二手 ZEUS TS1400-H #9188133 待售

網址複製成功!

單擊可縮放

ID: 9188133

晶圓大小: 6"

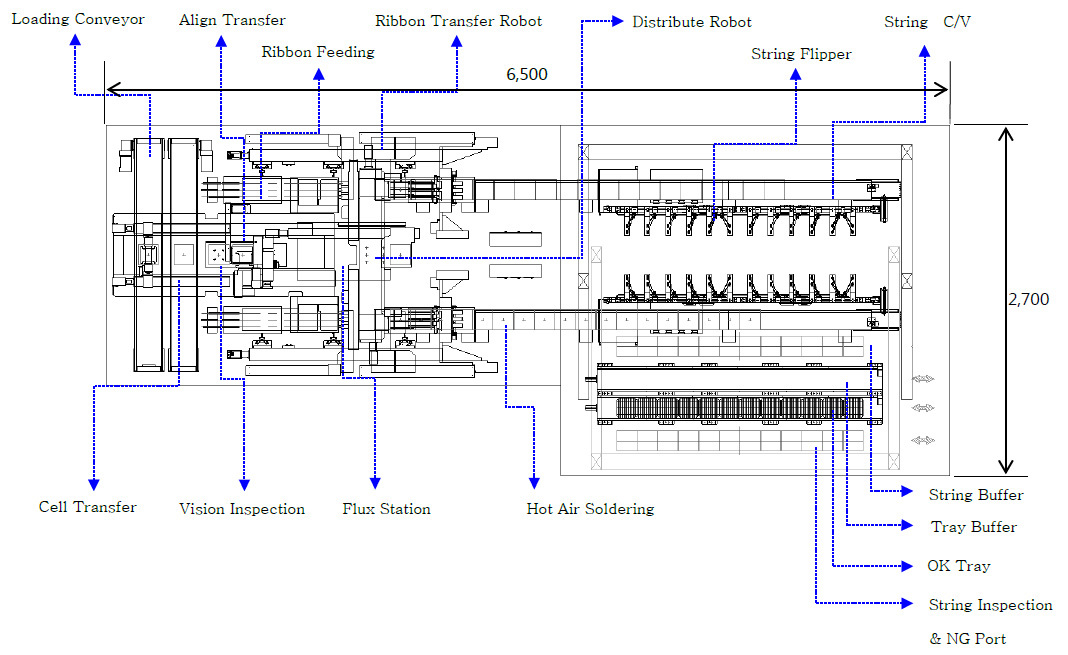

Tabbing / Stringing system, 6"

Specifications:

Type: Auto

Cell type: 2 & 3 Bus bar

Solar cell size: Mono and multi cell

Solar cell thickness: >160μm / 180μm mono (standard)

Cell: Auto

Magazine: Manual

Ribbon: Auto

Ribbon roll: Manual

String: 1~12 Cell (Auto 8~12 cell)

Ribbon:

Ribbon type: Pb & Pb free ribbon

Ribbon width: 1.5 mm, 2 mm

Solar cell spacing: 1.5-30 mm / 2.0 mm (standard)

Solar cell spacing accuracy: ±0.3 mm / 2.0±0.3 mm (standard)

String length: 156-1920 mm, ±1 mm

Vision align accuracy: ±0.1 mm

Ribbon position accuracy: ±0.3 mm / based on bus line center

Throughput: <1,400 cells / hr [cell to cell: 2.5 sec]

Breakage: <0.3% / base on the H/W issue [180um]

Technical availability: >95%

Noise level: Maximum 72 dB(A)

Electricity: 3Ф 380 V, 60 Hz, 66 kW

Compressed air: 0.6 MPa, 3000 L/Min / (8) Ф12 tubes

Gen exhaust: <360 m3/h / Ф200

Heat exhaust: <360m3/h / Ф125

Configuration:

(2) Loading conveyor units, free flow top chain conveyor

(10) Magazines, cell stock: 200EA/Magazine

Cell Wafer transfer robot, 2 axis cross robot (cell W/F transfer)

Align transfer robot, 4 axis linear

Vision inspection unit, 5 MP CCD camera, back light (LED)

NG port, NG bucket

Flux station unit, flux nozzle (dispensing type)

Distribute robot, 2 axis linear (cell W/F transport and distribution)

(2) Ribbon spool units, spool diameter: Ф160≥

(2) Ribbon feeding units (clamping / stretching / bending / cutting)

(2) Ribbon transfer robots, vacuum type

(2) String C/V unit, steel belt type, heater & vacuum conveyor

(2) Soldering units, hot air soldering

(2) String flippers, string reverse

String buffer, tray supply unit [steps: 5] + OK tray unit [steps: 5]

Signal tower & melody, warning and alarm

(5) EMO S/W, emergency switch

Operation panel, top swivel type orthotic

Includes:

Control panel

PLC / Electronic parts.

ZEUS TS1400-H是一款高效、最先進的太陽能生產設備,旨在以最高效率生產出質量最高的光伏電池板。TS1400-H采用了一系列先進的生產技術,在生產過程中提供前所未有的性能和可靠性。ZEUS TS1400-H采用了薄膜沈積技術,確保了陽光下的最佳能量轉換。薄膜厚度高達0.060mm,沈積設備能夠實現極精確的轉換效率,同時在光伏面板使用壽命的長期內保持優越的穩定性。TS1400-H還具有自動單元定位系統,可提高生產吞吐量和可靠性。精確度高達2 µm,該單元顯著減少了電池錯位,可提高效率,確保生產質量最高。ZEUS TS1400-H還利用高度精確的激光劃線機,執行切割光伏電池連接和剝離的關鍵任務。這樣,與傳統的劃線工藝相比,可以在一小部分時間內創建面板,同時確保精確可靠的連接。TS1400-H還具有最新的檢查和測試自動化功能,具有缺陷檢測功能,能夠對光伏輸出的質量進行可靠的評估。利用復雜的視覺算法,自動檢查員使用一系列功能來評估每個單元的生產質量。最後,宙斯TS1400-H帶有先進的工具控制和分析軟件,以及各種安全功能,包括緊急停止和安全圍欄。這樣就可以輕松集成到現有的生產系統中。總體而言,由於其先進的生產技術和先進的自動化檢查和測試系統,TS1400-H提供了最高水平的質量和性能。它旨在提供可靠的高質量光伏電池生產,而不犧牲質量或效率。這一尖端技術使得宙斯TS1400-H任何光伏生產應用的理想選擇。

還沒有評論