二手 RUDOLPH WS 3840 #9136132 待售

網址複製成功!

單擊可縮放

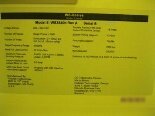

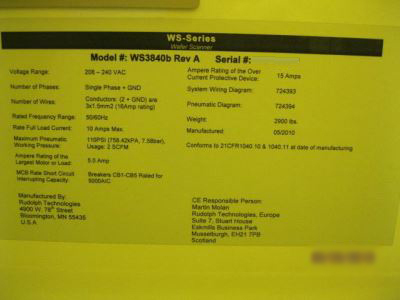

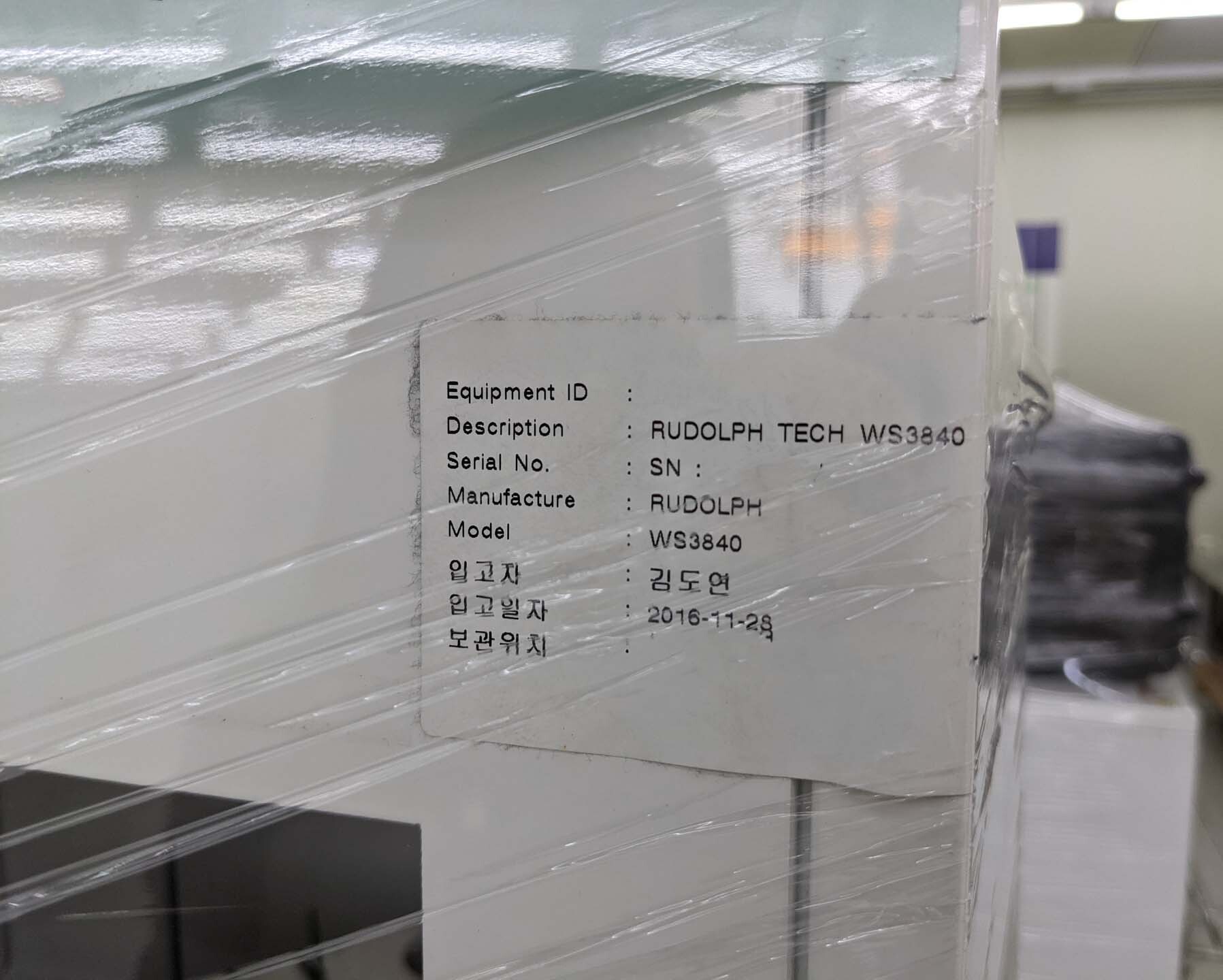

ID: 9136132

晶圓大小: 12"

