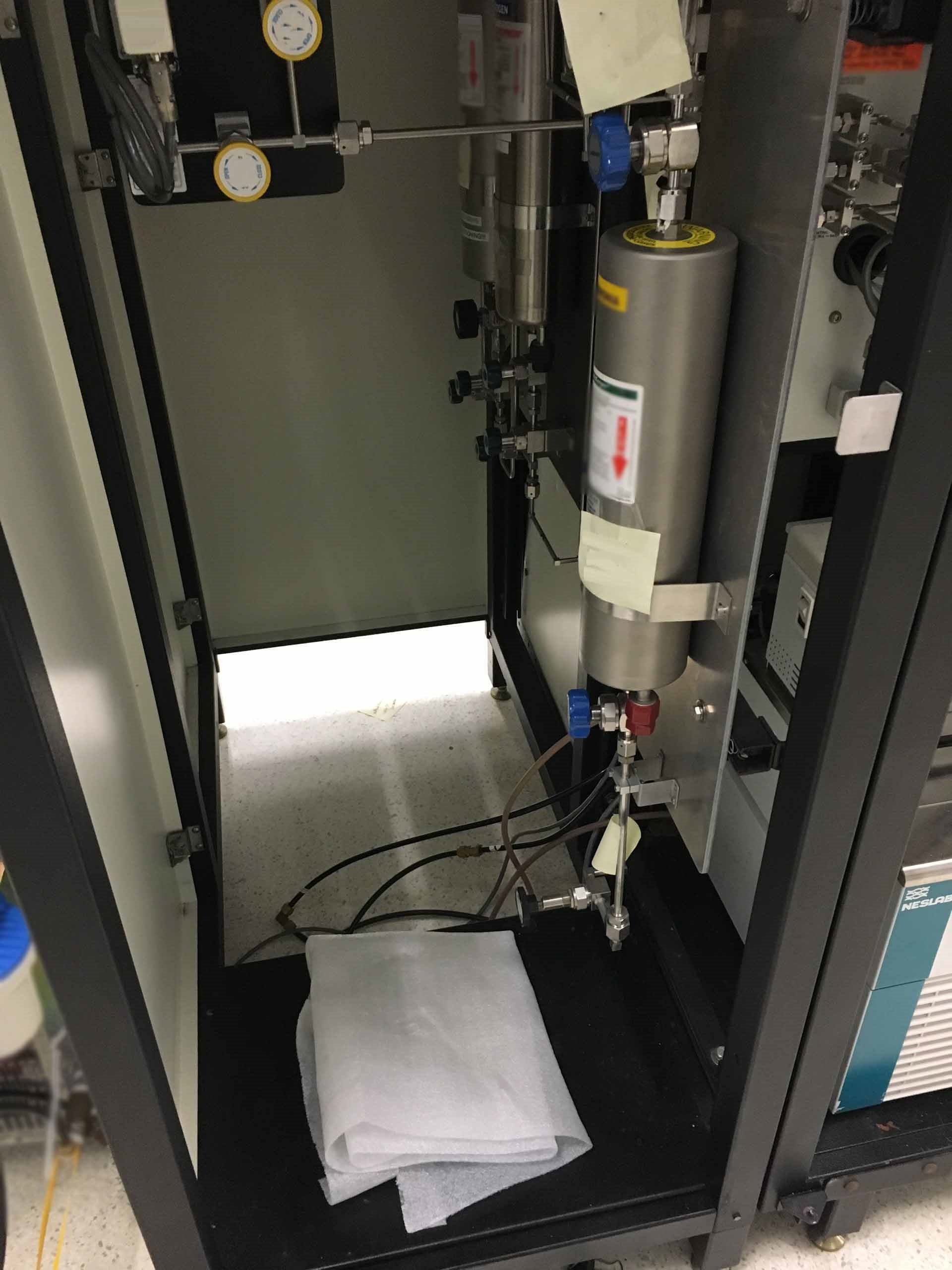

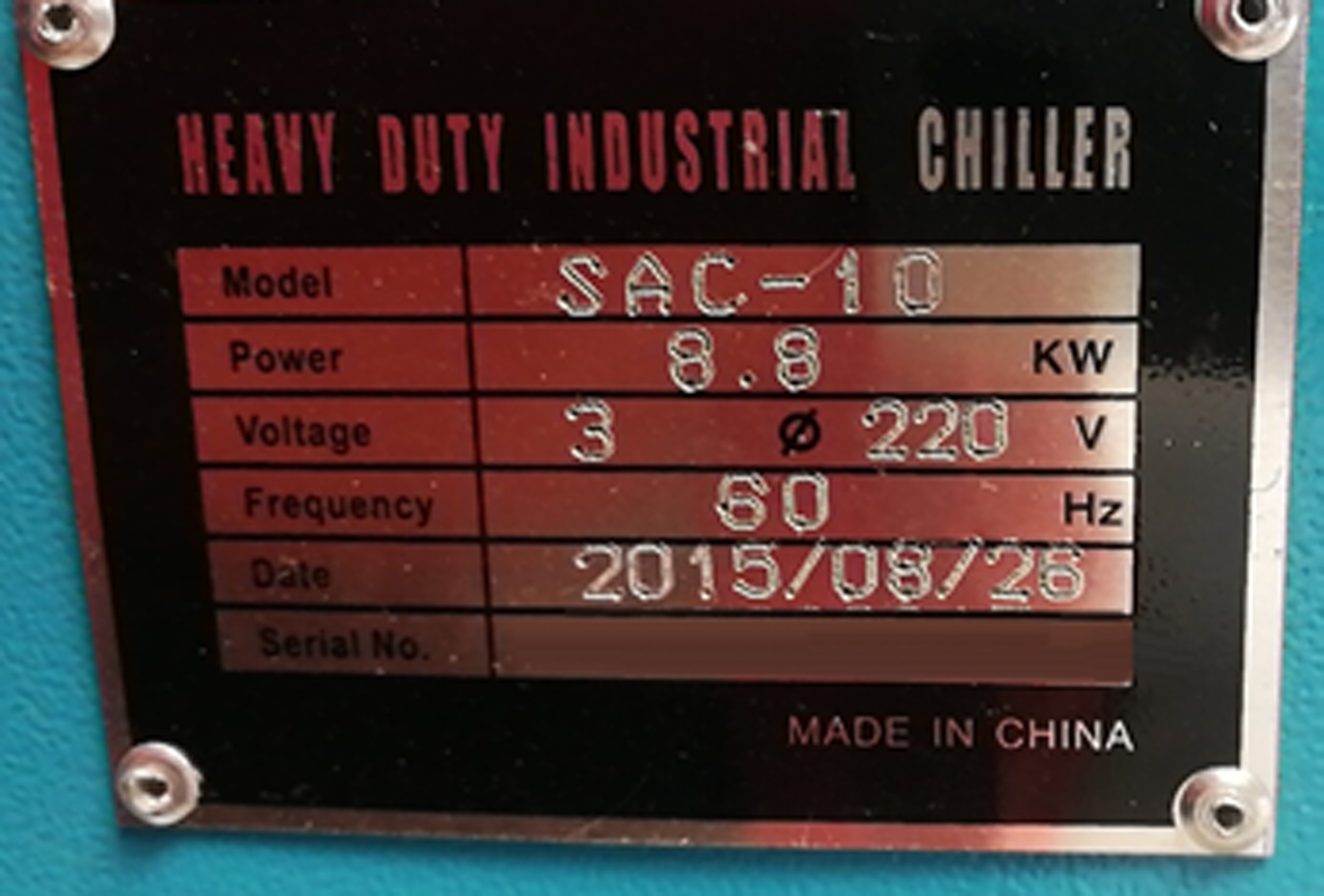

(2) Chillers

Semi-automatic wafer transfer

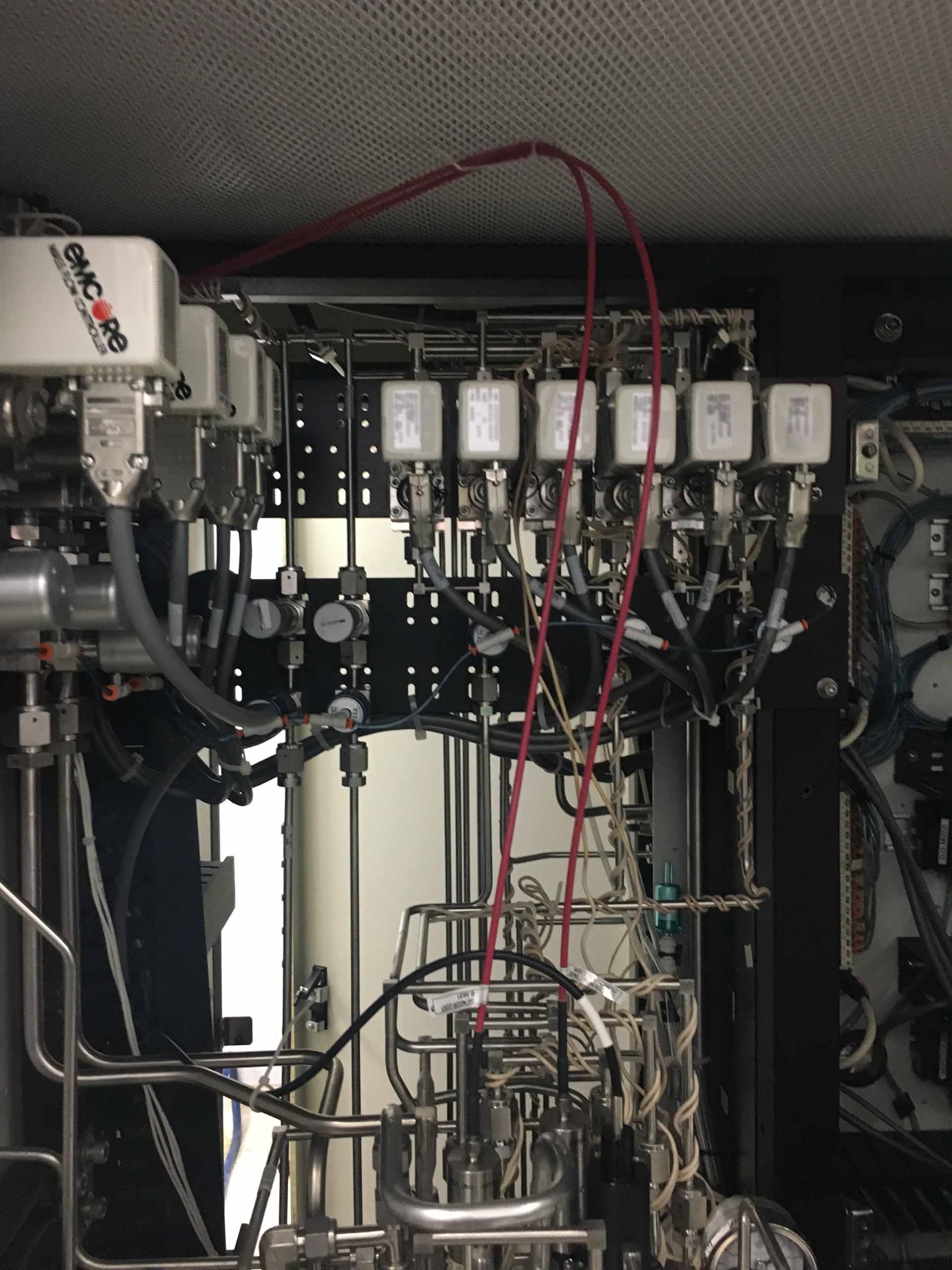

