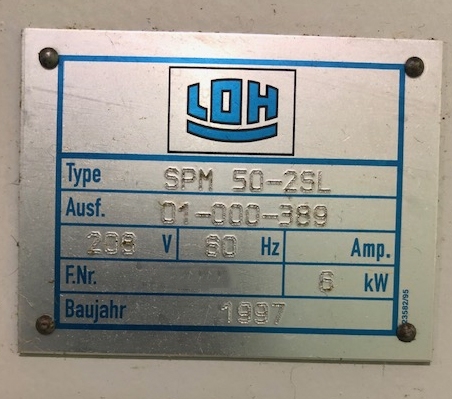

二手 SATISLOH SPM 50-2SL #9253846 待售

網址複製成功!

單擊可縮放

ID: 9253846

優質的: 1997

System

Controller:

Digitec industrial PC and color display

Pentium 233 MHz processor

7-Axis slot CNC

Flash disk: 512 MB

Working memory: 128 MB

Floppy Disk Drive (FDD), 3.5"

Operating system: Windows

Machine system: Y2K

Includes:

Automatic calculation of lens reception via center thickness measuring system

Sagittal height measuring instruments

Pivot-type generating process

Automatic feed regulation

Set-up mode for cutting simulation

Hydrodehn clamping system for holding the diamond grinding tool

Chiller unit to control the tool spindle temperature

Z-Axis measuring system for cross hutch pattern adjustment

Working range:

Work piece diameter: 5 mm to 60 mm System with synchrospeed mode

Dressing of polishing tools: Up to 80 mm

Work piece holder: Collet chuck / Vacuum chuck with 12.00 mm shaft

Work piece spindle: Directly driven by servo motor

Work piece speed: 20 to 1,500 rpm

Spindle controller: LUST MC Servo controller

Tool diameter: Up to 70 mm

Tool connection: Hydrodehn clamping system with diameter 12 mm

Tool spindle motor: (2) AC Spindle motors

Tool spindle speed: 2,000 Up to 30,000 rpm

Spindle controller: LUST VF-1408 Frequency converter

CNC Axis: 4-Axis with CNC controlled servo axis

Axis:

2-Linear axis

Rotary axis (Swivel head)

Rotary axis (Work piece spindle)

Servo drives:

(3) MOOG Servo valves (5 liters flow rate) motors with ITK-Kassen servo controller

AC Servo motor (work piece spindle) with LUST MC servo controller

Measuring system:

(2) HEIDENHAIN LS 406-170 Linear scales

HEIDENHAIN ERN 180-1024 Rotary encoder (Work piece spindle)

HEIDENHAIN ROD 450-0500 Rotary encoder (Swivel head)

MR 500 Sensors with scales and MR ISA Bus PC slot board

T18 Measuring sensor (CT-Measuring system)

Positioning accuracy:

X-Axis (Table): 0.001 mm

Y-Axis (Tailstock): 0.001 mm

C-Axis (Swivel head): 5 Seconds

Axis travel (Maximum):

X-Axis (Table): 116 mm

Y-Axis (Tailstock): 122 mm

C-Axis (Swivel head): ± 80°

Processing feed rate: Up to 30 mm/min

Coolant flow control: IFM Flow sensors ST 1604

Digitec Mini-PC:

TFT Color display with integrated standard keyboard

4-Axis CNC slot board

PLC Control: SIEMENS PLC Controller siematic S595U

Compressed air: 6 Bar

Power supply: 380 V + 10%, 3 Phase, 50 Hz AC

Power consumption: 6 kW

1997 vintage.

SATISLOH SPM 50-2SL是一種先進的晶圓研磨、研磨和拋光設備,其設計目的是在使用多種材料時提供優異的效果。該系統采用集成設計,能夠在不影響質量的情況下進行高效的研磨和研磨操作。它旨在容納各種晶圓尺寸,範圍從標準的25-125mm到任何定制尺寸。SATISLOH SPM 50-2 SL單元包括功能強大的拋光電動機、先進的電動機控制器、精密旅行機和先進的磨頭,以達到最佳性能和精度。該工具的集成驅動資產包括無刷直流電動機、行星齒輪和創新的safetyShut TM技術,如果檢測到磨頭超速,該技術將自動關閉電動機。電機的轉速範圍是可調的,允許以特定的轉速和力來傳遞恒定的拋光循環或研磨循環。該模型還包括帶有數字讀數的精確定位指南,允許精確調整以確保一致和準確的結果。使用集成夾具和可調節托盤,可以方便地裝卸晶片。一個特殊的晶片夾設備有助於確保安全配合和消除晶片碎裂和抓握損壞。該系統在一個緊湊高效的單元中提供研磨、研磨和拋光的能力。SATISLOH獲得專利的Smart StartTM單元可自動檢測過程何時啟動,並為理想的啟動設置正確的條件。該機還允許在研磨和研磨操作過程中進行精細的工藝控制調整。該工具提供兩個帶有圖形用戶界面的獨立控制系統,為用戶提供直觀體驗。第一個控制資產允許完全手動控制研磨和研磨操作,第二個控制模型提供創建和編輯程序以及將數據上載到計算機等附加功能。該設備還包括跟蹤系統,以跟蹤所有操作及其結果。SPM 50-2SL是晶圓研磨、研磨和拋光的先進設備。機器的集成設計允許高效研磨和研磨操作,並為用戶提供對過程的精確控制。該工具的直觀控制系統有助於確保每次都有可靠和一致的結果。

還沒有評論