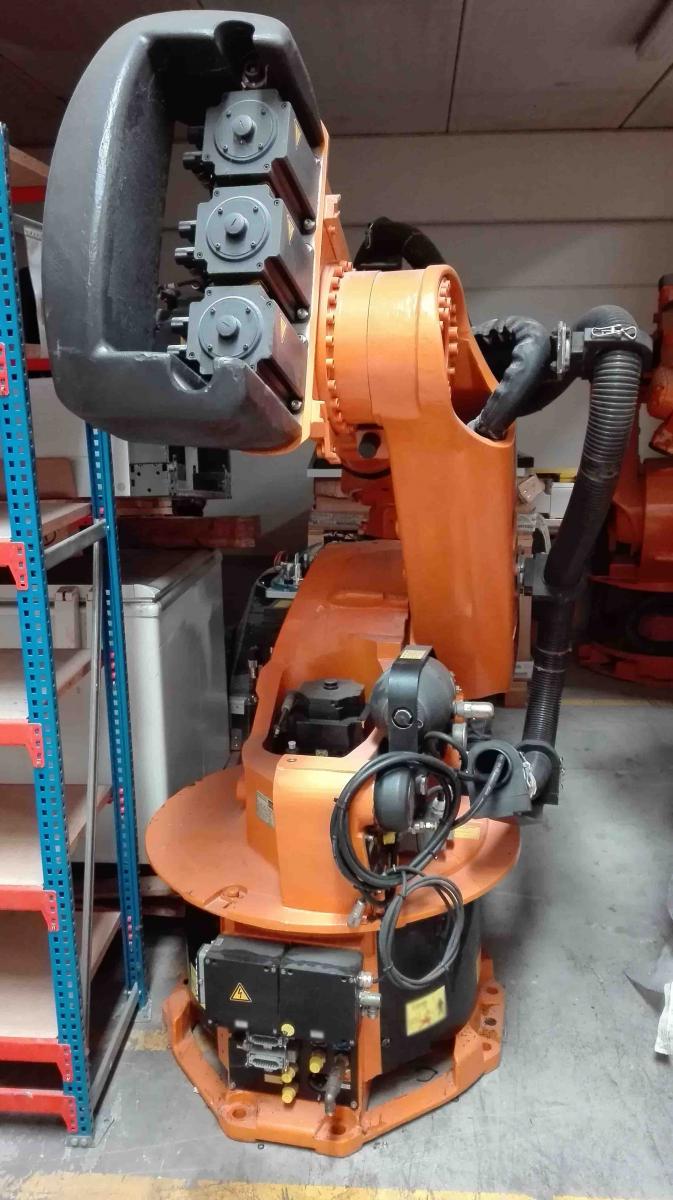

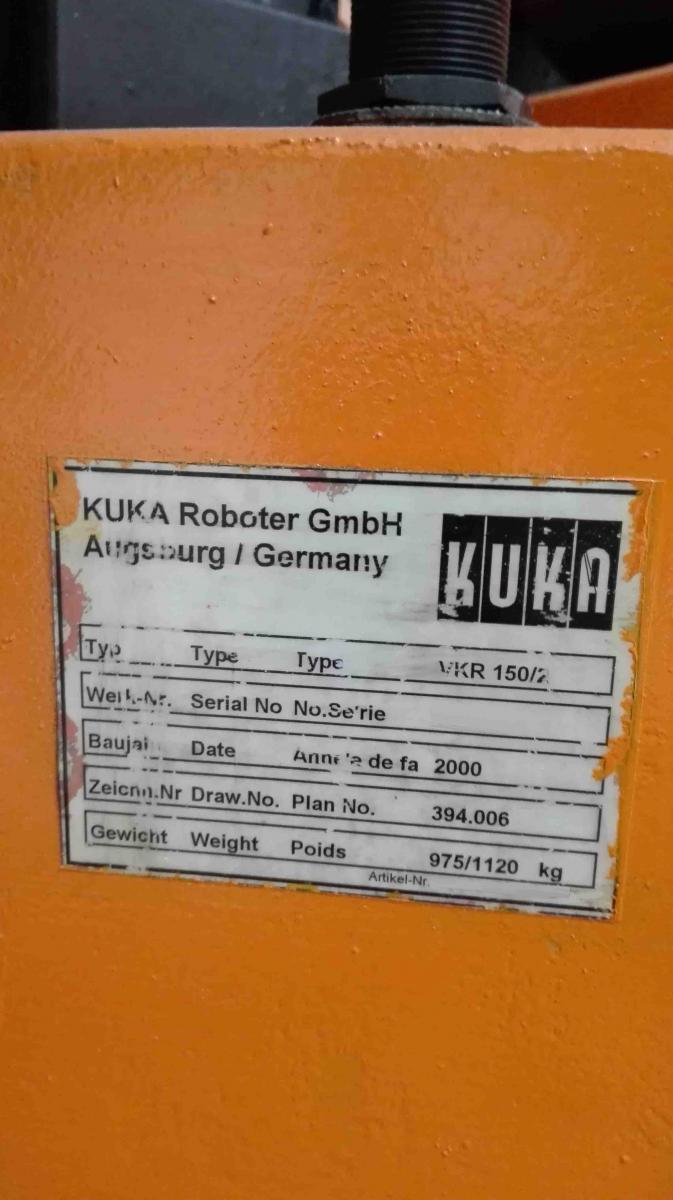

二手 KUKA Series 2000 #9180904 待售

網址複製成功!

