二手 PERKIN ELMER 4450 #9199550 待售

網址複製成功!

單擊可縮放

ID: 9199550

晶圓大小: 8"

Sputtering system, 8"

Wafer loading: Manual with load lock

Cathode:

(3) Delta shapes

(4) Circle shapes

Sputter method:

RF/DC

Diode / MAGNETRON

Process chamber:

8" Diameter x 12" High stainless steel cylinder with 6"

CF Flange view port and load lock port

28" Diameter stainless steel base plate

11/2" Air operated roughing isolation valve

Air operated gas inlet valve

Air operated vent valve

11/2" Blanked-off leak check port

Removable deposition shields

23" Diameter, 3-position water cooled annular substrate

Table with variable speed motorized table drive

Full circle shutter and vane shutter

Chain drive pallet carrier transport

Heavy duty electric hoist

Load lock:

30" x 28" x 8" Stainless steel load lock chamber

Aluminum cover

Chain drive pallet carrier transport

2" Air operated roughing isolation valve

Air operated vent valve

23" Diameter molybdenum annular substrate pallet

Elevator for pallet up and down function

Vacuum systems for process chamber:

(2) Stage cryo pumps

With 1000 l/s pumping speed for air

Includes:

Chevron

Water cooled compressor and lines

Automatic regeneration controller

Plumbing kit, 71/2"

Aluminum air operated gate valve: 6" ASA

Air operated venetian blind throttling valve

Mechanical pump or dry pump for process: 36.7 Cfm

Chamber and load lock

Gas line with MFC

N2

O2

SCCM

Customized

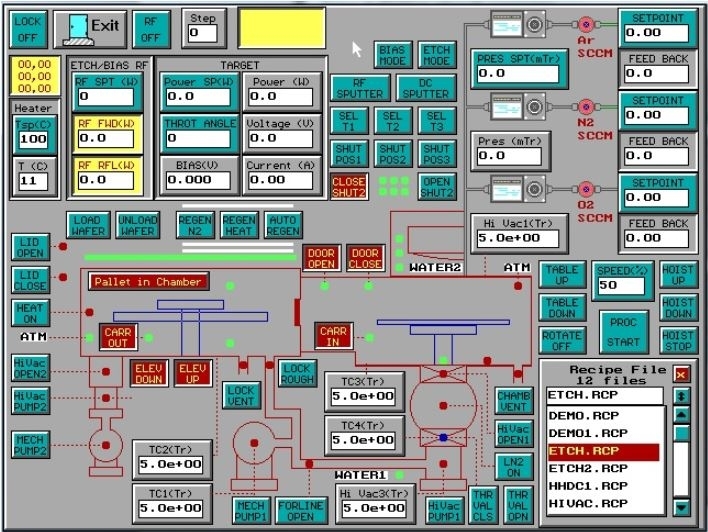

System PC control

Options:

Gas lines with MFC

N2

O2

Customized

Lamp tower alarm with buzzer:

Mechanical pump / Dry pump for process chamber and load lock

Independent mechanical pump / Dry pump for process chamber

Chiller for cooling plates and table

Turbo pump for load lock

Load lock lamp heating function: Up to 200°C

Chamber lamp heating function: Up to 300°C

Plasma etch function

Bias function

Co sputter function

Reactive sputter function

Materials:

AI+W

InSnO

AI2O3

Ag_

Au

C

Cr

Cr/Co

Cr/Au

Cr+Cu

Cr/Si

Cr/SiO

Cr/Si02

Si02

Mo

MoSi2

Mo2Si5

Mc>5Si3

Ni

Ni/Cr

Ni+Ni/Cr

Ni/Fe

Pt

Ti02

SiC

Ti/W

Si02+02

Si+N2(Si3N4)

Si+N2+B4C

Ta

TaC

Ta+Au

TaSi2

Ta+Si02

Zr

Ti02+Cr

Ti+Au

Ti+Au+Ni

Ni/Fe+Cu+Si02

Ti/W+Au

Ti/W+Au+Ta

Ti/W+AI/Si

Ti/W+Ni/Cr+Au

Ti/W+Pt

Al+Ti/W+Ag

W+AI2O3

Zn

Zri02

Basic configuration

Main frame

28" Diameter SST chamber top plate with ports and cathodes:

Configuration 4400 4410 / 4450

Cathode shape Circle Delta

Cathode size 8" Delta

Cathode quantity 1 to 4 1 to 3

Sputter power supply:

4400 4410 / 4450

DC Power 5 kW 5 kW / 10 kW

RF Power 1kW / 2kW 2 KW / 3 kW

Pulse DC Power 5 kW 5 KW / 10 kW

Power distribution box: AC380 V / 208 V / 3 Phase.

PERKIN ELMER 4450是一種高性能濺射設備,設計用於將薄層材料沈積到各種基板上。它利用磁控管或離子轟擊沈積技術,制造出金屬薄膜、氧化物和其他各種材料的超光滑層。該系統包括兩個3英寸直流濺射電極和一個非常適合低溫濺射操作的大型真空室。4450的高性能磁控管濺射工藝采用高效和高度可靠的冷卻裝置,以確保最大性能和運行壽命。通過在高壓條件下使用氙氣或氮氣,機器能夠以最佳的沈積速率創造出優越的薄膜性能。該工具還配備了先進的珠子清洗技術,以提高資產部件的使用壽命。該模型需要最少的維護,並提供卓越的真空泵.其低工作溫度有助於最小化基板加熱,提高覆蓋層質量。該設備還包括一個高精度電容厚度監測儀和一個脈沖調節監測儀,以確保優秀的層沈積。這款顯示器還允許不同的濺射電流,為用戶提供對塗層工藝的理想水平的控制。系統易於使用的界面使用戶能夠在不同的濺射參數和目標材料之間快速、輕松地進行更改。其低噪聲操作使得長時間使用安全可靠。它設計小巧輕巧,便於存儲和運輸到不同的工作站。PERKIN ELMER 4450是實驗室和工業濺射工藝的理想選擇。其先進的特性和易於使用的界面,使其成為那些尋求優越層沈積和優越性能的人的理想選擇。其先進的冷卻系統和低電流儀器使其在低溫濺射操作中具有很高的可靠性和效率。

還沒有評論