二手 G&N IDS 34 #142089 待售

網址複製成功!

單擊可縮放

ID: 142089

優質的: 2007

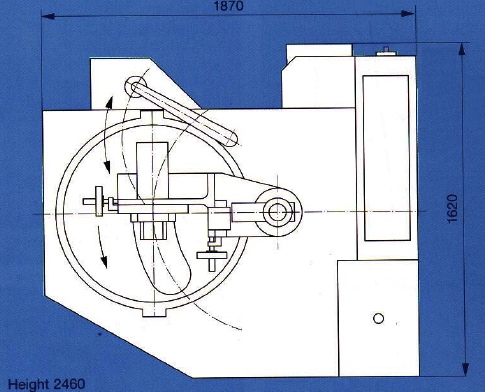

Inner diameter saw, 34"

Specifications:

Substrates capable: silicon, germanium, GGG, samariumcobalt, ferrite, glass, ceramic, semi-precious stones

Machine frame:

Vibration-free cast construction

Removable sheet metal covers on all sides

Swing type crystal holder: inner diameter saw blades up to 34" (860mm)

Frame rests on (6) shock and vibration absorbers

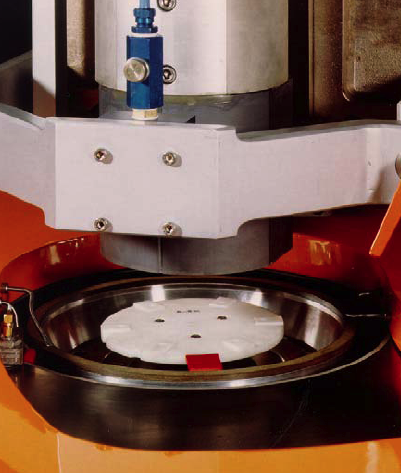

Blade mount:

Arranged horizontally

Axial and radial air bearings in optimum material combination

(2) Separate air connections for supply of air bearings

Air bearings sealed by labyrinth seals

Stationary inner cup: 260mm inner diamerter and (2) removable covers for control of the rotor disc

Massive rotor disc: heavy-duty special alluminum allow

Saw blade held by clamping ring

Spindle unit: horizontally adjustable, fitted to machine frame with (3) special screws

Supply pressure: 6 bar

Supply volume: maximum 30 m^3/hour

Axial runout of tensioning ring: less than 0.003 mm

Radial runout of tensioning ring: less than 0,015 mm

Radial runout of spindle pulley: less than 0.05 mm

If supply pressure drops below 4.5 bar, spindle drive is switched off via 2 air-lack differential switches, the monitors of axial and radial pressure

Top surface and inner diameter of supporting ring protected by welded stellite coat

Spindle drive:

AC motor: 3kW

Spring-pressure disk brake

Spindle drive: endless flat belt, grounding on both sides

Self-acting belt tensioning device

Power supply by electronic frequency converter

Spindle speed (infinitely variable): 500 to 1500 RPM

Spindle speed indication by 4-digit digital readout

Monitoring of the drive system by revolution control system

Machine automatically switched of if RPM is less than 900

Run-up time: less than 3 minutes

Run-down time: less than 2 minutes

Ingot infeed:

Arranged vertically to horizontal blade

Ingot clamping on the slide via holder, centering pin, quick clamping lever

Guide-ways of pre-loaded slide coated and grounded

Rolled ball screw pitch: 5mm

Top and bottom end position of the slide are limited by limit switches

Ingot dimensions:

Ingot dimensions: crystals up to 200mm ø and 570mm length

Orientation: ± 7° in (2) directions (scale graduation: 1 minute)

Thickness range: 0.6 to 6mm in 1µm increments

Index system repeatability: less than ±2µm

Infeed rates:

Up: 16 mm/sec

Down: 16mm/sec

Down: 2mm/sec

Cutting feed system:

Ingot feed mounted on massive, rigid, horizontal moving cast arm

Rests on large column and runs on (2) tapered polymer coated slide ways

Column clamped in a cast flange, screwed to machine frame

Cutting feed drive effected via ground ball screw, 2mm pitch, driven via disc gear motor, gimbal suspension of swing arm drive

Feed rate is infinitely variable, maximum 1800mm/min

Respective sawing positions can be preselected, monitored via potentiometers

Swing arm can be moved to extreme right hand position for saw blade or ingot change

Automatic wafer recovery system:

Wafer unloading within blade mount through 260mm dia bore of inner cup and air bearing spindle via a rigid linkage arrangement and a large surface vacuum chuck

Pick up chuck can be lowered 30mm, adjustable in end positions

Pick up chuck adjustable in (2) directions parallel to ingot to be cut

Additional height line feed

Vacuum and the back air for sawn wafer supplied thorugh linkage

Wafer transfer: blade bore

Swiveling handling arm with vacuum head takes sawn wafer from pick up chuck, lifts off and swivels through 900 to the rear

Wafer discharged in rear end position

Automatic switch off if wafer breakage or incorrect pick up

Possible control functions:

Set up:

All functions are operated individually, feed and infeed are interlocked

Single cut:

One feed motion without return

Automatic:

Fully automatic operation with automatic unloading

Pack slicing:

Adjustable for 1 to 999 cuts via three-decade selector switch

Signal bulbs:

Indication of faults: lack of air, vacuum, filter faults are indicated by signal lamps

Measuring and control unit Micro-Epsilon:

For monitoring and controlling saw blade with respect to saw quality and connected characteristics of saw blade

Supplies operator with information about possible unnecessary dressing procedures

Contactless gauging unit measures saw blade deviation during cutting cycle

Technical data:

Crystal range (dia x l): maximum 200 x 570mm

Packet cut of (2) crystals up to 125mm ø each

Sawblade diameter: 860 x 304mm

Rotational speed of spindle (infinitely variable): 500 to 1500 RPM

Spindle and drive:

Spindle: aerostatic bearings

Motor: 3kW, mechanical brake

Sawing feed:

Feed rate (infinitely variable): 0 to 150 mm/min maximum

Return speed: 1800 mm/min

Index system: 0.6 to 6mm

Indexing accuracy: 5 ± 2µm

Indexing speed: maximum 1500 mm/min

Orientation:

Adjustable: + 7° in two levels

Coolant:

Flow rate adjustable: up to 12 L/h

Indication: flow meter

Hydraulic system:

Pump: 0.55kW

Tank volume: 25 L

Pressure: 35 bar

Services:

Connected load: 7kW

Electrical supply: 220/380V, 50Hz

Compressed air: 6 bar

Features:

Automation:

Unloading device and vertical arrangement of crystal: automatic withdrawal of individual wafers without stopping machine

Simultaneous operation of other machines is possible

Predetermined number of wafers can be semiautomatically packet cut

Ergonomics:

Horizontal arrangement of sawhead allows for access and fitting of sawblade with (2) clamping collars

Precision:

Entire sawhead runs in radial and thrust aerostatic bearings

Adjustable on all levels

Electronic control and closed loop measuring system

Smallest infeed increment: approximately 0.6mm

Repeatability: < + 2µm

Rigidity:

Rigid construction and dynamically balanced rotating components

Demonstration machine

CE marked

2007 vintage.

G&N IDS 34是一款尖端的抄寫和切割設備,由德國公司Gerd&Netzgert創建。這種刻字和刻字系統是在強大的基礎上設計的,提供了許多創新的特點。該裝置采用伺服控制的氣動夾緊系統,以確保在電機驅動的切削葉片運動中切削的最高精度。它還采用伺服控制裝置定位和刀片組件的組合,快速完成切割操作。可自動縮回的切割頭有助於實現完美的成品。除了強大的基礎之外,IDS 34還提供多種性能功能。這臺機器具有一個簡單且用戶友好的控制單元,可以快速直接輸入代碼和產品數據。它的用戶界面有助於管理從頭到尾的處理周期。它還允許實時監測過程的進展,以確保產品的最高質量。G&N IDS 34允許從一種產品輕松地轉換到另一種產品,因為它包括一個用於操作人員友好處理的準備工具。此外,該工具還具有適合任何工作環境的符合人體工程學設計的機床底座。這種劃線和切割資產還可以靈活地加工。它可以處理厚度可達0.8mm、長度可達35mm的材料。切丁面積可設置為50 x 50mm,而切削深度可設置為12mm。鋸表的部分可移動性有助於導航即使是最復雜的輪廓。IDS 34配備了激光定位模型,用於刀片和工件的精確對準,從而實現更高的速度和精度。此外,它還可以精確切割最復雜的零件。G&N IDS 34設備是一個極好的解決方案,可以在極短的周期時間內提供精確和精確的切割。該系統具有創新的功能和易於使用的操作員界面,確保提供可靠、精確和高質量的產品。

還沒有評論