單擊可縮放

ID: 9180904

優質的: 2000

Robot

(5) Rating classes

Payloads: 150 to 270 kg

Different arm extensions

Mounting variants for the ceiling / floor

Repeatability: ±0.06 mm

Type: KR 150-2:

Maximum reach: 2,700 mm

Rated payload: 150 kg

Suppliment load, arm/link arm/rotating column: 50 / 100 / 300 kg

Suppliment load, arm + link arm, maximum: 100 kg

Maximum total load: 550 kg

(6) Axes

Mounting position: Floor, ceiling

Variant: Cleanroom, foundry

Positioning repeatability: ±0.06 mm

Controller: KR C2 edition2005

Temperature during operation: +10°C to +55°C

Protection classification: IP 65

Robot footprint: 1,006 mm x 1,006 mm

Connection: 7.3 kVA

Noise level: < 75 dB

Type: KR 150 L130-2:

Maximum reach: 2,900 mm

Rated payload: 130 kg

Suppliment load, arm/link arm/rotating column: 50 / 100 / 300 kg

Suppliment load, arm + link arm, maximum: 100 kg

Maximum total load: 530 kg

(6) Axes

Mounting position: Floor, ceiling

Variant: Cleanroom, foundry

Positioning repeatability: ±0.06 mm

Controller: KR C2 edition2005

Temperature during operation: +10°C to +55°C

Protection classification: IP 65

Robot footprint: 1,006 mm x 1,006 mm

Connection: 7.3 kVA

Noise level: < 75 dB

Type: KR 150 L110-2

Maximum reach: 3,100 mm

Rated payload: 110 kg

Suppliment load, arm/link arm/rotating column: 50 / 100 / 300 kg

Suppliment load, arm + link arm, maximum: 100 kg

Maximum total load: 510 kg

(6) Axes

Mounting position: Floor, ceiling

Variant: Cleanroom, foundry

Positioning repeatability: ±0.06 mm

Controller: KR C2 edition2005

Temperature during operation: +10°C to +55°C

Protection classification: IP 65

Robot footprint: 1,006 mm x 1,006 mm

Connection: 7.3 kVA

Noise level: < 75 dB

Speed with rated payload: 150 kg

Axis data Range (s/w) Speed with rated payload

Axis 1 (A1) ±185° 110°/s

Axis 2 (A2) 0°/–146° 110°/s

Axis 3 (A3) +155°/–119° 100°/s

Axis 4 (A4) ±350° 170°/s

Axis 5 (A5) ±125° 170°/s

Axis 6 (A6) ±350° 238°/s

Speed with rated payload: 130 kg

Axis data Range (s/w) Speed with rated payload

Axis 1 (A1) ±185° 105°/s

Axis 2 (A2) 0°/–146° 110°/s

Axis 3 (A3) +155°/–119° 95°/s

Axis 4 (A4) ±350° 170°/s

Axis 5 (A5) ±125° 170°/s

Axis 6 (A6) ±350° 238°/s

Speed with rated payload: 110 kg

Axis data Range (s/w) Speed with rated payload

Axis 1 (A1) ±185° 105°/s

Axis 2 (A2) 0°/–146° 110°/s

Axis 3 (A3) +155°/–119° 93°/s

Axis 4 (A4) ±350° 170°/s

Axis 5 (A5) ±125° 170°/s

Axis 6 (A6) ±350° 238°/s

2000 vintage.

KUKA Series 2000自動化晶圓處理器是一種集成到通用工業機器人系統中的機械臂。它能夠處理直徑達18英寸的晶片,以及精細的光電元件。手臂配有確保精確運動的高分辨率編碼器和用於晶圓處理的真空吸盤工具,以保護易碎部件。真空吸盤工具具有很高的柔韌性,可以配置為接受不同形狀和大小的晶片。Series 2000的可伸展臂最大可達8英寸,重復精度高達0.015毫米。它配備了先進的晶圓邊緣精確識別視覺系統,以及晶圓閉塞檢測的圖像處理程序。使用KUKA KUKA Studio軟件的工業級PC運行機器人手臂並確保可靠的操作。KUKA Series 2000能夠執行廣泛的晶圓處理任務。它能夠從不同來源拾取晶片,轉移到各個階段,進行精確定位操作。它還可以以互補的方式對齊晶片,如完美的精細對齊和預對齊。再者,它配備了一個快速的下降和選擇機制,允許一次快速操縱多個晶片。Series 2000廣泛應用於半導體和光子學行業。它為惡劣工業環境中的精確晶圓處理操作提供了可靠、準確的解決方案。它用途廣泛、可靠,由輕巧但堅固的組件組成,並且需要最少的維護。由於體積小巧,KUKA Series 2000可以輕松地集成到現有生產線中,並用於新工藝和現有工藝。

還沒有評論