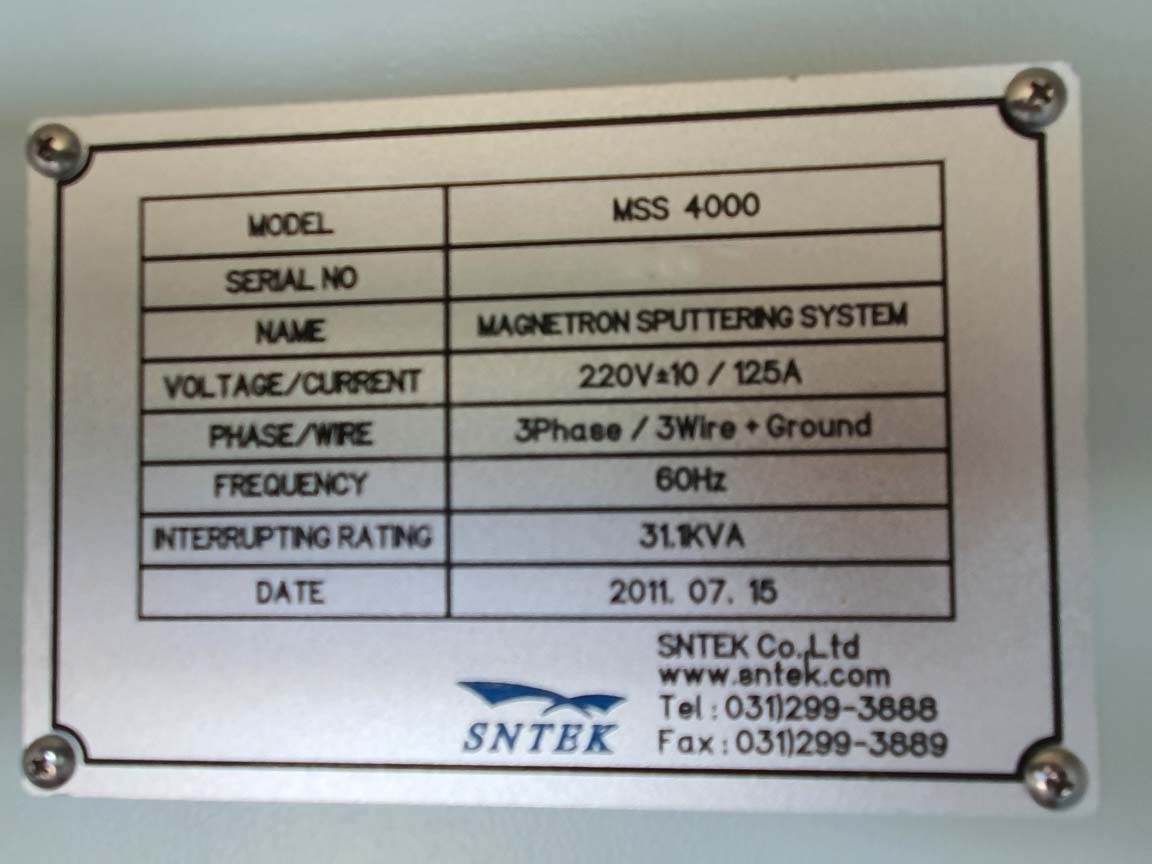

二手 SNTEK MSS 4000 #293638179 待售

網址複製成功!

單擊可縮放

ID: 293638179

優質的: 2011

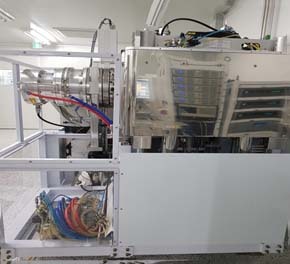

Sputtering system

Loadlock chamber and TM Arm concept

Metal sputtering process: Ti, Cu and Au

Maximum substrate: 320 mm (6) Loadings / Cassette

Magnetron sputtering source: (3) Tilt guns, 8"

Substrate rotation speed : 5~20 RPM

Maximum temperature sheath heater: 300°C on substrate

PLC Based PC Control: HMI, Semi-automation control

Compressed air drive: 6~7 kg/cm², ¼"

Chamber vent: 3~4 kg/cm², ¼"

Process gas: Ar, 1~2 kg/cm², ¼"

Chamber pump exhaust: Normal exhaust line, 25 pi

Vacuum pumping unit:

Rough pump: SUS304 E.P tube and bellows, 40 pi

Sputter chamber: TMP and Dry

Transfer chamber: TMP and Dry

Loadlock chamber: TM's share

Pressure control type: Downstream ( Auto TH/V)

Gas supply unit: MFC Control (Ar)

Cooling water:

Heater and chamber: 3~4 kg/cm², L/Min, ½"

Sputter gun: 3~4 kg/cm², L/Min, ½"

Electricity:

Power: 220 V, 3 Phase, 60 Hz, 120 A (3 wire)

Ground: Class A (10 Ω or below) (1 wire)

Power supply:

Main chamber: (3) DC Power, 5kW

Loadlock chamber: RF Power, 1kW

Plasma cleaning source with RF Power at loadlock system

2011 vintage.

SNTEK MSS 4000濺射設備是一種高真空沈積系統,旨在將薄膜和塗層沈積到基板上。采用三極管式磁控管濺射配置,MSS 4000可以沈積金屬、合金以及其他多種材料,具有極高的均勻性和重復性。該單元可用於創建薄膜、散裝塗層和分層結構。SNTEK MSS 4000配備了兩個獨立的濺射室,能夠在低於10-7 torr的壓力和高達400°C的溫度下運行。每個腔室可以單獨配置一個創新的、可配置的目標組件,允許用戶從各種各樣的目標形狀和大小中進行選擇。目標組件甚至能夠在軸上旋轉目標,以統一分布目標表面的磨損。MSS 4000由一個配備了多種選項和工具的綜合過程控制器驅動,以準確控制和監控沈積過程。該工藝控制器可實現精確的功率和氣流調節,以獲得最佳的沈積性能.此外,該工藝控制器能夠登記和儲存各種工藝參數,從而能夠準確分析沈積膜。SNTEK MSS 4000可與多種其他儀器連接,用於分析和測試薄膜。本機還配有遙控節能功能,節能提升整體效率。整體而言,MSS 4000濺射工具是沈積薄膜和塗層具有精確控制和可重復性的絕佳選擇。SNTEK MSS 4000允許用戶以最少的停機時間和資源來制作具有高均勻性和出色可重復性的影片。此外,該資產可以輕松地與其他流程工具集成,並為用戶提供一整套流程控制選項。

還沒有評論