二手 CVC 601 #28214 待售

網址複製成功!

單擊可縮放

ID: 28214

晶圓大小: Up to 8"

優質的: 1986

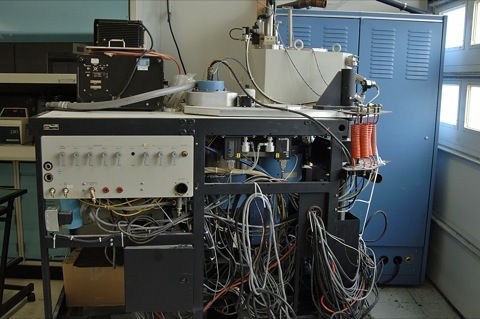

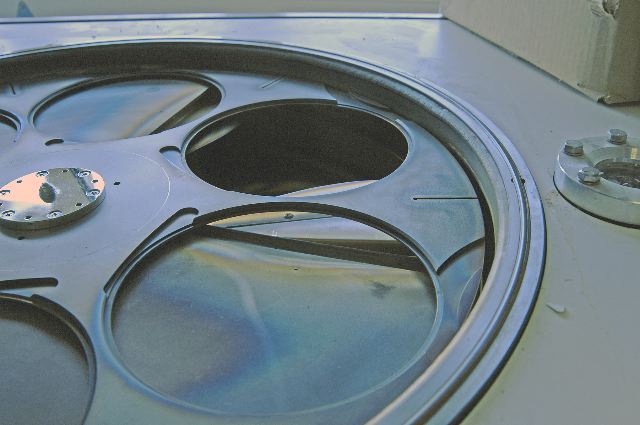

Batch type production sputtering system, up to 8"

Currently setup for Argon and Oxygen with the possibility for Nitrogen

Computer and cryopump included

Works in manual mode

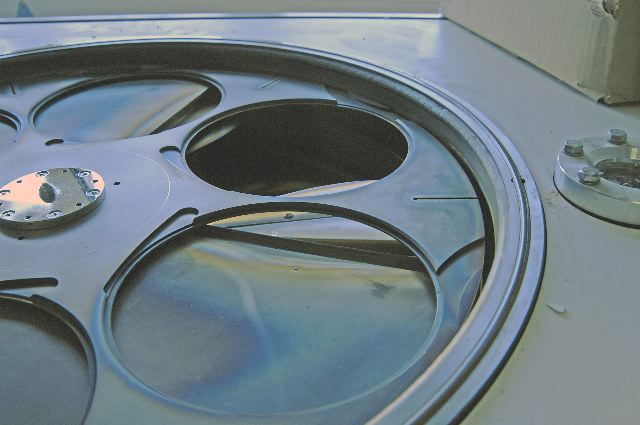

4 targets / wafer holders

Top loading machine

(Qty 4) work stations in the flat bottom of the 7" high work chamber

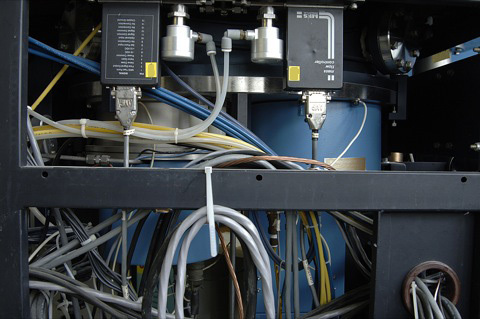

(Qty 2) DC stations

(Qty 1) RF station

(Qty 1) Ion cleaning station

Work heater / sintering accessory in the lid

Accessories for sputtering in several modes including DC Diode, RF Diode, DC Plasma Enriched Deposition ( PED, planar magnetron) and RF PED

Composed of a relay rack control center and cabinet which contains the vacuum chamber and pumping system

The computer interface is a Gould Model 484 Programmable controller

The DC Sputter Supply is an 10 KW Advanced Energy MDX Magnetron Drive

Unit has a CVC 3 KW AC Power Supply and a CVC 1 KW AC Supply

(Qty 4) Targets include:

Barium Titinate

Molybdenum Trioxide

Inconel

Titanium or Silicon

There are 4 target positions:

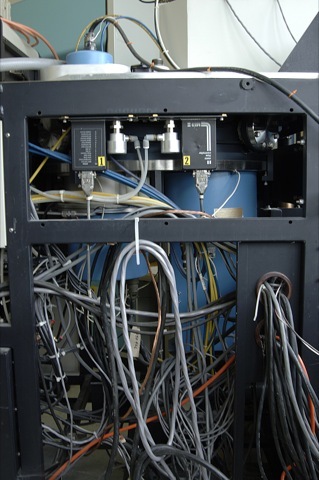

(Qty 1) RF Magnetron gun and matching unit

(Qty 2) DC Diode Sputtering unit with magnets in them for magnetron sputtering

The 4th target position has an Ion Cleaning Source

Project used only the RF PED Target position, DC targets were not used, in manual mode

Previous project used system with a P190/484 Programming panel

(Qty 2) Mass Flow Controllers

There is a cryo controller for N2-purge, and regeneration

Log book included

Packaged and stored

As-is

1986 vintage.

CVC 601是Cambridge Vacuum為一系列科學應用開發的最先進的濺射系統。它由一個帶有陽極和陰極的大型真空室組成,可以調整以允許樣品插入和工作距離。陰極由不銹鋼制成,而陽極由鎢構成。濺射室被封閉在一個手套箱中,通過它抽出空氣以產生高真空。一種氣體,如氦氣、氙氣或氮氣,可以用來填充腔室。為陰極充電,它連接到高壓電源。電壓可以設置為3000V。601包含各種控制系統,包括過程控制單元(PCU)、電源控制單元(PCU)和冷卻控制單元(CCU)。為保證運行平穩,有兩個水冷通道和高純度石墨支撐板。為了安全起見,CVC 601配備了一個真空計傳感器來監控濺射的效果。使用前,必須將601烘烤至所需溫度(通常800 °C,持續數小時),以除去水分和其他潛在汙染物。完成此操作後,可以打開系統並啟動進程。濺射過程從電源給陰極充電開始。這就產生了一個直流場,電子被加速到陽極。當電子與陽極接觸時,它們被吸收,陽極表面上的物質被濺射掉,濺射的物質再覆蓋目標物質,形成各層。濺射過程完成後,剩余的材料可以用刮刀從陽極上除去。然後,CVC 601可用於進一步處理,例如退火、蝕刻和沈積。總體而言,601濺射系統是參與薄膜加工的科學家和工程師的寶貴工具。其先進的控制系統確保了結果的準確性和可重復性,在高溫下充電、濺射和退火的能力是無與倫比的。它靈活的設計還可以輕松擴展和開發,從而為單個應用程序提供最佳定制。

還沒有評論