優質的: 2010

Bump inspection system, 12"

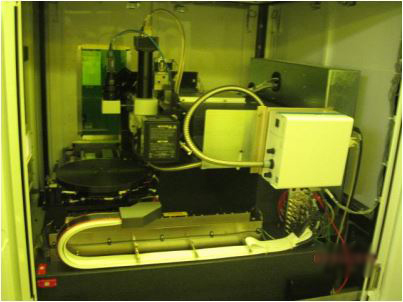

Granite base air bearing XY stages

Vacuum chuck with rotation for 5", 6", 8" and 12" wafers

Z Slide for focus control and wafer loading / Unloading

OLYMPUS Optical head with 5 positions auto lens turret

Bright field lighting

Low angle dark field lighting

Objective lenses: 1.25x, 2.5x, 5x and 10x

4K TDI Line scan camera & electronics

Image frame grabber

Dual quad core XENON processor PC based 2D vision engine

Computer with 3.2GHz P4 processor

RAM: 1GB

Hard disk: 250 GB

(2) Hot swap bays

CDRW / DVDRW

Operating system: Window XP

Console arm with (2) flat panel color monitors

Keyboard and mouse

(4) Positions light tower

Data analysis and reporting

Color defect review

Mini-environment fan / Filter units (ISO Class 2)

Electronic wafer maps (KLAINF, EF, WWW, Semi G85 and SECS S12)

721713 Option

Xport

Wafer scanner

ISO Class 1 clean high speed wafer handling EFEM outfitted

With dual arm robot

Wafer thicknesses: (725um)

Down to 400 microns thickness for 12" wafers

Down to 190 microns thickness for 8" wafers

Automated whole wafer handling

Dual arm vacuum assist backside wafer handling

Minimal contact end effector

Integrated laminar clean air flow mini-environment (ULPA Filtration)

Robot with integrated mapper

721753 2 Option

Bridge load port

BROOKS Vision / Cassette pivot, 8"

XENON Dual quad processor 2D vision engine

72054 1 Option, 3D Inspection, Hi Res 3D Sensor

High resolution: 4 MHz

3D Sensor scans up to a .6mm swath

Depth of field: 200um

1U Rack mount chassis

Dual INTEL quad-core XENON processor 2.5 GHz

DRAM: 2GB

SATA Hard disk drive: 250 GB

CD ROM Drive

Ethernet

RUDOLPH PCIDSP Board

(5) Microns ultra high resolution 3D sensor

716983 1 Standard, 3D Height Verif Wafer, 100um, 300mm

716810 1 Option, Dual OCR

X Port

66807 1 Computer, Remote defect review

Wafer capability, 8"-12"

Ultra flat chuck: <5 Microns chuck

2010 vintage.

RUDOLPH WS 3840是為半導體器件公司設計的晶圓測試和計量設備。它是一個自動化的系統,集成和分析來自多個測量設備的計量數據。該單元由連接到中央服務器的一系列高性能工作站組成,每個工作站處理和存儲來自單個測量設備的計量數據。它能夠處理多種類型的計量數據,包括晶圓面積、螺距、模具尺寸和模具放置。該機精度高、可重復,能夠快速檢測和分析設備結構變化。它還具有先進的2D成像功能來分析缺陷計數和晶圓特征,如突起和模數。該工具還包括許多其他功能,包括易於操作和直觀的軟件,允許用戶快速設置和訪問分析數據。它還具有參數驅動的資產,允許自定義分析數據、輸出格式和用戶首選項。為了保證模型的準確性,模型利用模式識別來檢測和分析設計中的小變化。這包括自適應光學元件,它可以通過一系列透鏡調整焦點或提供更好的照明。該設備采用堅固的設計,可實現高可靠性和耐用性。它還提供了先進的可擴展性,允許用戶輕松執行大規模的計量任務。最後,系統提供了高度的安全性,允許遠程訪問和操作。它符合若幹行業標準,並附帶全面的支持服務,包括安裝、培訓和維護。總之,RUDOLPH WS3840是一個先進的晶圓測試和計量單元,旨在滿足半導體器件公司的需求。它為用戶提供了一系列的特性和功能,允許準確和高效的計量測試。

還沒有評論