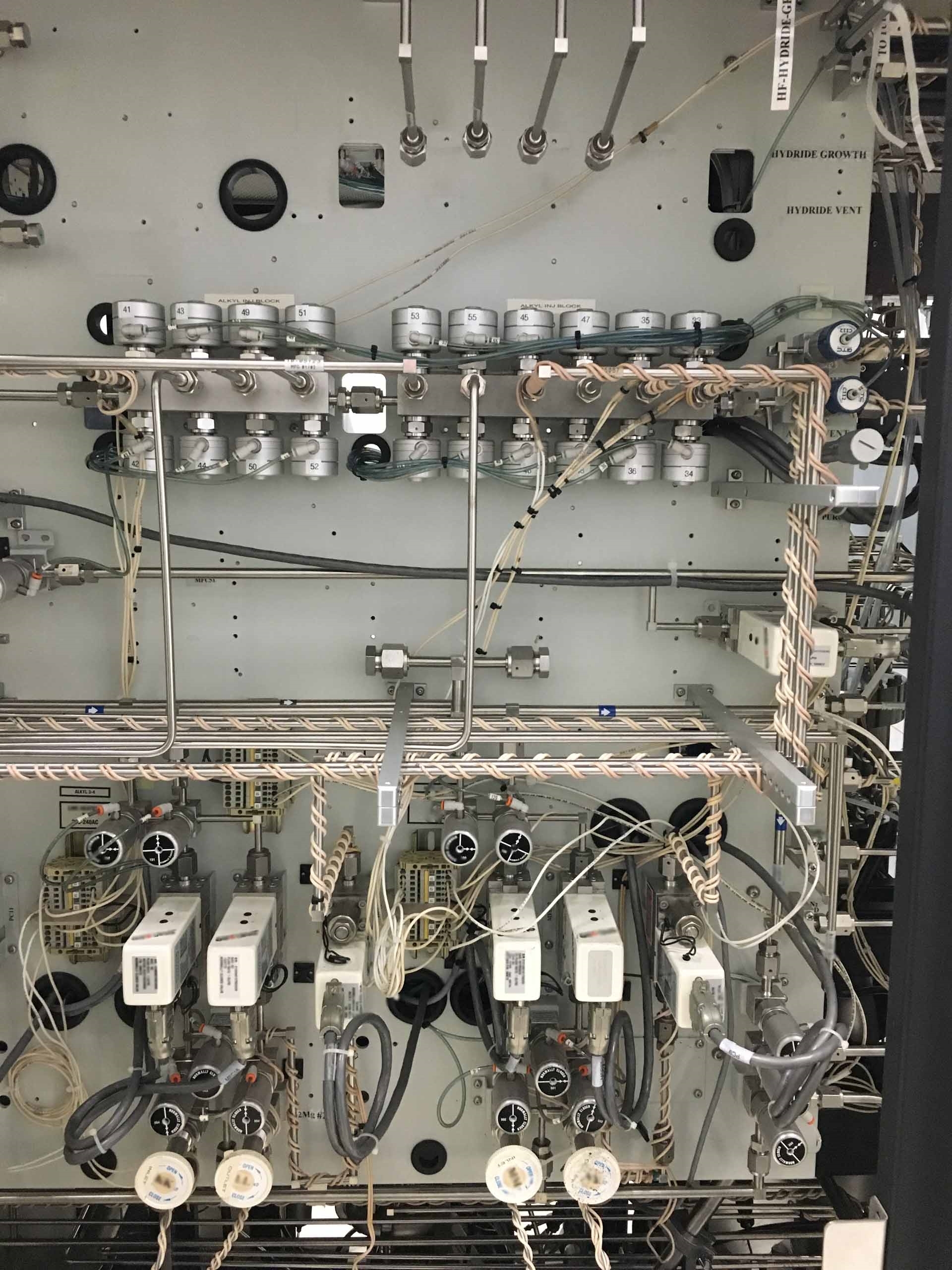

Gas delivery system

Flanges constructed of 316L stainless steel

Reactor & gas panel: With exhaust vented steel & polycarbonate cabinet panels

HEPA Filtered wafer loading area

With system cabinet

7-8 Metal organic channels (Switchable from N2 to H2 carrier gas)

