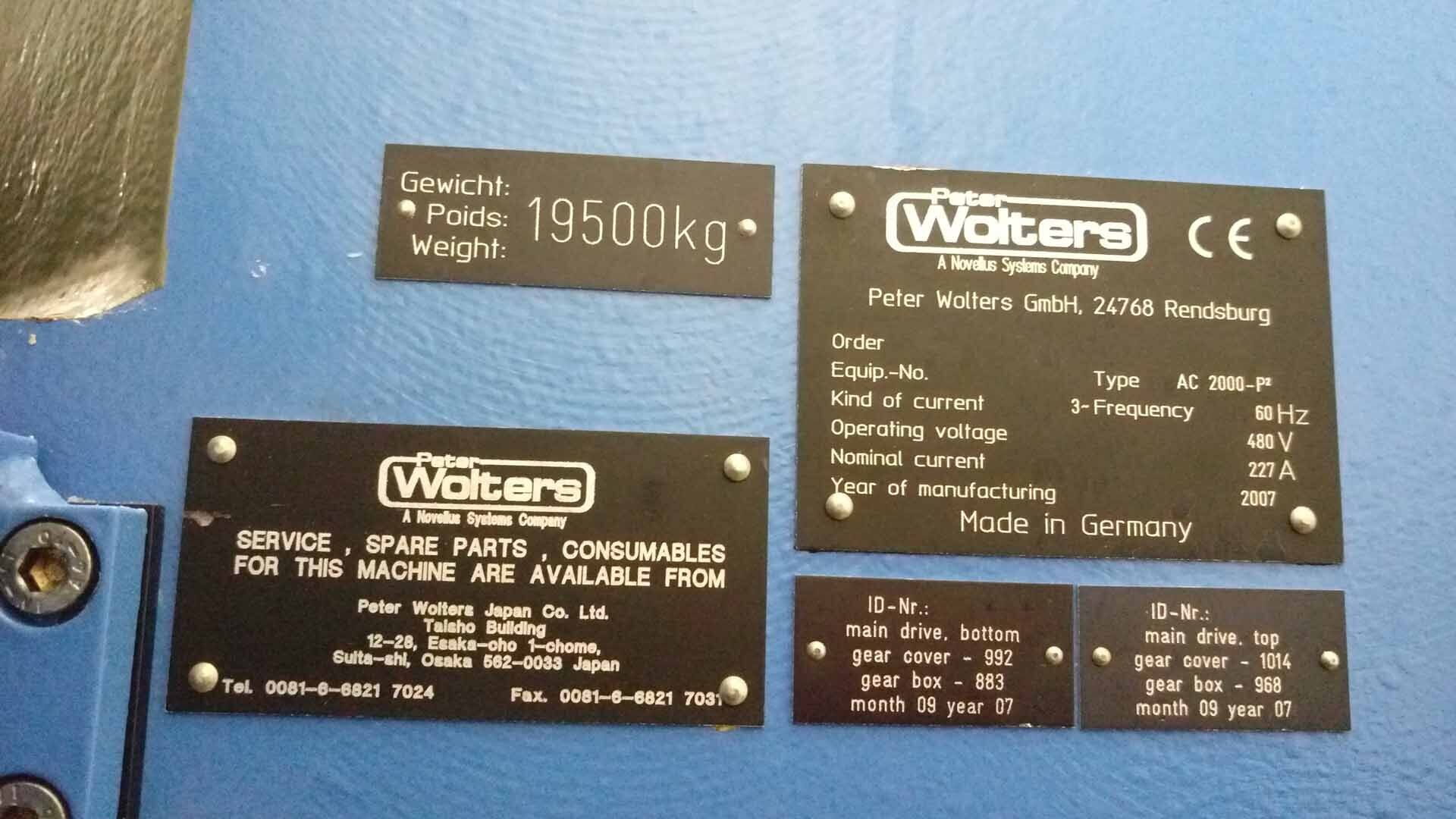

二手 PETER WOLTERS / LAPMASTER microLine AC 2000-P2 #9352425 待售

看起來這件物品已經賣了。檢查下面的類似產品或與我們聯系,我們經驗豐富的團隊將為您找到它。

單擊可縮放

已售出

ID: 9352425

晶圓大小: 12"

優質的: 2007

Double side polishing machine, 12"

Wheel dimensions:

Outer: 1935 mm

Ring width: 686 mm

Thickness: 80 mm

Wheel distance: 190 mm With 80 mm wheel thickness

Pneumatic:

Maximum load pressure: 3500 daN

Compressed air: 6,5 Bar

Electronic equipment:

Servo drives digitally controller

Upper wheel: 46 kW/40 min⁻¹

Lower wheel: 46 kW/40 min⁻¹

Inner workpiece drive: 7,5 kW/min⁻¹

Outer workpiece drive: 7,5 kW/min⁻¹

Hold the drive aggregates for lower working wheel and workpiece drive

Electromechanical height adjustment for outer and inner pin ring

Splash guard pan

Assembly connections for easy access

Pneumatic load control

Interception device

Weighting device

Drives

Working wheels

Safety device

Corrosion resistant design

Electric switch cabinet (Air cooled)

CNC Controller

Operating panel

Polishing media connection and metering

Slurry distribution system

Polishing media collecting channel

Tool kit

Basical range of CNC Control S7-400 With visualization

Pressure control via proportional valve and pressure sensor

Display of the actual pressure value

13-Pressure ranges

Variable speed of rotation change in each pressure range of each drive

Variable change of rotation direction

Automatic swiveling in / out

5-Conditioning program with recorded inception heights

Alternative list for selective programming functions:

Swiveling device

Starting of the drives

Feeding of the polishing media

Wet mode

0020: Brush program

0030: Cooling water temperature monitoring

0040: Rinsing and spraying device (Chemical polishing)

0050: Spraying device

0060: Levelling device for horizontal adjustment of the upper working wheel

0070: Epicyclic work holder drive system

0080: (2) Polishing wheels

0090: Back up

Options:

0100: Power backup

0110: Polishing compound connection

0120: Cable identification

0130: Mixing block

0140: Taiwan electrics

Electrics: 460 V

UPS: 230 V

0150: Packing

0160: Commissioning

0170: Status light

0180: Loading counter

0190: Second hand operation station

0200: Shower guns for DI- Water

0210: (2) Heating / Cooling aggregate (WRK) 12760 W

0220: Heating / Cooling aggregate Heating possibility up to 55°C

0230: Fittings for cooling water circulation system with refrigeration unit

0240: 6-Step polishing program

0260: Fiberglas cable

0270: Separate drive security

0290: Signal tower with LED

0300: Indication of signal tower

0310: Upgrades

0320: 80-Polishing feed holes

0330: Anti-syphoning package

0340: Measuring device (Flatness)

0350: Distance block set

0360: Steel straight edge, 2000-0 mm

0370: Additional cable length

0380: Engineering costs

0390: PDR System

Power supply: 400 V + 6%-10% (Acc. DIN IEC 38)

Frequency: 50 Hz

Control voltage: 203 V / 24 VDC

2007 vintage.

LAPMASTER AC 2000-P2是一種用於半導體晶片的晶片研磨、研磨和拋光設備。它是一種精密儀器,具有計算機化控制器、模塊化無錯誤主軸傳動裝置以及多種優質磨料和快速更換安裝在工業級花崗巖基座上。該系統設計處理200-300毫米晶圓研磨,精度和重復性最高。交流2000-P2采用兩階段研磨和拋光工藝。每個階段分為兩個部分:第一階段由一個安裝站、一個晶圓夾板和一個堅固的研磨輪組成。第二階段采用不同的研磨輪,具有拋光墊支架和粗細的研磨劑。這兩個階段都包括變速調整,允許操作員根據需要增加或降低速度。交流2000-P2還設有計算機化控制器,為操作員提供詳細數據,包括運行時間、進程設置、自動關閉和機器狀態指示燈。控制器極具彈性,可以接受廣泛的輸入選擇選項,例如手動、半自動和全自動模式。該單元還提供壓力、滑移和振動極限調節等可調節參數,以確保最高的工藝精度。該機還有一個集成的除塵工具。空氣葉片清除產生的磨料灰塵,同時將其放置在機器外部。塵埃收集網也有可調的設置,以滿足最嚴格的顆粒要求。PETER WOLTERS AC 2000-P2配備了可提供高精度操作的模塊化無錯誤主軸驅動器。這種精密的設計結合了人體工程學和交流電機技術的原理,提供了可靠和安全的操作。資產還包括各種可選模塊,例如用於晶圓夾緊和超壓控制的空氣單元,以及高精度的振動保護模型。這些特性使得PETER WOLTERS/LAPMASTER AC 2000-P2一種高精度晶片量產的理想機器。其精密的工程設計和靈活性提供了真正的「一體」設備,能夠研磨、拋光、吹風以及生產過程中所需的任何其他改進。系統的控制器使操作員能夠完全控制過程,從而實現卓越的過程質量。交流2000-P2是尋找制造半導體晶片的可靠裝置的生產商的理想選擇。

還沒有評論