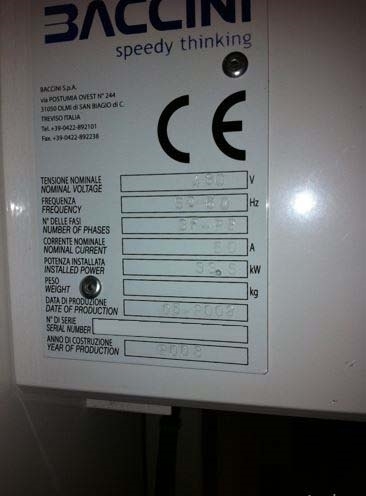

二手 BACCINI / AMAT / APPLIED MATERIALS Softline 2.0 #9187077 待售

網址複製成功!

單擊可縮放

ID: 9187077

優質的: 2008

Dual screen printer

Wafers semi square (Mono crystalline): 125 x 125 mm

Wafers poly Si square (Multi crystalline): 125 x 125 mm

Wafers semi square (Mono crystalline): 156 x 156 mm (95 mm Diameter)

Wafers poly Si square (Multi crystalline): 156 x 156 mm

BACCINI Line loader for stack magazines

(5) Empty magazines

(5) Full magazines

Cells each magazine: 200-300 (Depending on thickness)

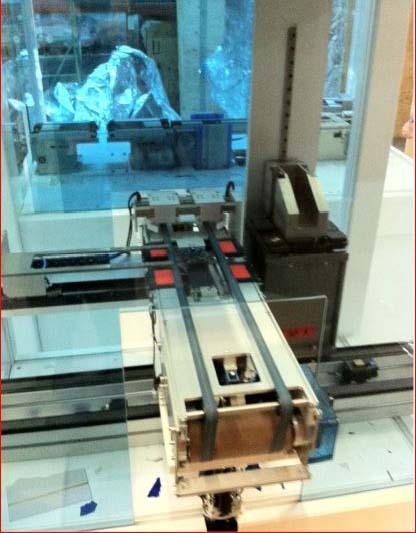

Transport belt:

Powered by servo motors are controlled by encoders

Soft rotary printer (Front print):

Fully automated high-speed solar cell printer

With rotary table and soft handling concept

Print head:

Screen frame: Type 10, 355 x 355 mm

Maximal printing area: 170 x 170 mm

Maximal squeegee stroke: 240 mm

Maximal squeegee speed: 333 mm/s

Maximal squeegee pressure: 150 N

Camera aligning system:

Alignment tolerance: < ± 20 µm

Flat belt dryer:

IR-Lamp heating system in combination

With blowing hot air

Technical data:

(3) IR Heating zones

Air heating zone

Exhaust

Maximum temperature: 250°C

Maximum temperature tolerance: +/- 5°C

Drying time (min./ max.): 20 s to 40 s

Lifting device with (2) fixed cassette magazine sidewalls

Equipped with motorized width

Adjustment to adapt to different wafer sizes

Working principle: FILO

Transport belt section

Cell presence control

Furnace loader:

Electro welded steel

Sick light barriers for easy access by operator

Firing furnace: With dryer section

Firing furnace unloader:

With double stack buffer

Stack magazines: 2 or 4 (2 + 2)

Wafers per magazine: 300 (Depends on wafer thickness)

Squeegees screen frame adapter

Industrial-PC with keyboard

TFT Screen

Graphical User Interface (GUI)

Wafer bow:

Room temperature:

Before firing: < 1 mm (Center to edge)

After firing: < 4 mm (Center to edge)