3-4 Hydride channels

Standard non-emissivity corrected pyrometer included

Up to 3 2"/1 3" wafers per run capability

(4) SiC Coated wafer carriers: (2) Standard 3 x 2" / (2) Custom configurations

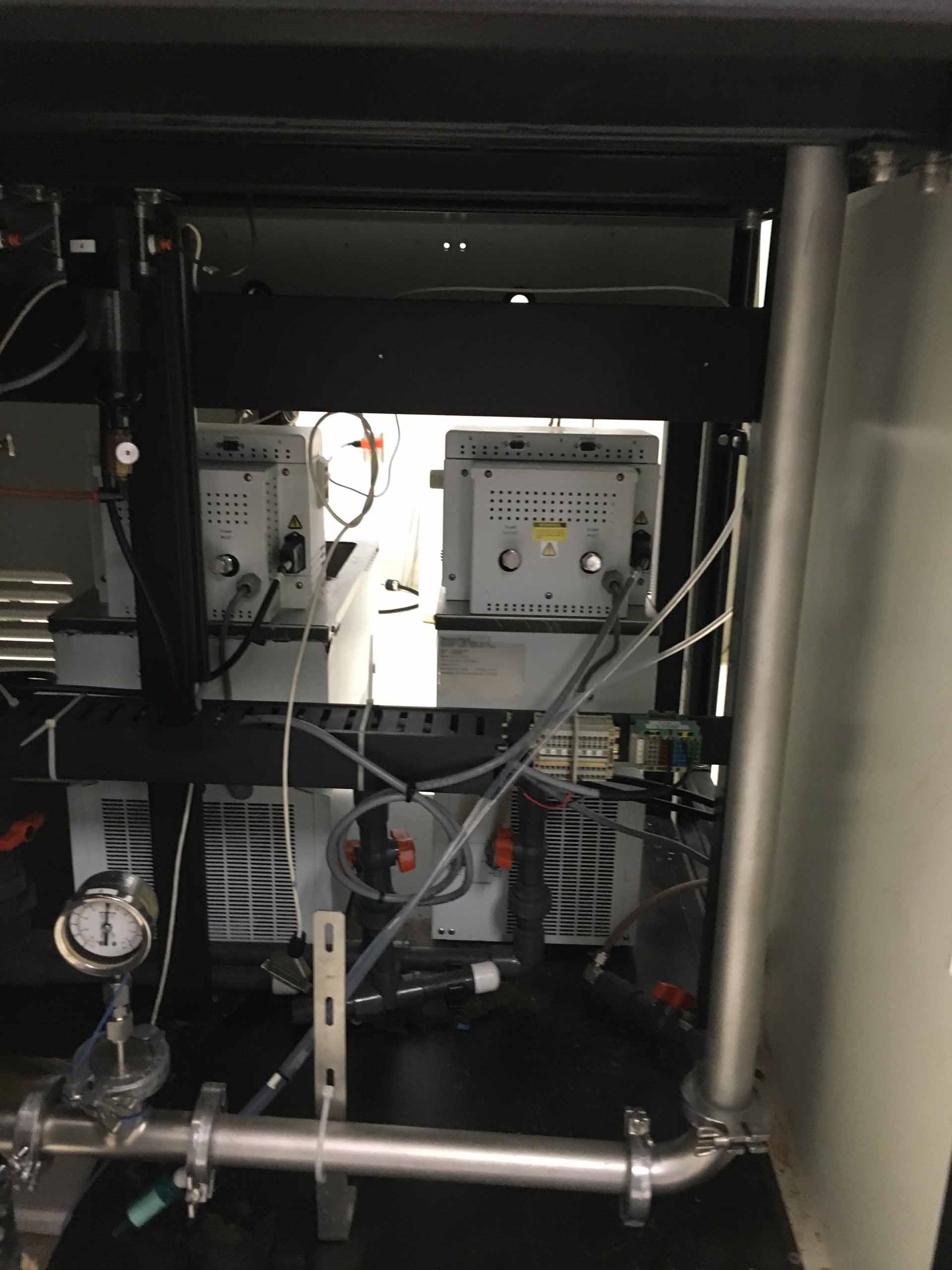

EBARA A70W Process pump

MKS Butterfly reactor exhaust line pressure control valve

