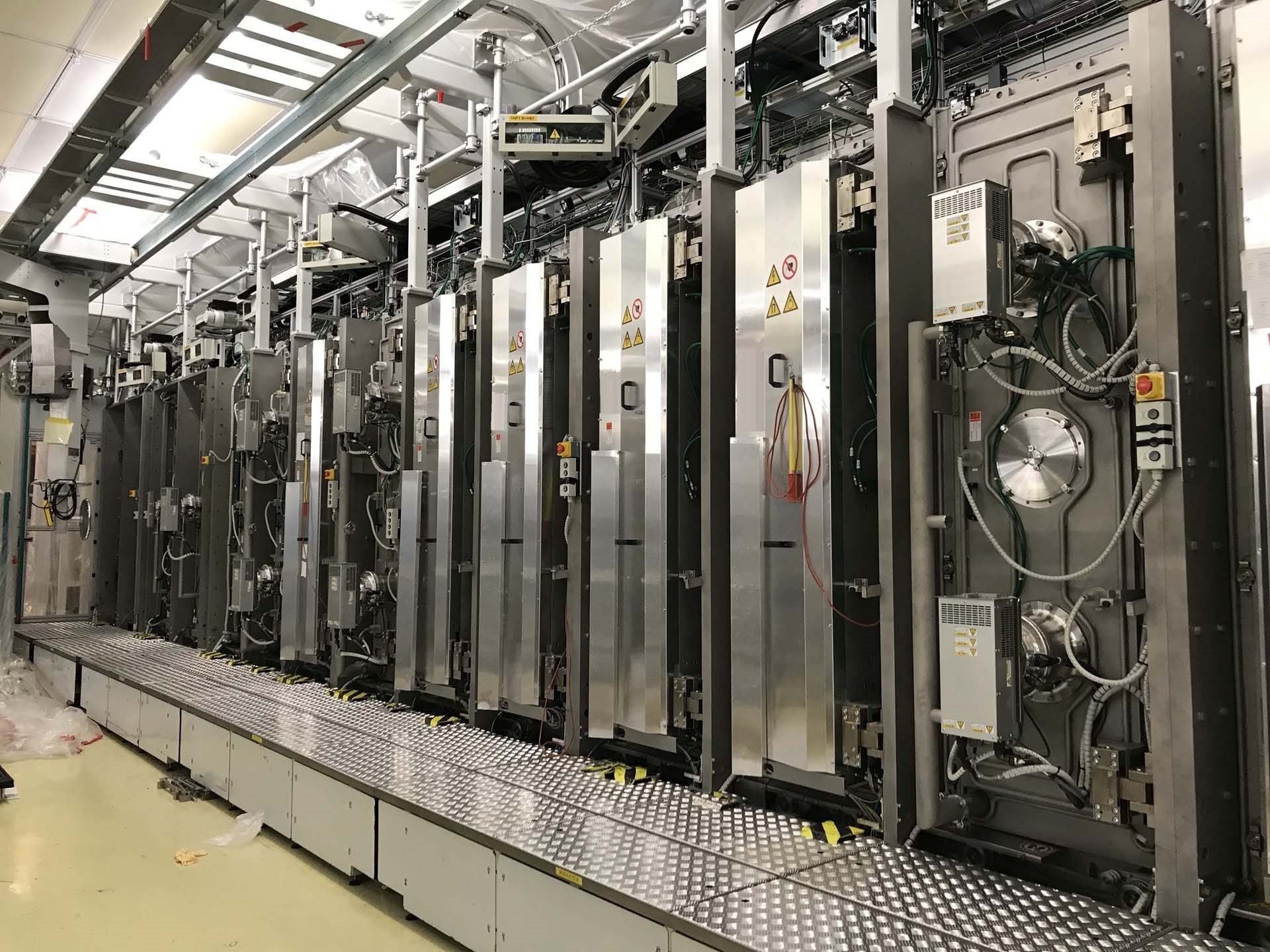

二手 AMAT / APPLIED MATERIALS NAR 1800 Twin #9243193 待售

網址複製成功!

