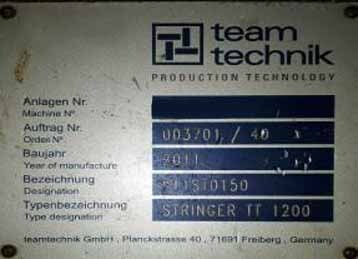

二手 TEAM TECHNIK TT1200 #9176069 待售

網址複製成功!

單擊可縮放

ID: 9176069

優質的: 2011

Single track stringer system

3BB

Hold-down device

Geometrical quality

Linearity

Length tolerance

Cell gap

Soldering technology: IR Light / laser

Cell technology / Types:

Mono / Poly-crystalline

Front and back side contacted

Cell alignment:

Optical alignment via camera

ROBOT For busbar / edge positioning

Cell inspection:

Vision system (camera)

Detection of accuracy for cracks

Broken edges and scratches: 0.5 x 0.5 mm

Grid-completeness check

Accurate cell and ribbon handling

IR Light soldering station

Suitable for lead-free (Pb) ribbons

Number of interconnection ribbons: 2-3 / 3-4

Range of solar cell sizes:

125 sq - 156 sq, 5"

Standard, 6"

Requires changeover parts, 5"

Busbar spacing:

30 - 78 mm

Standard 52 mm

Cell spacing: 2.0 - 35.0 mm

Cell positioning accuracy: ± 0.2 mm

Maximum length of strings: 2,000 mm

Accuracy in length: ± 1mm

1,400 cycles / hr

10 Cell-string with cell fluxing 1,272 Cells / hr

30 / 32 / 36 MWp pa

Technical availability: 95%

Noise level: 72 dB (A)

Electrical power requirement:

IR Light: 30 kVA / 17.5 kW / h

Compressed air: 600 kPa

Consumption (at 1 bar): 450 l / min

Cell thickness:

160 - 250 µm

Standard 180 µm

Flux application:

Fluxed with adjustable

Metered micro spray

Standard (Both sides)

Breakage rate:

Cell thicknesses down 180 μm

< 0.3 %

Ribbon sizes: Width > 1.0 mm

Ribbon positioning accuracy: ± 0.2 mm

Changeover time 2-3bb / 3-4bb: 2 Hours (Approx)

Operator interface (HMI):

Color touch screen with German / English / Chinese or Korean language

High throughput: < 2.5 Seconds cycle time

Low breakage rate: < 0.1 - 0.3%

Availability: > 95%

2011 vintage.

TEAM TECHNIK TT1200是一種先進的太陽能生產設備,為住宅和商業應用提供可靠、高效的串串生產。該機采用集成的自動電池定位設備,可實現精確、高速的生產.機器的運動控制提供了卓越的精度和可重復性。TEAM TECHNIK TT 1200配有用戶友好的彩色觸摸屏界面,可讓操作員管理各種機器設置。它還提供高級故障排除功能,可更快、更輕松地進行維護。該系統具有數據記錄能力,具有可調的超時參數,保證了最佳生產。TT1200配有先進的視覺單元,利用圖樣識別、厚度檢查和顏色與對比度檢測,有助於提高細胞質量。視覺機允許用戶輕松檢測錯誤,增加可靠的生產並減少停機時間。機器上先進的包裝單元確保了電池的高效移動和包裝。封裝工具自動將單元格送入擠壓站,確保質量連接。該資產還包括防剪接安全傳感器,以防止過度擁擠和拒絕故障單元。TT 1200有一個集成的冷卻模式,有助於保持整個生產周期的溫度穩定。冷卻設備設計用於散熱、減少降解和延長電池壽命。總體而言,TEAM TECHNIK TT1200是目前市場上最先進的太陽能生產設備之一。該機具有精確、可重復的運動控制和先進的視覺系統,確保了可靠高效的太陽能生產周期。其集成的冷卻單元、封裝單元和防剪接安全傳感器確保了高質量的產品、改進的電池質量和最小化的停機時間。

還沒有評論