With PID control

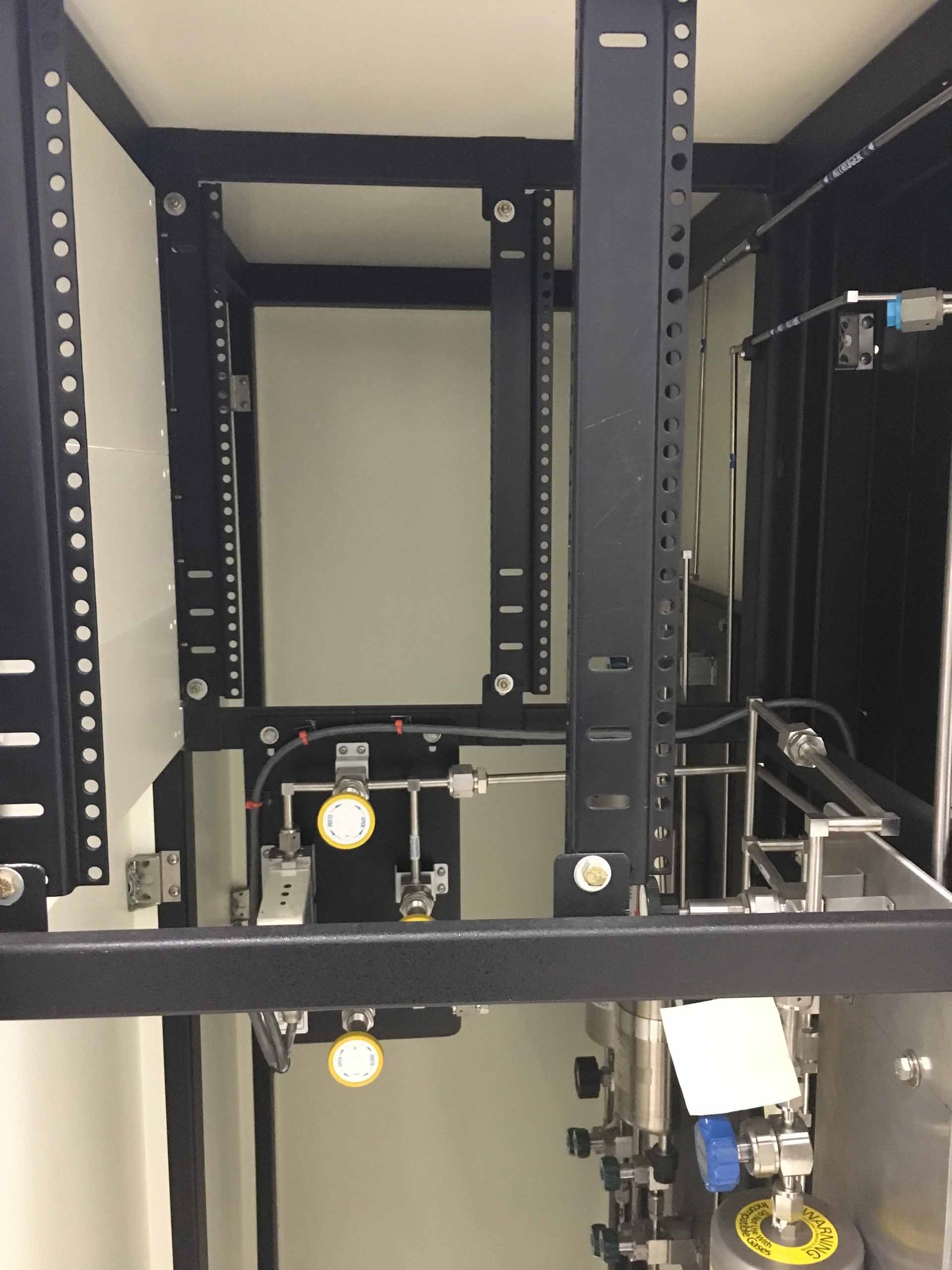

Turbo molecular pump / Scroll dry pump for load lock

CTC Controller with low noise analog card for T/C channel

MO & Hydride delivery SS lines

Heaters and controls

(5) MO Bath water chillers

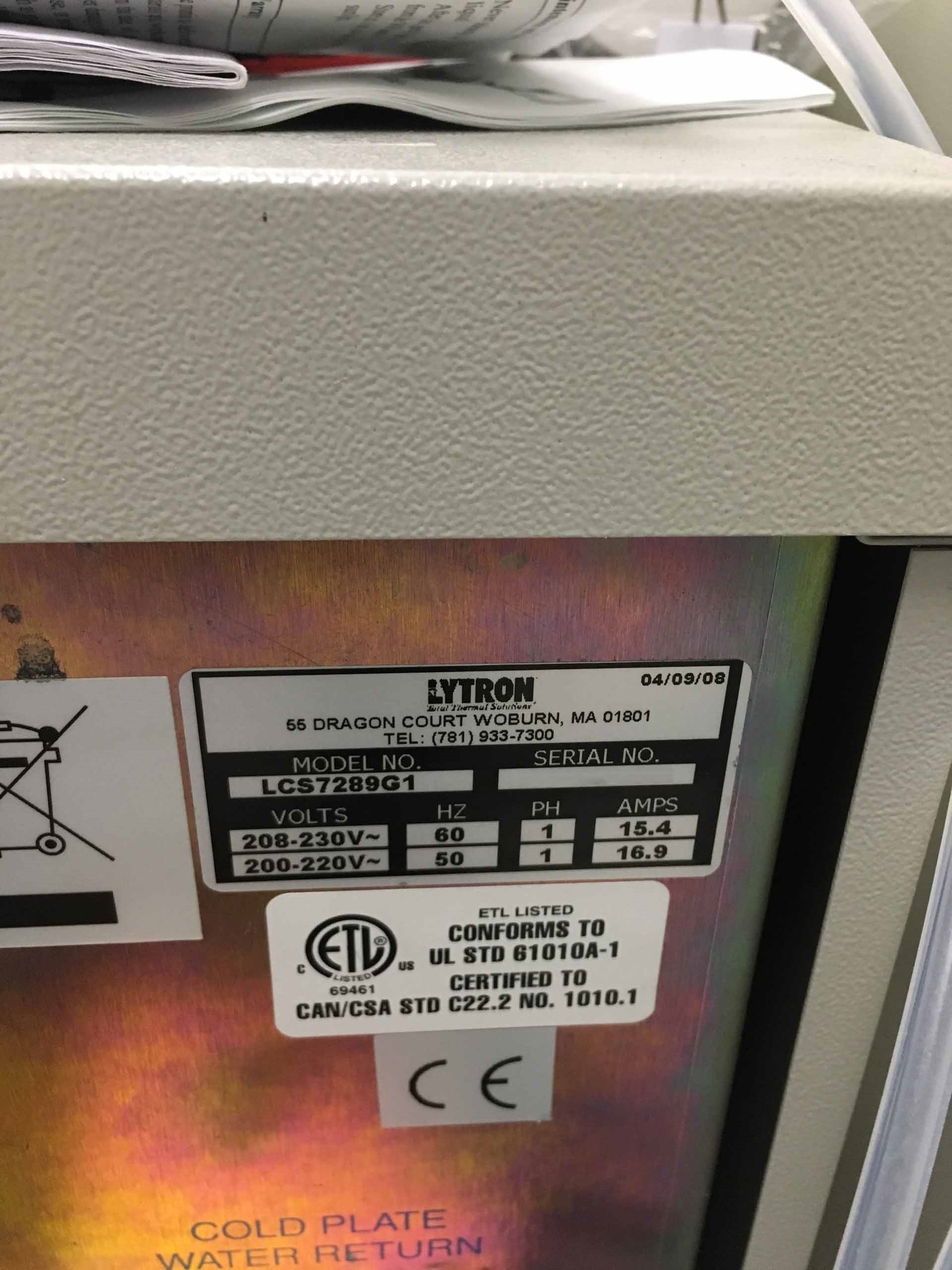

