二手 G&N V400 #9208430 待售

網址複製成功!

單擊可縮放

ID: 9208430

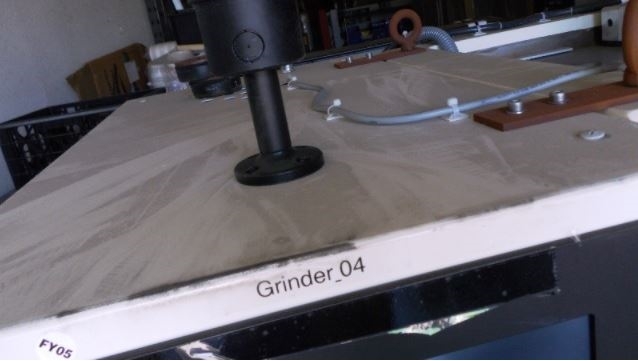

Ceramic wafer grinding machine

With its polymer concrete casting for better vibration absorption

Improve structural integrity

Rigidity & stiffness to grind advanced materials

Technical data:

Motor: 4 kW

Spindle speed: 1450 RPM

Total connected load: 8 kW

Chucks: 28x2” 16x3” 12x4” - 9x5” 6x6” 3x8” 1x12”

Rotary tabl: 520 mm

Rotary table speed: 1 - 30 rpm

Cup grinding wheel:

Vitrified: 250 x 40 x 76

Diamond / CBN: 250 x 40 x 76

Z-Axis & rotary table motion: PMAC-Lite (4 Axes) Control

Compressed air: 60 - 90 PSI

Fine down feed:

Range: 200 mm

Step: 1 µm

Machine control:

Retrieve data and communicate directly with program 15" TFT touch screen & industrial computer support

Dual spindle machine for fast stock removal & ultra-fine surface finish

Coolant treatment:

Closed-loop chiller controls grinding coolant temperature & coolant

Integrated filter system separates Ga As & other material particles for disposal & reclaiming

Power supply: 220/380/440 V, 60 Hz.

G&N V400晶片研磨、研磨和拋光設備是一種強大而高效的機器,設計用於直徑8英寸的矽片的濕磨和幹磨、研磨和拋光。該系統由一個封閉式不銹鋼研磨罐組成,具有集成的循環過濾系統,垂直電機驅動的底板,上部拋光板,全部與計算機控制的主控制器相連。該單元使用獨特的3軸運動機運行,該機由一個垂直方向的電機驅動的底板進行旋轉和傾斜調節,以及一個上部拋光板,提供精確的橫向和徑向運動。該運動工具提供了高度精確的研磨和拋光結果。拋光板裝有精密空氣軸承,用於晶圓的垂直旋轉。晶圓研磨過程通過專用控制單元進行控制,用戶可以調節研磨速度、壓力、時間和研磨石材或墊片的形狀等參數。該資產還配備了高精度觸摸探頭,以確保在研磨過程中可以進行精確的表面粗糙度測量。該型號可進一步配備一系列旨在提高生產率的配件。一個旋轉炮塔式的起重設備,它提供了快速和容易的加載和卸載晶片到研磨罐。真空夾具系統也可用於晶圓的完美對準.V400晶片研磨、研磨和拋光裝置是一種高效、精密的生產機器,適用於各種薄膜和晶片的應用。精細的控制和方便的裝卸能力使該工具非常適合批量處理,提供卓越的質量和生產率。

還沒有評論