單擊可縮放

ID: 9243193

Vertical inline sputtering system

Substrate carrier:

Substrate dimensions: 730 x 920 mm

Carrier dimensions:

Approximate 1840 mm length

Approximate 2527 mm height

Carrier loading capacity: (4) Substrates

Carrier material: Ti / Al

Glass breakage rate within vacuum area:

Glass thickness:

< 0.5 mm: 0.3%

≥ 0.5 mm: 0.1%

Vacuum measuring equipment:

Pirani vacuum meter:

Range: 10³ hPa to 1x10^-3 hPa

Ionization gauge:

Range: 10^-2 hPa to 1x10^-9 hPa

Capacitance vacuum meter sensor head:

Range: 10^-2 hPa to 10^-4 hPa

Pumps:

SHIMADZU TPH1503 Turbo-molecular pump

Rough vacuum pump SP630 plus WSU-2001

Sputter cathodes:

Type: Rotary cathode & water cooled

Material of backing tube: Stainless steel

Magnetic field: Static magnet array

Target: sprayed onto backing tube

Target length: 2150 mm

Planar cathode:

Type: DC Magnetron

Material of backing plate: Titanium with water cooling channels

ITO / MO BP

Al (2) BP

Magnetic field: Move mag

Target fixing: Bonding

Target length: 2100 mm

(2) 300 x 265 x 9 mm³ (Two end pcs)

1500 x 265 x 7 mm³ (Middle part segmented in pcs)

Heater system:

Heating chamber equipped with resistance heater which emits IR radiation

Mode of operation: PID Regulation

Heater set point capability: 650°C

Shielding:

Shielding material: Stainless steel

High sticking coefficient to prevent particle generation

Machine control system:

Programmable logic controller with decentralized IO’s

Digital & analog controls:

Pumps

Valves

Power supplies

Interlocks for water and compressed air

Error messages

Operating system: Windows

Cooling water:

Pressure: 5/7 Bar absolute

Maximum back pressure: Open drain

Water inlet temperature range: 18-25°C

Temperature level within: ± 2°C (for TMP’s only)

Hardness of water: 6-8°dH (Equivalent 107-143 ppm CaCO3)

Electric conductivity: 100 - 200 μS/cm

pH-Value: 8 - 10

Foreign particles size: Maximum 100 μm

Foreign particles concentration: Maximum 10/cm³

Dissolved Cl: Maximum 20 mg/l

Dissolved CO2: Maximum 15 mg/l

Compressed air:

Pressure: 6/8 Bar absolute

Sputter gases:

Argon

Oxygen

Nitrogen

Argon / Oxygen

Purity of sputter gas: 99.999 %

Venting gas: Nitrogen or dry compressed air

Dew point: ≤ -30°C

Pressure maximum: 1.5 Bar absolute

Ambient requirements:

Temperature at machine & machine control room: 20-30°C

Relative humidity: ≤ 60 %

Machine SiO2 / ITO Track consumption values:

Power: 760 kVA / 1000 A

Machine metal track consumption values:

Power: 1000 kVA / 1500 A

Electric power: 400 V ±10 %, 50/60 Hz, 3 Phase, 5 wires (3 AC, N, PE).

AMAT/APPLIED MATERIALS NAR 1800 Twin是一種濺射設備,設計用於將材料薄膜塗覆或沈積到基板上。它是一個兩室系統,意味著它有兩個獨立的真空室,可用於在一個操作周期內濺射不同的材料。設備是為無人值守操作而設置的,允許用戶設置參數並讓機器無人值守,直到所需的薄膜沈積完畢。它以高真空、直流電、平面磁控管濺射技術為基礎,可配合雙陰極運行。這樣可以在整個基板上實現高沈積速率和優異的均勻性。該工具還可以與負載鎖對接,以自動處理基板。資產能夠沈積鋁、不銹鋼、鈦、銅、鎢、鉻等材料。它還能夠在一個操作周期內沈積多層,從而形成多層薄膜,還能在曲面上產生凹凸結構。在操作規格上,該車型的真空室容積為4升,底壓為2x10-7 torr,陰極配置為兩個單面平面磁控管,功率高達每磁控管2000瓦。該設備還可以容納直徑不超過200毫米的基板,基板加熱範圍從室溫到600C不等。AMAT NAR 1800 Twin是一種安全可靠的濺射系統,具有優異的性能和均勻性。

還沒有評論