AFFINITY / LYTRON / Equivalent heat exchanger

Turbo rotation: 1500 RPM

Safety alarm system

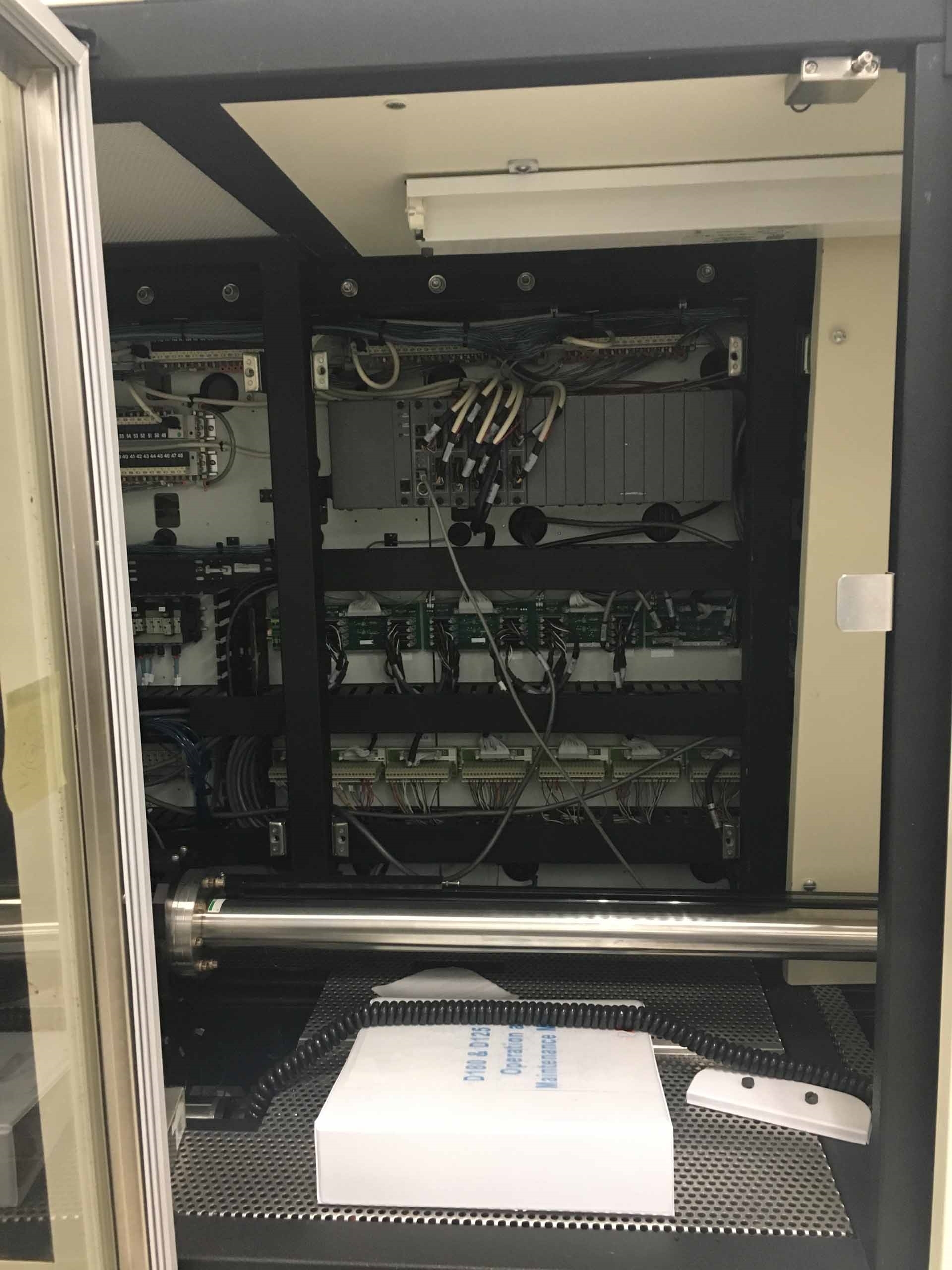

Control system:

Operating system: Windows 7

Personal computer (PC)

With flat panel monitor

Alarms

Routines provide unparalleled control system versatility

Spare parts:

