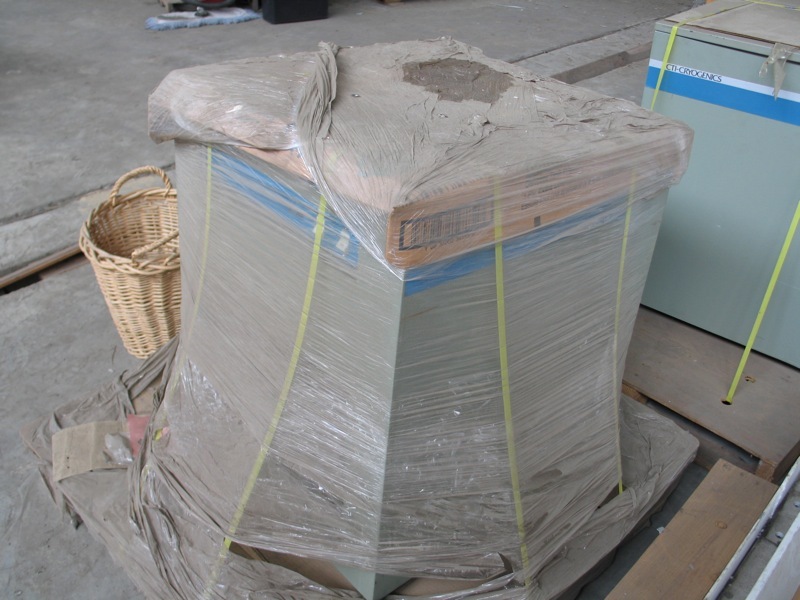

二手 SIGMA Sputtering System #193698 待售

網址複製成功!

單擊可縮放

ID: 193698

Roll to roll sputtering system

8 Ball Vacuum Chamber & Chassis

(2) CTI Model 1020CP Cold Head Cryo Pump

(2) CTI Model 1020R Compressors

Leybold RuVac WS500 Roots Blower

Sliding Door Face Plate

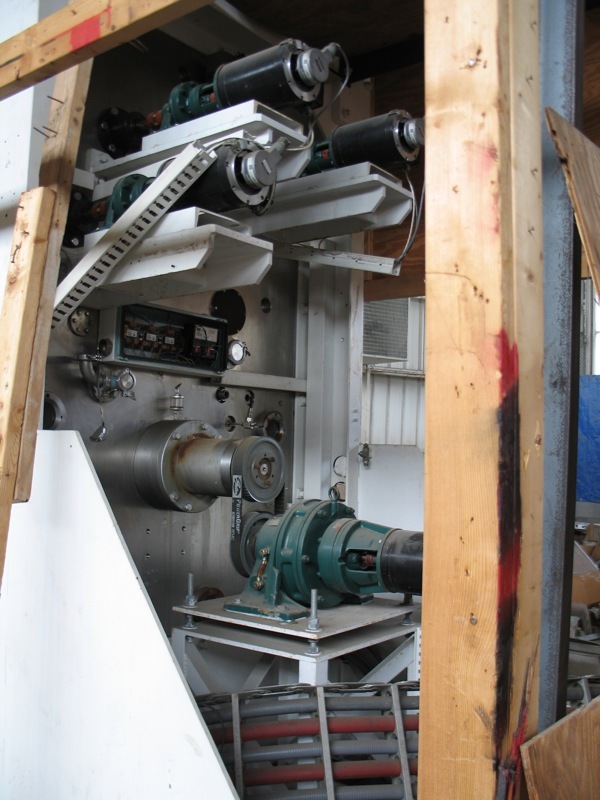

Sputtering system:

RF Matching Networks

Mass Flow Controllers

Web system:

(4) Black Max Motors & Gearboxes (Unwind, rewind, drum and tension drive)

Chilled Drum

Drum Motor Stand

Control system:

Human Machine Interface (HMI) - An operator touch-screen for manual and automated operations

HMI - A Eurotherm Drives touchscreen for web control

Eurotherm Control Cabinet & Network

General Control Panel

Utilities and accessories:

Chiller

Air Compressor

Cathode Cooling Water Manifold

Flexible Electric Trunking

Valving:

Roughing

Vent and interlocks

Cryo gate

Cryo throttle

Regeneration

Purge

Gauges:

Convection gauges (low mtorr range)

Baratron gauges

Ion gauges

Hydrogen vapor pressure gauges

Tension drive, load cells and amplifiers

Drum rotation motor and gearbox

Rewind and unwind motors

Gas system and control

PLC card

Signal connections

Auto pumping

Rewind and unwind control

Plasma treater

Sputtering controls: manual, regulate and direct mode

RF control, DC control

Maintenance mode

Missing parts:

Leybold DK200 rough pump (rotary piston pump)

DK200 Gearbox

(2) Cryo Throttle Valves (Butterfly Valves)

(1) Cryo-pump gate valve

(2) Hydrogen Vapor Pressure Gauges

Ion Gauge

Baratron Gauge

(4) Convectron Gauges

(6) Pneumatic Valves (regeneration valves for cryo pumps; purge valves for cryo pumps, rough pump Vent valves)

Chamber Connecting Flange for Drum Feed-through

Tension Roller Feed-through

Unwind/Rewind Feed-through

(6) DC Cathodes (40” x 6”)

(6) MDX 5 KW sputtering power supplies

Gas Control System

Gas Lines

(3) Load cells

(3) Load Cell Amplifiers

(1) Unwind/Rewind Shafts

Steel Pressure Plate for Floor

Gantry System and Crane (parts missing)

Door Drive Train

Side Steps to gain access to Cathodes

Steel Ladder

Mezzanine

480 V, 3 phase, approx. 1,000 A.

SIGMA濺射設備是一種先進的、最先進的濺射系統,旨在將薄膜沈積到基板上。用於多種應用,如半導體器件制造、光學塗層、研發、醫療等多個行業。該單元由一個小腔室組成,該小腔室內充斥著氙氣,以及一個電壓設置可變的電源。一種目標材料,如鋁或鈦,放置在腔內的陰極板上,並帶正電荷生成等離子體。等離子體產生電離的等離子體粒子流,轟擊目標物質,釋放帶正電的離子。這些離子隨後被吸引到帶負電的基板表面,金屬原子在薄層中沈積到基板上。SIGMA Sputtering Machine由一個精密的軟件套件控制,允許用戶設置廣泛的參數以達到最佳效果。用戶可以調整各種參數來優化工具,如沈積速率、離子濃度和隨時間的沈積均勻性。該軟件還允許用戶監測和控制沈積速率,使他們能夠根據需要停止和啟動,而不會幹擾最終沈積過程。濺射資產還具有幹式濺射模型,有助於防止不需要的顆粒附著在基板上。設備配有後加工幹蝕刻,通過去除基板表面可能存在的任何顆粒或汙染物,進一步凈化沈積層。此外,SIGMA Sputtering System還提供各種附件,例如樣品進紙器、晶圓處理程序、盒式磁帶和夾具,以及使設備更通用的其他功能。總體而言,濺射機是一種先進、可靠的金屬沈積應用解決方案.它具有很高的可自定義性,為用戶提供了多種參數可供選擇,以實現所需的結果。此外,其幹法和後工藝蝕刻特性確保了均勻和純凈的沈積層。

還沒有評論