Up time: >95 %

Mechanical yield: 99.5 %

Minimum thickness of the wafers: 140 µm

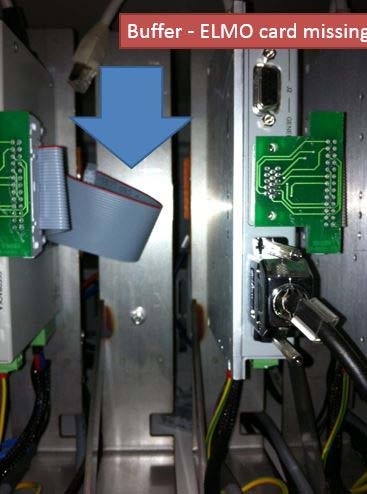

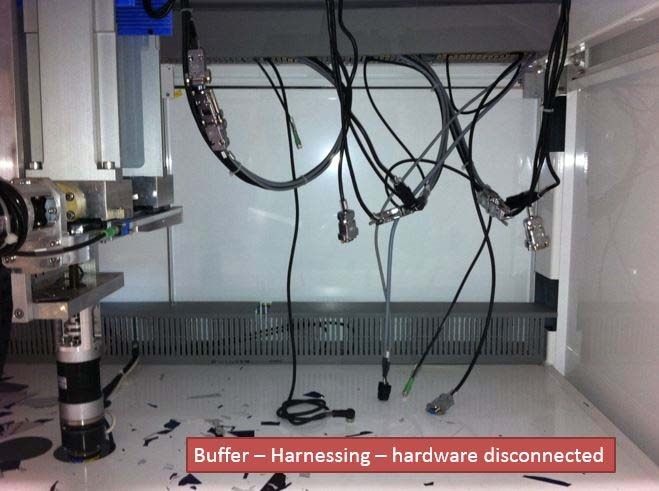

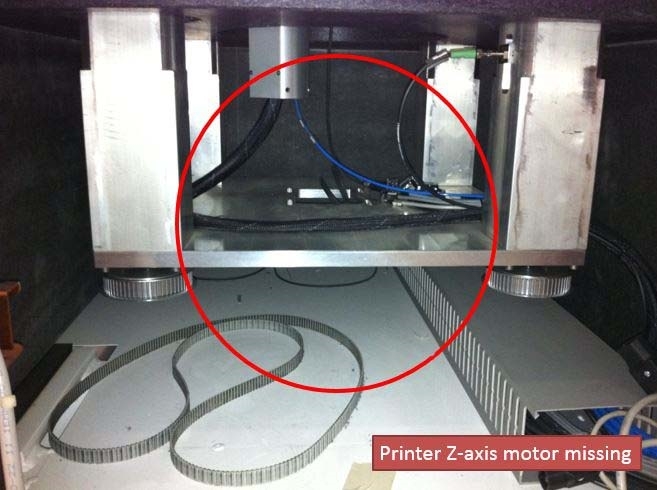

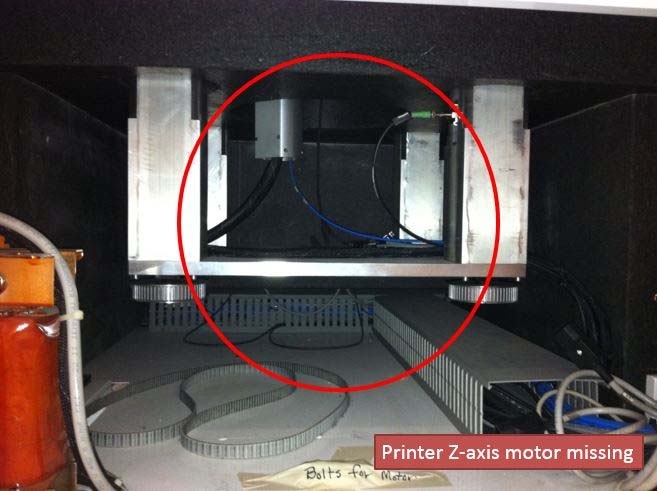

Missing parts:

ELMO Card

ELMO Card 115MG

Printer Z-axis motor

2008 vintage.

AMAT Softline 2.0是一款專為制造太陽能電池而設計的高效太陽能生產機器。該機采用先進技術,以經濟高效的方式生產出高質量的太陽能電池。它是與BACCINI公司合作開發的,是25年以上密集研發的成果。軟線2.0集成了融合了最先進設備的強大光伏生產線。自動電池生產系統能夠處理大量標準和定制編程的基於矽的材料,以便為從住宅到商業安裝的廣泛應用提供動力。還可以配置生產線,方便用創新材料生產高效太陽能電池,包括有機半導體。Softline 2.0機械的一部分是一種紋理工具,其設計目的是為生產更高效的太陽能電池實現紋理化表面。該工具采用多級堿性蝕刻工藝,以獲得所需的紋理圖案。此外,它還配備了高功率紅外發射器和控制溫度室,以控制紋理圖樣深度和提高太陽能電池效率。Softline 2.0還配備了晶圓切片模塊,用於在半導體材料加工之前進行制備。該模塊采用超精密鋸片,能夠切片晶片,切削精度在10微米以內。這是用來確保晶片切片的尺寸和厚度正確,用於高質量的太陽能電池生產。此外,該機器還配備了一個用於測量太陽能電池性能的計量過程的測試站。Prober station附帶專門的軟件,可以檢測和糾正任何有缺陷的太陽能電池。這對於質量保證和遵守國際安全標準至關重要。最後,Softline 2.0的能效很高,幾乎不產生任何排放,這使其成為制造商的環保選擇。其先進的技術顯著降低了能耗,而用戶友好的設計確保了可操作性、更快的吞吐量和更高的產量。總體而言,APPLIED MATERIALS Softline 2.0是一款頂級太陽能生產機器,以精簡、經濟實惠的方式提供一系列太陽能電池生產功能。

還沒有評論