(3) Analog cards

(2) Digital cards

(2) MFC

PCU

Baratron

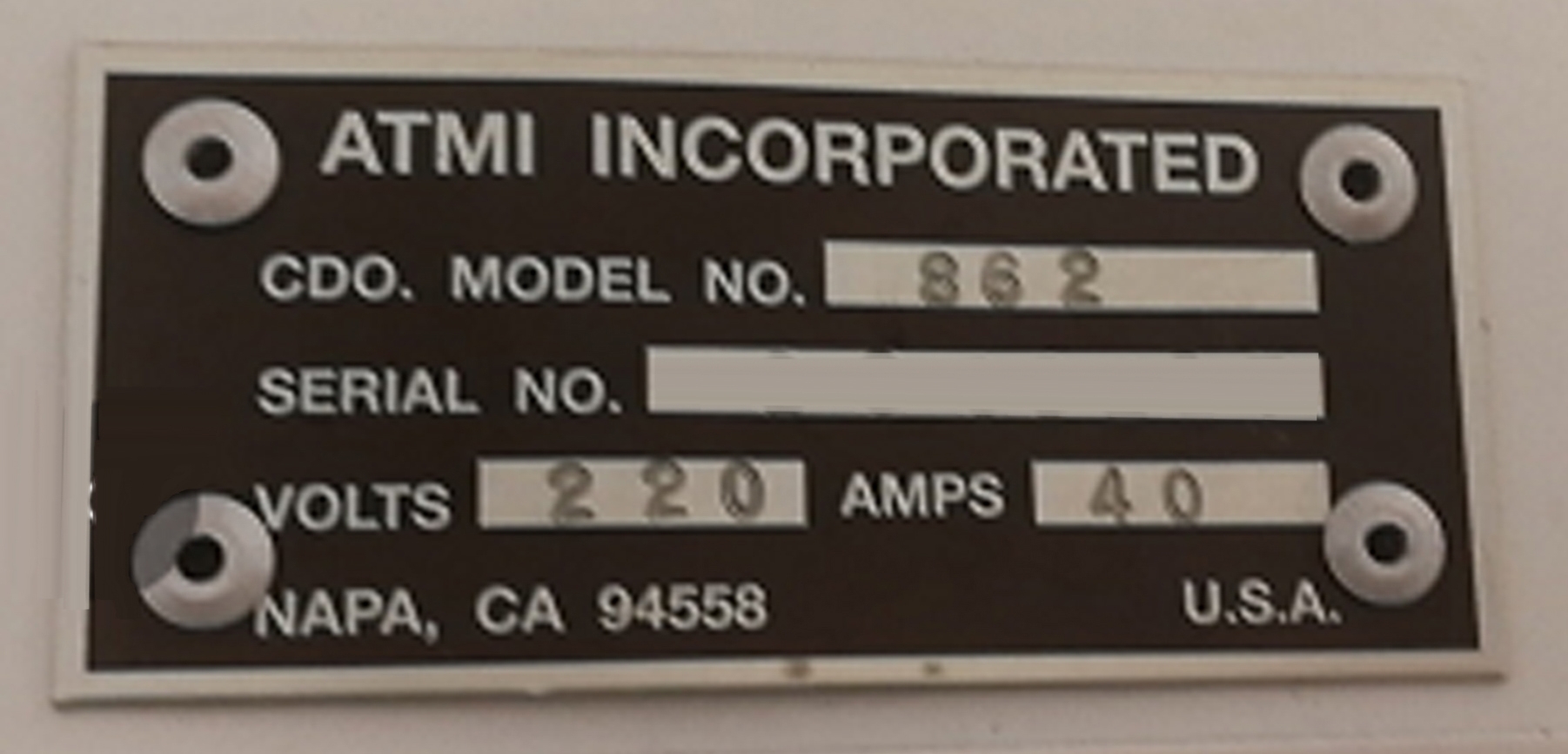

ATMI CDO 862 Abatement system

Combination scrubber and burn-box

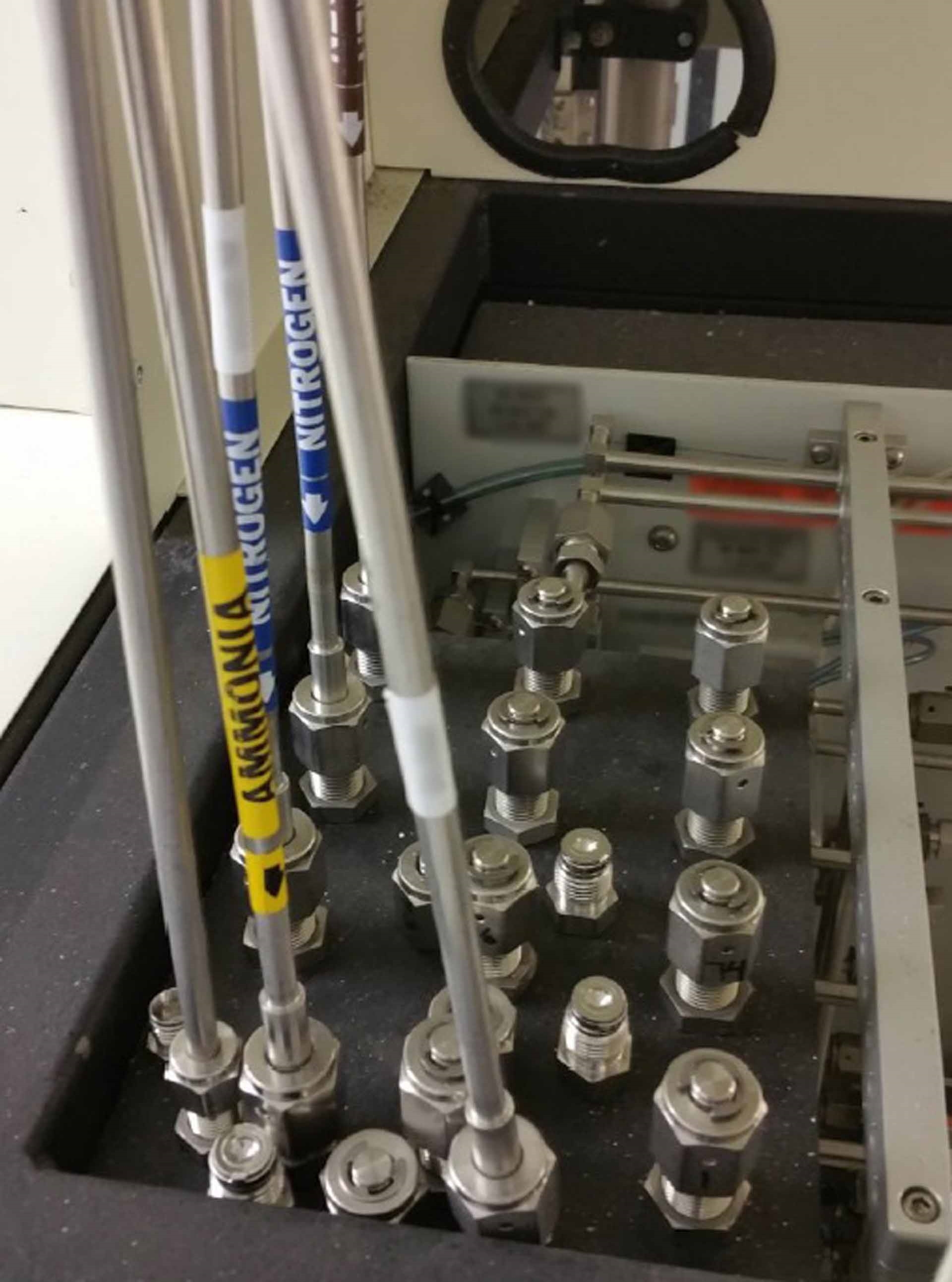

Nitride MOCVD precursors: NH3, H2, SiH4, MOs

Handling maximum D125/D180 gas flows (according to OEM specifications)

Scrubber water: Recirculated in loop

PRAXAIR (3) Bottles ULTRA PURGE ammonia gas cabinet

Internal gas network: ULTRA PURGE Controller

(2) 501b ammonia bottles

Does not include nitrogen purge bottle

Air products AP10, 24" silane gas cabinet

Touch screen controls

(2) SILANE Bottles

Indoor gas distribution panel for hydrogen and nitrogen:

Anodized aluminum: 3 ft. x 4 ft./ Smaller gas panel

Cylinder banks and nitrogen purge: Manifold with (2) hydrogen inlets

(2) Pressure regulators

(3) Check valves

(2) Inline particle filters

(8) Manual valves

High purify 1/4 inch tubing

Tees

Weldments (Orbital welding)

(2) Pressure gauges

Leak checking and certification of leak integrity

Outdoor gas distribution panel for hydrogen with nitrogen purging capability:

36 in x 9 in / Smaller anodized aluminum gas panel

Purging & switching manifolds for (2) six pack cylinders

Manual valves and (2) check valves

UHP 1/4 inch Tubing

Weldments (Orbital welding)

(2) Pressure gauges

