二手 PERKIN ELMER 4400 #9201790 待售

網址複製成功!

單擊可縮放

ID: 9201790

晶圓大小: 6"

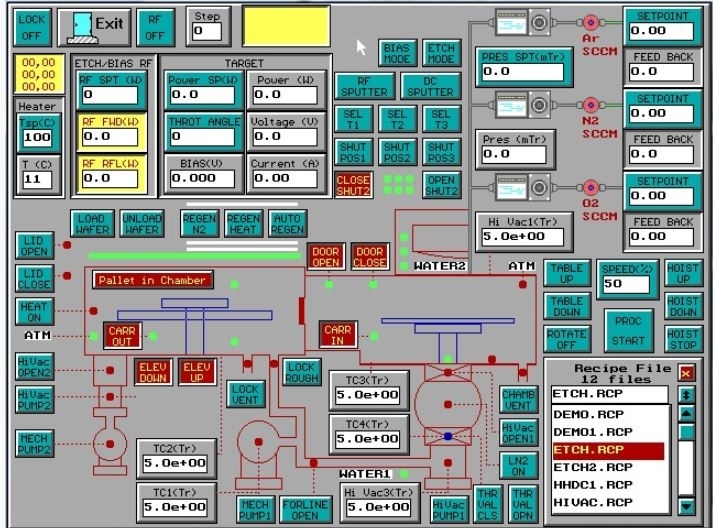

Sputtering system, 6"

Wafer loading: Manual

With load lock

Cathodes: Circle shape, 8″ & 4 max

Sputter methods: RF / DC

Diode / MAGNETRON

Gas lines: 1~3 MFC

Options:

Gas lines with MFC

N2

O2

Customized

Lamp tower alarm with buzzer:

Mechanical pump / Dry pump for process chamber and load lock

Independent mechanical pump / Dry pump for process chamber

Chiller for cooling plates and table

Turbo pump for load lock

Load lock lamp heating function: Up to 200°C

Chamber lamp heating function: Up to 300°C

Plasma etch function

Bias function

Co sputter function

Reactive sputter function

Main frame

28" Diameter SST chamber top plate with ports and cathodes:

Configuration 4400 4410 / 4450

Cathode shape Circle Delta

Cathode size 8" Delta

Cathode quantity 1 to 4 1 to 3

Sputter power supply:

4400 4410 / 4450

DC Power 5 kW 5 kW / 10 kW

RF Power 1kW / 2kW 2 kW / 3 kW

Pulse DC Power 5 kW 5 kW / 10 kW

Process chamber:

8" Diameter x 12" High stainless steel cylinder with 6"

CF Flange view port and load lock port

28" Diameter stainless steel base plate

11/2" Air operated roughing isolation valve

Air operated gas inlet valve

Air operated vent valve

11/2" Blanked-off leak check port

Removable deposition shields

23" Diameter, 3-position water cooled annular substrate

Table with variable speed motorized table drive

Full circle shutter and vane shutter

Chain drive pallet carrier transport

Heavy duty electric hoist

Load lock:

30" x 28" x 8" Stainless steel load lock chamber

Aluminum cover

Chain drive pallet carrier transport

2" Air operated roughing isolation valve

Air operated vent valve

23" Diameter molybdenum annular substrate pallet

Elevator for pallet up and down function

Vacuum systems for process chamber:

(2) Stage cryo pumps

With 1000 l/s pumping speed for air

Includes:

Chevron

Water cooled compressor and lines

Automatic regeneration controller

Plumbing kit, 71/2"

Aluminum air operated gate valve: 6" ASA

Air operated venetian blind throttling valve

Mechanical pump or dry pump for process: 36.7 Cfm

Chamber and load lock

Replaced obsolete controls:

Auto pump down controller

Load lock controller

Digital clock timer

Table raise / Lower control

Throttle valve control system

Pressure control system

Sputter head controls

Gas line with MFC

Ar, 200 SCCM, customized

Power box: AC 380 V / 208 V / 3 Phase.

PERKIN ELMER 4400是一種最先進的濺射設備,已成為薄膜真空沈積的通用通用工具。這個濺射工具是一個多源系統,允許濺射任何金屬或介電材料在其三室設計與其定制的端部安裝晶片支架。4400可實現精密沈積厚度降至1埃,薄膜均勻性降至1納米。通過獲得專利的銅目標保護方法實現了這種精確測量,該方法還確保了工藝的可重復性以及較長的周期生產時間。采用TRIO-MIM^TM密封磁控管技術,保證薄膜材料沈積過程中腔室不受汙染。TRIO-MIM^TM密封磁控管技術加熱濺射目標,從而打開了改變工藝參數的額外潛力。這允許高密度、高導電性薄膜以及更復雜的有機材料在沈積過程中需要更高的底物溫度的性能。PERKIN ELMER 4400是一種可靠且易於操作的設備。這種濺射設備在晶片支架的尺寸方面提供了靈活性,並且能夠通過實時軟件控制來調整濺射參數,從而提高工藝精度。使用內置的自動校準功能可以方便地進行機器校準。對於生產環境中的UL認證操作,它也是一個足夠強大的工具。除了其一般的沈積應用外,在創建高級設備組件時還經常使用4400。它對基板進行機械拋光,以確保表面光滑,而濺射過程在設備上產生微觀的微觀特征。PERKIN ELMER 4400是一種可靠、高效的濺射資產,可提供局部和全室濺射濺射,並提供可選的原位沈積和退火。該模型的特點允許生產質量最高的薄膜,同時控制生產成本。

還沒有評論