Leak checking & certification of leak integrity

System electrical specification:

208 / 220V

50 or 60 Hz

3 φ 150 A per φ

5 Wire with GND

Gas supply specification

Type / Rating / Max flow / Mean flow

Purified H2 / 30-40-100 PSIG / 65 SLM / 30-40 SLM

Purified N2 / 80-100 PSIG / 70 SLM / 20-40 SLM

N2 House feed / 80-100 PSIG / 50 SLM / 25 SLM

CDA/N2 for pneumatics / 80-100 PSIG / 50 SLM / < 15 SLM

NHa / 40-60 PSIG / 30 SLM / -

100 ppm SiH« in UHP H2 / 20-30 PSIG / 22 SLM / -

2003 vintage.

VEECO/EMCORE D125是一種通用反應堆設備,旨在支持先進的工藝開發、學術研究和生產規模的制造作業。VEECO D125集成了常用於異構催化工藝和納米材料應用的先進熱壁技術。反應堆系統經過特別優化,以實現精確的溫度、壓力和停留時間控制,同時也為各種各樣的工藝提供了最高的產量生產率。EMCORE D125的模塊化設計允許自定義配置,以最好地滿足用戶的應用程序需求。它具有一個集成的加熱墻設施,最高溫度可達220°C,內部壓力可達22 bar。加熱壁由環形縫組成,可有效地從壁傳熱到工藝。可適應的模塊化體系結構允許對設備進行修改以支持批處理和連續處理。再者,反應堆的整體設計和調整簡單明了,可以輕松配置,以適應不同的反應堆尺寸、溫度、壓力和停留時間。D125為用戶提供各種過程控制選項,從手動控制到自動化控制,使復雜過程的開發更加輕松靈活。可以合並自動化控制系統來監視關鍵參數、調整設置和數據記錄,從而產生可重現的結果。過程時間軸模擬可針對重復策略進行編程,例如循環溫度傾斜和壓力增加/降低。對於需要高處理靈敏度的操作,可以對VEECO/EMCORE D125進行巧妙的配置,以提供全面的危害控制和超出通常提供的措施(如安全關閉)的措施。VEECO D125具有廣泛的跨行業和應用。它可以部署在UV-Vis光譜、閃爍計數和電鍍過程中。此外,該裝置用於質譜、色譜、電化學表征和藥物發現。EMCORE D125非常適合在生化工業中制造藥品、碳納米管和其他蛋白質。而且它的先進技術對於納米材料合成特別有用,因為納米材料的合成通常需要非常高的溫度、高流速或更長的反應時間。總體而言,D125是一種靈活、堅固、可靠的反應堆機器,經過優化,可支持先進的工藝開發、學術研究和性能驅動的生產應用。高性能、模塊化的設計提供了集成的控制、精確的溫度、壓力和駐留時間控制、提高的生產率以及改進的安全功能,確保了可靠、可重現和可重復的過程結果。

還沒有評論